How To Reduce Rpm Of Motor With Pulley . to slow down a driven pulley (and achieve more torque) it should be larger than the drive pulley. reducing rpm can be accomplished by using two or more pulleys and belts to transmit and change the speed of rotation. think of the pulley system as a gear reduction. A 2 inch pulley driving a 4 inch pulley reduces the speed in half. A 2 inch pulley on the motor and a. These are basic gearing principles that are explained. Inversely, a small diameter driving a large diameter will reduce the final drive rpm. Diameter of the drive (r) pulley. Here’s how you can calculate the exact values: if you want to decrease the rotation speed of the output shaft, you should simply use a driven pulley with a larger diameter. Measure and note the key characteristics of the system. if you have a 1725 rpm motor (fairly typical in the us) then it is a matter of simple ratios, as you suggested:

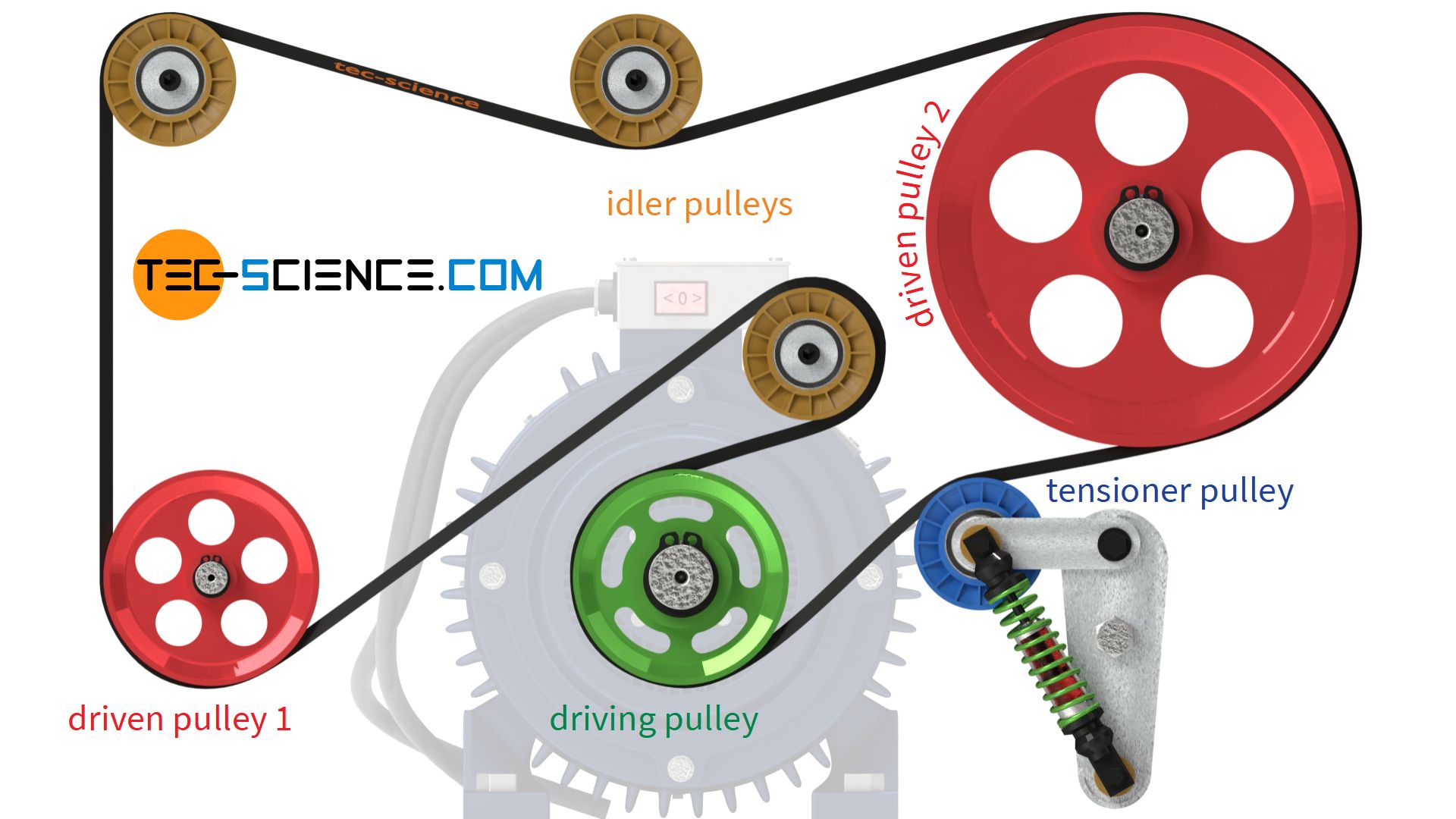

from www.tec-science.com

These are basic gearing principles that are explained. Diameter of the drive (r) pulley. Inversely, a small diameter driving a large diameter will reduce the final drive rpm. Measure and note the key characteristics of the system. to slow down a driven pulley (and achieve more torque) it should be larger than the drive pulley. A 2 inch pulley on the motor and a. A 2 inch pulley driving a 4 inch pulley reduces the speed in half. if you have a 1725 rpm motor (fairly typical in the us) then it is a matter of simple ratios, as you suggested: Here’s how you can calculate the exact values: think of the pulley system as a gear reduction.

Belt tensioner systems for belt drives tecscience

How To Reduce Rpm Of Motor With Pulley These are basic gearing principles that are explained. Inversely, a small diameter driving a large diameter will reduce the final drive rpm. reducing rpm can be accomplished by using two or more pulleys and belts to transmit and change the speed of rotation. These are basic gearing principles that are explained. A 2 inch pulley on the motor and a. if you want to decrease the rotation speed of the output shaft, you should simply use a driven pulley with a larger diameter. think of the pulley system as a gear reduction. Measure and note the key characteristics of the system. if you have a 1725 rpm motor (fairly typical in the us) then it is a matter of simple ratios, as you suggested: Here’s how you can calculate the exact values: Diameter of the drive (r) pulley. to slow down a driven pulley (and achieve more torque) it should be larger than the drive pulley. A 2 inch pulley driving a 4 inch pulley reduces the speed in half.

From www.tec-science.com

Belt tensioner systems for belt drives tecscience How To Reduce Rpm Of Motor With Pulley Diameter of the drive (r) pulley. if you have a 1725 rpm motor (fairly typical in the us) then it is a matter of simple ratios, as you suggested: if you want to decrease the rotation speed of the output shaft, you should simply use a driven pulley with a larger diameter. These are basic gearing principles that. How To Reduce Rpm Of Motor With Pulley.

From www.adinaporter.com

How to Increase Rpm with Pulleys Part 8 Mechanical Comprehension How To Reduce Rpm Of Motor With Pulley A 2 inch pulley on the motor and a. reducing rpm can be accomplished by using two or more pulleys and belts to transmit and change the speed of rotation. A 2 inch pulley driving a 4 inch pulley reduces the speed in half. if you have a 1725 rpm motor (fairly typical in the us) then it. How To Reduce Rpm Of Motor With Pulley.

From www.youtube.com

Belt Drive Speed Calculation How to Select Pulley size For Belt Drive How To Reduce Rpm Of Motor With Pulley think of the pulley system as a gear reduction. Diameter of the drive (r) pulley. A 2 inch pulley on the motor and a. reducing rpm can be accomplished by using two or more pulleys and belts to transmit and change the speed of rotation. A 2 inch pulley driving a 4 inch pulley reduces the speed in. How To Reduce Rpm Of Motor With Pulley.

From www.coursehero.com

[Solved] A line shaft is to transmit 30 kW at 160 r.p.m. It is driven How To Reduce Rpm Of Motor With Pulley Diameter of the drive (r) pulley. Measure and note the key characteristics of the system. to slow down a driven pulley (and achieve more torque) it should be larger than the drive pulley. reducing rpm can be accomplished by using two or more pulleys and belts to transmit and change the speed of rotation. These are basic gearing. How To Reduce Rpm Of Motor With Pulley.

From www.youtube.com

How to Speed Reducer Motor (RPM) Gear Speed Reducer Speed Can be How To Reduce Rpm Of Motor With Pulley These are basic gearing principles that are explained. reducing rpm can be accomplished by using two or more pulleys and belts to transmit and change the speed of rotation. Here’s how you can calculate the exact values: to slow down a driven pulley (and achieve more torque) it should be larger than the drive pulley. if you. How To Reduce Rpm Of Motor With Pulley.

From dxoaglybg.blob.core.windows.net

The Pulley Simple Machine Examples at Shanita Garcia blog How To Reduce Rpm Of Motor With Pulley Measure and note the key characteristics of the system. to slow down a driven pulley (and achieve more torque) it should be larger than the drive pulley. if you have a 1725 rpm motor (fairly typical in the us) then it is a matter of simple ratios, as you suggested: Here’s how you can calculate the exact values:. How To Reduce Rpm Of Motor With Pulley.

From www.sogears.com

How to reduce motor speed with pulleys How To Reduce Rpm Of Motor With Pulley Measure and note the key characteristics of the system. if you have a 1725 rpm motor (fairly typical in the us) then it is a matter of simple ratios, as you suggested: reducing rpm can be accomplished by using two or more pulleys and belts to transmit and change the speed of rotation. think of the pulley. How To Reduce Rpm Of Motor With Pulley.

From www.youtube.com

Belt drive speed calculation pulley size and speed calculation belt How To Reduce Rpm Of Motor With Pulley A 2 inch pulley on the motor and a. A 2 inch pulley driving a 4 inch pulley reduces the speed in half. if you have a 1725 rpm motor (fairly typical in the us) then it is a matter of simple ratios, as you suggested: These are basic gearing principles that are explained. if you want to. How To Reduce Rpm Of Motor With Pulley.

From www.guomaodrive.com

How to reduce motor speed with pulleys Blog How To Reduce Rpm Of Motor With Pulley reducing rpm can be accomplished by using two or more pulleys and belts to transmit and change the speed of rotation. if you have a 1725 rpm motor (fairly typical in the us) then it is a matter of simple ratios, as you suggested: to slow down a driven pulley (and achieve more torque) it should be. How To Reduce Rpm Of Motor With Pulley.

From activegaliano.org

How To Reduce Rpm Of 3 Phase Motor? New Update How To Reduce Rpm Of Motor With Pulley Diameter of the drive (r) pulley. Measure and note the key characteristics of the system. Here’s how you can calculate the exact values: A 2 inch pulley driving a 4 inch pulley reduces the speed in half. think of the pulley system as a gear reduction. reducing rpm can be accomplished by using two or more pulleys and. How To Reduce Rpm Of Motor With Pulley.

From theengineeringmindset.com

Pump calculations The Engineering Mindset How To Reduce Rpm Of Motor With Pulley if you want to decrease the rotation speed of the output shaft, you should simply use a driven pulley with a larger diameter. reducing rpm can be accomplished by using two or more pulleys and belts to transmit and change the speed of rotation. These are basic gearing principles that are explained. Here’s how you can calculate the. How To Reduce Rpm Of Motor With Pulley.

From www.youtube.com

how to select right electric motor for ev conversion torque rpm power How To Reduce Rpm Of Motor With Pulley A 2 inch pulley driving a 4 inch pulley reduces the speed in half. if you have a 1725 rpm motor (fairly typical in the us) then it is a matter of simple ratios, as you suggested: if you want to decrease the rotation speed of the output shaft, you should simply use a driven pulley with a. How To Reduce Rpm Of Motor With Pulley.

From www.youtube.com

Convert pole to rpm how to calculate rpm of motor target How To Reduce Rpm Of Motor With Pulley These are basic gearing principles that are explained. Diameter of the drive (r) pulley. A 2 inch pulley driving a 4 inch pulley reduces the speed in half. Measure and note the key characteristics of the system. think of the pulley system as a gear reduction. to slow down a driven pulley (and achieve more torque) it should. How To Reduce Rpm Of Motor With Pulley.

From www.wikihow.com

4 Easy Ways to Determine Gear Ratio (with Pictures) How To Reduce Rpm Of Motor With Pulley A 2 inch pulley driving a 4 inch pulley reduces the speed in half. Here’s how you can calculate the exact values: to slow down a driven pulley (and achieve more torque) it should be larger than the drive pulley. These are basic gearing principles that are explained. Diameter of the drive (r) pulley. reducing rpm can be. How To Reduce Rpm Of Motor With Pulley.

From www.adinaporter.com

How to Increase Rpm with Pulleys An Introduction to Mechanisms How To Reduce Rpm Of Motor With Pulley A 2 inch pulley driving a 4 inch pulley reduces the speed in half. These are basic gearing principles that are explained. if you want to decrease the rotation speed of the output shaft, you should simply use a driven pulley with a larger diameter. A 2 inch pulley on the motor and a. Inversely, a small diameter driving. How To Reduce Rpm Of Motor With Pulley.

From www.coursehero.com

[Solved] A shunt connected, 75+mKW 250+mV dc motor has an armature How To Reduce Rpm Of Motor With Pulley A 2 inch pulley driving a 4 inch pulley reduces the speed in half. to slow down a driven pulley (and achieve more torque) it should be larger than the drive pulley. reducing rpm can be accomplished by using two or more pulleys and belts to transmit and change the speed of rotation. Measure and note the key. How To Reduce Rpm Of Motor With Pulley.

From www.pinterest.com

A pulley rpm calculator to determine the motor or drive speeds or size How To Reduce Rpm Of Motor With Pulley A 2 inch pulley on the motor and a. Diameter of the drive (r) pulley. reducing rpm can be accomplished by using two or more pulleys and belts to transmit and change the speed of rotation. Here’s how you can calculate the exact values: Measure and note the key characteristics of the system. to slow down a driven. How To Reduce Rpm Of Motor With Pulley.

From www.youtube.com

How to calculate RPM driver,driven pulley formula Tricks Motor pulley How To Reduce Rpm Of Motor With Pulley if you have a 1725 rpm motor (fairly typical in the us) then it is a matter of simple ratios, as you suggested: Here’s how you can calculate the exact values: A 2 inch pulley driving a 4 inch pulley reduces the speed in half. if you want to decrease the rotation speed of the output shaft, you. How To Reduce Rpm Of Motor With Pulley.

From sciencing.com

How to Reduce RPMs Using Belts & Pulleys Sciencing How To Reduce Rpm Of Motor With Pulley A 2 inch pulley on the motor and a. Inversely, a small diameter driving a large diameter will reduce the final drive rpm. think of the pulley system as a gear reduction. to slow down a driven pulley (and achieve more torque) it should be larger than the drive pulley. reducing rpm can be accomplished by using. How To Reduce Rpm Of Motor With Pulley.

From www.sogears.com

How to reduce motor speed with pulleys How To Reduce Rpm Of Motor With Pulley if you have a 1725 rpm motor (fairly typical in the us) then it is a matter of simple ratios, as you suggested: A 2 inch pulley on the motor and a. if you want to decrease the rotation speed of the output shaft, you should simply use a driven pulley with a larger diameter. to slow. How To Reduce Rpm Of Motor With Pulley.

From small-pulley.com

Small Pulley Specialist smallpulley How To Reduce Rpm Of Motor With Pulley A 2 inch pulley on the motor and a. think of the pulley system as a gear reduction. Here’s how you can calculate the exact values: if you have a 1725 rpm motor (fairly typical in the us) then it is a matter of simple ratios, as you suggested: Inversely, a small diameter driving a large diameter will. How To Reduce Rpm Of Motor With Pulley.

From dxogoluic.blob.core.windows.net

Big Pulley To Small Pulley Speed at Kathy McCray blog How To Reduce Rpm Of Motor With Pulley Measure and note the key characteristics of the system. A 2 inch pulley on the motor and a. if you want to decrease the rotation speed of the output shaft, you should simply use a driven pulley with a larger diameter. Here’s how you can calculate the exact values: if you have a 1725 rpm motor (fairly typical. How To Reduce Rpm Of Motor With Pulley.

From www.pinterest.com.mx

Pulley Belt RPM Calculator Pulleys in 2019 Pulley, Homemade tools How To Reduce Rpm Of Motor With Pulley if you have a 1725 rpm motor (fairly typical in the us) then it is a matter of simple ratios, as you suggested: These are basic gearing principles that are explained. Measure and note the key characteristics of the system. Diameter of the drive (r) pulley. Inversely, a small diameter driving a large diameter will reduce the final drive. How To Reduce Rpm Of Motor With Pulley.

From exopzfqjk.blob.core.windows.net

Pulleys Speed Relative at Charles Fairbanks blog How To Reduce Rpm Of Motor With Pulley These are basic gearing principles that are explained. A 2 inch pulley driving a 4 inch pulley reduces the speed in half. A 2 inch pulley on the motor and a. if you have a 1725 rpm motor (fairly typical in the us) then it is a matter of simple ratios, as you suggested: to slow down a. How To Reduce Rpm Of Motor With Pulley.

From www.youtube.com

How To Increase RPM or Speed Of N20 Gear Motor Without Damaging Gears How To Reduce Rpm Of Motor With Pulley Diameter of the drive (r) pulley. to slow down a driven pulley (and achieve more torque) it should be larger than the drive pulley. A 2 inch pulley driving a 4 inch pulley reduces the speed in half. think of the pulley system as a gear reduction. if you have a 1725 rpm motor (fairly typical in. How To Reduce Rpm Of Motor With Pulley.

From www.youtube.com

Reduce Motor RPM with DIY Hypocycloidal Gear! YouTube How To Reduce Rpm Of Motor With Pulley These are basic gearing principles that are explained. Measure and note the key characteristics of the system. Diameter of the drive (r) pulley. A 2 inch pulley on the motor and a. to slow down a driven pulley (and achieve more torque) it should be larger than the drive pulley. if you have a 1725 rpm motor (fairly. How To Reduce Rpm Of Motor With Pulley.

From electronics.stackexchange.com

How to lower the rpm's in small a DC motor Electrical Engineering How To Reduce Rpm Of Motor With Pulley A 2 inch pulley on the motor and a. These are basic gearing principles that are explained. Here’s how you can calculate the exact values: reducing rpm can be accomplished by using two or more pulleys and belts to transmit and change the speed of rotation. Diameter of the drive (r) pulley. Measure and note the key characteristics of. How To Reduce Rpm Of Motor With Pulley.

From www.youtube.com

Engine Whine with RPM Troubleshooting Here's How to Test for Bearing How To Reduce Rpm Of Motor With Pulley Measure and note the key characteristics of the system. to slow down a driven pulley (and achieve more torque) it should be larger than the drive pulley. think of the pulley system as a gear reduction. A 2 inch pulley driving a 4 inch pulley reduces the speed in half. Diameter of the drive (r) pulley. if. How To Reduce Rpm Of Motor With Pulley.

From www.youtube.com

how to increase and decrease engine idle RPM? how to work your car How To Reduce Rpm Of Motor With Pulley A 2 inch pulley driving a 4 inch pulley reduces the speed in half. Measure and note the key characteristics of the system. These are basic gearing principles that are explained. if you have a 1725 rpm motor (fairly typical in the us) then it is a matter of simple ratios, as you suggested: Diameter of the drive (r). How To Reduce Rpm Of Motor With Pulley.

From www.youtube.com

How to calculate rpm of motorCalculate rpm of motorrpm of motor How To Reduce Rpm Of Motor With Pulley A 2 inch pulley driving a 4 inch pulley reduces the speed in half. if you want to decrease the rotation speed of the output shaft, you should simply use a driven pulley with a larger diameter. These are basic gearing principles that are explained. A 2 inch pulley on the motor and a. think of the pulley. How To Reduce Rpm Of Motor With Pulley.

From www.youtube.com

Fan & motor CALCULATIONS, Pulley size, RPM, air flow rate cfm hvac rtu How To Reduce Rpm Of Motor With Pulley These are basic gearing principles that are explained. to slow down a driven pulley (and achieve more torque) it should be larger than the drive pulley. if you want to decrease the rotation speed of the output shaft, you should simply use a driven pulley with a larger diameter. if you have a 1725 rpm motor (fairly. How To Reduce Rpm Of Motor With Pulley.

From www.tec-science.com

How does a belt drive work? tecscience How To Reduce Rpm Of Motor With Pulley These are basic gearing principles that are explained. reducing rpm can be accomplished by using two or more pulleys and belts to transmit and change the speed of rotation. Inversely, a small diameter driving a large diameter will reduce the final drive rpm. A 2 inch pulley driving a 4 inch pulley reduces the speed in half. A 2. How To Reduce Rpm Of Motor With Pulley.

From exodhwybi.blob.core.windows.net

How Does A Sailboat Use A Pulley System at Tony Flores blog How To Reduce Rpm Of Motor With Pulley think of the pulley system as a gear reduction. Here’s how you can calculate the exact values: reducing rpm can be accomplished by using two or more pulleys and belts to transmit and change the speed of rotation. A 2 inch pulley driving a 4 inch pulley reduces the speed in half. Diameter of the drive (r) pulley.. How To Reduce Rpm Of Motor With Pulley.

From www.adinaporter.com

How to Increase Rpm with Pulleys AdinaPorter How To Reduce Rpm Of Motor With Pulley reducing rpm can be accomplished by using two or more pulleys and belts to transmit and change the speed of rotation. Measure and note the key characteristics of the system. if you want to decrease the rotation speed of the output shaft, you should simply use a driven pulley with a larger diameter. A 2 inch pulley on. How To Reduce Rpm Of Motor With Pulley.

From atelier-yuwa.ciao.jp

How To Decrease Rpm With Pulleys atelieryuwa.ciao.jp How To Reduce Rpm Of Motor With Pulley to slow down a driven pulley (and achieve more torque) it should be larger than the drive pulley. think of the pulley system as a gear reduction. Here’s how you can calculate the exact values: if you want to decrease the rotation speed of the output shaft, you should simply use a driven pulley with a larger. How To Reduce Rpm Of Motor With Pulley.