Laser Welding Wire . Choosing the right laser welding wire requires a thoughtful consideration of various factors, including material compatibility, wire diameter, composition, feed rate, surface. Laserstar laser welding wires have been evaluated and tested for functionality, performance, strength and homogeneous alloy characteristics to assure the highest quality material. Global laser tek supplies high quality small diameter wires for the laser and micro welding in wide range of industries including tool & die repair, electronics, aerospace, automotive, dental. By incorporating additional welding wire, it ensures robust joints and improved weld quality. 4.5/5 (7,841) 4.5/5 (7,841) Our maxphotonics weld star laser welding equipment is supplied as a compact unit with an integrated wire feeder and a fibre laser welding. In this article, you’ll uncover the.

from www.aliexpress.com

Global laser tek supplies high quality small diameter wires for the laser and micro welding in wide range of industries including tool & die repair, electronics, aerospace, automotive, dental. Our maxphotonics weld star laser welding equipment is supplied as a compact unit with an integrated wire feeder and a fibre laser welding. 4.5/5 (7,841) Laserstar laser welding wires have been evaluated and tested for functionality, performance, strength and homogeneous alloy characteristics to assure the highest quality material. In this article, you’ll uncover the. Choosing the right laser welding wire requires a thoughtful consideration of various factors, including material compatibility, wire diameter, composition, feed rate, surface. 4.5/5 (7,841) By incorporating additional welding wire, it ensures robust joints and improved weld quality.

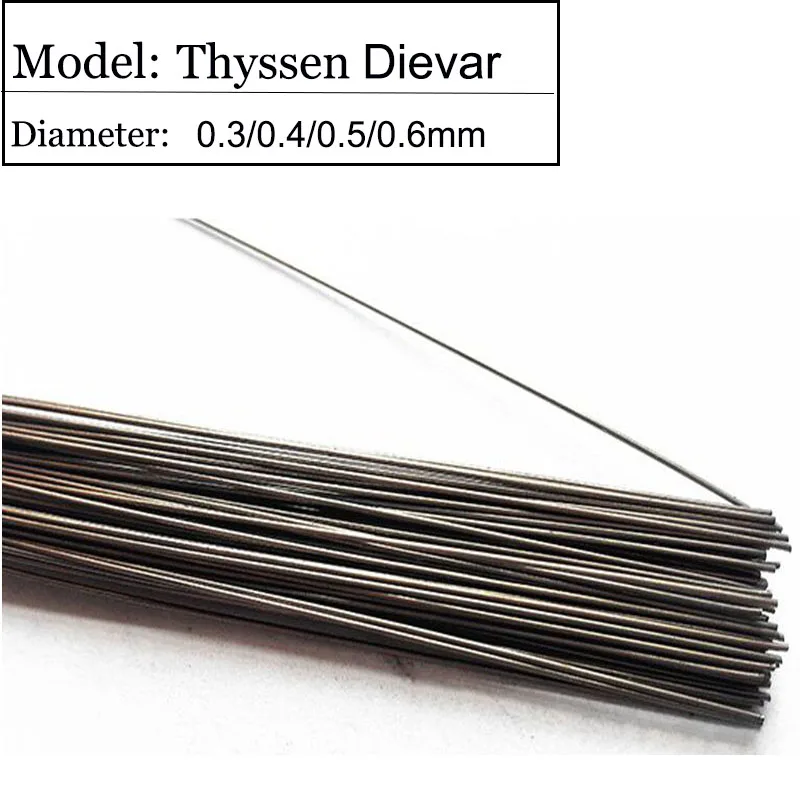

GM Laser welding wire Thyssen Dievar of 0.3/0.4/0.5/0.6/0.8mm Filler

Laser Welding Wire Laserstar laser welding wires have been evaluated and tested for functionality, performance, strength and homogeneous alloy characteristics to assure the highest quality material. 4.5/5 (7,841) By incorporating additional welding wire, it ensures robust joints and improved weld quality. Choosing the right laser welding wire requires a thoughtful consideration of various factors, including material compatibility, wire diameter, composition, feed rate, surface. Laserstar laser welding wires have been evaluated and tested for functionality, performance, strength and homogeneous alloy characteristics to assure the highest quality material. In this article, you’ll uncover the. Our maxphotonics weld star laser welding equipment is supplied as a compact unit with an integrated wire feeder and a fibre laser welding. 4.5/5 (7,841) Global laser tek supplies high quality small diameter wires for the laser and micro welding in wide range of industries including tool & die repair, electronics, aerospace, automotive, dental.

From www.laserpuls.com

Laser Welding Wire Laser Welding Wire Laserstar laser welding wires have been evaluated and tested for functionality, performance, strength and homogeneous alloy characteristics to assure the highest quality material. Choosing the right laser welding wire requires a thoughtful consideration of various factors, including material compatibility, wire diameter, composition, feed rate, surface. 4.5/5 (7,841) In this article, you’ll uncover the. Our maxphotonics weld star laser welding. Laser Welding Wire.

From airwelder.com

How to Select Laser Welding Wire Airwelder Laser Welding Wire Global laser tek supplies high quality small diameter wires for the laser and micro welding in wide range of industries including tool & die repair, electronics, aerospace, automotive, dental. In this article, you’ll uncover the. 4.5/5 (7,841) 4.5/5 (7,841) Our maxphotonics weld star laser welding equipment is supplied as a compact unit with an integrated wire feeder and. Laser Welding Wire.

From metrorekayasa.com

Laser Welding Wire PT Metro Rekayasa Indonesia Laser Welding Wire 4.5/5 (7,841) Global laser tek supplies high quality small diameter wires for the laser and micro welding in wide range of industries including tool & die repair, electronics, aerospace, automotive, dental. Our maxphotonics weld star laser welding equipment is supplied as a compact unit with an integrated wire feeder and a fibre laser welding. By incorporating additional welding wire,. Laser Welding Wire.

From www.aliexpress.com

Buy Laser Welding Wire Thyssen DAC MAGIC Advanced Die Laser Welding Wire In this article, you’ll uncover the. Our maxphotonics weld star laser welding equipment is supplied as a compact unit with an integrated wire feeder and a fibre laser welding. Global laser tek supplies high quality small diameter wires for the laser and micro welding in wide range of industries including tool & die repair, electronics, aerospace, automotive, dental. 4.5/5 . Laser Welding Wire.

From www.aliexpress.com

SKD61/SKD11/H13/P20/S136 Laser welding wire precision cold welding die Laser Welding Wire Our maxphotonics weld star laser welding equipment is supplied as a compact unit with an integrated wire feeder and a fibre laser welding. Choosing the right laser welding wire requires a thoughtful consideration of various factors, including material compatibility, wire diameter, composition, feed rate, surface. Laserstar laser welding wires have been evaluated and tested for functionality, performance, strength and homogeneous. Laser Welding Wire.

From www.aliexpress.com

Laser Welding Wire Trader SKD11 0.2/0.3/0.4/0.5/0.6mm 1Roll/Pack for Laser Welding Wire Our maxphotonics weld star laser welding equipment is supplied as a compact unit with an integrated wire feeder and a fibre laser welding. Choosing the right laser welding wire requires a thoughtful consideration of various factors, including material compatibility, wire diameter, composition, feed rate, surface. 4.5/5 (7,841) 4.5/5 (7,841) Laserstar laser welding wires have been evaluated and tested. Laser Welding Wire.

From www.aliexpress.com

GM Laser welding wire Thyssen Dievar of 0.3/0.4/0.5/0.6/0.8mm Filler Laser Welding Wire 4.5/5 (7,841) Global laser tek supplies high quality small diameter wires for the laser and micro welding in wide range of industries including tool & die repair, electronics, aerospace, automotive, dental. By incorporating additional welding wire, it ensures robust joints and improved weld quality. Choosing the right laser welding wire requires a thoughtful consideration of various factors, including material. Laser Welding Wire.

From www.aliexpress.com

Laser Welding Wire Trader S136 Filler metal for weld Welding electrode Laser Welding Wire Laserstar laser welding wires have been evaluated and tested for functionality, performance, strength and homogeneous alloy characteristics to assure the highest quality material. 4.5/5 (7,841) By incorporating additional welding wire, it ensures robust joints and improved weld quality. Our maxphotonics weld star laser welding equipment is supplied as a compact unit with an integrated wire feeder and a fibre. Laser Welding Wire.

From shop.alliancelasersales.com

Laser Welding Wire — Alliance Specialties and Laser Sales Laser Welding Wire Global laser tek supplies high quality small diameter wires for the laser and micro welding in wide range of industries including tool & die repair, electronics, aerospace, automotive, dental. Our maxphotonics weld star laser welding equipment is supplied as a compact unit with an integrated wire feeder and a fibre laser welding. By incorporating additional welding wire, it ensures robust. Laser Welding Wire.

From www.aliexpress.com

Kemers Laser Welding Wire Solder Thyssen SKD11 of 0.2mm Mould Steel Laser Welding Wire 4.5/5 (7,841) Our maxphotonics weld star laser welding equipment is supplied as a compact unit with an integrated wire feeder and a fibre laser welding. By incorporating additional welding wire, it ensures robust joints and improved weld quality. In this article, you’ll uncover the. Global laser tek supplies high quality small diameter wires for the laser and micro welding. Laser Welding Wire.

From www.dim-international.com

Laser Welding Wire Supply DIM International Laser Welding Wire 4.5/5 (7,841) Laserstar laser welding wires have been evaluated and tested for functionality, performance, strength and homogeneous alloy characteristics to assure the highest quality material. In this article, you’ll uncover the. Our maxphotonics weld star laser welding equipment is supplied as a compact unit with an integrated wire feeder and a fibre laser welding. Global laser tek supplies high. Laser Welding Wire.

From ar.inspiredpencil.com

Laser Welding Wire Laser Welding Wire 4.5/5 (7,841) In this article, you’ll uncover the. Global laser tek supplies high quality small diameter wires for the laser and micro welding in wide range of industries including tool & die repair, electronics, aerospace, automotive, dental. 4.5/5 (7,841) Our maxphotonics weld star laser welding equipment is supplied as a compact unit with an integrated wire feeder and. Laser Welding Wire.

From www.laserchina.com

Laser Welding Wire How To Choose The Best One In 2024 Laser Welding Wire 4.5/5 (7,841) Our maxphotonics weld star laser welding equipment is supplied as a compact unit with an integrated wire feeder and a fibre laser welding. Laserstar laser welding wires have been evaluated and tested for functionality, performance, strength and homogeneous alloy characteristics to assure the highest quality material. Global laser tek supplies high quality small diameter wires for the. Laser Welding Wire.

From eitlaser.com

Laser welding wire for wearresistant materials • EIT LASERTECHNIK Laser Welding Wire 4.5/5 (7,841) 4.5/5 (7,841) Laserstar laser welding wires have been evaluated and tested for functionality, performance, strength and homogeneous alloy characteristics to assure the highest quality material. Choosing the right laser welding wire requires a thoughtful consideration of various factors, including material compatibility, wire diameter, composition, feed rate, surface. Our maxphotonics weld star laser welding equipment is supplied. Laser Welding Wire.

From www.indiamart.com

Castoweld Laser Welding Wire P20 0.3 0.6 X 500 mm at Rs 1800/pack Laser Welding Wire 4.5/5 (7,841) Choosing the right laser welding wire requires a thoughtful consideration of various factors, including material compatibility, wire diameter, composition, feed rate, surface. Our maxphotonics weld star laser welding equipment is supplied as a compact unit with an integrated wire feeder and a fibre laser welding. 4.5/5 (7,841) Global laser tek supplies high quality small diameter wires. Laser Welding Wire.

From tfmicrowelding.com

Laser Welding Wire STAVAX Laser Welding Wire 4.5/5 (7,841) Global laser tek supplies high quality small diameter wires for the laser and micro welding in wide range of industries including tool & die repair, electronics, aerospace, automotive, dental. By incorporating additional welding wire, it ensures robust joints and improved weld quality. 4.5/5 (7,841) Our maxphotonics weld star laser welding equipment is supplied as a compact. Laser Welding Wire.

From www.youtube.com

Double wire feed laser welding machine YouTube Laser Welding Wire Choosing the right laser welding wire requires a thoughtful consideration of various factors, including material compatibility, wire diameter, composition, feed rate, surface. Global laser tek supplies high quality small diameter wires for the laser and micro welding in wide range of industries including tool & die repair, electronics, aerospace, automotive, dental. By incorporating additional welding wire, it ensures robust joints. Laser Welding Wire.

From www.dsilaser.com

Laser Welding Filler Wire DSI Laser Service (Thailand) Co., Ltd. Laser Welding Wire Our maxphotonics weld star laser welding equipment is supplied as a compact unit with an integrated wire feeder and a fibre laser welding. In this article, you’ll uncover the. Laserstar laser welding wires have been evaluated and tested for functionality, performance, strength and homogeneous alloy characteristics to assure the highest quality material. 4.5/5 (7,841) By incorporating additional welding wire,. Laser Welding Wire.

From shop.alliancelasersales.com

Laser Welding Wire — Alliance Specialties and Laser Sales Laser Welding Wire By incorporating additional welding wire, it ensures robust joints and improved weld quality. Global laser tek supplies high quality small diameter wires for the laser and micro welding in wide range of industries including tool & die repair, electronics, aerospace, automotive, dental. In this article, you’ll uncover the. 4.5/5 (7,841) 4.5/5 (7,841) Laserstar laser welding wires have been. Laser Welding Wire.

From shop.alphalaser.de

Laser welding wire DIM LAmpcoTrode940 Buy at ALPHA LASER Laser Welding Wire Our maxphotonics weld star laser welding equipment is supplied as a compact unit with an integrated wire feeder and a fibre laser welding. 4.5/5 (7,841) By incorporating additional welding wire, it ensures robust joints and improved weld quality. Global laser tek supplies high quality small diameter wires for the laser and micro welding in wide range of industries including. Laser Welding Wire.

From metrorekayasa.com

Laser Welding Wire PT Metro Rekayasa Indonesia Laser Welding Wire 4.5/5 (7,841) 4.5/5 (7,841) In this article, you’ll uncover the. Laserstar laser welding wires have been evaluated and tested for functionality, performance, strength and homogeneous alloy characteristics to assure the highest quality material. Our maxphotonics weld star laser welding equipment is supplied as a compact unit with an integrated wire feeder and a fibre laser welding. By incorporating. Laser Welding Wire.

From superwavelaser.en.made-in-china.com

High Standard Durable Laser Welding Wire China Aluminum Wire and Laser Welding Wire In this article, you’ll uncover the. Our maxphotonics weld star laser welding equipment is supplied as a compact unit with an integrated wire feeder and a fibre laser welding. By incorporating additional welding wire, it ensures robust joints and improved weld quality. Choosing the right laser welding wire requires a thoughtful consideration of various factors, including material compatibility, wire diameter,. Laser Welding Wire.

From www.youtube.com

hand held laser welding machine with wire filling system YouTube Laser Welding Wire By incorporating additional welding wire, it ensures robust joints and improved weld quality. In this article, you’ll uncover the. Global laser tek supplies high quality small diameter wires for the laser and micro welding in wide range of industries including tool & die repair, electronics, aerospace, automotive, dental. Choosing the right laser welding wire requires a thoughtful consideration of various. Laser Welding Wire.

From laserknechtel.de

Laser welding wire L & A GmbH Laser Welding Wire 4.5/5 (7,841) Global laser tek supplies high quality small diameter wires for the laser and micro welding in wide range of industries including tool & die repair, electronics, aerospace, automotive, dental. Laserstar laser welding wires have been evaluated and tested for functionality, performance, strength and homogeneous alloy characteristics to assure the highest quality material. Our maxphotonics weld star laser. Laser Welding Wire.

From medium.com

Laser Welding Wire How to Choose the Right One for Your Machine by Laser Welding Wire Choosing the right laser welding wire requires a thoughtful consideration of various factors, including material compatibility, wire diameter, composition, feed rate, surface. By incorporating additional welding wire, it ensures robust joints and improved weld quality. Laserstar laser welding wires have been evaluated and tested for functionality, performance, strength and homogeneous alloy characteristics to assure the highest quality material. Global laser. Laser Welding Wire.

From www.suntoplaser.com

Laser Welding Wires Manufacturer Suntop Laser Welding Wire Choosing the right laser welding wire requires a thoughtful consideration of various factors, including material compatibility, wire diameter, composition, feed rate, surface. In this article, you’ll uncover the. 4.5/5 (7,841) Laserstar laser welding wires have been evaluated and tested for functionality, performance, strength and homogeneous alloy characteristics to assure the highest quality material. Global laser tek supplies high quality. Laser Welding Wire.

From castonelectrode.in

Copper Laser Welding Wire Caston Electrode Company Laser Welding Wire Global laser tek supplies high quality small diameter wires for the laser and micro welding in wide range of industries including tool & die repair, electronics, aerospace, automotive, dental. Laserstar laser welding wires have been evaluated and tested for functionality, performance, strength and homogeneous alloy characteristics to assure the highest quality material. Our maxphotonics weld star laser welding equipment is. Laser Welding Wire.

From tfmicrowelding.com

Brass Micro Laser Welding Wire, Filler wires Laser Welding Wire By incorporating additional welding wire, it ensures robust joints and improved weld quality. In this article, you’ll uncover the. Global laser tek supplies high quality small diameter wires for the laser and micro welding in wide range of industries including tool & die repair, electronics, aerospace, automotive, dental. Our maxphotonics weld star laser welding equipment is supplied as a compact. Laser Welding Wire.

From cnptengineering.com

Introduction of wire feeder for laser welding machine Laser Welding Wire In this article, you’ll uncover the. By incorporating additional welding wire, it ensures robust joints and improved weld quality. Our maxphotonics weld star laser welding equipment is supplied as a compact unit with an integrated wire feeder and a fibre laser welding. 4.5/5 (7,841) Laserstar laser welding wires have been evaluated and tested for functionality, performance, strength and homogeneous. Laser Welding Wire.

From www.aliexpress.com

CU90 P20 H13 NAK80 S136 S136H SKD11 SKD61 Laser Welding Rods Cold Laser Welding Wire Choosing the right laser welding wire requires a thoughtful consideration of various factors, including material compatibility, wire diameter, composition, feed rate, surface. By incorporating additional welding wire, it ensures robust joints and improved weld quality. 4.5/5 (7,841) Global laser tek supplies high quality small diameter wires for the laser and micro welding in wide range of industries including tool. Laser Welding Wire.

From tfmicrowelding.com

Laser Welding Wire STAVAX Laser Welding Wire Laserstar laser welding wires have been evaluated and tested for functionality, performance, strength and homogeneous alloy characteristics to assure the highest quality material. 4.5/5 (7,841) In this article, you’ll uncover the. 4.5/5 (7,841) Global laser tek supplies high quality small diameter wires for the laser and micro welding in wide range of industries including tool & die repair,. Laser Welding Wire.

From www.aliexpress.com

Laser Welding Wire WELDMOLD 700 For Nickle Molding of 0.2/0.3/0.4/0.5/0 Laser Welding Wire 4.5/5 (7,841) Global laser tek supplies high quality small diameter wires for the laser and micro welding in wide range of industries including tool & die repair, electronics, aerospace, automotive, dental. 4.5/5 (7,841) Laserstar laser welding wires have been evaluated and tested for functionality, performance, strength and homogeneous alloy characteristics to assure the highest quality material. Our maxphotonics. Laser Welding Wire.

From edmsuperstore.com

308 Stainless Laser Welding Wire (pack of 25) Laser Welding Wire By incorporating additional welding wire, it ensures robust joints and improved weld quality. Choosing the right laser welding wire requires a thoughtful consideration of various factors, including material compatibility, wire diameter, composition, feed rate, surface. In this article, you’ll uncover the. Laserstar laser welding wires have been evaluated and tested for functionality, performance, strength and homogeneous alloy characteristics to assure. Laser Welding Wire.

From www.youtube.com

laser welding with wire YouTube Laser Welding Wire Laserstar laser welding wires have been evaluated and tested for functionality, performance, strength and homogeneous alloy characteristics to assure the highest quality material. Our maxphotonics weld star laser welding equipment is supplied as a compact unit with an integrated wire feeder and a fibre laser welding. By incorporating additional welding wire, it ensures robust joints and improved weld quality. Choosing. Laser Welding Wire.

From www.dim-international.com

Laser Welding Wire Supply DIM International Laser Welding Wire 4.5/5 (7,841) Global laser tek supplies high quality small diameter wires for the laser and micro welding in wide range of industries including tool & die repair, electronics, aerospace, automotive, dental. 4.5/5 (7,841) Choosing the right laser welding wire requires a thoughtful consideration of various factors, including material compatibility, wire diameter, composition, feed rate, surface. Our maxphotonics weld. Laser Welding Wire.