Work Holding Devices In Lathe . If the workpiece is not attached. Work holding devices in a lathe are used either for holding the workpiece or for supporting the workpiece during machining. Chucks can have 2, 3, 4, or 6 jaws, however 3 and 4 jaw chucks are the most popular. Work holding device is a general term for devices that attach and fix a workpiece to a machine tool. Common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. Chucks are probably the most widely adopted type of workholding device on the lathe. One of the most popular ways to hold work on in a lathe is by using chucks or jaw chucks. Work holding methods are crucial in lathe machines as they play a significant role in ensuring precision and safety during machining operations. 1 what is workholding in machining? Chuck, face plate, lathe centers, steady rest and mandrels, etc. 3 different types of workholding devices. 2 what are the importance’s of workholding? Are common lathe machine accessories and the functions of. They are efficient and accurate and work. Work holding devices in lathe machine.

from www.youtube.com

They are efficient and accurate and work. 1 what is workholding in machining? 3 different types of workholding devices. Are common lathe machine accessories and the functions of. Chucks can have 2, 3, 4, or 6 jaws, however 3 and 4 jaw chucks are the most popular. Common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. Work holding device is a general term for devices that attach and fix a workpiece to a machine tool. Work holding devices in lathe machine. Chuck, face plate, lathe centers, steady rest and mandrels, etc. Work holding methods are crucial in lathe machines as they play a significant role in ensuring precision and safety during machining operations.

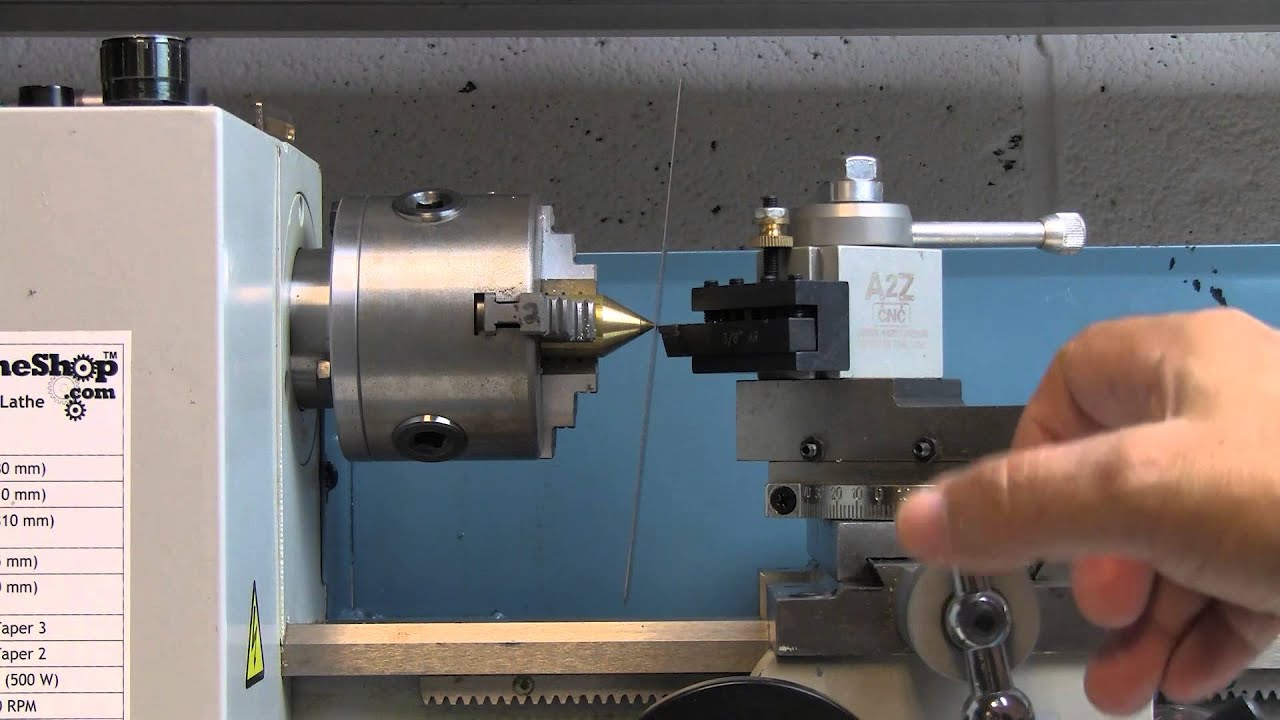

How to Perfectly Center your Lathe Tool YouTube

Work Holding Devices In Lathe Chuck, face plate, lathe centers, steady rest and mandrels, etc. Chuck, face plate, lathe centers, steady rest and mandrels, etc. They are efficient and accurate and work. Chucks are probably the most widely adopted type of workholding device on the lathe. Work holding methods are crucial in lathe machines as they play a significant role in ensuring precision and safety during machining operations. 1 what is workholding in machining? Chucks can have 2, 3, 4, or 6 jaws, however 3 and 4 jaw chucks are the most popular. Are common lathe machine accessories and the functions of. One of the most popular ways to hold work on in a lathe is by using chucks or jaw chucks. 2 what are the importance’s of workholding? 3 different types of workholding devices. Work holding device is a general term for devices that attach and fix a workpiece to a machine tool. Common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. If the workpiece is not attached. Work holding devices in lathe machine. Work holding devices in a lathe are used either for holding the workpiece or for supporting the workpiece during machining.

From toolnotes.com

Lathe Workholding ToolNotes Work Holding Devices In Lathe 1 what is workholding in machining? They are efficient and accurate and work. Work holding devices in a lathe are used either for holding the workpiece or for supporting the workpiece during machining. 2 what are the importance’s of workholding? 3 different types of workholding devices. One of the most popular ways to hold work on in a lathe is. Work Holding Devices In Lathe.

From www.youtube.com

Work and Tool Holding Devices for Lathes YouTube Work Holding Devices In Lathe Chucks are probably the most widely adopted type of workholding device on the lathe. Work holding devices in lathe machine. Work holding methods are crucial in lathe machines as they play a significant role in ensuring precision and safety during machining operations. 3 different types of workholding devices. They are efficient and accurate and work. Work holding devices in a. Work Holding Devices In Lathe.

From www.youtube.com

How to Perfectly Center your Lathe Tool YouTube Work Holding Devices In Lathe Are common lathe machine accessories and the functions of. 3 different types of workholding devices. Work holding devices in lathe machine. Chucks are probably the most widely adopted type of workholding device on the lathe. 2 what are the importance’s of workholding? Common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. 1 what. Work Holding Devices In Lathe.

From www.youtube.com

Tool and Work holding devices for CNC machines and their types with Work Holding Devices In Lathe If the workpiece is not attached. One of the most popular ways to hold work on in a lathe is by using chucks or jaw chucks. Work holding methods are crucial in lathe machines as they play a significant role in ensuring precision and safety during machining operations. Work holding device is a general term for devices that attach and. Work Holding Devices In Lathe.

From news.thomasnet.com

Genius Vise Is Smartest New Workholding Device for Precision 5Axis Milling Work Holding Devices In Lathe If the workpiece is not attached. 1 what is workholding in machining? Chucks can have 2, 3, 4, or 6 jaws, however 3 and 4 jaw chucks are the most popular. Common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. Chuck, face plate, lathe centers, steady rest and mandrels, etc. Work holding devices. Work Holding Devices In Lathe.

From toolnotes.com

Lathe Workholding ToolNotes Work Holding Devices In Lathe Work holding devices in a lathe are used either for holding the workpiece or for supporting the workpiece during machining. Work holding methods are crucial in lathe machines as they play a significant role in ensuring precision and safety during machining operations. Chuck, face plate, lathe centers, steady rest and mandrels, etc. 1 what is workholding in machining? 3 different. Work Holding Devices In Lathe.

From www.youtube.com

Holding threaded items for machining in the metal lathe or mill YouTube Work Holding Devices In Lathe 2 what are the importance’s of workholding? If the workpiece is not attached. Work holding device is a general term for devices that attach and fix a workpiece to a machine tool. Chucks can have 2, 3, 4, or 6 jaws, however 3 and 4 jaw chucks are the most popular. 1 what is workholding in machining? Common accessories for. Work Holding Devices In Lathe.

From www.youtube.com

Lathe Workholding Devices 5minFriday 11 YouTube Work Holding Devices In Lathe Work holding device is a general term for devices that attach and fix a workpiece to a machine tool. Common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. One of the most popular ways to hold work on in a lathe is by using chucks or jaw chucks. 1 what is workholding in. Work Holding Devices In Lathe.

From www.engtechgroup.com

Standard or bespoke Hyfore and ETG Workholding have the full Work Holding Devices In Lathe If the workpiece is not attached. 3 different types of workholding devices. They are efficient and accurate and work. Common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. 1 what is workholding in machining? One of the most popular ways to hold work on in a lathe is by using chucks or jaw. Work Holding Devices In Lathe.

From www.scribd.com

Work Holding Devices in Lathe PDF Work Holding Devices In Lathe 3 different types of workholding devices. If the workpiece is not attached. Work holding methods are crucial in lathe machines as they play a significant role in ensuring precision and safety during machining operations. Work holding devices in lathe machine. Work holding device is a general term for devices that attach and fix a workpiece to a machine tool. Are. Work Holding Devices In Lathe.

From toolnotes.com

Lathe Workholding ToolNotes Work Holding Devices In Lathe Work holding device is a general term for devices that attach and fix a workpiece to a machine tool. Work holding devices in lathe machine. Work holding devices in a lathe are used either for holding the workpiece or for supporting the workpiece during machining. 3 different types of workholding devices. Work holding methods are crucial in lathe machines as. Work Holding Devices In Lathe.

From rdbarrett.co.uk

CNC Lathe Tool Holder Types Uses & Benefits R.D. Barrett Work Holding Devices In Lathe One of the most popular ways to hold work on in a lathe is by using chucks or jaw chucks. Work holding devices in lathe machine. Are common lathe machine accessories and the functions of. Common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. Work holding device is a general term for devices. Work Holding Devices In Lathe.

From www.slideserve.com

PPT Work Holding and Tool Holding PowerPoint Presentation, free Work Holding Devices In Lathe Chuck, face plate, lathe centers, steady rest and mandrels, etc. 2 what are the importance’s of workholding? Are common lathe machine accessories and the functions of. Chucks are probably the most widely adopted type of workholding device on the lathe. Work holding devices in lathe machine. Work holding devices in a lathe are used either for holding the workpiece or. Work Holding Devices In Lathe.

From www.youtube.com

What CNC Modular Fixtures Do and Why You Need Them CNC Workholding Work Holding Devices In Lathe Work holding device is a general term for devices that attach and fix a workpiece to a machine tool. If the workpiece is not attached. Work holding devices in a lathe are used either for holding the workpiece or for supporting the workpiece during machining. 2 what are the importance’s of workholding? Common accessories for a lathe machine include chuck,. Work Holding Devices In Lathe.

From www.abmtools.com

Work Holding Devices ABM Tools Work Holding Devices In Lathe One of the most popular ways to hold work on in a lathe is by using chucks or jaw chucks. If the workpiece is not attached. Chuck, face plate, lathe centers, steady rest and mandrels, etc. Work holding methods are crucial in lathe machines as they play a significant role in ensuring precision and safety during machining operations. 2 what. Work Holding Devices In Lathe.

From toolsonblog.blogspot.com

Work Holding Devices on Lathe Tools on Blog Work Holding Devices In Lathe They are efficient and accurate and work. 1 what is workholding in machining? Work holding devices in lathe machine. 2 what are the importance’s of workholding? One of the most popular ways to hold work on in a lathe is by using chucks or jaw chucks. Work holding devices in a lathe are used either for holding the workpiece or. Work Holding Devices In Lathe.

From www.youtube.com

Lathe Work Holding Devices Basics YouTube Work Holding Devices In Lathe Chucks are probably the most widely adopted type of workholding device on the lathe. 1 what is workholding in machining? 2 what are the importance’s of workholding? Chuck, face plate, lathe centers, steady rest and mandrels, etc. Work holding device is a general term for devices that attach and fix a workpiece to a machine tool. Work holding devices in. Work Holding Devices In Lathe.

From www.youtube.com

Work holding Devices for Lathes Lathe Machine A.S.K.Azad Work Holding Devices In Lathe Work holding device is a general term for devices that attach and fix a workpiece to a machine tool. Chucks are probably the most widely adopted type of workholding device on the lathe. 2 what are the importance’s of workholding? They are efficient and accurate and work. If the workpiece is not attached. 3 different types of workholding devices. Are. Work Holding Devices In Lathe.

From www.slideserve.com

PPT Introduction to the Lathe Machine PowerPoint Presentation ID Work Holding Devices In Lathe 2 what are the importance’s of workholding? Chucks can have 2, 3, 4, or 6 jaws, however 3 and 4 jaw chucks are the most popular. Work holding methods are crucial in lathe machines as they play a significant role in ensuring precision and safety during machining operations. Work holding devices in lathe machine. Chucks are probably the most widely. Work Holding Devices In Lathe.

From www.youtube.com

4/7 Work holding Devices for Lathes Lathe Machine ASKAzad Work Holding Devices In Lathe They are efficient and accurate and work. Are common lathe machine accessories and the functions of. Work holding devices in a lathe are used either for holding the workpiece or for supporting the workpiece during machining. 2 what are the importance’s of workholding? One of the most popular ways to hold work on in a lathe is by using chucks. Work Holding Devices In Lathe.

From informacionpublica.svet.gob.gt

Work Holding Devices In Lathe Machine Technology Work Holding Devices In Lathe Chucks can have 2, 3, 4, or 6 jaws, however 3 and 4 jaw chucks are the most popular. Chucks are probably the most widely adopted type of workholding device on the lathe. Work holding devices in a lathe are used either for holding the workpiece or for supporting the workpiece during machining. 3 different types of workholding devices. If. Work Holding Devices In Lathe.

From seisanzai-japan.com

Machining 08 What are work holding devices? Industry and Work Holding Devices In Lathe Chucks are probably the most widely adopted type of workholding device on the lathe. Work holding device is a general term for devices that attach and fix a workpiece to a machine tool. 1 what is workholding in machining? They are efficient and accurate and work. Are common lathe machine accessories and the functions of. 2 what are the importance’s. Work Holding Devices In Lathe.

From www.youtube.com

Lathe Work Holding Devices Types Chucks Part1 YouTube Work Holding Devices In Lathe Chucks are probably the most widely adopted type of workholding device on the lathe. If the workpiece is not attached. Chucks can have 2, 3, 4, or 6 jaws, however 3 and 4 jaw chucks are the most popular. Work holding methods are crucial in lathe machines as they play a significant role in ensuring precision and safety during machining. Work Holding Devices In Lathe.

From www.youtube.com

Metal Lathe 121 Work Holding Intro, Safety, and Tool Force YouTube Work Holding Devices In Lathe Are common lathe machine accessories and the functions of. 1 what is workholding in machining? One of the most popular ways to hold work on in a lathe is by using chucks or jaw chucks. Work holding device is a general term for devices that attach and fix a workpiece to a machine tool. Common accessories for a lathe machine. Work Holding Devices In Lathe.

From toolnotes.com

Lathe Workholding ToolNotes Work Holding Devices In Lathe Work holding device is a general term for devices that attach and fix a workpiece to a machine tool. Work holding devices in a lathe are used either for holding the workpiece or for supporting the workpiece during machining. 3 different types of workholding devices. Work holding methods are crucial in lathe machines as they play a significant role in. Work Holding Devices In Lathe.

From www.cnccookbook.com

Total Guide to CNC Jigs, Fixtures, and Workholding Solutions for Mills Work Holding Devices In Lathe 1 what is workholding in machining? Work holding device is a general term for devices that attach and fix a workpiece to a machine tool. 2 what are the importance’s of workholding? 3 different types of workholding devices. Common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. Chucks are probably the most widely. Work Holding Devices In Lathe.

From www.youtube.com

WORK HOLDING DEVICES OF LATHE MACHINE YouTube Work Holding Devices In Lathe 3 different types of workholding devices. Work holding devices in a lathe are used either for holding the workpiece or for supporting the workpiece during machining. 2 what are the importance’s of workholding? Common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. One of the most popular ways to hold work on in. Work Holding Devices In Lathe.

From www.youtube.com

5 Work Holding Devices in Semi automatic Lathes Jaw Chucks and Collet Work Holding Devices In Lathe Chucks are probably the most widely adopted type of workholding device on the lathe. Work holding methods are crucial in lathe machines as they play a significant role in ensuring precision and safety during machining operations. Chuck, face plate, lathe centers, steady rest and mandrels, etc. Work holding devices in a lathe are used either for holding the workpiece or. Work Holding Devices In Lathe.

From www.hvrmagnet.com

Workholding for Lathe/Grinding/Milling/CNC Machining Centers Work Holding Devices In Lathe 2 what are the importance’s of workholding? Work holding devices in a lathe are used either for holding the workpiece or for supporting the workpiece during machining. 1 what is workholding in machining? Are common lathe machine accessories and the functions of. Chucks are probably the most widely adopted type of workholding device on the lathe. If the workpiece is. Work Holding Devices In Lathe.

From www.youtube.com

Metal Lathe 124 Work Holding with Centers YouTube Work Holding Devices In Lathe Work holding methods are crucial in lathe machines as they play a significant role in ensuring precision and safety during machining operations. Work holding devices in a lathe are used either for holding the workpiece or for supporting the workpiece during machining. Chucks can have 2, 3, 4, or 6 jaws, however 3 and 4 jaw chucks are the most. Work Holding Devices In Lathe.

From www.youtube.com

Lathe Tutorial P 7 Work Holding YouTube Work Holding Devices In Lathe Common accessories for a lathe machine include chuck, face plate, lathe centers, steady rest, and mandrels. Chuck, face plate, lathe centers, steady rest and mandrels, etc. 1 what is workholding in machining? Work holding methods are crucial in lathe machines as they play a significant role in ensuring precision and safety during machining operations. Work holding devices in a lathe. Work Holding Devices In Lathe.

From www.youtube.com

Metal Lathe 127 Work Holding with Steady Rest YouTube Work Holding Devices In Lathe If the workpiece is not attached. 1 what is workholding in machining? Work holding devices in a lathe are used either for holding the workpiece or for supporting the workpiece during machining. Work holding devices in lathe machine. Chucks are probably the most widely adopted type of workholding device on the lathe. Work holding device is a general term for. Work Holding Devices In Lathe.

From mecrockers.blogspot.com

The machining operations generally carried out in centre lathes are Work Holding Devices In Lathe Work holding device is a general term for devices that attach and fix a workpiece to a machine tool. Chuck, face plate, lathe centers, steady rest and mandrels, etc. Chucks can have 2, 3, 4, or 6 jaws, however 3 and 4 jaw chucks are the most popular. 1 what is workholding in machining? Work holding devices in a lathe. Work Holding Devices In Lathe.

From www.mechical.com

Work Holding Devices in Lathe Machine and Their Types Work Holding Devices In Lathe They are efficient and accurate and work. If the workpiece is not attached. Are common lathe machine accessories and the functions of. Chucks can have 2, 3, 4, or 6 jaws, however 3 and 4 jaw chucks are the most popular. Work holding methods are crucial in lathe machines as they play a significant role in ensuring precision and safety. Work Holding Devices In Lathe.

From www.youtube.com

Work and Tool Holding in the Metal Lathe YouTube Work Holding Devices In Lathe 3 different types of workholding devices. 1 what is workholding in machining? Chucks can have 2, 3, 4, or 6 jaws, however 3 and 4 jaw chucks are the most popular. Work holding device is a general term for devices that attach and fix a workpiece to a machine tool. Work holding methods are crucial in lathe machines as they. Work Holding Devices In Lathe.