Best Concrete Finish For Cattle . There are five types of floor resurfacing: Scabbling — roughen the surface and create a wide, shallow line. Ideal floor finish maintains the right type of grooves and surface texture to attain needed traction. Grooving — etching lines into the concrete surface. Rubber matting — covering areas with cushion mats. This combination can be produced by. The finish on concrete should be deep. This floor is suitable for handling. Concrete is an attractive flooring material to the dairy producer because it is readily available, durable, comparatively economical, relatively easy to place as it conforms well to irregular areas and can be finished in various ways to provide some level of traction. Milling — removing a thin layer to even the area and create a textured surface. Grooving machines can be rented from a concrete supply company. Use an air entrained concrete mixture with a minimum of strength of 3,500 pounds per square inch (psi) and adequate.

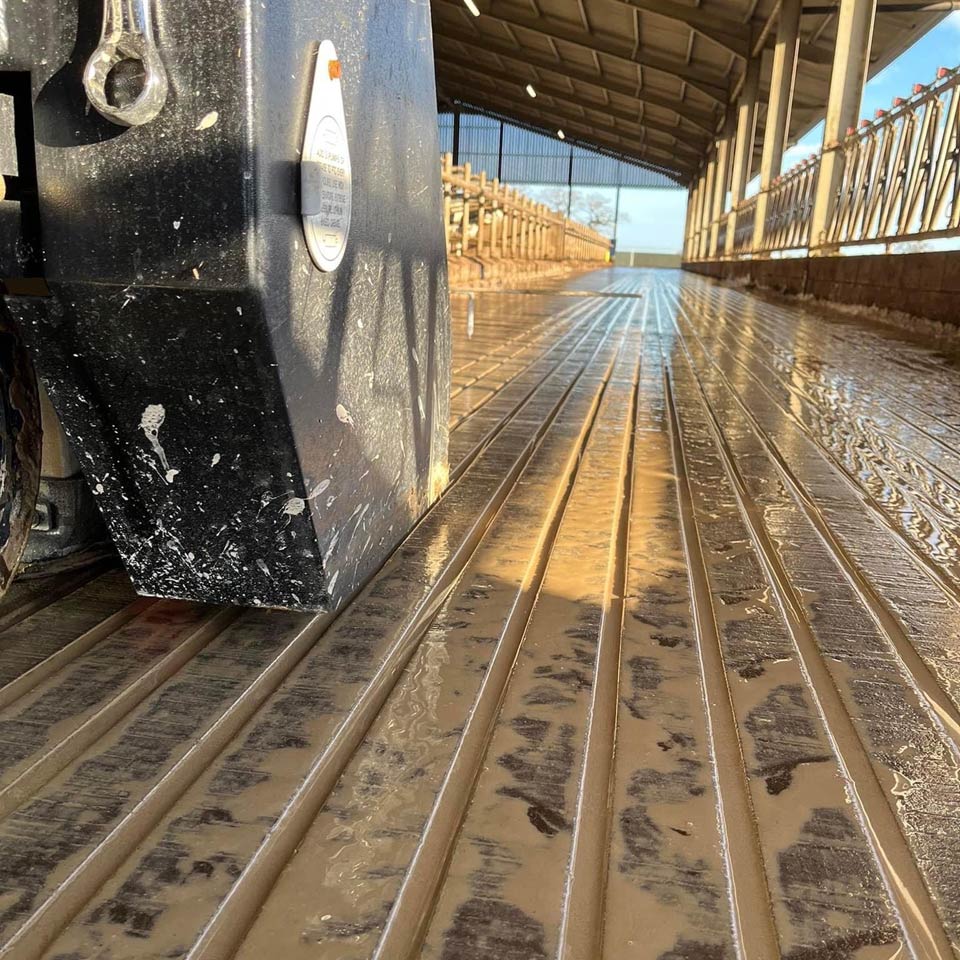

from kirbycattleservicesltd.com

Grooving — etching lines into the concrete surface. There are five types of floor resurfacing: Scabbling — roughen the surface and create a wide, shallow line. This combination can be produced by. Rubber matting — covering areas with cushion mats. Grooving machines can be rented from a concrete supply company. Concrete is an attractive flooring material to the dairy producer because it is readily available, durable, comparatively economical, relatively easy to place as it conforms well to irregular areas and can be finished in various ways to provide some level of traction. The finish on concrete should be deep. Use an air entrained concrete mixture with a minimum of strength of 3,500 pounds per square inch (psi) and adequate. Ideal floor finish maintains the right type of grooves and surface texture to attain needed traction.

Concrete Grooving For Cattle Sheds Kirby Cattle Services

Best Concrete Finish For Cattle This floor is suitable for handling. The finish on concrete should be deep. Scabbling — roughen the surface and create a wide, shallow line. Use an air entrained concrete mixture with a minimum of strength of 3,500 pounds per square inch (psi) and adequate. Grooving machines can be rented from a concrete supply company. Rubber matting — covering areas with cushion mats. Grooving — etching lines into the concrete surface. Milling — removing a thin layer to even the area and create a textured surface. Ideal floor finish maintains the right type of grooves and surface texture to attain needed traction. This floor is suitable for handling. Concrete is an attractive flooring material to the dairy producer because it is readily available, durable, comparatively economical, relatively easy to place as it conforms well to irregular areas and can be finished in various ways to provide some level of traction. This combination can be produced by. There are five types of floor resurfacing:

From dallcon.com.au

Concrete Cattle Grids Free Delivery 500 km Dallcon Best Concrete Finish For Cattle Rubber matting — covering areas with cushion mats. Grooving machines can be rented from a concrete supply company. There are five types of floor resurfacing: Use an air entrained concrete mixture with a minimum of strength of 3,500 pounds per square inch (psi) and adequate. This combination can be produced by. Scabbling — roughen the surface and create a wide,. Best Concrete Finish For Cattle.

From clsa.us

Concrete Floors For Cattle Clsa Flooring Guide Best Concrete Finish For Cattle Concrete is an attractive flooring material to the dairy producer because it is readily available, durable, comparatively economical, relatively easy to place as it conforms well to irregular areas and can be finished in various ways to provide some level of traction. Use an air entrained concrete mixture with a minimum of strength of 3,500 pounds per square inch (psi). Best Concrete Finish For Cattle.

From www.agriculture-xprt.com

Hanson Precast Concrete Agricultural Storage Cattle Slats & Deep Pit Barns By Hanson Silo Best Concrete Finish For Cattle Rubber matting — covering areas with cushion mats. This combination can be produced by. Use an air entrained concrete mixture with a minimum of strength of 3,500 pounds per square inch (psi) and adequate. Ideal floor finish maintains the right type of grooves and surface texture to attain needed traction. Grooving machines can be rented from a concrete supply company.. Best Concrete Finish For Cattle.

From www.moore-concrete.com

Cattle Slats Concrete Specialists Moore Concrete Best Concrete Finish For Cattle Grooving machines can be rented from a concrete supply company. Milling — removing a thin layer to even the area and create a textured surface. Use an air entrained concrete mixture with a minimum of strength of 3,500 pounds per square inch (psi) and adequate. Ideal floor finish maintains the right type of grooves and surface texture to attain needed. Best Concrete Finish For Cattle.

From www.moore-concrete.com

Livestock Housing Concrete Specialists Moore Concrete Best Concrete Finish For Cattle There are five types of floor resurfacing: This combination can be produced by. The finish on concrete should be deep. Milling — removing a thin layer to even the area and create a textured surface. Ideal floor finish maintains the right type of grooves and surface texture to attain needed traction. Rubber matting — covering areas with cushion mats. This. Best Concrete Finish For Cattle.

From www.vanhessche.be

Cattle slats cow barn concrete slats concrete cattle slats Vanhessche Best Concrete Finish For Cattle Concrete is an attractive flooring material to the dairy producer because it is readily available, durable, comparatively economical, relatively easy to place as it conforms well to irregular areas and can be finished in various ways to provide some level of traction. Grooving machines can be rented from a concrete supply company. Ideal floor finish maintains the right type of. Best Concrete Finish For Cattle.

From www.ontario.ca

Floor finish options for dairy freestall housing ontario.ca Best Concrete Finish For Cattle Concrete is an attractive flooring material to the dairy producer because it is readily available, durable, comparatively economical, relatively easy to place as it conforms well to irregular areas and can be finished in various ways to provide some level of traction. Ideal floor finish maintains the right type of grooves and surface texture to attain needed traction. The finish. Best Concrete Finish For Cattle.

From civiconcepts.com

10 Stunning Concrete Finishes You Must See Best Concrete Finish For Cattle Grooving — etching lines into the concrete surface. This combination can be produced by. Concrete is an attractive flooring material to the dairy producer because it is readily available, durable, comparatively economical, relatively easy to place as it conforms well to irregular areas and can be finished in various ways to provide some level of traction. This floor is suitable. Best Concrete Finish For Cattle.

From www.moore-concrete.com

Cattle Slats Concrete Specialists Moore Concrete Best Concrete Finish For Cattle Grooving machines can be rented from a concrete supply company. Use an air entrained concrete mixture with a minimum of strength of 3,500 pounds per square inch (psi) and adequate. The finish on concrete should be deep. This floor is suitable for handling. There are five types of floor resurfacing: Ideal floor finish maintains the right type of grooves and. Best Concrete Finish For Cattle.

From shieldagriculture.co.uk

Concrete Cattle Slats Shield Agriculture Best Concrete Finish For Cattle There are five types of floor resurfacing: This combination can be produced by. Ideal floor finish maintains the right type of grooves and surface texture to attain needed traction. Milling — removing a thin layer to even the area and create a textured surface. Scabbling — roughen the surface and create a wide, shallow line. Use an air entrained concrete. Best Concrete Finish For Cattle.

From traceyconcrete.com

Cattle Slats Tracey Concrete Best Concrete Finish For Cattle Milling — removing a thin layer to even the area and create a textured surface. This combination can be produced by. Use an air entrained concrete mixture with a minimum of strength of 3,500 pounds per square inch (psi) and adequate. Scabbling — roughen the surface and create a wide, shallow line. This floor is suitable for handling. Grooving machines. Best Concrete Finish For Cattle.

From dallcon.com.au

Everything You Need To Know About Cattle Grids Dallcon Best Concrete Finish For Cattle Concrete is an attractive flooring material to the dairy producer because it is readily available, durable, comparatively economical, relatively easy to place as it conforms well to irregular areas and can be finished in various ways to provide some level of traction. Milling — removing a thin layer to even the area and create a textured surface. Grooving — etching. Best Concrete Finish For Cattle.

From kirbycattleservicesltd.com

Concrete Grooving For Cattle Sheds Kirby Cattle Services Best Concrete Finish For Cattle Grooving machines can be rented from a concrete supply company. There are five types of floor resurfacing: This combination can be produced by. Grooving — etching lines into the concrete surface. This floor is suitable for handling. Concrete is an attractive flooring material to the dairy producer because it is readily available, durable, comparatively economical, relatively easy to place as. Best Concrete Finish For Cattle.

From hansonsilo.com

Concrete Feed Bunks Hanson Silo Company Best Concrete Finish For Cattle Grooving — etching lines into the concrete surface. Milling — removing a thin layer to even the area and create a textured surface. Ideal floor finish maintains the right type of grooves and surface texture to attain needed traction. Scabbling — roughen the surface and create a wide, shallow line. Grooving machines can be rented from a concrete supply company.. Best Concrete Finish For Cattle.

From vanhessche.be

Cattle slats cow barn concrete slats concrete cattle slats Vanhessche Best Concrete Finish For Cattle Ideal floor finish maintains the right type of grooves and surface texture to attain needed traction. Rubber matting — covering areas with cushion mats. There are five types of floor resurfacing: Grooving machines can be rented from a concrete supply company. Use an air entrained concrete mixture with a minimum of strength of 3,500 pounds per square inch (psi) and. Best Concrete Finish For Cattle.

From www.spanwright.co.uk

Cattle Slats Cow Comfort Animal Slats Concrete Slats Best Concrete Finish For Cattle Grooving — etching lines into the concrete surface. Scabbling — roughen the surface and create a wide, shallow line. This combination can be produced by. There are five types of floor resurfacing: Use an air entrained concrete mixture with a minimum of strength of 3,500 pounds per square inch (psi) and adequate. Ideal floor finish maintains the right type of. Best Concrete Finish For Cattle.

From www.moore-concrete.com

Cattle Slats Concrete Specialists Moore Concrete Best Concrete Finish For Cattle Use an air entrained concrete mixture with a minimum of strength of 3,500 pounds per square inch (psi) and adequate. Concrete is an attractive flooring material to the dairy producer because it is readily available, durable, comparatively economical, relatively easy to place as it conforms well to irregular areas and can be finished in various ways to provide some level. Best Concrete Finish For Cattle.

From www.gomaco.com

GOMACO, Manufacturer of Concrete Slipform Paving Equipment GOMACO World Best Concrete Finish For Cattle Milling — removing a thin layer to even the area and create a textured surface. The finish on concrete should be deep. Concrete is an attractive flooring material to the dairy producer because it is readily available, durable, comparatively economical, relatively easy to place as it conforms well to irregular areas and can be finished in various ways to provide. Best Concrete Finish For Cattle.

From dallcon.com.au

Everything You Need To Know About Cattle Grids Dallcon Best Concrete Finish For Cattle This floor is suitable for handling. Grooving — etching lines into the concrete surface. Rubber matting — covering areas with cushion mats. Scabbling — roughen the surface and create a wide, shallow line. This combination can be produced by. Use an air entrained concrete mixture with a minimum of strength of 3,500 pounds per square inch (psi) and adequate. Milling. Best Concrete Finish For Cattle.

From croomconcrete.ie

High Performance Precast Concrete Cattle Slats Cow Comfort at its best Best Concrete Finish For Cattle Milling — removing a thin layer to even the area and create a textured surface. This combination can be produced by. This floor is suitable for handling. Grooving machines can be rented from a concrete supply company. Concrete is an attractive flooring material to the dairy producer because it is readily available, durable, comparatively economical, relatively easy to place as. Best Concrete Finish For Cattle.

From irrigationdirect.com.au

Concrete Cattle Stock Troughs Irrigation Direct Best Concrete Finish For Cattle Rubber matting — covering areas with cushion mats. Scabbling — roughen the surface and create a wide, shallow line. Ideal floor finish maintains the right type of grooves and surface texture to attain needed traction. Use an air entrained concrete mixture with a minimum of strength of 3,500 pounds per square inch (psi) and adequate. This floor is suitable for. Best Concrete Finish For Cattle.

From www.southgippslandconcrete.com.au

Concrete Cattle Laneway in Toora North South Gippsland Concrete Pty Ltd Concrete Contractors Best Concrete Finish For Cattle This combination can be produced by. Rubber matting — covering areas with cushion mats. Use an air entrained concrete mixture with a minimum of strength of 3,500 pounds per square inch (psi) and adequate. This floor is suitable for handling. Scabbling — roughen the surface and create a wide, shallow line. There are five types of floor resurfacing: Concrete is. Best Concrete Finish For Cattle.

From shieldagriculture.co.uk

Concrete Cattle Slats Shield Agriculture Best Concrete Finish For Cattle This combination can be produced by. Use an air entrained concrete mixture with a minimum of strength of 3,500 pounds per square inch (psi) and adequate. The finish on concrete should be deep. Grooving machines can be rented from a concrete supply company. Rubber matting — covering areas with cushion mats. Ideal floor finish maintains the right type of grooves. Best Concrete Finish For Cattle.

From www.moore-concrete.com

Cattle Slats Concrete Specialists Moore Concrete Best Concrete Finish For Cattle Rubber matting — covering areas with cushion mats. Grooving — etching lines into the concrete surface. Grooving machines can be rented from a concrete supply company. Concrete is an attractive flooring material to the dairy producer because it is readily available, durable, comparatively economical, relatively easy to place as it conforms well to irregular areas and can be finished in. Best Concrete Finish For Cattle.

From shieldagriculture.co.uk

Concrete Cattle Slats Shield Agriculture Best Concrete Finish For Cattle There are five types of floor resurfacing: Milling — removing a thin layer to even the area and create a textured surface. Scabbling — roughen the surface and create a wide, shallow line. The finish on concrete should be deep. Rubber matting — covering areas with cushion mats. Ideal floor finish maintains the right type of grooves and surface texture. Best Concrete Finish For Cattle.

From shieldagriculture.co.uk

Concrete Cattle Slats Shield Agriculture Best Concrete Finish For Cattle This floor is suitable for handling. Milling — removing a thin layer to even the area and create a textured surface. This combination can be produced by. Use an air entrained concrete mixture with a minimum of strength of 3,500 pounds per square inch (psi) and adequate. The finish on concrete should be deep. Scabbling — roughen the surface and. Best Concrete Finish For Cattle.

From www.agproud.com

Designing concrete floors for dairy facilities to reduce lameness incidences Ag Proud Best Concrete Finish For Cattle The finish on concrete should be deep. Use an air entrained concrete mixture with a minimum of strength of 3,500 pounds per square inch (psi) and adequate. Concrete is an attractive flooring material to the dairy producer because it is readily available, durable, comparatively economical, relatively easy to place as it conforms well to irregular areas and can be finished. Best Concrete Finish For Cattle.

From civilmint.com

Concrete Finishes Types And Tools For Finishing Best Concrete Finish For Cattle The finish on concrete should be deep. Grooving — etching lines into the concrete surface. This floor is suitable for handling. Concrete is an attractive flooring material to the dairy producer because it is readily available, durable, comparatively economical, relatively easy to place as it conforms well to irregular areas and can be finished in various ways to provide some. Best Concrete Finish For Cattle.

From shieldagriculture.co.uk

Concrete Cattle Slats Shield Agriculture Best Concrete Finish For Cattle Grooving machines can be rented from a concrete supply company. Concrete is an attractive flooring material to the dairy producer because it is readily available, durable, comparatively economical, relatively easy to place as it conforms well to irregular areas and can be finished in various ways to provide some level of traction. This floor is suitable for handling. Milling —. Best Concrete Finish For Cattle.

From www.pinterest.com

Slatted Floor Manure Storage Dairy Stalls Rem Jem Precast Concrete Cattle farming, Precast Best Concrete Finish For Cattle Scabbling — roughen the surface and create a wide, shallow line. Concrete is an attractive flooring material to the dairy producer because it is readily available, durable, comparatively economical, relatively easy to place as it conforms well to irregular areas and can be finished in various ways to provide some level of traction. Milling — removing a thin layer to. Best Concrete Finish For Cattle.

From shieldagriculture.co.uk

Concrete Cattle Slats Shield Agriculture Best Concrete Finish For Cattle Grooving — etching lines into the concrete surface. There are five types of floor resurfacing: This floor is suitable for handling. The finish on concrete should be deep. Scabbling — roughen the surface and create a wide, shallow line. Rubber matting — covering areas with cushion mats. Concrete is an attractive flooring material to the dairy producer because it is. Best Concrete Finish For Cattle.

From www.moore-concrete.com

Cattle Slats Concrete Specialists Moore Concrete Best Concrete Finish For Cattle Rubber matting — covering areas with cushion mats. Ideal floor finish maintains the right type of grooves and surface texture to attain needed traction. Concrete is an attractive flooring material to the dairy producer because it is readily available, durable, comparatively economical, relatively easy to place as it conforms well to irregular areas and can be finished in various ways. Best Concrete Finish For Cattle.

From www.farmcompare.com

Creagh Concrete 2600mm Cattle Single 6 Rib Slats Farm Compare Farm Compare Best Concrete Finish For Cattle The finish on concrete should be deep. Grooving — etching lines into the concrete surface. Use an air entrained concrete mixture with a minimum of strength of 3,500 pounds per square inch (psi) and adequate. There are five types of floor resurfacing: Rubber matting — covering areas with cushion mats. Ideal floor finish maintains the right type of grooves and. Best Concrete Finish For Cattle.

From thefarmingforum.co.uk

Concrete finish for cattle? The Farming Forum Best Concrete Finish For Cattle This floor is suitable for handling. Ideal floor finish maintains the right type of grooves and surface texture to attain needed traction. Rubber matting — covering areas with cushion mats. There are five types of floor resurfacing: Use an air entrained concrete mixture with a minimum of strength of 3,500 pounds per square inch (psi) and adequate. The finish on. Best Concrete Finish For Cattle.

From croomconcrete.ie

High Performance Precast Concrete Cattle Slats Cow Comfort at its best Best Concrete Finish For Cattle Use an air entrained concrete mixture with a minimum of strength of 3,500 pounds per square inch (psi) and adequate. Ideal floor finish maintains the right type of grooves and surface texture to attain needed traction. This floor is suitable for handling. This combination can be produced by. There are five types of floor resurfacing: Milling — removing a thin. Best Concrete Finish For Cattle.