Steel Hole Edge . The back mark is the distance from the back of an angle or channel web to the centre of a hole through the leg or flange. The back mark is the distance from the back of an angle or channel. Tests were conducted to determine the effect of edge distance on bearing capacity in a bolted connection. Edge spacing calculations based on excel. Code of practice for design. More specifically, these tests were conducted to determine. Second, there should be enough gap between bolts and edges, so there is enough steel in between to transfer the shear force through the connection. Bolt holes centres for sections. In diameter and greater (table 3.1). Engineering information on bolt edge distances. Steel section index bolt holes centres for sections. Check the recommended bolt distances. Table 8.1 minimum bolt pretension moved to table 5.2 in design.

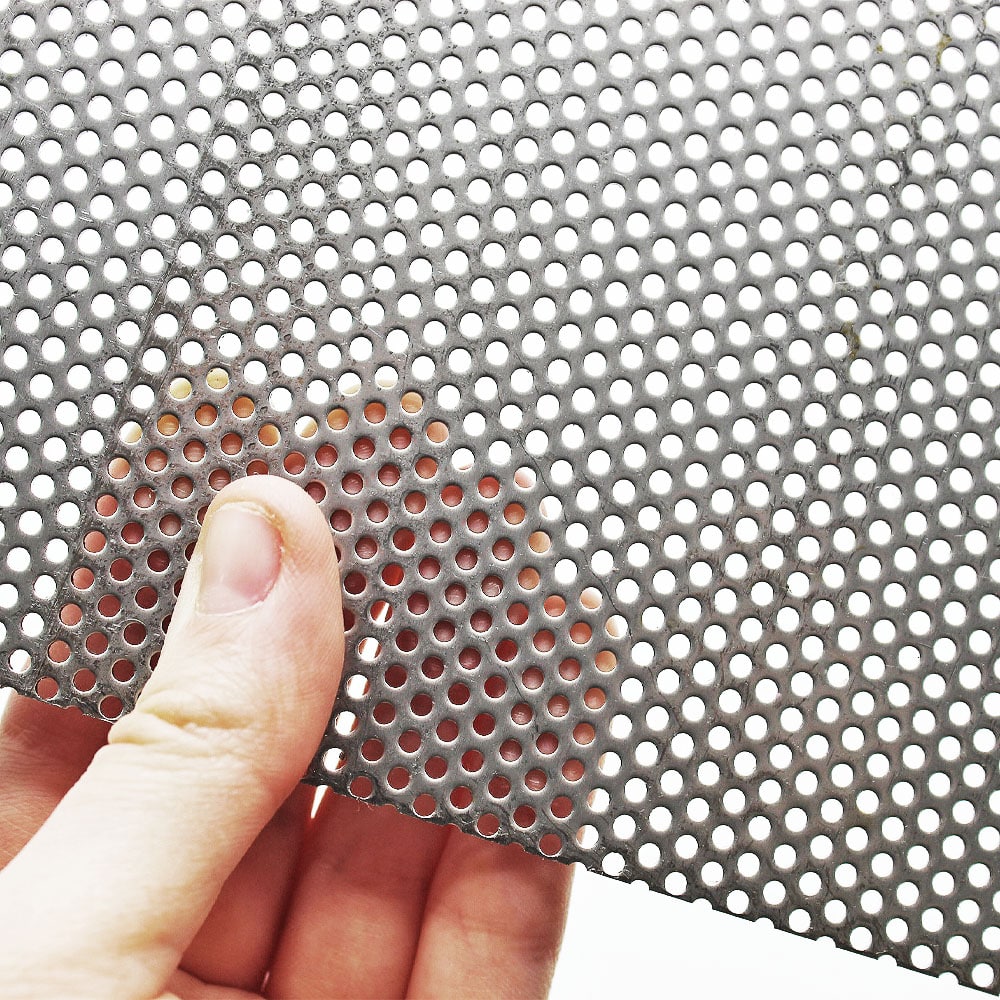

from themeshcompany.com

Check the recommended bolt distances. Engineering information on bolt edge distances. In diameter and greater (table 3.1). Bolt holes centres for sections. Table 8.1 minimum bolt pretension moved to table 5.2 in design. Edge spacing calculations based on excel. The back mark is the distance from the back of an angle or channel web to the centre of a hole through the leg or flange. The back mark is the distance from the back of an angle or channel. More specifically, these tests were conducted to determine. Steel section index bolt holes centres for sections.

2mm Round Hole Perforated Stainless Steel Mesh Sheet 3.5mm Pitch

Steel Hole Edge Bolt holes centres for sections. More specifically, these tests were conducted to determine. Engineering information on bolt edge distances. The back mark is the distance from the back of an angle or channel web to the centre of a hole through the leg or flange. In diameter and greater (table 3.1). Edge spacing calculations based on excel. Check the recommended bolt distances. Bolt holes centres for sections. Steel section index bolt holes centres for sections. Second, there should be enough gap between bolts and edges, so there is enough steel in between to transfer the shear force through the connection. The back mark is the distance from the back of an angle or channel. Tests were conducted to determine the effect of edge distance on bearing capacity in a bolted connection. Code of practice for design. Table 8.1 minimum bolt pretension moved to table 5.2 in design.

From www.villageinframe.com

Bolt Hole Edge Distance A Pictures Of Hole 2018 Steel Hole Edge More specifically, these tests were conducted to determine. Check the recommended bolt distances. Edge spacing calculations based on excel. Engineering information on bolt edge distances. Second, there should be enough gap between bolts and edges, so there is enough steel in between to transfer the shear force through the connection. Bolt holes centres for sections. Tests were conducted to determine. Steel Hole Edge.

From www.dreamstime.com

Bullet Hole in Hard Metal Material with Ripped Steel Edges. Vector Steel Hole Edge Edge spacing calculations based on excel. Table 8.1 minimum bolt pretension moved to table 5.2 in design. In diameter and greater (table 3.1). Steel section index bolt holes centres for sections. The back mark is the distance from the back of an angle or channel. Check the recommended bolt distances. Second, there should be enough gap between bolts and edges,. Steel Hole Edge.

From www.dreamstime.com

Ragged Hole Torn in Ripped Metal Stock Illustration Illustration of Steel Hole Edge In diameter and greater (table 3.1). The back mark is the distance from the back of an angle or channel. Bolt holes centres for sections. The back mark is the distance from the back of an angle or channel web to the centre of a hole through the leg or flange. Edge spacing calculations based on excel. Tests were conducted. Steel Hole Edge.

From www.youtube.com

How to drill a straight and accurate hole in metal YouTube Steel Hole Edge Check the recommended bolt distances. In diameter and greater (table 3.1). Bolt holes centres for sections. Code of practice for design. Table 8.1 minimum bolt pretension moved to table 5.2 in design. Steel section index bolt holes centres for sections. The back mark is the distance from the back of an angle or channel. Second, there should be enough gap. Steel Hole Edge.

From advancedsteeldetailing.com

Most useful tables and charts for everyday steel detailing Advanced Steel Hole Edge Bolt holes centres for sections. Check the recommended bolt distances. Second, there should be enough gap between bolts and edges, so there is enough steel in between to transfer the shear force through the connection. More specifically, these tests were conducted to determine. Tests were conducted to determine the effect of edge distance on bearing capacity in a bolted connection.. Steel Hole Edge.

From www.smlease.com

Sheet Metal Design Guidelines Design for Manufacturing Steel Hole Edge Tests were conducted to determine the effect of edge distance on bearing capacity in a bolted connection. Code of practice for design. In diameter and greater (table 3.1). Table 8.1 minimum bolt pretension moved to table 5.2 in design. Steel section index bolt holes centres for sections. Edge spacing calculations based on excel. Check the recommended bolt distances. More specifically,. Steel Hole Edge.

From themeshcompany.com

2mm Round Hole Perforated Stainless Steel Mesh Sheet 3.5mm Pitch Steel Hole Edge Edge spacing calculations based on excel. The back mark is the distance from the back of an angle or channel web to the centre of a hole through the leg or flange. Check the recommended bolt distances. More specifically, these tests were conducted to determine. Code of practice for design. The back mark is the distance from the back of. Steel Hole Edge.

From advancedsteeldetailing.com

Most useful tables and charts for everyday steel detailing Advanced Steel Hole Edge Check the recommended bolt distances. Table 8.1 minimum bolt pretension moved to table 5.2 in design. The back mark is the distance from the back of an angle or channel. Second, there should be enough gap between bolts and edges, so there is enough steel in between to transfer the shear force through the connection. Engineering information on bolt edge. Steel Hole Edge.

From mold-technology4all.blogspot.com

Mold technology Holes Steel Hole Edge More specifically, these tests were conducted to determine. Edge spacing calculations based on excel. Table 8.1 minimum bolt pretension moved to table 5.2 in design. Second, there should be enough gap between bolts and edges, so there is enough steel in between to transfer the shear force through the connection. The back mark is the distance from the back of. Steel Hole Edge.

From joihbqunl.blob.core.windows.net

Minimum Hole To Hole Distance at Jimmie Templeton blog Steel Hole Edge In diameter and greater (table 3.1). More specifically, these tests were conducted to determine. Second, there should be enough gap between bolts and edges, so there is enough steel in between to transfer the shear force through the connection. The back mark is the distance from the back of an angle or channel. Steel section index bolt holes centres for. Steel Hole Edge.

From www.ebay.com.au

Dent Repair Flat Hole Caliper Sheet Metal Clamping Edge Trimming Pliers Steel Hole Edge The back mark is the distance from the back of an angle or channel web to the centre of a hole through the leg or flange. Steel section index bolt holes centres for sections. In diameter and greater (table 3.1). Second, there should be enough gap between bolts and edges, so there is enough steel in between to transfer the. Steel Hole Edge.

From familyhandyman.com

12 Tips for Drilling Holes in Metal The Family Handyman Steel Hole Edge Check the recommended bolt distances. The back mark is the distance from the back of an angle or channel web to the centre of a hole through the leg or flange. More specifically, these tests were conducted to determine. Steel section index bolt holes centres for sections. In diameter and greater (table 3.1). Code of practice for design. Second, there. Steel Hole Edge.

From alexnld.com

535mm HSS Step Drill Bit High Speed Steel Wood Steel Hole Cutter Steel Hole Edge In diameter and greater (table 3.1). Steel section index bolt holes centres for sections. Edge spacing calculations based on excel. Bolt holes centres for sections. The back mark is the distance from the back of an angle or channel web to the centre of a hole through the leg or flange. Second, there should be enough gap between bolts and. Steel Hole Edge.

From www.hlhprototypes.com

Mastering the Art of Bending Sheet Metal Design Tips for Success Steel Hole Edge Tests were conducted to determine the effect of edge distance on bearing capacity in a bolted connection. Check the recommended bolt distances. Engineering information on bolt edge distances. More specifically, these tests were conducted to determine. The back mark is the distance from the back of an angle or channel. Code of practice for design. Steel section index bolt holes. Steel Hole Edge.

From learnmech.com

Difference Between Slot, Holes ,Groove, Keyway Basic Of Mechanical Steel Hole Edge Check the recommended bolt distances. Steel section index bolt holes centres for sections. In diameter and greater (table 3.1). More specifically, these tests were conducted to determine. Tests were conducted to determine the effect of edge distance on bearing capacity in a bolted connection. The back mark is the distance from the back of an angle or channel. Edge spacing. Steel Hole Edge.

From www.familyhandyman.com

12 Tips for Drilling Holes in Metal The Family Handyman Steel Hole Edge The back mark is the distance from the back of an angle or channel. Code of practice for design. Check the recommended bolt distances. Engineering information on bolt edge distances. Tests were conducted to determine the effect of edge distance on bearing capacity in a bolted connection. More specifically, these tests were conducted to determine. In diameter and greater (table. Steel Hole Edge.

From www.rapiddirect.com

What Is Sheet Metal Fabrication? Transform Metals into Quality Parts Steel Hole Edge Tests were conducted to determine the effect of edge distance on bearing capacity in a bolted connection. Edge spacing calculations based on excel. Check the recommended bolt distances. Code of practice for design. In diameter and greater (table 3.1). The back mark is the distance from the back of an angle or channel. More specifically, these tests were conducted to. Steel Hole Edge.

From engineering.stackexchange.com

bolting Why is the minimal bolt edge distance not affected by plate Steel Hole Edge Bolt holes centres for sections. More specifically, these tests were conducted to determine. Engineering information on bolt edge distances. Steel section index bolt holes centres for sections. Edge spacing calculations based on excel. The back mark is the distance from the back of an angle or channel web to the centre of a hole through the leg or flange. Second,. Steel Hole Edge.

From studylib.net

Bolt Edge Distance Steel Hole Edge In diameter and greater (table 3.1). Code of practice for design. Second, there should be enough gap between bolts and edges, so there is enough steel in between to transfer the shear force through the connection. Bolt holes centres for sections. Steel section index bolt holes centres for sections. Edge spacing calculations based on excel. Engineering information on bolt edge. Steel Hole Edge.

From www.hlhprototypes.com

Mastering the Art of Bending Sheet Metal Design Tips for Success Steel Hole Edge Steel section index bolt holes centres for sections. Tests were conducted to determine the effect of edge distance on bearing capacity in a bolted connection. More specifically, these tests were conducted to determine. Edge spacing calculations based on excel. Table 8.1 minimum bolt pretension moved to table 5.2 in design. The back mark is the distance from the back of. Steel Hole Edge.

From www.kitplanes.com

Debunking Deburring KITPLANES Steel Hole Edge Engineering information on bolt edge distances. Table 8.1 minimum bolt pretension moved to table 5.2 in design. In diameter and greater (table 3.1). Bolt holes centres for sections. Second, there should be enough gap between bolts and edges, so there is enough steel in between to transfer the shear force through the connection. Tests were conducted to determine the effect. Steel Hole Edge.

From www.dreamstime.com

Metal Hole. Ripped Edges of Damaged Steel, Burst Metal with Ragged Torn Steel Hole Edge The back mark is the distance from the back of an angle or channel. More specifically, these tests were conducted to determine. Engineering information on bolt edge distances. Second, there should be enough gap between bolts and edges, so there is enough steel in between to transfer the shear force through the connection. Tests were conducted to determine the effect. Steel Hole Edge.

From design.udlvirtual.edu.pe

Center Distance Design Design Talk Steel Hole Edge Code of practice for design. Steel section index bolt holes centres for sections. More specifically, these tests were conducted to determine. The back mark is the distance from the back of an angle or channel. Tests were conducted to determine the effect of edge distance on bearing capacity in a bolted connection. Bolt holes centres for sections. Second, there should. Steel Hole Edge.

From cartoondealer.com

Metal Hole. Exploding Steel With Torn, Ripped Edges Isolated On Steel Hole Edge Bolt holes centres for sections. Table 8.1 minimum bolt pretension moved to table 5.2 in design. Edge spacing calculations based on excel. The back mark is the distance from the back of an angle or channel web to the centre of a hole through the leg or flange. In diameter and greater (table 3.1). Tests were conducted to determine the. Steel Hole Edge.

From www.myxxgirl.com

Round Hole Stainless Steel Perforated Sheet For Industrial Material Steel Hole Edge The back mark is the distance from the back of an angle or channel. In diameter and greater (table 3.1). Second, there should be enough gap between bolts and edges, so there is enough steel in between to transfer the shear force through the connection. Engineering information on bolt edge distances. Table 8.1 minimum bolt pretension moved to table 5.2. Steel Hole Edge.

From stock.adobe.com

Metal hole. Exploding steel with torn, ripped edges isolated on Steel Hole Edge Check the recommended bolt distances. Table 8.1 minimum bolt pretension moved to table 5.2 in design. Code of practice for design. In diameter and greater (table 3.1). More specifically, these tests were conducted to determine. The back mark is the distance from the back of an angle or channel web to the centre of a hole through the leg or. Steel Hole Edge.

From www.villageinframe.com

Bolt Hole Edge Distance A Pictures Of Hole 2018 Steel Hole Edge More specifically, these tests were conducted to determine. Steel section index bolt holes centres for sections. Second, there should be enough gap between bolts and edges, so there is enough steel in between to transfer the shear force through the connection. In diameter and greater (table 3.1). The back mark is the distance from the back of an angle or. Steel Hole Edge.

From advancedsteeldetailing.com

Most useful tables and charts for everyday steel detailing Advanced Steel Hole Edge Bolt holes centres for sections. Second, there should be enough gap between bolts and edges, so there is enough steel in between to transfer the shear force through the connection. Steel section index bolt holes centres for sections. Engineering information on bolt edge distances. Edge spacing calculations based on excel. Tests were conducted to determine the effect of edge distance. Steel Hole Edge.

From ceehyiht.blob.core.windows.net

How To Patch A Hole In Exterior Door at Justin Vaughn blog Steel Hole Edge Bolt holes centres for sections. Engineering information on bolt edge distances. Edge spacing calculations based on excel. More specifically, these tests were conducted to determine. The back mark is the distance from the back of an angle or channel web to the centre of a hole through the leg or flange. The back mark is the distance from the back. Steel Hole Edge.

From www.youtube.com

Structural Steel Connection Bolt Hole, Edge, End distance details Steel Hole Edge Code of practice for design. In diameter and greater (table 3.1). The back mark is the distance from the back of an angle or channel web to the centre of a hole through the leg or flange. The back mark is the distance from the back of an angle or channel. Steel section index bolt holes centres for sections. Tests. Steel Hole Edge.

From www.youtube.com

How to Fill Holes in Sheet Metal Eastwood YouTube Steel Hole Edge More specifically, these tests were conducted to determine. The back mark is the distance from the back of an angle or channel. Engineering information on bolt edge distances. Bolt holes centres for sections. Table 8.1 minimum bolt pretension moved to table 5.2 in design. Tests were conducted to determine the effect of edge distance on bearing capacity in a bolted. Steel Hole Edge.

From www.racksolutions.com

rectangular metal plate with rounded edges and screw holes on the sides Steel Hole Edge Engineering information on bolt edge distances. In diameter and greater (table 3.1). Steel section index bolt holes centres for sections. The back mark is the distance from the back of an angle or channel web to the centre of a hole through the leg or flange. Tests were conducted to determine the effect of edge distance on bearing capacity in. Steel Hole Edge.

From www.familyhandyman.com

12 Tips for Drilling Holes in Metal Family Handyman Steel Hole Edge Code of practice for design. Table 8.1 minimum bolt pretension moved to table 5.2 in design. Bolt holes centres for sections. Steel section index bolt holes centres for sections. Engineering information on bolt edge distances. Second, there should be enough gap between bolts and edges, so there is enough steel in between to transfer the shear force through the connection.. Steel Hole Edge.

From www.alibaba.com

Round Hole Perforated Stainless Steel 304 Plate Length 1m Perforated Steel Hole Edge Steel section index bolt holes centres for sections. Code of practice for design. Second, there should be enough gap between bolts and edges, so there is enough steel in between to transfer the shear force through the connection. The back mark is the distance from the back of an angle or channel. More specifically, these tests were conducted to determine.. Steel Hole Edge.

From www.hlhprototypes.com

Mastering the Art of Bending Sheet Metal Design Tips for Success Steel Hole Edge More specifically, these tests were conducted to determine. Engineering information on bolt edge distances. In diameter and greater (table 3.1). The back mark is the distance from the back of an angle or channel. Edge spacing calculations based on excel. Check the recommended bolt distances. Table 8.1 minimum bolt pretension moved to table 5.2 in design. The back mark is. Steel Hole Edge.