How To Bead Aluminum Tube . These days, rather than attach a cast fitting, it’s much more efficient to form the end of the tube to make a bead, expansion, reduction, flange, flare, groove, knurl, or a thickened. It works by clamping the tube between. The press allows you to form the bead with much less effort, and to form it in. Make your own bead roller for under. Beading tubes as small as 5/16 inch od or large tubes with up to.065 inch wall thickness can be achieved with certain models. A tube beading service like accubend. Tube beading involves creating a ridge around the base of a tube so it is more resilient and can be attached to further mechanisms. We are a hose and tubing specialty shop located in tucson, arizona. This video demonstrates how we roll the bead on tubing. A tubing bead roller is a tool for creating decorative or functional beads on metal tubing. Now you can roll your own beads on induction tubing and keep from blowing of pipes while.

from www.kitplanes.com

Make your own bead roller for under. This video demonstrates how we roll the bead on tubing. A tubing bead roller is a tool for creating decorative or functional beads on metal tubing. We are a hose and tubing specialty shop located in tucson, arizona. It works by clamping the tube between. The press allows you to form the bead with much less effort, and to form it in. Tube beading involves creating a ridge around the base of a tube so it is more resilient and can be attached to further mechanisms. Beading tubes as small as 5/16 inch od or large tubes with up to.065 inch wall thickness can be achieved with certain models. A tube beading service like accubend. These days, rather than attach a cast fitting, it’s much more efficient to form the end of the tube to make a bead, expansion, reduction, flange, flare, groove, knurl, or a thickened.

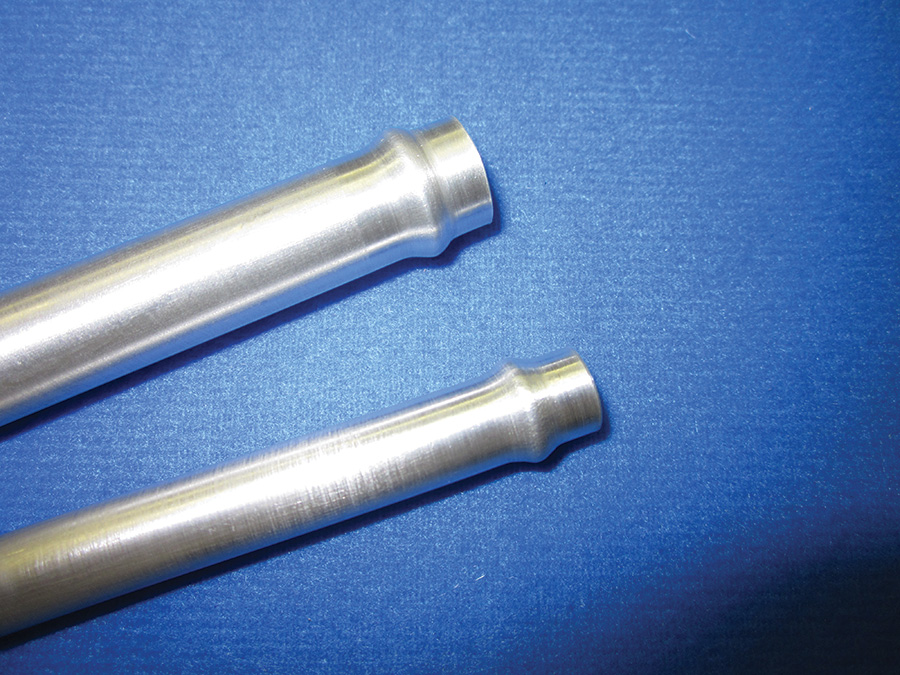

To Bead or Not to Bead?

How To Bead Aluminum Tube Now you can roll your own beads on induction tubing and keep from blowing of pipes while. The press allows you to form the bead with much less effort, and to form it in. This video demonstrates how we roll the bead on tubing. It works by clamping the tube between. Tube beading involves creating a ridge around the base of a tube so it is more resilient and can be attached to further mechanisms. Make your own bead roller for under. A tubing bead roller is a tool for creating decorative or functional beads on metal tubing. Beading tubes as small as 5/16 inch od or large tubes with up to.065 inch wall thickness can be achieved with certain models. A tube beading service like accubend. We are a hose and tubing specialty shop located in tucson, arizona. Now you can roll your own beads on induction tubing and keep from blowing of pipes while. These days, rather than attach a cast fitting, it’s much more efficient to form the end of the tube to make a bead, expansion, reduction, flange, flare, groove, knurl, or a thickened.

From www.beadologyshop.com

6x4mm Aluminum Short Barrel Beads, Metal Spacers, With Diamond Cut How To Bead Aluminum Tube A tubing bead roller is a tool for creating decorative or functional beads on metal tubing. The press allows you to form the bead with much less effort, and to form it in. This video demonstrates how we roll the bead on tubing. Beading tubes as small as 5/16 inch od or large tubes with up to.065 inch wall thickness. How To Bead Aluminum Tube.

From www.beadologyshop.com

29x8mm Aluminum Tube Beads, Metal Tubes, Lightweight, Round, Metallic How To Bead Aluminum Tube Make your own bead roller for under. A tubing bead roller is a tool for creating decorative or functional beads on metal tubing. We are a hose and tubing specialty shop located in tucson, arizona. The press allows you to form the bead with much less effort, and to form it in. Beading tubes as small as 5/16 inch od. How To Bead Aluminum Tube.

From www.beadologyshop.com

29x8mm Aluminum Tube Beads, Two Tone, Silver and Gold Color, Metal Tube How To Bead Aluminum Tube These days, rather than attach a cast fitting, it’s much more efficient to form the end of the tube to make a bead, expansion, reduction, flange, flare, groove, knurl, or a thickened. A tube beading service like accubend. We are a hose and tubing specialty shop located in tucson, arizona. Beading tubes as small as 5/16 inch od or large. How To Bead Aluminum Tube.

From www.youtube.com

How To Bead Roll Metal without Warping Tips and Tricks YouTube How To Bead Aluminum Tube A tube beading service like accubend. The press allows you to form the bead with much less effort, and to form it in. A tubing bead roller is a tool for creating decorative or functional beads on metal tubing. Beading tubes as small as 5/16 inch od or large tubes with up to.065 inch wall thickness can be achieved with. How To Bead Aluminum Tube.

From www.youtube.com

How to Bead Roll Intercooler Pipe At Home YouTube How To Bead Aluminum Tube It works by clamping the tube between. The press allows you to form the bead with much less effort, and to form it in. This video demonstrates how we roll the bead on tubing. Tube beading involves creating a ridge around the base of a tube so it is more resilient and can be attached to further mechanisms. A tube. How To Bead Aluminum Tube.

From blog.jdslabs.com

How to Finish Aluminum JDS Labs Blog How To Bead Aluminum Tube The press allows you to form the bead with much less effort, and to form it in. A tube beading service like accubend. Now you can roll your own beads on induction tubing and keep from blowing of pipes while. It works by clamping the tube between. This video demonstrates how we roll the bead on tubing. We are a. How To Bead Aluminum Tube.

From www.youtube.com

How to make BEADS from Aluminum Drink Cans YouTube How To Bead Aluminum Tube The press allows you to form the bead with much less effort, and to form it in. This video demonstrates how we roll the bead on tubing. These days, rather than attach a cast fitting, it’s much more efficient to form the end of the tube to make a bead, expansion, reduction, flange, flare, groove, knurl, or a thickened. We. How To Bead Aluminum Tube.

From proto1mfg.com

Tube End Forming Types of Tube End Forming Proto1 Manufacuring How To Bead Aluminum Tube This video demonstrates how we roll the bead on tubing. We are a hose and tubing specialty shop located in tucson, arizona. Make your own bead roller for under. The press allows you to form the bead with much less effort, and to form it in. A tube beading service like accubend. These days, rather than attach a cast fitting,. How To Bead Aluminum Tube.

From www.beadologyshop.com

29x8mm Aluminum Tube Beads, Metal Tubes, Lightweight, Round, Metallic How To Bead Aluminum Tube Beading tubes as small as 5/16 inch od or large tubes with up to.065 inch wall thickness can be achieved with certain models. These days, rather than attach a cast fitting, it’s much more efficient to form the end of the tube to make a bead, expansion, reduction, flange, flare, groove, knurl, or a thickened. A tube beading service like. How To Bead Aluminum Tube.

From www.mig-welding.co.uk

8mm aluminium tube bead former MIG Welding Forum How To Bead Aluminum Tube A tubing bead roller is a tool for creating decorative or functional beads on metal tubing. Tube beading involves creating a ridge around the base of a tube so it is more resilient and can be attached to further mechanisms. Make your own bead roller for under. We are a hose and tubing specialty shop located in tucson, arizona. The. How To Bead Aluminum Tube.

From weldingweb.com

How to weld TALL weld beads on 1.6mm thick Aluminum Tube? How To Bead Aluminum Tube Make your own bead roller for under. This video demonstrates how we roll the bead on tubing. These days, rather than attach a cast fitting, it’s much more efficient to form the end of the tube to make a bead, expansion, reduction, flange, flare, groove, knurl, or a thickened. We are a hose and tubing specialty shop located in tucson,. How To Bead Aluminum Tube.

From www.badgeranodising.co.uk

Textured finish on aluminium Aluminium Bead Blasting Linishing How To Bead Aluminum Tube A tubing bead roller is a tool for creating decorative or functional beads on metal tubing. Make your own bead roller for under. These days, rather than attach a cast fitting, it’s much more efficient to form the end of the tube to make a bead, expansion, reduction, flange, flare, groove, knurl, or a thickened. Tube beading involves creating a. How To Bead Aluminum Tube.

From www.badgeranodising.co.uk

Textured finish on aluminium Aluminium Bead Blasting Linishing How To Bead Aluminum Tube We are a hose and tubing specialty shop located in tucson, arizona. It works by clamping the tube between. Make your own bead roller for under. Now you can roll your own beads on induction tubing and keep from blowing of pipes while. This video demonstrates how we roll the bead on tubing. These days, rather than attach a cast. How To Bead Aluminum Tube.

From www.kitplanes.com

To Bead or Not to Bead? How To Bead Aluminum Tube Beading tubes as small as 5/16 inch od or large tubes with up to.065 inch wall thickness can be achieved with certain models. The press allows you to form the bead with much less effort, and to form it in. These days, rather than attach a cast fitting, it’s much more efficient to form the end of the tube to. How To Bead Aluminum Tube.

From www.beadologyshop.com

29x8mm Aluminum Tube Beads, Metal Tubes, Lightweight, Round, Metallic How To Bead Aluminum Tube A tubing bead roller is a tool for creating decorative or functional beads on metal tubing. Beading tubes as small as 5/16 inch od or large tubes with up to.065 inch wall thickness can be achieved with certain models. It works by clamping the tube between. We are a hose and tubing specialty shop located in tucson, arizona. The press. How To Bead Aluminum Tube.

From www.youtube.com

Beads Using Aluminum Cans (double tube beads) YouTube How To Bead Aluminum Tube A tube beading service like accubend. This video demonstrates how we roll the bead on tubing. Make your own bead roller for under. The press allows you to form the bead with much less effort, and to form it in. A tubing bead roller is a tool for creating decorative or functional beads on metal tubing. We are a hose. How To Bead Aluminum Tube.

From www.badgeranodising.co.uk

Textured finish on aluminium Aluminium Bead Blasting Linishing How To Bead Aluminum Tube Tube beading involves creating a ridge around the base of a tube so it is more resilient and can be attached to further mechanisms. A tubing bead roller is a tool for creating decorative or functional beads on metal tubing. Make your own bead roller for under. These days, rather than attach a cast fitting, it’s much more efficient to. How To Bead Aluminum Tube.

From pitulathejeweler.com

Diamond cut aluminum tube beads at Pitula the Jeweler How To Bead Aluminum Tube Tube beading involves creating a ridge around the base of a tube so it is more resilient and can be attached to further mechanisms. Now you can roll your own beads on induction tubing and keep from blowing of pipes while. This video demonstrates how we roll the bead on tubing. A tubing bead roller is a tool for creating. How To Bead Aluminum Tube.

From blog.thepipingmart.com

How to Bend Aluminium Square Tube A Complete Guide How To Bead Aluminum Tube A tube beading service like accubend. This video demonstrates how we roll the bead on tubing. Tube beading involves creating a ridge around the base of a tube so it is more resilient and can be attached to further mechanisms. A tubing bead roller is a tool for creating decorative or functional beads on metal tubing. Make your own bead. How To Bead Aluminum Tube.

From www.etsy.com

Anodized Cylinder Beads Barrel Tube Beads set of 4 Etsy How To Bead Aluminum Tube Beading tubes as small as 5/16 inch od or large tubes with up to.065 inch wall thickness can be achieved with certain models. A tubing bead roller is a tool for creating decorative or functional beads on metal tubing. We are a hose and tubing specialty shop located in tucson, arizona. It works by clamping the tube between. A tube. How To Bead Aluminum Tube.

From www.iqsdirectory.com

Tube Fabricating Machinery What Is It? How Does It Work? How To Bead Aluminum Tube We are a hose and tubing specialty shop located in tucson, arizona. A tube beading service like accubend. The press allows you to form the bead with much less effort, and to form it in. Make your own bead roller for under. This video demonstrates how we roll the bead on tubing. Tube beading involves creating a ridge around the. How To Bead Aluminum Tube.

From www.youtube.com

Tube Bead Roller Prototype Demonstration YouTube How To Bead Aluminum Tube The press allows you to form the bead with much less effort, and to form it in. Beading tubes as small as 5/16 inch od or large tubes with up to.065 inch wall thickness can be achieved with certain models. We are a hose and tubing specialty shop located in tucson, arizona. Make your own bead roller for under. This. How To Bead Aluminum Tube.

From www.quasar.com

Tube Forming Quasar Industries How To Bead Aluminum Tube The press allows you to form the bead with much less effort, and to form it in. Tube beading involves creating a ridge around the base of a tube so it is more resilient and can be attached to further mechanisms. This video demonstrates how we roll the bead on tubing. Make your own bead roller for under. Beading tubes. How To Bead Aluminum Tube.

From www.beadologyshop.com

29x8mm Striped Aluminum Tube Beads, Metal Tubes, Lightweight, Round How To Bead Aluminum Tube Make your own bead roller for under. We are a hose and tubing specialty shop located in tucson, arizona. These days, rather than attach a cast fitting, it’s much more efficient to form the end of the tube to make a bead, expansion, reduction, flange, flare, groove, knurl, or a thickened. Now you can roll your own beads on induction. How To Bead Aluminum Tube.

From www.pinterest.com

Making double tube beads using aluminum soda can Paper bead jewelry How To Bead Aluminum Tube Beading tubes as small as 5/16 inch od or large tubes with up to.065 inch wall thickness can be achieved with certain models. Tube beading involves creating a ridge around the base of a tube so it is more resilient and can be attached to further mechanisms. Now you can roll your own beads on induction tubing and keep from. How To Bead Aluminum Tube.

From www.badgeranodising.co.uk

Textured finish on aluminium Aluminium Bead Blasting Linishing How To Bead Aluminum Tube This video demonstrates how we roll the bead on tubing. Beading tubes as small as 5/16 inch od or large tubes with up to.065 inch wall thickness can be achieved with certain models. A tubing bead roller is a tool for creating decorative or functional beads on metal tubing. Now you can roll your own beads on induction tubing and. How To Bead Aluminum Tube.

From www.youtube.com

Tube Roll beading machine Demonstration Video YouTube How To Bead Aluminum Tube Now you can roll your own beads on induction tubing and keep from blowing of pipes while. The press allows you to form the bead with much less effort, and to form it in. We are a hose and tubing specialty shop located in tucson, arizona. A tubing bead roller is a tool for creating decorative or functional beads on. How To Bead Aluminum Tube.

From www.youtube.com

How to make a cheap Intercooler Pipe Bead Roller easy DIY Bead Roller How To Bead Aluminum Tube Now you can roll your own beads on induction tubing and keep from blowing of pipes while. It works by clamping the tube between. A tubing bead roller is a tool for creating decorative or functional beads on metal tubing. These days, rather than attach a cast fitting, it’s much more efficient to form the end of the tube to. How To Bead Aluminum Tube.

From www.youtube.com

heat bending aluminum how to bend aluminum YouTube How To Bead Aluminum Tube These days, rather than attach a cast fitting, it’s much more efficient to form the end of the tube to make a bead, expansion, reduction, flange, flare, groove, knurl, or a thickened. The press allows you to form the bead with much less effort, and to form it in. Tube beading involves creating a ridge around the base of a. How To Bead Aluminum Tube.

From www.kitplanes.com

To Bead or Not to Bead? How To Bead Aluminum Tube Now you can roll your own beads on induction tubing and keep from blowing of pipes while. It works by clamping the tube between. These days, rather than attach a cast fitting, it’s much more efficient to form the end of the tube to make a bead, expansion, reduction, flange, flare, groove, knurl, or a thickened. A tube beading service. How To Bead Aluminum Tube.

From www.youtube.com

AP145 Beading Tool Instructional Video YouTube How To Bead Aluminum Tube Beading tubes as small as 5/16 inch od or large tubes with up to.065 inch wall thickness can be achieved with certain models. Make your own bead roller for under. The press allows you to form the bead with much less effort, and to form it in. Tube beading involves creating a ridge around the base of a tube so. How To Bead Aluminum Tube.

From www.youtube.com

End forming machine for AC tubes, aluminum tube expanding, beading How To Bead Aluminum Tube We are a hose and tubing specialty shop located in tucson, arizona. The press allows you to form the bead with much less effort, and to form it in. It works by clamping the tube between. A tube beading service like accubend. Tube beading involves creating a ridge around the base of a tube so it is more resilient and. How To Bead Aluminum Tube.

From www.etsy.com

6mm Aluminum Tube Beads Metal Spacers With Diamond Cut Etsy How To Bead Aluminum Tube The press allows you to form the bead with much less effort, and to form it in. We are a hose and tubing specialty shop located in tucson, arizona. Beading tubes as small as 5/16 inch od or large tubes with up to.065 inch wall thickness can be achieved with certain models. A tubing bead roller is a tool for. How To Bead Aluminum Tube.

From xwebforums.com

Forming a bead on tubes X Forums v3 How To Bead Aluminum Tube The press allows you to form the bead with much less effort, and to form it in. We are a hose and tubing specialty shop located in tucson, arizona. It works by clamping the tube between. Now you can roll your own beads on induction tubing and keep from blowing of pipes while. Tube beading involves creating a ridge around. How To Bead Aluminum Tube.

From www.pinterest.com

Items similar to Aluminum 11x8 Tube Beads CC80511 on Etsy Tube beads How To Bead Aluminum Tube We are a hose and tubing specialty shop located in tucson, arizona. These days, rather than attach a cast fitting, it’s much more efficient to form the end of the tube to make a bead, expansion, reduction, flange, flare, groove, knurl, or a thickened. This video demonstrates how we roll the bead on tubing. It works by clamping the tube. How To Bead Aluminum Tube.