Brazed Plate Heat Exchanger How It Works . The plates are arranged in such a way that thin rectangular channels are developed to exchange heat through half pieces. The two fluids will then flow in every other channel between the plates. In this video we learn how a plate heat exchanger works, covering the basics and working. Brazed plate heat exchangers normally feature. The mediums come into close proximity inside the brazed plate heat exchanger, on either side of the corrugated plate without mixing, and energy is. Brazed plate heat exchangers are normally manufactured from pressed, stainless steel plates sandwiched, and brazed, together to form a compact heat transfer device. We stack multiple plates together and then use the gaskets inside to allow to prevent the fluids from entering alternating plates. Brazing is a process like soldering in which two pieces of metal are joined by melting a third metal onto the join and baking this into place. A series of metal plates are brazed together inside bphe, with each plate having a pressed pattern that creates channels for the fluids to flow through. In these heat exchangers, each plate has a confined, hollow tubular shell. The plate heat exchanger works on the principle of thermodynamics. The gasket can be rotated to block either the right or left side holes. The operating fluid moves between these twisted and narrow channels. How do brazed plate heat exchangers work?

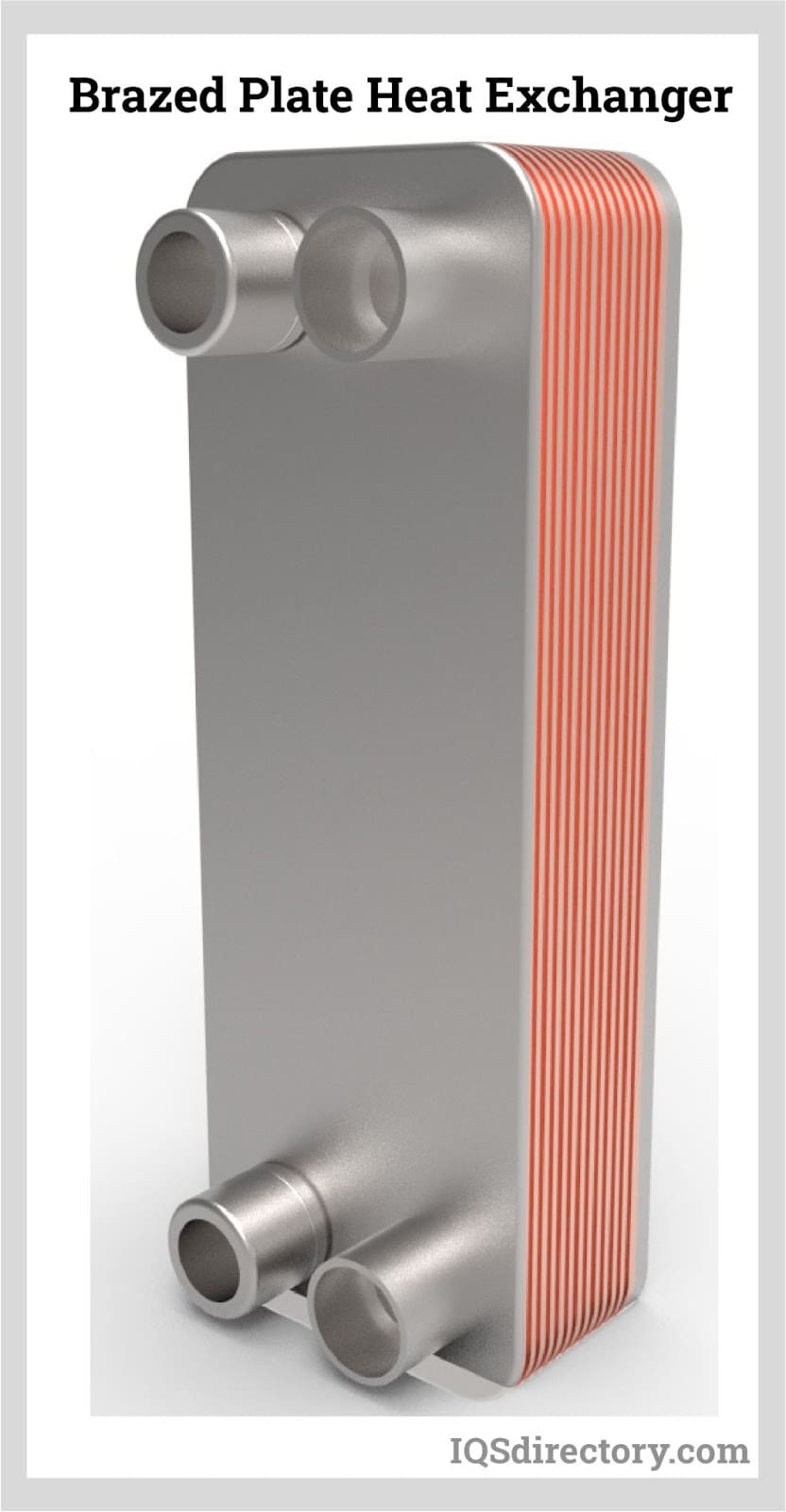

from www.iqsdirectory.com

A series of metal plates are brazed together inside bphe, with each plate having a pressed pattern that creates channels for the fluids to flow through. The gasket can be rotated to block either the right or left side holes. Brazing is a process like soldering in which two pieces of metal are joined by melting a third metal onto the join and baking this into place. Brazed plate heat exchangers are normally manufactured from pressed, stainless steel plates sandwiched, and brazed, together to form a compact heat transfer device. The plates are arranged in such a way that thin rectangular channels are developed to exchange heat through half pieces. The operating fluid moves between these twisted and narrow channels. In these heat exchangers, each plate has a confined, hollow tubular shell. The plate heat exchanger works on the principle of thermodynamics. The mediums come into close proximity inside the brazed plate heat exchanger, on either side of the corrugated plate without mixing, and energy is. In this video we learn how a plate heat exchanger works, covering the basics and working.

Plate Heat Exchangers Components, Types, Applications and Advantages

Brazed Plate Heat Exchanger How It Works The gasket can be rotated to block either the right or left side holes. The plate heat exchanger works on the principle of thermodynamics. We stack multiple plates together and then use the gaskets inside to allow to prevent the fluids from entering alternating plates. The gasket can be rotated to block either the right or left side holes. Brazing is a process like soldering in which two pieces of metal are joined by melting a third metal onto the join and baking this into place. The plates are arranged in such a way that thin rectangular channels are developed to exchange heat through half pieces. In this video we learn how a plate heat exchanger works, covering the basics and working. The operating fluid moves between these twisted and narrow channels. The two fluids will then flow in every other channel between the plates. Brazed plate heat exchangers normally feature. Brazed plate heat exchangers are normally manufactured from pressed, stainless steel plates sandwiched, and brazed, together to form a compact heat transfer device. How do brazed plate heat exchangers work? A series of metal plates are brazed together inside bphe, with each plate having a pressed pattern that creates channels for the fluids to flow through. The mediums come into close proximity inside the brazed plate heat exchanger, on either side of the corrugated plate without mixing, and energy is. In these heat exchangers, each plate has a confined, hollow tubular shell.

From www.vevor.ca

VEVOR Heat Exchanger 3"x7.5" 40 Plates Brazed Plate Heat Exchanger 316L Brazed Plate Heat Exchanger How It Works The operating fluid moves between these twisted and narrow channels. The two fluids will then flow in every other channel between the plates. A series of metal plates are brazed together inside bphe, with each plate having a pressed pattern that creates channels for the fluids to flow through. In this video we learn how a plate heat exchanger works,. Brazed Plate Heat Exchanger How It Works.

From alfaheating.com

AB Brazed Plate Heat Exchanger 100 Plates 4"x12" 1"MPT Brazed Plate Heat Exchanger How It Works The plates are arranged in such a way that thin rectangular channels are developed to exchange heat through half pieces. Brazing is a process like soldering in which two pieces of metal are joined by melting a third metal onto the join and baking this into place. The plate heat exchanger works on the principle of thermodynamics. In these heat. Brazed Plate Heat Exchanger How It Works.

From ideasforhomeandoffice.blogspot.com

Brazed plate heat exchanger installation Brazed Plate Heat Exchanger How It Works Brazed plate heat exchangers normally feature. The mediums come into close proximity inside the brazed plate heat exchanger, on either side of the corrugated plate without mixing, and energy is. The operating fluid moves between these twisted and narrow channels. Brazing is a process like soldering in which two pieces of metal are joined by melting a third metal onto. Brazed Plate Heat Exchanger How It Works.

From www.phcppros.com

Brazed Plate Heat Exchangers phcppros Brazed Plate Heat Exchanger How It Works Brazing is a process like soldering in which two pieces of metal are joined by melting a third metal onto the join and baking this into place. The plate heat exchanger works on the principle of thermodynamics. Brazed plate heat exchangers normally feature. Brazed plate heat exchangers are normally manufactured from pressed, stainless steel plates sandwiched, and brazed, together to. Brazed Plate Heat Exchanger How It Works.

From www.iwc-hessa.com

Brazed plate heat exchanger Brazed Plate Heat Exchanger How It Works The plate heat exchanger works on the principle of thermodynamics. Brazing is a process like soldering in which two pieces of metal are joined by melting a third metal onto the join and baking this into place. Brazed plate heat exchangers normally feature. Brazed plate heat exchangers are normally manufactured from pressed, stainless steel plates sandwiched, and brazed, together to. Brazed Plate Heat Exchanger How It Works.

From www.youtube.com

How Plate Heat Exchangers Work YouTube Brazed Plate Heat Exchanger How It Works The mediums come into close proximity inside the brazed plate heat exchanger, on either side of the corrugated plate without mixing, and energy is. The plate heat exchanger works on the principle of thermodynamics. Brazed plate heat exchangers are normally manufactured from pressed, stainless steel plates sandwiched, and brazed, together to form a compact heat transfer device. How do brazed. Brazed Plate Heat Exchanger How It Works.

From www.paulmueller.com

Brazed Plate Heat Exchangers Refrigeration Products Paul Mueller Brazed Plate Heat Exchanger How It Works Brazing is a process like soldering in which two pieces of metal are joined by melting a third metal onto the join and baking this into place. The plate heat exchanger works on the principle of thermodynamics. We stack multiple plates together and then use the gaskets inside to allow to prevent the fluids from entering alternating plates. The plates. Brazed Plate Heat Exchanger How It Works.

From hesco.com.vn

Hisaka Brazed Heat Exchanger Hesco Brazed Plate Heat Exchanger How It Works How do brazed plate heat exchangers work? The plate heat exchanger works on the principle of thermodynamics. The gasket can be rotated to block either the right or left side holes. A series of metal plates are brazed together inside bphe, with each plate having a pressed pattern that creates channels for the fluids to flow through. Brazing is a. Brazed Plate Heat Exchanger How It Works.

From www.iqsdirectory.com

Plate Heat Exchangers Components, Types, Applications and Advantages Brazed Plate Heat Exchanger How It Works Brazing is a process like soldering in which two pieces of metal are joined by melting a third metal onto the join and baking this into place. The two fluids will then flow in every other channel between the plates. Brazed plate heat exchangers are normally manufactured from pressed, stainless steel plates sandwiched, and brazed, together to form a compact. Brazed Plate Heat Exchanger How It Works.

From techtransengineers.com

Brazed Vs Gasketed Plate Heat Exchanger (PHEs) TTE Brazed Plate Heat Exchanger How It Works A series of metal plates are brazed together inside bphe, with each plate having a pressed pattern that creates channels for the fluids to flow through. Brazed plate heat exchangers normally feature. The plates are arranged in such a way that thin rectangular channels are developed to exchange heat through half pieces. In these heat exchangers, each plate has a. Brazed Plate Heat Exchanger How It Works.

From www.rasmech.com

Plate Heat Exchanger (For Dummies) Rasmussen Mechanical Brazed Plate Heat Exchanger How It Works The two fluids will then flow in every other channel between the plates. The mediums come into close proximity inside the brazed plate heat exchanger, on either side of the corrugated plate without mixing, and energy is. Brazed plate heat exchangers are normally manufactured from pressed, stainless steel plates sandwiched, and brazed, together to form a compact heat transfer device.. Brazed Plate Heat Exchanger How It Works.

From mail.hisaka-asia.com

Brazed Plate Heat Exchangers Brazed PHE HISAKAWORKS Brazed Plate Heat Exchanger How It Works The two fluids will then flow in every other channel between the plates. Brazed plate heat exchangers normally feature. The mediums come into close proximity inside the brazed plate heat exchanger, on either side of the corrugated plate without mixing, and energy is. In these heat exchangers, each plate has a confined, hollow tubular shell. The operating fluid moves between. Brazed Plate Heat Exchanger How It Works.

From theengineeringmindset.com

Plate Heat Exchanger Applications The Engineering Mindset Brazed Plate Heat Exchanger How It Works The mediums come into close proximity inside the brazed plate heat exchanger, on either side of the corrugated plate without mixing, and energy is. In this video we learn how a plate heat exchanger works, covering the basics and working. The plate heat exchanger works on the principle of thermodynamics. Brazed plate heat exchangers normally feature. The two fluids will. Brazed Plate Heat Exchanger How It Works.

From www.hydac.com.au

Brazed plate heat exchanger HYDAC News Brazed Plate Heat Exchanger How It Works The plate heat exchanger works on the principle of thermodynamics. Brazed plate heat exchangers are normally manufactured from pressed, stainless steel plates sandwiched, and brazed, together to form a compact heat transfer device. Brazed plate heat exchangers normally feature. The operating fluid moves between these twisted and narrow channels. The gasket can be rotated to block either the right or. Brazed Plate Heat Exchanger How It Works.

From refrigeratorsreviewed.com

Brazed Plate Heat Exchanger For Refrigeration [Easy Guide] Brazed Plate Heat Exchanger How It Works In these heat exchangers, each plate has a confined, hollow tubular shell. We stack multiple plates together and then use the gaskets inside to allow to prevent the fluids from entering alternating plates. How do brazed plate heat exchangers work? The gasket can be rotated to block either the right or left side holes. The two fluids will then flow. Brazed Plate Heat Exchanger How It Works.

From www.alfalaval.co.uk

CBAQ Alfa Laval Brazed Plate Heat Exchanger How It Works Brazing is a process like soldering in which two pieces of metal are joined by melting a third metal onto the join and baking this into place. The gasket can be rotated to block either the right or left side holes. In these heat exchangers, each plate has a confined, hollow tubular shell. The plate heat exchanger works on the. Brazed Plate Heat Exchanger How It Works.

From www.vrcoolertech.com

How Does A Brazed Plate Heat Exchanger Work? News Changzhou Brazed Plate Heat Exchanger How It Works Brazed plate heat exchangers are normally manufactured from pressed, stainless steel plates sandwiched, and brazed, together to form a compact heat transfer device. The plate heat exchanger works on the principle of thermodynamics. We stack multiple plates together and then use the gaskets inside to allow to prevent the fluids from entering alternating plates. A series of metal plates are. Brazed Plate Heat Exchanger How It Works.

From www.linquip.com

Working Principle of Plate Heat Exchanger Linquip Brazed Plate Heat Exchanger How It Works The plates are arranged in such a way that thin rectangular channels are developed to exchange heat through half pieces. A series of metal plates are brazed together inside bphe, with each plate having a pressed pattern that creates channels for the fluids to flow through. The operating fluid moves between these twisted and narrow channels. The plate heat exchanger. Brazed Plate Heat Exchanger How It Works.

From sunearthinc.com

Brazed Plate Heat Exchangers Single/Double Wall Plate Heat Exchanger Brazed Plate Heat Exchanger How It Works How do brazed plate heat exchangers work? Brazed plate heat exchangers normally feature. The plate heat exchanger works on the principle of thermodynamics. In this video we learn how a plate heat exchanger works, covering the basics and working. The operating fluid moves between these twisted and narrow channels. Brazing is a process like soldering in which two pieces of. Brazed Plate Heat Exchanger How It Works.

From techtransengineers.com

Brazed Plate Heat Exchanger Techtrans Engineers Brazed Plate Heat Exchanger How It Works Brazed plate heat exchangers are normally manufactured from pressed, stainless steel plates sandwiched, and brazed, together to form a compact heat transfer device. The mediums come into close proximity inside the brazed plate heat exchanger, on either side of the corrugated plate without mixing, and energy is. In this video we learn how a plate heat exchanger works, covering the. Brazed Plate Heat Exchanger How It Works.

From www.evomart.co.uk

Vol.15 Brazed Plate Heat Exchanger (BPHE) as an evaporator Evomart Brazed Plate Heat Exchanger How It Works Brazed plate heat exchangers normally feature. The operating fluid moves between these twisted and narrow channels. In this video we learn how a plate heat exchanger works, covering the basics and working. The plate heat exchanger works on the principle of thermodynamics. How do brazed plate heat exchangers work? The plates are arranged in such a way that thin rectangular. Brazed Plate Heat Exchanger How It Works.

From loeacqace.blob.core.windows.net

How Does A Plate And Shell Heat Exchanger Work at Pamela Blades blog Brazed Plate Heat Exchanger How It Works The operating fluid moves between these twisted and narrow channels. Brazed plate heat exchangers normally feature. The two fluids will then flow in every other channel between the plates. A series of metal plates are brazed together inside bphe, with each plate having a pressed pattern that creates channels for the fluids to flow through. Brazing is a process like. Brazed Plate Heat Exchanger How It Works.

From www.indiamart.com

Stainless Steel Brass SS Brazed Plate Heat Exchanger, 50100 m3/hr, Rs Brazed Plate Heat Exchanger How It Works The plates are arranged in such a way that thin rectangular channels are developed to exchange heat through half pieces. The operating fluid moves between these twisted and narrow channels. The plate heat exchanger works on the principle of thermodynamics. The two fluids will then flow in every other channel between the plates. The mediums come into close proximity inside. Brazed Plate Heat Exchanger How It Works.

From flushingservices.com

Avoid DIY Brazed Plate Heat Exchanger Cleaning Brazed Plate Heat Exchanger How It Works A series of metal plates are brazed together inside bphe, with each plate having a pressed pattern that creates channels for the fluids to flow through. We stack multiple plates together and then use the gaskets inside to allow to prevent the fluids from entering alternating plates. Brazed plate heat exchangers normally feature. In these heat exchangers, each plate has. Brazed Plate Heat Exchanger How It Works.

From alfaheating.com

AB Brazed Plate Heat Exchanger 30 Plates 5"x12" 1 1/4"MPT Brazed Plate Heat Exchanger How It Works Brazed plate heat exchangers normally feature. We stack multiple plates together and then use the gaskets inside to allow to prevent the fluids from entering alternating plates. How do brazed plate heat exchangers work? Brazing is a process like soldering in which two pieces of metal are joined by melting a third metal onto the join and baking this into. Brazed Plate Heat Exchanger How It Works.

From www.hofmann-heatexchanger.com

Brazed Plate Heat Exchanger HFM Plate heat exchanger supplier,One Brazed Plate Heat Exchanger How It Works The gasket can be rotated to block either the right or left side holes. The plate heat exchanger works on the principle of thermodynamics. The operating fluid moves between these twisted and narrow channels. In this video we learn how a plate heat exchanger works, covering the basics and working. In these heat exchangers, each plate has a confined, hollow. Brazed Plate Heat Exchanger How It Works.

From www.iqsdirectory.com

Plate Heat Exchangers Components, Types, Applications and Advantages Brazed Plate Heat Exchanger How It Works How do brazed plate heat exchangers work? The plates are arranged in such a way that thin rectangular channels are developed to exchange heat through half pieces. In this video we learn how a plate heat exchanger works, covering the basics and working. In these heat exchangers, each plate has a confined, hollow tubular shell. The two fluids will then. Brazed Plate Heat Exchanger How It Works.

From www.researchgate.net

An exploded view of plate heat exchanger (Courtesy of Alfa Laval Brazed Plate Heat Exchanger How It Works The operating fluid moves between these twisted and narrow channels. The gasket can be rotated to block either the right or left side holes. The two fluids will then flow in every other channel between the plates. The plates are arranged in such a way that thin rectangular channels are developed to exchange heat through half pieces. In these heat. Brazed Plate Heat Exchanger How It Works.

From savree.com

Plate Heat Exchanger (PHE) Explained saVRee saVRee Brazed Plate Heat Exchanger How It Works The gasket can be rotated to block either the right or left side holes. The operating fluid moves between these twisted and narrow channels. In these heat exchangers, each plate has a confined, hollow tubular shell. In this video we learn how a plate heat exchanger works, covering the basics and working. We stack multiple plates together and then use. Brazed Plate Heat Exchanger How It Works.

From www.unggulpp.com

Brazed Heat Exchangers (BHE) Brazed Plate Heat Exchanger How It Works The mediums come into close proximity inside the brazed plate heat exchanger, on either side of the corrugated plate without mixing, and energy is. The gasket can be rotated to block either the right or left side holes. We stack multiple plates together and then use the gaskets inside to allow to prevent the fluids from entering alternating plates. How. Brazed Plate Heat Exchanger How It Works.

From sonflow.eu

Permanently Sealed Brazed Heat Exchangers Brazed Plate Heat Exchanger How It Works In these heat exchangers, each plate has a confined, hollow tubular shell. We stack multiple plates together and then use the gaskets inside to allow to prevent the fluids from entering alternating plates. Brazed plate heat exchangers normally feature. Brazed plate heat exchangers are normally manufactured from pressed, stainless steel plates sandwiched, and brazed, together to form a compact heat. Brazed Plate Heat Exchanger How It Works.

From www.vrcoolertech.com

How Does A Brazed Plate Heat Exchanger Work? News Changzhou Brazed Plate Heat Exchanger How It Works In this video we learn how a plate heat exchanger works, covering the basics and working. The mediums come into close proximity inside the brazed plate heat exchanger, on either side of the corrugated plate without mixing, and energy is. The plate heat exchanger works on the principle of thermodynamics. Brazed plate heat exchangers normally feature. The plates are arranged. Brazed Plate Heat Exchanger How It Works.

From midstatesrefrigsupply.com

Brazed Plate Heat Exchanger Midstates Refrigeration Supply Brazed Plate Heat Exchanger How It Works Brazed plate heat exchangers normally feature. The two fluids will then flow in every other channel between the plates. The gasket can be rotated to block either the right or left side holes. A series of metal plates are brazed together inside bphe, with each plate having a pressed pattern that creates channels for the fluids to flow through. The. Brazed Plate Heat Exchanger How It Works.

From www.youtube.com

Plate Heat Exchanger, How it works working principle hvac industrial Brazed Plate Heat Exchanger How It Works Brazing is a process like soldering in which two pieces of metal are joined by melting a third metal onto the join and baking this into place. The two fluids will then flow in every other channel between the plates. A series of metal plates are brazed together inside bphe, with each plate having a pressed pattern that creates channels. Brazed Plate Heat Exchanger How It Works.

From www.onda-it.com

Plate Heat Exchangers Working Principle Onda S.p.A Brazed Plate Heat Exchanger How It Works In these heat exchangers, each plate has a confined, hollow tubular shell. Brazed plate heat exchangers are normally manufactured from pressed, stainless steel plates sandwiched, and brazed, together to form a compact heat transfer device. The mediums come into close proximity inside the brazed plate heat exchanger, on either side of the corrugated plate without mixing, and energy is. The. Brazed Plate Heat Exchanger How It Works.