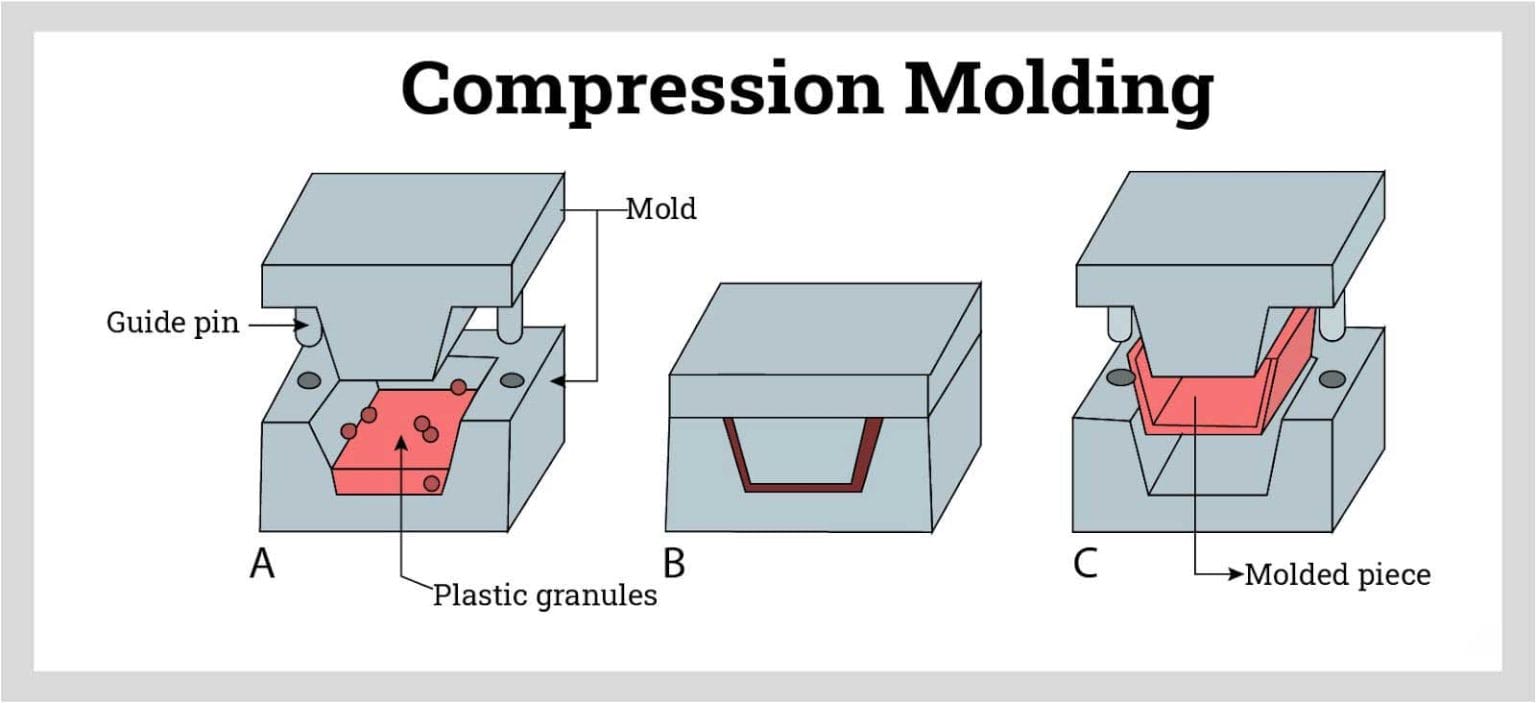

Compression Moulding Effect . Within this article, martin’s rubber explains what compression moulding is and demonstrates some of the main advantages and disadvantages of producing a compression. Compression molding is a simple, discontinuous technique using a mold inserted between heated metal platens in a hydraulic press. Through a mixture of heat and high pressure, it squeezes materials—like. Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. Compression molding is a manufacturing process used to create plastic and composite parts. Compression molding is a manufacturing method for fabrication of composite materials. Compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. In this method, a preheated material is placed into an.

from www.longshengmfg.com

Compression molding is a manufacturing process used to create plastic and composite parts. In this method, a preheated material is placed into an. Compression molding is a manufacturing method for fabrication of composite materials. Compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. Compression molding is a simple, discontinuous technique using a mold inserted between heated metal platens in a hydraulic press. Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. Through a mixture of heat and high pressure, it squeezes materials—like. Within this article, martin’s rubber explains what compression moulding is and demonstrates some of the main advantages and disadvantages of producing a compression.

Compression Molding vs. Injection Molding Difference Comparison

Compression Moulding Effect Compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. Through a mixture of heat and high pressure, it squeezes materials—like. In this method, a preheated material is placed into an. Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. Compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. Within this article, martin’s rubber explains what compression moulding is and demonstrates some of the main advantages and disadvantages of producing a compression. Compression molding is a manufacturing method for fabrication of composite materials. Compression molding is a simple, discontinuous technique using a mold inserted between heated metal platens in a hydraulic press. Compression molding is a manufacturing process used to create plastic and composite parts.

From www.researchgate.net

Schematic diagram of the compression molding machine. Reproduced with Compression Moulding Effect Compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. Compression molding is a manufacturing method for fabrication of composite materials. Through a mixture of heat and high pressure,. Compression Moulding Effect.

From polymer360.blogspot.com

Compression Moulding Compression Moulding Effect Compression molding is a simple, discontinuous technique using a mold inserted between heated metal platens in a hydraulic press. Compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. In this method, a preheated material is placed into an. Compression molding is a manufacturing method for fabrication of composite materials.. Compression Moulding Effect.

From slidetodoc.com

Plastic Processing Extrusion Compression Moulding Injection Moulding Compression Moulding Effect Compression molding is a manufacturing method for fabrication of composite materials. Compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. Compression molding is a manufacturing process used to create plastic and composite parts. Through a mixture of heat and high pressure, it squeezes materials—like. Compression moulding uses a heated. Compression Moulding Effect.

From www.researchgate.net

Schematics of the compression molding setup and the curing schemes used Compression Moulding Effect In this method, a preheated material is placed into an. Compression molding is a manufacturing method for fabrication of composite materials. Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. Compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer. Compression Moulding Effect.

From www.researchgate.net

17 Diagram of the compressionmoulding process of GFTPU composites Compression Moulding Effect Compression molding is a manufacturing method for fabrication of composite materials. In this method, a preheated material is placed into an. Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. Within this article, martin’s rubber explains what compression moulding is and demonstrates some of the main advantages and. Compression Moulding Effect.

From www.wemould.com

What is Compression Mould 2k mould, gas assisted mould, compression mould Compression Moulding Effect Compression molding is a manufacturing process used to create plastic and composite parts. Compression molding is a manufacturing method for fabrication of composite materials. Through a mixture of heat and high pressure, it squeezes materials—like. Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. Compression molding, a technique. Compression Moulding Effect.

From formlabs.com

Guide to Compression Molding From Prototyping to Mass Production Compression Moulding Effect In this method, a preheated material is placed into an. Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. Through a mixture of heat and high pressure, it squeezes materials—like. Compression molding is a simple, discontinuous technique using a mold inserted between heated metal platens in a hydraulic. Compression Moulding Effect.

From engineeringproductdesign.com

Compression Moulding, Types & Applications? Pros & Cons Compression Moulding Effect Within this article, martin’s rubber explains what compression moulding is and demonstrates some of the main advantages and disadvantages of producing a compression. Compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. Through a mixture of heat and high pressure, it squeezes materials—like. Compression moulding uses a heated cavity. Compression Moulding Effect.

From www.longshengmfg.com

Compression Molding vs. Injection Molding Difference Comparison Compression Moulding Effect Compression molding is a simple, discontinuous technique using a mold inserted between heated metal platens in a hydraulic press. Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. In this method, a preheated material is placed into an. Compression molding is a manufacturing process used to create plastic. Compression Moulding Effect.

From www.mdpi.com

J. Compos. Sci. Free FullText Edge RaceTracking during Film Compression Moulding Effect In this method, a preheated material is placed into an. Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. Within this article, martin’s rubber explains what compression moulding is and demonstrates some of the main advantages and disadvantages of producing a compression. Compression molding is a manufacturing method. Compression Moulding Effect.

From www.iqsdirectory.com

Compression Molding Process, Types of Molds, Features and Benefits Compression Moulding Effect In this method, a preheated material is placed into an. Compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. Compression molding is a manufacturing method for fabrication of composite materials. Within this article, martin’s rubber explains what compression moulding is and demonstrates some of the main advantages and disadvantages. Compression Moulding Effect.

From www.hardwareinterviews.fyi

Basics of Compression Molding Consumer Hardware Guide Hardware FYI Compression Moulding Effect Compression molding is a manufacturing method for fabrication of composite materials. Compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. In this method, a preheated material is placed into an. Compression molding is a manufacturing process used to create plastic and composite parts. Compression moulding uses a heated cavity. Compression Moulding Effect.

From www.slideserve.com

PPT COMPOSITE MATERIALS PowerPoint Presentation, free download ID Compression Moulding Effect Compression molding is a manufacturing process used to create plastic and composite parts. Through a mixture of heat and high pressure, it squeezes materials—like. Compression molding is a manufacturing method for fabrication of composite materials. Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. Within this article, martin’s. Compression Moulding Effect.

From www.iqsdirectory.com

Compression Molding Process, Types of Molds, Features and Benefits Compression Moulding Effect Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. Compression molding is a simple, discontinuous technique using a mold inserted between heated metal platens in a hydraulic press. Compression molding is a manufacturing process used to create plastic and composite parts. Compression molding is a manufacturing method for. Compression Moulding Effect.

From www.researchgate.net

The schematic of compression moulding process. Download Scientific Compression Moulding Effect Within this article, martin’s rubber explains what compression moulding is and demonstrates some of the main advantages and disadvantages of producing a compression. In this method, a preheated material is placed into an. Compression molding is a manufacturing process used to create plastic and composite parts. Compression molding, a technique that finds its roots in the early 20th century, entails. Compression Moulding Effect.

From www.hardwareinterviews.fyi

Basics of Compression Molding Consumer Hardware Guide Hardware FYI Compression Moulding Effect Within this article, martin’s rubber explains what compression moulding is and demonstrates some of the main advantages and disadvantages of producing a compression. Compression molding is a manufacturing process used to create plastic and composite parts. Compression molding is a manufacturing method for fabrication of composite materials. Through a mixture of heat and high pressure, it squeezes materials—like. Compression moulding. Compression Moulding Effect.

From www.engineeringclicks.com

Compression Molding manufacturing process guide EngineeringClicks Compression Moulding Effect Compression molding is a simple, discontinuous technique using a mold inserted between heated metal platens in a hydraulic press. Compression molding is a manufacturing method for fabrication of composite materials. Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. Within this article, martin’s rubber explains what compression moulding. Compression Moulding Effect.

From learnmech.com

Compression molding Process Advantages and Disadvantages Compression Moulding Effect Compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. Through a mixture of heat and high pressure, it squeezes materials—like. Within this article, martin’s rubber explains what compression moulding is and demonstrates some of the main advantages and disadvantages of producing a compression. In this method, a preheated material. Compression Moulding Effect.

From www.iqsdirectory.com

Rubber Overmolding Process, Uses, Considerations & Benefits Compression Moulding Effect In this method, a preheated material is placed into an. Compression molding is a simple, discontinuous technique using a mold inserted between heated metal platens in a hydraulic press. Within this article, martin’s rubber explains what compression moulding is and demonstrates some of the main advantages and disadvantages of producing a compression. Compression molding is a manufacturing process used to. Compression Moulding Effect.

From www.researchgate.net

Hot ¯ow compression moulding schematic. Download Scientific Diagram Compression Moulding Effect Compression molding is a manufacturing process used to create plastic and composite parts. In this method, a preheated material is placed into an. Compression molding is a manufacturing method for fabrication of composite materials. Within this article, martin’s rubber explains what compression moulding is and demonstrates some of the main advantages and disadvantages of producing a compression. Through a mixture. Compression Moulding Effect.

From www.researchgate.net

Schematic illustration showing the compressionmoulding process for Compression Moulding Effect Compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. Compression molding is a manufacturing process used to create plastic and composite parts. Within this article, martin’s rubber explains what compression moulding is and demonstrates some of the main advantages and disadvantages of producing a compression. Compression molding is a. Compression Moulding Effect.

From www.researchgate.net

Process principle of compression moulding Download HighResolution Compression Moulding Effect In this method, a preheated material is placed into an. Within this article, martin’s rubber explains what compression moulding is and demonstrates some of the main advantages and disadvantages of producing a compression. Compression molding is a simple, discontinuous technique using a mold inserted between heated metal platens in a hydraulic press. Compression molding is a manufacturing process used to. Compression Moulding Effect.

From siliconemakers.com

A Comprehensive Guide to Silicone Compression Molding Compression Moulding Effect Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. Compression molding is a manufacturing process used to create plastic and composite parts. Compression molding is a manufacturing method for fabrication of composite materials. Compression molding is a simple, discontinuous technique using a mold inserted between heated metal platens. Compression Moulding Effect.

From www.mdpi.com

Materials Free FullText Influence of Processing Parameters on the Compression Moulding Effect Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. In this method, a preheated material is placed into an. Compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. Through a mixture of heat and high pressure, it. Compression Moulding Effect.

From www.iqsdirectory.com

Compression Molding Process, Types of Molds, Features and Benefits Compression Moulding Effect Compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. Compression molding is a simple, discontinuous technique using a mold inserted between heated metal platens in a hydraulic press. In this method, a preheated material is placed into an. Compression moulding uses a heated cavity to shape the material under. Compression Moulding Effect.

From www.rpmrubberparts.com

Compression Molding Defects What Can Go Wrong? Compression Moulding Effect In this method, a preheated material is placed into an. Compression molding is a simple, discontinuous technique using a mold inserted between heated metal platens in a hydraulic press. Through a mixture of heat and high pressure, it squeezes materials—like. Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a. Compression Moulding Effect.

From higherproductdesign.blogspot.com

Higher Product Design Blog Compression Moulding Compression Moulding Effect Compression molding is a simple, discontinuous technique using a mold inserted between heated metal platens in a hydraulic press. Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. Compression molding is a manufacturing process used to create plastic and composite parts. Within this article, martin’s rubber explains what. Compression Moulding Effect.

From slidetodoc.com

Plastic Processing Extrusion Compression Moulding Injection Moulding Compression Moulding Effect Compression molding is a manufacturing process used to create plastic and composite parts. Within this article, martin’s rubber explains what compression moulding is and demonstrates some of the main advantages and disadvantages of producing a compression. Compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. Compression moulding uses a. Compression Moulding Effect.

From www.youtube.com

What is Rubber Compression Molding? YouTube Compression Moulding Effect Compression molding is a simple, discontinuous technique using a mold inserted between heated metal platens in a hydraulic press. Compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. Within this article, martin’s rubber explains what compression moulding is and demonstrates some of the main advantages and disadvantages of producing. Compression Moulding Effect.

From www.sealengineering.no

Simulation in compression molding Seal Engineering Compression Moulding Effect Compression molding is a simple, discontinuous technique using a mold inserted between heated metal platens in a hydraulic press. Through a mixture of heat and high pressure, it squeezes materials—like. In this method, a preheated material is placed into an. Compression molding is a manufacturing method for fabrication of composite materials. Compression molding is a manufacturing process used to create. Compression Moulding Effect.

From www.researchgate.net

(a) Picture of the instrumented compression mould placed on an Instron Compression Moulding Effect Compression molding is a manufacturing process used to create plastic and composite parts. Compression molding is a manufacturing method for fabrication of composite materials. Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. Within this article, martin’s rubber explains what compression moulding is and demonstrates some of the. Compression Moulding Effect.

From www.flickriver.com

Compression moulding a photo on Flickriver Compression Moulding Effect Compression molding is a manufacturing method for fabrication of composite materials. Through a mixture of heat and high pressure, it squeezes materials—like. Compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. Within this article, martin’s rubber explains what compression moulding is and demonstrates some of the main advantages and. Compression Moulding Effect.

From www.researchgate.net

Schematic setup of compression molding process [64]. Download Compression Moulding Effect Compression molding is a simple, discontinuous technique using a mold inserted between heated metal platens in a hydraulic press. Compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. In this method, a preheated material is placed into an. Compression molding is a manufacturing process used to create plastic and. Compression Moulding Effect.

From dpseals.com

Rubber Moulding Process Comparisons DP Seals Compression Moulding Effect Compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. Compression molding is a manufacturing method for fabrication of composite materials. Compression molding is a manufacturing process used to create plastic and composite parts. Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects. Compression Moulding Effect.

From www.rutlandplastics.co.uk

Plastics Moulding Methods Compression Rutland Plastics Compression Moulding Effect Through a mixture of heat and high pressure, it squeezes materials—like. Compression molding is a manufacturing process used to create plastic and composite parts. Compression molding, a technique that finds its roots in the early 20th century, entails the transformation of polymer materials into. Compression molding is a simple, discontinuous technique using a mold inserted between heated metal platens in. Compression Moulding Effect.