Chemicals Used In Plating Process . Plating and anodizing chemicals and supplies include chrome stripper solutions, nickel activator solutions, and immersion plating solutions, as well as brush plating accessories and platinized. Learn how electroplating works, what are the common metals and. Electroplating is a technique that uses electricity to bond thin layers of metal to another metal surface. Learn how zinc electroplating is done to coat metals and provide protection against corrosion. See the steps involved in cleaning, activation, plating, and rinsing the substrate, and the pros and. Learn about the most commonly used metals in electroplating, such as gold, silver, copper, nickel, and chromium, and why they are. Learn about electroplating, the process of plating one metal onto another by hydrolysis, most commonly for decorative purposes or to prevent corrosion of a metal.

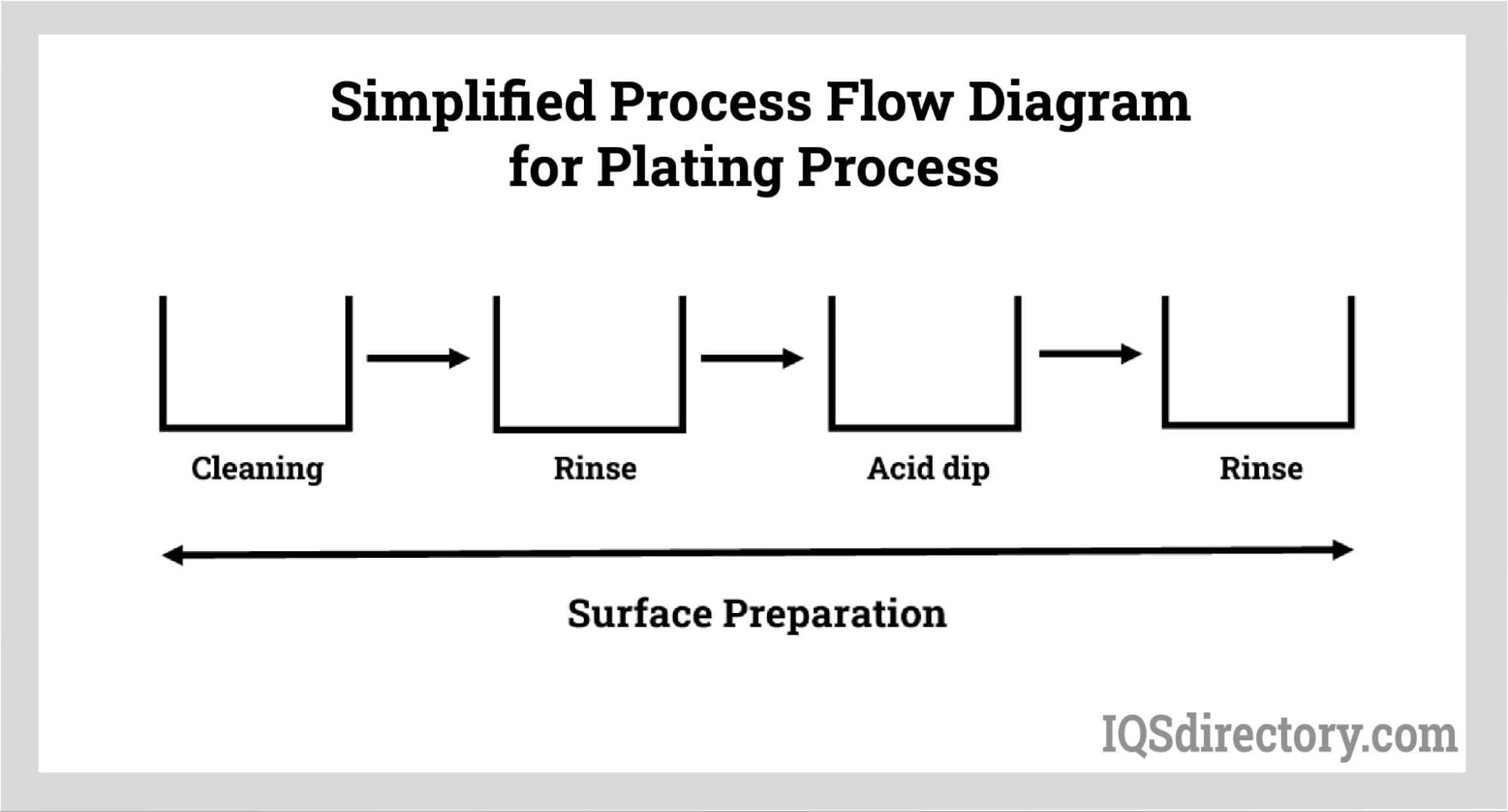

from www.iqsdirectory.com

Plating and anodizing chemicals and supplies include chrome stripper solutions, nickel activator solutions, and immersion plating solutions, as well as brush plating accessories and platinized. Electroplating is a technique that uses electricity to bond thin layers of metal to another metal surface. Learn about electroplating, the process of plating one metal onto another by hydrolysis, most commonly for decorative purposes or to prevent corrosion of a metal. See the steps involved in cleaning, activation, plating, and rinsing the substrate, and the pros and. Learn how zinc electroplating is done to coat metals and provide protection against corrosion. Learn how electroplating works, what are the common metals and. Learn about the most commonly used metals in electroplating, such as gold, silver, copper, nickel, and chromium, and why they are.

Electroless Nickel Plating Variations, Types, Applications, and Benefits

Chemicals Used In Plating Process Learn how zinc electroplating is done to coat metals and provide protection against corrosion. Learn about electroplating, the process of plating one metal onto another by hydrolysis, most commonly for decorative purposes or to prevent corrosion of a metal. Plating and anodizing chemicals and supplies include chrome stripper solutions, nickel activator solutions, and immersion plating solutions, as well as brush plating accessories and platinized. Learn how zinc electroplating is done to coat metals and provide protection against corrosion. See the steps involved in cleaning, activation, plating, and rinsing the substrate, and the pros and. Electroplating is a technique that uses electricity to bond thin layers of metal to another metal surface. Learn how electroplating works, what are the common metals and. Learn about the most commonly used metals in electroplating, such as gold, silver, copper, nickel, and chromium, and why they are.

From www.ourpcb.com

PCB Edge Plating Metalizing Circuit Board Edges via Electroless Copper Plating Chemicals Used In Plating Process Learn about the most commonly used metals in electroplating, such as gold, silver, copper, nickel, and chromium, and why they are. Learn about electroplating, the process of plating one metal onto another by hydrolysis, most commonly for decorative purposes or to prevent corrosion of a metal. Learn how electroplating works, what are the common metals and. Plating and anodizing chemicals. Chemicals Used In Plating Process.

From www.greenspec.co.uk

Toxic Chemistry Hexavalent chromium (aka Chromium6 ) Chemicals Used In Plating Process Learn how zinc electroplating is done to coat metals and provide protection against corrosion. Learn about the most commonly used metals in electroplating, such as gold, silver, copper, nickel, and chromium, and why they are. Plating and anodizing chemicals and supplies include chrome stripper solutions, nickel activator solutions, and immersion plating solutions, as well as brush plating accessories and platinized.. Chemicals Used In Plating Process.

From www.researchgate.net

(a) The procedure for electroless Cu plating and (b) the chemical... Download Scientific Diagram Chemicals Used In Plating Process Learn about electroplating, the process of plating one metal onto another by hydrolysis, most commonly for decorative purposes or to prevent corrosion of a metal. Plating and anodizing chemicals and supplies include chrome stripper solutions, nickel activator solutions, and immersion plating solutions, as well as brush plating accessories and platinized. Electroplating is a technique that uses electricity to bond thin. Chemicals Used In Plating Process.

From www.masteretching.com

Chemical Etching Process What is Chemical Etching? Chemicals Used In Plating Process Learn how electroplating works, what are the common metals and. Plating and anodizing chemicals and supplies include chrome stripper solutions, nickel activator solutions, and immersion plating solutions, as well as brush plating accessories and platinized. Learn about the most commonly used metals in electroplating, such as gold, silver, copper, nickel, and chromium, and why they are. Learn how zinc electroplating. Chemicals Used In Plating Process.

From elcoats.com

Types of Metal Plating Elcoats Allied Industries Chemicals Used In Plating Process Learn how zinc electroplating is done to coat metals and provide protection against corrosion. Electroplating is a technique that uses electricity to bond thin layers of metal to another metal surface. Learn how electroplating works, what are the common metals and. Plating and anodizing chemicals and supplies include chrome stripper solutions, nickel activator solutions, and immersion plating solutions, as well. Chemicals Used In Plating Process.

From www.researchgate.net

Schematic of the electroless plating process used to form gold... Download Scientific Diagram Chemicals Used In Plating Process Learn about the most commonly used metals in electroplating, such as gold, silver, copper, nickel, and chromium, and why they are. Learn how zinc electroplating is done to coat metals and provide protection against corrosion. Learn about electroplating, the process of plating one metal onto another by hydrolysis, most commonly for decorative purposes or to prevent corrosion of a metal.. Chemicals Used In Plating Process.

From www.chemtexltd.com

Phosphating Chemicals Chemtex Speciality Limited Chemicals Used In Plating Process Learn about electroplating, the process of plating one metal onto another by hydrolysis, most commonly for decorative purposes or to prevent corrosion of a metal. See the steps involved in cleaning, activation, plating, and rinsing the substrate, and the pros and. Learn how electroplating works, what are the common metals and. Plating and anodizing chemicals and supplies include chrome stripper. Chemicals Used In Plating Process.

From www.nwengineeringllc.com

PCB Surface Plating Materials and Their Advantages NWES Blog Chemicals Used In Plating Process See the steps involved in cleaning, activation, plating, and rinsing the substrate, and the pros and. Learn about the most commonly used metals in electroplating, such as gold, silver, copper, nickel, and chromium, and why they are. Learn about electroplating, the process of plating one metal onto another by hydrolysis, most commonly for decorative purposes or to prevent corrosion of. Chemicals Used In Plating Process.

From www.wiringdraw.com

Draw A Simple Circuit Diagram To Show Electroplating Chemicals Used In Plating Process Learn how electroplating works, what are the common metals and. Learn about the most commonly used metals in electroplating, such as gold, silver, copper, nickel, and chromium, and why they are. Learn about electroplating, the process of plating one metal onto another by hydrolysis, most commonly for decorative purposes or to prevent corrosion of a metal. See the steps involved. Chemicals Used In Plating Process.

From www.mdpi.com

Free FullText Finishing of Chemically Treated Chemicals Used In Plating Process Plating and anodizing chemicals and supplies include chrome stripper solutions, nickel activator solutions, and immersion plating solutions, as well as brush plating accessories and platinized. See the steps involved in cleaning, activation, plating, and rinsing the substrate, and the pros and. Learn how electroplating works, what are the common metals and. Learn about the most commonly used metals in electroplating,. Chemicals Used In Plating Process.

From www.alamy.com

Electroplating with copper using copper sulfate electrolyte. Electrolysis of copper(II) sulfate Chemicals Used In Plating Process Electroplating is a technique that uses electricity to bond thin layers of metal to another metal surface. Learn how electroplating works, what are the common metals and. Learn about the most commonly used metals in electroplating, such as gold, silver, copper, nickel, and chromium, and why they are. See the steps involved in cleaning, activation, plating, and rinsing the substrate,. Chemicals Used In Plating Process.

From www.researchgate.net

Schematic diagram of electroless plating process of CuSnAg coreshell... Download Scientific Chemicals Used In Plating Process Learn about the most commonly used metals in electroplating, such as gold, silver, copper, nickel, and chromium, and why they are. Electroplating is a technique that uses electricity to bond thin layers of metal to another metal surface. Learn how zinc electroplating is done to coat metals and provide protection against corrosion. Learn about electroplating, the process of plating one. Chemicals Used In Plating Process.

From uniglobekisco.com

Plating Chemicals for Semiconductors Uniglobe Kisco Inc Chemicals Used In Plating Process Learn how zinc electroplating is done to coat metals and provide protection against corrosion. Learn how electroplating works, what are the common metals and. See the steps involved in cleaning, activation, plating, and rinsing the substrate, and the pros and. Plating and anodizing chemicals and supplies include chrome stripper solutions, nickel activator solutions, and immersion plating solutions, as well as. Chemicals Used In Plating Process.

From www.mdpi.com

Free FullText Finishing of Chemically Treated Chemicals Used In Plating Process Electroplating is a technique that uses electricity to bond thin layers of metal to another metal surface. Plating and anodizing chemicals and supplies include chrome stripper solutions, nickel activator solutions, and immersion plating solutions, as well as brush plating accessories and platinized. Learn how electroplating works, what are the common metals and. Learn how zinc electroplating is done to coat. Chemicals Used In Plating Process.

From www.deepakfasteners.com

Deepak Fasteners Limited Zinc Electroplating Chemicals Used In Plating Process Learn about the most commonly used metals in electroplating, such as gold, silver, copper, nickel, and chromium, and why they are. Learn how electroplating works, what are the common metals and. Electroplating is a technique that uses electricity to bond thin layers of metal to another metal surface. Plating and anodizing chemicals and supplies include chrome stripper solutions, nickel activator. Chemicals Used In Plating Process.

From www.researchgate.net

a Schematic diagram of the electroless plating process of CuSnAg... Download Scientific Diagram Chemicals Used In Plating Process Learn about electroplating, the process of plating one metal onto another by hydrolysis, most commonly for decorative purposes or to prevent corrosion of a metal. Plating and anodizing chemicals and supplies include chrome stripper solutions, nickel activator solutions, and immersion plating solutions, as well as brush plating accessories and platinized. See the steps involved in cleaning, activation, plating, and rinsing. Chemicals Used In Plating Process.

From www.researchgate.net

Generalized plating process current applied onto Mg alloys routes... Download Scientific Diagram Chemicals Used In Plating Process Electroplating is a technique that uses electricity to bond thin layers of metal to another metal surface. Plating and anodizing chemicals and supplies include chrome stripper solutions, nickel activator solutions, and immersion plating solutions, as well as brush plating accessories and platinized. Learn how electroplating works, what are the common metals and. Learn about the most commonly used metals in. Chemicals Used In Plating Process.

From www.youtube.com

Electroplating Process YouTube Chemicals Used In Plating Process Learn about the most commonly used metals in electroplating, such as gold, silver, copper, nickel, and chromium, and why they are. See the steps involved in cleaning, activation, plating, and rinsing the substrate, and the pros and. Learn how electroplating works, what are the common metals and. Plating and anodizing chemicals and supplies include chrome stripper solutions, nickel activator solutions,. Chemicals Used In Plating Process.

From altaherchemicals.com

Electroplating Chemical Suppliers in Dubai, UAE Chemicals Used In Plating Process Learn about electroplating, the process of plating one metal onto another by hydrolysis, most commonly for decorative purposes or to prevent corrosion of a metal. Learn how electroplating works, what are the common metals and. Learn how zinc electroplating is done to coat metals and provide protection against corrosion. Learn about the most commonly used metals in electroplating, such as. Chemicals Used In Plating Process.

From blog.thepipingmart.com

Copper Nickel Chrome Plating Process and Advantages Chemicals Used In Plating Process Electroplating is a technique that uses electricity to bond thin layers of metal to another metal surface. Learn how zinc electroplating is done to coat metals and provide protection against corrosion. Learn how electroplating works, what are the common metals and. Plating and anodizing chemicals and supplies include chrome stripper solutions, nickel activator solutions, and immersion plating solutions, as well. Chemicals Used In Plating Process.

From sensorex.com

Electroplating The Process & Uses in Liquid Analysis Explained Sensorex Chemicals Used In Plating Process Plating and anodizing chemicals and supplies include chrome stripper solutions, nickel activator solutions, and immersion plating solutions, as well as brush plating accessories and platinized. Electroplating is a technique that uses electricity to bond thin layers of metal to another metal surface. Learn how zinc electroplating is done to coat metals and provide protection against corrosion. Learn how electroplating works,. Chemicals Used In Plating Process.

From mungfali.com

Copper Plating Process Chemicals Used In Plating Process Electroplating is a technique that uses electricity to bond thin layers of metal to another metal surface. Learn about the most commonly used metals in electroplating, such as gold, silver, copper, nickel, and chromium, and why they are. Learn how zinc electroplating is done to coat metals and provide protection against corrosion. See the steps involved in cleaning, activation, plating,. Chemicals Used In Plating Process.

From www.youtube.com

Electroless plating process/Electroless deposition Corrosion Control YouTube Chemicals Used In Plating Process Learn how zinc electroplating is done to coat metals and provide protection against corrosion. Electroplating is a technique that uses electricity to bond thin layers of metal to another metal surface. See the steps involved in cleaning, activation, plating, and rinsing the substrate, and the pros and. Learn about the most commonly used metals in electroplating, such as gold, silver,. Chemicals Used In Plating Process.

From www.daelyuk.com

DAELYUK CO,.Ltd Chemicals Used In Plating Process Learn about electroplating, the process of plating one metal onto another by hydrolysis, most commonly for decorative purposes or to prevent corrosion of a metal. Learn about the most commonly used metals in electroplating, such as gold, silver, copper, nickel, and chromium, and why they are. Plating and anodizing chemicals and supplies include chrome stripper solutions, nickel activator solutions, and. Chemicals Used In Plating Process.

From www.youtube.com

Metal Plating Process A Complete Guide To Its Types And Technique. YouTube Chemicals Used In Plating Process Learn about the most commonly used metals in electroplating, such as gold, silver, copper, nickel, and chromium, and why they are. Learn about electroplating, the process of plating one metal onto another by hydrolysis, most commonly for decorative purposes or to prevent corrosion of a metal. Learn how zinc electroplating is done to coat metals and provide protection against corrosion.. Chemicals Used In Plating Process.

From www.valencesurfacetech.com

Anodizing Vs. Plating Key Differences And Similarities Chemicals Used In Plating Process Learn about electroplating, the process of plating one metal onto another by hydrolysis, most commonly for decorative purposes or to prevent corrosion of a metal. See the steps involved in cleaning, activation, plating, and rinsing the substrate, and the pros and. Plating and anodizing chemicals and supplies include chrome stripper solutions, nickel activator solutions, and immersion plating solutions, as well. Chemicals Used In Plating Process.

From mantavya.com

What Is Electroplating & How does it work 2021 Guide Mantavya Chemicals Used In Plating Process Learn about electroplating, the process of plating one metal onto another by hydrolysis, most commonly for decorative purposes or to prevent corrosion of a metal. Learn how zinc electroplating is done to coat metals and provide protection against corrosion. Plating and anodizing chemicals and supplies include chrome stripper solutions, nickel activator solutions, and immersion plating solutions, as well as brush. Chemicals Used In Plating Process.

From www.researchgate.net

7 Methods for copper electrode deposition [1] (a) throughmask... Download Scientific Diagram Chemicals Used In Plating Process Learn how zinc electroplating is done to coat metals and provide protection against corrosion. Electroplating is a technique that uses electricity to bond thin layers of metal to another metal surface. Learn about the most commonly used metals in electroplating, such as gold, silver, copper, nickel, and chromium, and why they are. Learn about electroplating, the process of plating one. Chemicals Used In Plating Process.

From www.youtube.com

Chrome Plating Process What Chemicals Used in Chrome Plating? Hard Chrome Plating Coating Chemicals Used In Plating Process See the steps involved in cleaning, activation, plating, and rinsing the substrate, and the pros and. Learn how zinc electroplating is done to coat metals and provide protection against corrosion. Learn how electroplating works, what are the common metals and. Learn about the most commonly used metals in electroplating, such as gold, silver, copper, nickel, and chromium, and why they. Chemicals Used In Plating Process.

From www.iqsdirectory.com

Electroless Nickel Plating Variations, Types, Applications, and Benefits Chemicals Used In Plating Process Learn about the most commonly used metals in electroplating, such as gold, silver, copper, nickel, and chromium, and why they are. See the steps involved in cleaning, activation, plating, and rinsing the substrate, and the pros and. Learn about electroplating, the process of plating one metal onto another by hydrolysis, most commonly for decorative purposes or to prevent corrosion of. Chemicals Used In Plating Process.

From www.dupont.com

Copper pillar electroplating tutorial Chemicals Used In Plating Process See the steps involved in cleaning, activation, plating, and rinsing the substrate, and the pros and. Learn how zinc electroplating is done to coat metals and provide protection against corrosion. Learn about electroplating, the process of plating one metal onto another by hydrolysis, most commonly for decorative purposes or to prevent corrosion of a metal. Electroplating is a technique that. Chemicals Used In Plating Process.

From dlpplus.com

DLP Co.,Ltd Chemicals Used In Plating Process Learn how zinc electroplating is done to coat metals and provide protection against corrosion. Learn how electroplating works, what are the common metals and. Plating and anodizing chemicals and supplies include chrome stripper solutions, nickel activator solutions, and immersion plating solutions, as well as brush plating accessories and platinized. Learn about the most commonly used metals in electroplating, such as. Chemicals Used In Plating Process.

From narodnatribuna.info

Electroplating Diagram Chemicals Used In Plating Process Plating and anodizing chemicals and supplies include chrome stripper solutions, nickel activator solutions, and immersion plating solutions, as well as brush plating accessories and platinized. Electroplating is a technique that uses electricity to bond thin layers of metal to another metal surface. Learn about electroplating, the process of plating one metal onto another by hydrolysis, most commonly for decorative purposes. Chemicals Used In Plating Process.

From www.chemistrylearner.com

Electroplating Definition, Process, Example, and Equation Chemicals Used In Plating Process Learn about the most commonly used metals in electroplating, such as gold, silver, copper, nickel, and chromium, and why they are. See the steps involved in cleaning, activation, plating, and rinsing the substrate, and the pros and. Electroplating is a technique that uses electricity to bond thin layers of metal to another metal surface. Learn how zinc electroplating is done. Chemicals Used In Plating Process.

From www.iqsdirectory.com

Electroless Nickel Plating Variations, Types, Applications, and Benefits Chemicals Used In Plating Process Learn about the most commonly used metals in electroplating, such as gold, silver, copper, nickel, and chromium, and why they are. See the steps involved in cleaning, activation, plating, and rinsing the substrate, and the pros and. Electroplating is a technique that uses electricity to bond thin layers of metal to another metal surface. Learn about electroplating, the process of. Chemicals Used In Plating Process.