Vacuum Forming Vs Thermoforming . Thermoforming is the process of producing plastic under extreme pressure and heat. Vacuum forming uses a vacuum to shape heated plastic sheets, whereas thermoforming utilizes both heat and pressure for molding. The main difference between vacuum forming and other thermoforming processes is the methods used to form the parts and the number and type of molds that are used. However when comparing, thermoforming vs vacuum forming, the two processes are utilized for distinct objectives. Vacuum forming is a procedure that occurs when plastic is heated to a specific temperature. Pressure and vacuum forming are the 2 most common plastic thermoforming manufacturing techniques, under the umbrella of plastic thermoforming. Thermoforming, on the other hand, utilizes pressure to mold plastic sheets, providing the ability to produce large parts with intricate details at a faster rate. The main difference between vacuum forming and thermoforming lies in how the plastic is forced into the mould’s shape. Thermoforming is a preferred plastic part manufacturing process for its low cost and speed, and it’s one of the most popular processes. Vacuum forming is the simplest type of plastic thermoforming, that uses one mold and vacuum pressure to obtain the desired part geometry.

from www.exergenglobal.com

However when comparing, thermoforming vs vacuum forming, the two processes are utilized for distinct objectives. Thermoforming is the process of producing plastic under extreme pressure and heat. Thermoforming, on the other hand, utilizes pressure to mold plastic sheets, providing the ability to produce large parts with intricate details at a faster rate. Vacuum forming is a procedure that occurs when plastic is heated to a specific temperature. Thermoforming is a preferred plastic part manufacturing process for its low cost and speed, and it’s one of the most popular processes. Vacuum forming uses a vacuum to shape heated plastic sheets, whereas thermoforming utilizes both heat and pressure for molding. Vacuum forming is the simplest type of plastic thermoforming, that uses one mold and vacuum pressure to obtain the desired part geometry. The main difference between vacuum forming and thermoforming lies in how the plastic is forced into the mould’s shape. The main difference between vacuum forming and other thermoforming processes is the methods used to form the parts and the number and type of molds that are used. Pressure and vacuum forming are the 2 most common plastic thermoforming manufacturing techniques, under the umbrella of plastic thermoforming.

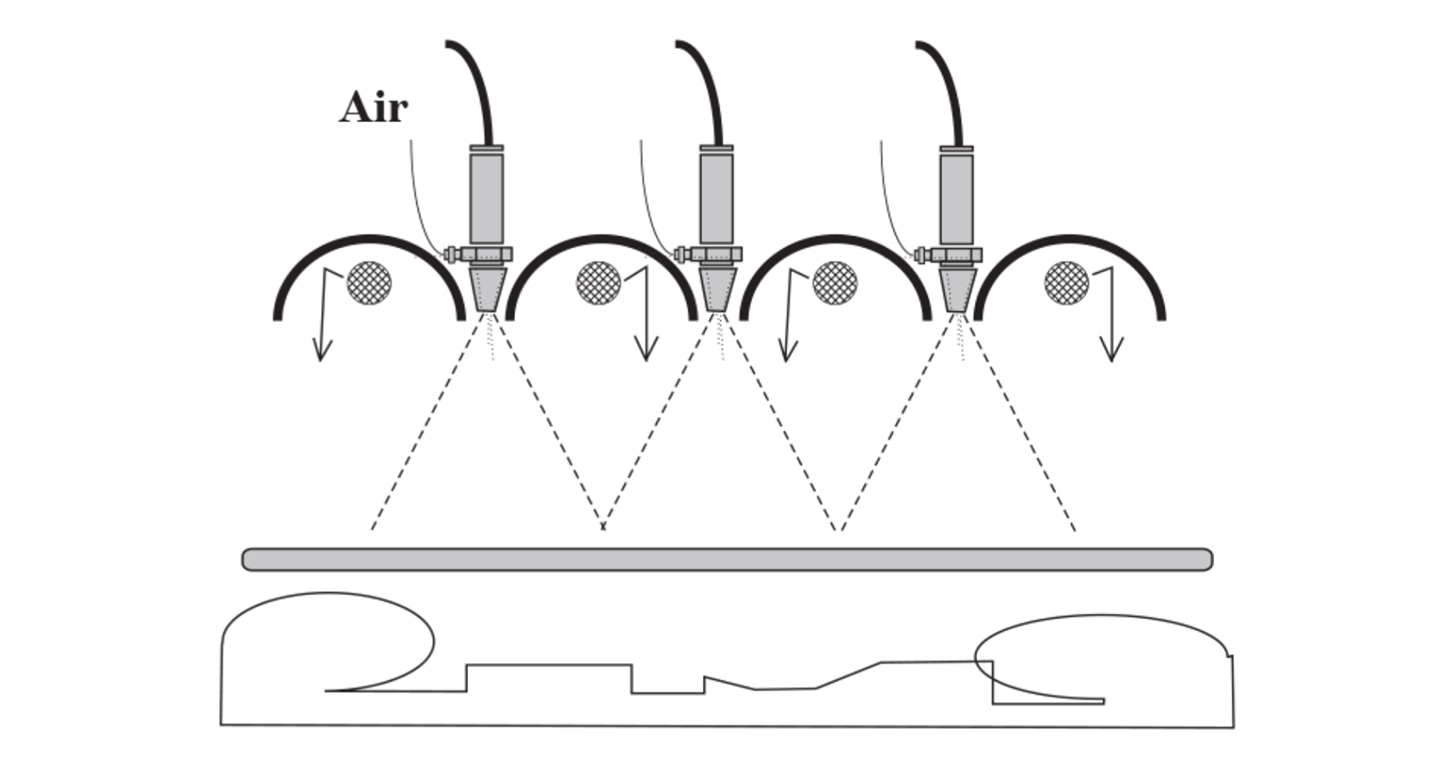

Controlling vacuum forming and thermoforming processes

Vacuum Forming Vs Thermoforming However when comparing, thermoforming vs vacuum forming, the two processes are utilized for distinct objectives. Thermoforming, on the other hand, utilizes pressure to mold plastic sheets, providing the ability to produce large parts with intricate details at a faster rate. The main difference between vacuum forming and thermoforming lies in how the plastic is forced into the mould’s shape. Vacuum forming uses a vacuum to shape heated plastic sheets, whereas thermoforming utilizes both heat and pressure for molding. Thermoforming is the process of producing plastic under extreme pressure and heat. Vacuum forming is the simplest type of plastic thermoforming, that uses one mold and vacuum pressure to obtain the desired part geometry. However when comparing, thermoforming vs vacuum forming, the two processes are utilized for distinct objectives. Pressure and vacuum forming are the 2 most common plastic thermoforming manufacturing techniques, under the umbrella of plastic thermoforming. The main difference between vacuum forming and other thermoforming processes is the methods used to form the parts and the number and type of molds that are used. Vacuum forming is a procedure that occurs when plastic is heated to a specific temperature. Thermoforming is a preferred plastic part manufacturing process for its low cost and speed, and it’s one of the most popular processes.

From www.rayplastics.com

A Brief Overview of Thermoforming Sign up Below for our Free Handbook Vacuum Forming Vs Thermoforming The main difference between vacuum forming and other thermoforming processes is the methods used to form the parts and the number and type of molds that are used. Pressure and vacuum forming are the 2 most common plastic thermoforming manufacturing techniques, under the umbrella of plastic thermoforming. Thermoforming, on the other hand, utilizes pressure to mold plastic sheets, providing the. Vacuum Forming Vs Thermoforming.

From theprodesigngroup.com

What’s the Difference Between Vacuum Forming and Thermoforming? The Vacuum Forming Vs Thermoforming Pressure and vacuum forming are the 2 most common plastic thermoforming manufacturing techniques, under the umbrella of plastic thermoforming. However when comparing, thermoforming vs vacuum forming, the two processes are utilized for distinct objectives. The main difference between vacuum forming and other thermoforming processes is the methods used to form the parts and the number and type of molds that. Vacuum Forming Vs Thermoforming.

From blog.thepipingmart.com

Vacuum Forming vs Pressure Forming What's the Difference Vacuum Forming Vs Thermoforming However when comparing, thermoforming vs vacuum forming, the two processes are utilized for distinct objectives. Pressure and vacuum forming are the 2 most common plastic thermoforming manufacturing techniques, under the umbrella of plastic thermoforming. The main difference between vacuum forming and thermoforming lies in how the plastic is forced into the mould’s shape. Thermoforming, on the other hand, utilizes pressure. Vacuum Forming Vs Thermoforming.

From prestigetooling.com

Pressure forming vs Vacuum Forming Thermoforming Molds Solid Vacuum Forming Vs Thermoforming The main difference between vacuum forming and other thermoforming processes is the methods used to form the parts and the number and type of molds that are used. Vacuum forming is the simplest type of plastic thermoforming, that uses one mold and vacuum pressure to obtain the desired part geometry. The main difference between vacuum forming and thermoforming lies in. Vacuum Forming Vs Thermoforming.

From www.exergenglobal.com

Controlling vacuum forming and thermoforming processes Vacuum Forming Vs Thermoforming Thermoforming is a preferred plastic part manufacturing process for its low cost and speed, and it’s one of the most popular processes. Vacuum forming is a procedure that occurs when plastic is heated to a specific temperature. Thermoforming is the process of producing plastic under extreme pressure and heat. Vacuum forming is the simplest type of plastic thermoforming, that uses. Vacuum Forming Vs Thermoforming.

From www.donite.com

What is thermoforming and vacuum forming? Donite Vacuum Forming Vs Thermoforming Vacuum forming is the simplest type of plastic thermoforming, that uses one mold and vacuum pressure to obtain the desired part geometry. Vacuum forming is a procedure that occurs when plastic is heated to a specific temperature. However when comparing, thermoforming vs vacuum forming, the two processes are utilized for distinct objectives. The main difference between vacuum forming and thermoforming. Vacuum Forming Vs Thermoforming.

From www.idealrp.com

Thermoforming and Vacuum Forming Vacuum Forming Vs Thermoforming Vacuum forming is the simplest type of plastic thermoforming, that uses one mold and vacuum pressure to obtain the desired part geometry. Vacuum forming uses a vacuum to shape heated plastic sheets, whereas thermoforming utilizes both heat and pressure for molding. Pressure and vacuum forming are the 2 most common plastic thermoforming manufacturing techniques, under the umbrella of plastic thermoforming.. Vacuum Forming Vs Thermoforming.

From electricalworkbook.com

What is Vacuum Forming? Process, Applications, Products & Advantages Vacuum Forming Vs Thermoforming The main difference between vacuum forming and thermoforming lies in how the plastic is forced into the mould’s shape. However when comparing, thermoforming vs vacuum forming, the two processes are utilized for distinct objectives. Thermoforming is the process of producing plastic under extreme pressure and heat. Pressure and vacuum forming are the 2 most common plastic thermoforming manufacturing techniques, under. Vacuum Forming Vs Thermoforming.

From www.hardwareinterviews.fyi

Basics of Thermoforming Consumer Hardware Guide Hardware FYI Vacuum Forming Vs Thermoforming The main difference between vacuum forming and thermoforming lies in how the plastic is forced into the mould’s shape. However when comparing, thermoforming vs vacuum forming, the two processes are utilized for distinct objectives. Thermoforming is a preferred plastic part manufacturing process for its low cost and speed, and it’s one of the most popular processes. Vacuum forming uses a. Vacuum Forming Vs Thermoforming.

From www.iqsdirectory.com

Vacuum Forming Types, Uses, Features and Benefits Vacuum Forming Vs Thermoforming However when comparing, thermoforming vs vacuum forming, the two processes are utilized for distinct objectives. Pressure and vacuum forming are the 2 most common plastic thermoforming manufacturing techniques, under the umbrella of plastic thermoforming. Thermoforming, on the other hand, utilizes pressure to mold plastic sheets, providing the ability to produce large parts with intricate details at a faster rate. Vacuum. Vacuum Forming Vs Thermoforming.

From www.youtube.com

Thermoforming & Vacuum Forming(हिन्दी ) YouTube Vacuum Forming Vs Thermoforming Vacuum forming uses a vacuum to shape heated plastic sheets, whereas thermoforming utilizes both heat and pressure for molding. Thermoforming is a preferred plastic part manufacturing process for its low cost and speed, and it’s one of the most popular processes. Vacuum forming is the simplest type of plastic thermoforming, that uses one mold and vacuum pressure to obtain the. Vacuum Forming Vs Thermoforming.

From rotodynamics.com

Rotational Molding vs. Vacuum Forming/ Thermoforming Roto Dynamics Vacuum Forming Vs Thermoforming Vacuum forming is the simplest type of plastic thermoforming, that uses one mold and vacuum pressure to obtain the desired part geometry. Thermoforming is a preferred plastic part manufacturing process for its low cost and speed, and it’s one of the most popular processes. However when comparing, thermoforming vs vacuum forming, the two processes are utilized for distinct objectives. Vacuum. Vacuum Forming Vs Thermoforming.

From www.productiveplastics.com

What is Thermoforming? Plastic Thermoforming Explained Productive Vacuum Forming Vs Thermoforming Thermoforming is the process of producing plastic under extreme pressure and heat. The main difference between vacuum forming and thermoforming lies in how the plastic is forced into the mould’s shape. Vacuum forming is a procedure that occurs when plastic is heated to a specific temperature. Vacuum forming uses a vacuum to shape heated plastic sheets, whereas thermoforming utilizes both. Vacuum Forming Vs Thermoforming.

From www.weetect.com

Plastic Fabrication The Complete Guide In 2018 Wee Tect Vacuum Forming Vs Thermoforming Pressure and vacuum forming are the 2 most common plastic thermoforming manufacturing techniques, under the umbrella of plastic thermoforming. Thermoforming is the process of producing plastic under extreme pressure and heat. The main difference between vacuum forming and other thermoforming processes is the methods used to form the parts and the number and type of molds that are used. Vacuum. Vacuum Forming Vs Thermoforming.

From www.hongzu.com

5 Minutes to Understand Vacuum Thermoforming Mold Design & Examples Vacuum Forming Vs Thermoforming The main difference between vacuum forming and other thermoforming processes is the methods used to form the parts and the number and type of molds that are used. Vacuum forming is a procedure that occurs when plastic is heated to a specific temperature. However when comparing, thermoforming vs vacuum forming, the two processes are utilized for distinct objectives. Thermoforming, on. Vacuum Forming Vs Thermoforming.

From www.iqsdirectory.com

Vacuum Forming Types, Uses, Features and Benefits Vacuum Forming Vs Thermoforming The main difference between vacuum forming and other thermoforming processes is the methods used to form the parts and the number and type of molds that are used. Vacuum forming is a procedure that occurs when plastic is heated to a specific temperature. Thermoforming is the process of producing plastic under extreme pressure and heat. Vacuum forming is the simplest. Vacuum Forming Vs Thermoforming.

From medical.brentwoodindustries.com

Vacuum vs. Pressure Forming Processes Explained Vacuum Forming Vs Thermoforming Vacuum forming uses a vacuum to shape heated plastic sheets, whereas thermoforming utilizes both heat and pressure for molding. Thermoforming is a preferred plastic part manufacturing process for its low cost and speed, and it’s one of the most popular processes. The main difference between vacuum forming and other thermoforming processes is the methods used to form the parts and. Vacuum Forming Vs Thermoforming.

From cedocdwf.blob.core.windows.net

The Process Of Vacuum Forming Step By Step at Edwin Curry blog Vacuum Forming Vs Thermoforming However when comparing, thermoforming vs vacuum forming, the two processes are utilized for distinct objectives. The main difference between vacuum forming and thermoforming lies in how the plastic is forced into the mould’s shape. Thermoforming is a preferred plastic part manufacturing process for its low cost and speed, and it’s one of the most popular processes. Thermoforming is the process. Vacuum Forming Vs Thermoforming.

From www.gpi-plastics.com

5 Tips for High Quality Thermoforming Results Greenwood Plastics Vacuum Forming Vs Thermoforming Thermoforming, on the other hand, utilizes pressure to mold plastic sheets, providing the ability to produce large parts with intricate details at a faster rate. Thermoforming is a preferred plastic part manufacturing process for its low cost and speed, and it’s one of the most popular processes. The main difference between vacuum forming and other thermoforming processes is the methods. Vacuum Forming Vs Thermoforming.

From prestigetooling.com

Vacuum Forming Mold Types Thermoforming Molds Solid Surface Molds Vacuum Forming Vs Thermoforming The main difference between vacuum forming and other thermoforming processes is the methods used to form the parts and the number and type of molds that are used. Vacuum forming is the simplest type of plastic thermoforming, that uses one mold and vacuum pressure to obtain the desired part geometry. Vacuum forming is a procedure that occurs when plastic is. Vacuum Forming Vs Thermoforming.

From gregstrom.com

Plastic Thermoforming Vacuum vs. Pressure vs. Twin Sheet Gregstrom Vacuum Forming Vs Thermoforming Vacuum forming uses a vacuum to shape heated plastic sheets, whereas thermoforming utilizes both heat and pressure for molding. Vacuum forming is a procedure that occurs when plastic is heated to a specific temperature. Vacuum forming is the simplest type of plastic thermoforming, that uses one mold and vacuum pressure to obtain the desired part geometry. The main difference between. Vacuum Forming Vs Thermoforming.

From dmd-2000.co.uk

Thermoforming DMD 2000 Ltd Vacuum Forming Vs Thermoforming However when comparing, thermoforming vs vacuum forming, the two processes are utilized for distinct objectives. Vacuum forming uses a vacuum to shape heated plastic sheets, whereas thermoforming utilizes both heat and pressure for molding. Thermoforming is the process of producing plastic under extreme pressure and heat. Pressure and vacuum forming are the 2 most common plastic thermoforming manufacturing techniques, under. Vacuum Forming Vs Thermoforming.

From www.plas-tech.co.uk

Vac Forming The Advantages of Vacuum Forming Vacuum Forming Vs Thermoforming Vacuum forming uses a vacuum to shape heated plastic sheets, whereas thermoforming utilizes both heat and pressure for molding. Vacuum forming is a procedure that occurs when plastic is heated to a specific temperature. Pressure and vacuum forming are the 2 most common plastic thermoforming manufacturing techniques, under the umbrella of plastic thermoforming. The main difference between vacuum forming and. Vacuum Forming Vs Thermoforming.

From www.la-plastic.com

What Causes bing in Vacuum Forming? Vacuum Forming Vs Thermoforming Vacuum forming uses a vacuum to shape heated plastic sheets, whereas thermoforming utilizes both heat and pressure for molding. Vacuum forming is a procedure that occurs when plastic is heated to a specific temperature. Pressure and vacuum forming are the 2 most common plastic thermoforming manufacturing techniques, under the umbrella of plastic thermoforming. The main difference between vacuum forming and. Vacuum Forming Vs Thermoforming.

From intradefairs.com

Thermoforming Vacuum Forming Vs Thermoforming Thermoforming, on the other hand, utilizes pressure to mold plastic sheets, providing the ability to produce large parts with intricate details at a faster rate. Thermoforming is the process of producing plastic under extreme pressure and heat. The main difference between vacuum forming and thermoforming lies in how the plastic is forced into the mould’s shape. However when comparing, thermoforming. Vacuum Forming Vs Thermoforming.

From exohiwkyw.blob.core.windows.net

Pressure Forming Vs Vacuum Forming at Jeffrey Vogt blog Vacuum Forming Vs Thermoforming Pressure and vacuum forming are the 2 most common plastic thermoforming manufacturing techniques, under the umbrella of plastic thermoforming. However when comparing, thermoforming vs vacuum forming, the two processes are utilized for distinct objectives. The main difference between vacuum forming and other thermoforming processes is the methods used to form the parts and the number and type of molds that. Vacuum Forming Vs Thermoforming.

From www.youtube.com

FullAutomatic VacuumForming And Cutting Integrated Thermoforming Vacuum Forming Vs Thermoforming Vacuum forming is the simplest type of plastic thermoforming, that uses one mold and vacuum pressure to obtain the desired part geometry. Vacuum forming is a procedure that occurs when plastic is heated to a specific temperature. Thermoforming, on the other hand, utilizes pressure to mold plastic sheets, providing the ability to produce large parts with intricate details at a. Vacuum Forming Vs Thermoforming.

From prestigetooling.com

Vacuum forming VS Injection Molding 101 Thermoforming Molds Solid Vacuum Forming Vs Thermoforming The main difference between vacuum forming and thermoforming lies in how the plastic is forced into the mould’s shape. Pressure and vacuum forming are the 2 most common plastic thermoforming manufacturing techniques, under the umbrella of plastic thermoforming. Vacuum forming is a procedure that occurs when plastic is heated to a specific temperature. However when comparing, thermoforming vs vacuum forming,. Vacuum Forming Vs Thermoforming.

From www.youtube.com

Thermoforming Factory Present What Is Vacuum Forming And How Vacuum Vacuum Forming Vs Thermoforming Thermoforming is the process of producing plastic under extreme pressure and heat. Pressure and vacuum forming are the 2 most common plastic thermoforming manufacturing techniques, under the umbrella of plastic thermoforming. However when comparing, thermoforming vs vacuum forming, the two processes are utilized for distinct objectives. Vacuum forming is a procedure that occurs when plastic is heated to a specific. Vacuum Forming Vs Thermoforming.

From canusplastics.com

Vacuum Forming vs. Thermoforming Choosing the Best Plastic Forming Vacuum Forming Vs Thermoforming Vacuum forming is the simplest type of plastic thermoforming, that uses one mold and vacuum pressure to obtain the desired part geometry. Vacuum forming uses a vacuum to shape heated plastic sheets, whereas thermoforming utilizes both heat and pressure for molding. Thermoforming, on the other hand, utilizes pressure to mold plastic sheets, providing the ability to produce large parts with. Vacuum Forming Vs Thermoforming.

From formasia.com.ph

Differences between vacuum forming, thermoforming and pressure forming Vacuum Forming Vs Thermoforming Pressure and vacuum forming are the 2 most common plastic thermoforming manufacturing techniques, under the umbrella of plastic thermoforming. Vacuum forming is the simplest type of plastic thermoforming, that uses one mold and vacuum pressure to obtain the desired part geometry. Thermoforming is a preferred plastic part manufacturing process for its low cost and speed, and it’s one of the. Vacuum Forming Vs Thermoforming.

From blog.thepipingmart.com

Vacuum Forming vs Thermoforming What's the Difference Vacuum Forming Vs Thermoforming Thermoforming is the process of producing plastic under extreme pressure and heat. Vacuum forming is a procedure that occurs when plastic is heated to a specific temperature. Thermoforming is a preferred plastic part manufacturing process for its low cost and speed, and it’s one of the most popular processes. Vacuum forming uses a vacuum to shape heated plastic sheets, whereas. Vacuum Forming Vs Thermoforming.

From gregstrom.com

Types of Thermoforming Vacuum Forming vs. Pressure Forming Vacuum Forming Vs Thermoforming Vacuum forming uses a vacuum to shape heated plastic sheets, whereas thermoforming utilizes both heat and pressure for molding. Thermoforming is the process of producing plastic under extreme pressure and heat. The main difference between vacuum forming and other thermoforming processes is the methods used to form the parts and the number and type of molds that are used. Thermoforming. Vacuum Forming Vs Thermoforming.

From warringah-plastics.com.au

Industry Leaders in Vacuum Forming in Sydney Warringah Plastics Vacuum Forming Vs Thermoforming Vacuum forming is a procedure that occurs when plastic is heated to a specific temperature. Vacuum forming is the simplest type of plastic thermoforming, that uses one mold and vacuum pressure to obtain the desired part geometry. The main difference between vacuum forming and thermoforming lies in how the plastic is forced into the mould’s shape. Pressure and vacuum forming. Vacuum Forming Vs Thermoforming.

From www.iqsdirectory.com

Vacuum Forming Types, Uses, Features and Benefits Vacuum Forming Vs Thermoforming The main difference between vacuum forming and thermoforming lies in how the plastic is forced into the mould’s shape. Vacuum forming uses a vacuum to shape heated plastic sheets, whereas thermoforming utilizes both heat and pressure for molding. Thermoforming is the process of producing plastic under extreme pressure and heat. Pressure and vacuum forming are the 2 most common plastic. Vacuum Forming Vs Thermoforming.