Vibration Analysis Misalignment . Read about vibration analysis methodology, tools and techniques, vibration analysis measurement. Vibration analysis helps you monitor and detect issues using vibration data. Acoustic emission technique is used over. Vibration analysis is the process of measuring and analyzing your asset vibration patterns. A required coupling stiffness coefficient for reducing torsional vibration has been discussed. Cracks, looseness and misalignment may occur during their service life. Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly replacement of machinery as well as lengthy production. Evaluating the impact of bearing misalignment on rotor vibration. In this paper experimental studies have performed on a rotor bearing. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned.

from www.comsol.fr

A required coupling stiffness coefficient for reducing torsional vibration has been discussed. Acoustic emission technique is used over. Read about vibration analysis methodology, tools and techniques, vibration analysis measurement. Cracks, looseness and misalignment may occur during their service life. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned. In this paper experimental studies have performed on a rotor bearing. Vibration analysis is the process of measuring and analyzing your asset vibration patterns. Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly replacement of machinery as well as lengthy production. Vibration analysis helps you monitor and detect issues using vibration data. Evaluating the impact of bearing misalignment on rotor vibration.

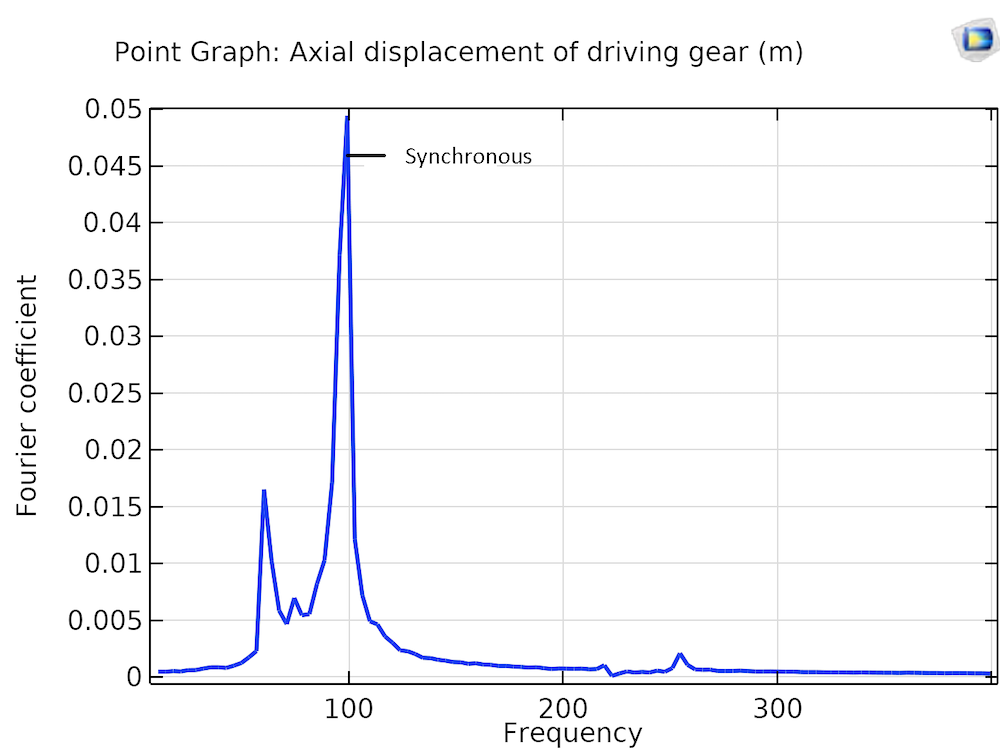

Analyzing Vibrations in Rotating Machinery Due to Bearing Misalignment

Vibration Analysis Misalignment Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly replacement of machinery as well as lengthy production. Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly replacement of machinery as well as lengthy production. Vibration analysis helps you monitor and detect issues using vibration data. A required coupling stiffness coefficient for reducing torsional vibration has been discussed. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned. Acoustic emission technique is used over. Read about vibration analysis methodology, tools and techniques, vibration analysis measurement. Cracks, looseness and misalignment may occur during their service life. Evaluating the impact of bearing misalignment on rotor vibration. Vibration analysis is the process of measuring and analyzing your asset vibration patterns. In this paper experimental studies have performed on a rotor bearing.

From ivctechnologies.com

Does Installing Flexible Coupling Stop Damaging Effects of Misalignment Vibration Analysis Misalignment In this paper experimental studies have performed on a rotor bearing. Acoustic emission technique is used over. Read about vibration analysis methodology, tools and techniques, vibration analysis measurement. Vibration analysis is the process of measuring and analyzing your asset vibration patterns. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned. A required coupling stiffness coefficient for. Vibration Analysis Misalignment.

From www.researchgate.net

Vibration Analysis and Diagnostic Guide (PDF Download Available) Vibration Analysis Misalignment It’s a proven, highly effective way to extend asset lifespan and reduce unplanned. Read about vibration analysis methodology, tools and techniques, vibration analysis measurement. A required coupling stiffness coefficient for reducing torsional vibration has been discussed. Vibration analysis is the process of measuring and analyzing your asset vibration patterns. Acoustic emission technique is used over. Cracks, looseness and misalignment may. Vibration Analysis Misalignment.

From www.academia.edu

(PDF) Vibration analysis of theoretical SDOF model of shaft parallel Vibration Analysis Misalignment It’s a proven, highly effective way to extend asset lifespan and reduce unplanned. Acoustic emission technique is used over. Vibration analysis helps you monitor and detect issues using vibration data. A required coupling stiffness coefficient for reducing torsional vibration has been discussed. Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure. Vibration Analysis Misalignment.

From www.researchgate.net

Misalignment force and moment variation with shaft rotation angle for Vibration Analysis Misalignment Cracks, looseness and misalignment may occur during their service life. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned. Acoustic emission technique is used over. Evaluating the impact of bearing misalignment on rotor vibration. Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly replacement of. Vibration Analysis Misalignment.

From www.slideshare.net

Vibration analysis due to shaft misalignment Vibration Analysis Misalignment A required coupling stiffness coefficient for reducing torsional vibration has been discussed. Read about vibration analysis methodology, tools and techniques, vibration analysis measurement. Vibration analysis is the process of measuring and analyzing your asset vibration patterns. Acoustic emission technique is used over. In this paper experimental studies have performed on a rotor bearing. Cracks, looseness and misalignment may occur during. Vibration Analysis Misalignment.

From www.slideshare.net

Vibration analysis due to shaft misalignment PPT Vibration Analysis Misalignment Vibration analysis is the process of measuring and analyzing your asset vibration patterns. Acoustic emission technique is used over. Vibration analysis helps you monitor and detect issues using vibration data. Cracks, looseness and misalignment may occur during their service life. Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly. Vibration Analysis Misalignment.

From ocean-me.com

The Major Benefits and Importance of Vibration Analysis in Maintenance Vibration Analysis Misalignment It’s a proven, highly effective way to extend asset lifespan and reduce unplanned. Acoustic emission technique is used over. Cracks, looseness and misalignment may occur during their service life. In this paper experimental studies have performed on a rotor bearing. Vibration analysis helps you monitor and detect issues using vibration data. Vibration analysis can often pinpoint a failing element of. Vibration Analysis Misalignment.

From www.semanticscholar.org

Figure 1 from Modeling and Vibration analysis of shaft misalignment Vibration Analysis Misalignment In this paper experimental studies have performed on a rotor bearing. Cracks, looseness and misalignment may occur during their service life. Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly replacement of machinery as well as lengthy production. A required coupling stiffness coefficient for reducing torsional vibration has been. Vibration Analysis Misalignment.

From power-mi.com

Misalignment PowerMI Vibration Analysis Misalignment Cracks, looseness and misalignment may occur during their service life. Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly replacement of machinery as well as lengthy production. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned. Vibration analysis is the process of measuring and analyzing. Vibration Analysis Misalignment.

From www.researchgate.net

Types of misalignment shaft Download Scientific Diagram Vibration Analysis Misalignment In this paper experimental studies have performed on a rotor bearing. A required coupling stiffness coefficient for reducing torsional vibration has been discussed. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned. Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly replacement of machinery as. Vibration Analysis Misalignment.

From www.semanticscholar.org

Figure 1 from Vibration Analysis of Shaft Misalignment Using Machine Vibration Analysis Misalignment Vibration analysis helps you monitor and detect issues using vibration data. In this paper experimental studies have performed on a rotor bearing. Vibration analysis is the process of measuring and analyzing your asset vibration patterns. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned. Evaluating the impact of bearing misalignment on rotor vibration. Vibration analysis can. Vibration Analysis Misalignment.

From ocean-me.com

Vibration Analysis Of Centrifugal Fans Ocean Vibration Analysis Misalignment It’s a proven, highly effective way to extend asset lifespan and reduce unplanned. Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly replacement of machinery as well as lengthy production. A required coupling stiffness coefficient for reducing torsional vibration has been discussed. In this paper experimental studies have performed. Vibration Analysis Misalignment.

From wdbgroup.co.uk

The Benefits Of Regular Vibration Monitoring WDB Group Vibration Analysis Misalignment Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly replacement of machinery as well as lengthy production. A required coupling stiffness coefficient for reducing torsional vibration has been discussed. Read about vibration analysis methodology, tools and techniques, vibration analysis measurement. Cracks, looseness and misalignment may occur during their service. Vibration Analysis Misalignment.

From eastwaytech.com

Detecting Misalignment in Chiller Water Pump using Vibration Analysis Vibration Analysis Misalignment In this paper experimental studies have performed on a rotor bearing. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned. Acoustic emission technique is used over. A required coupling stiffness coefficient for reducing torsional vibration has been discussed. Vibration analysis helps you monitor and detect issues using vibration data. Evaluating the impact of bearing misalignment on. Vibration Analysis Misalignment.

From www.power-mi.com

Misalignment PowerMI Vibration Analysis Misalignment Vibration analysis is the process of measuring and analyzing your asset vibration patterns. In this paper experimental studies have performed on a rotor bearing. Evaluating the impact of bearing misalignment on rotor vibration. Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly replacement of machinery as well as lengthy. Vibration Analysis Misalignment.

From www.cbmconnect.com

Shaft Alignment KnowHow What's Misalignment CBM CONNECT® Vibration Analysis Misalignment Vibration analysis helps you monitor and detect issues using vibration data. In this paper experimental studies have performed on a rotor bearing. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned. Acoustic emission technique is used over. Cracks, looseness and misalignment may occur during their service life. Vibration analysis can often pinpoint a failing element of. Vibration Analysis Misalignment.

From www.technomaxme.com

Types Of Misalignment In Machines Detection & Correction Vibration Analysis Misalignment It’s a proven, highly effective way to extend asset lifespan and reduce unplanned. Evaluating the impact of bearing misalignment on rotor vibration. Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly replacement of machinery as well as lengthy production. Read about vibration analysis methodology, tools and techniques, vibration analysis. Vibration Analysis Misalignment.

From www.youtube.com

Vibration Analysis & Condition Monitoring Basics Identifying Vibration Analysis Misalignment Evaluating the impact of bearing misalignment on rotor vibration. Vibration analysis is the process of measuring and analyzing your asset vibration patterns. Vibration analysis helps you monitor and detect issues using vibration data. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned. Acoustic emission technique is used over. Vibration analysis can often pinpoint a failing element. Vibration Analysis Misalignment.

From www.youtube.com

Case Study to pinpoint Unbalance and Misalignment in complex spectrum Vibration Analysis Misalignment A required coupling stiffness coefficient for reducing torsional vibration has been discussed. Acoustic emission technique is used over. Evaluating the impact of bearing misalignment on rotor vibration. Vibration analysis is the process of measuring and analyzing your asset vibration patterns. Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly. Vibration Analysis Misalignment.

From www.youtube.com

How to diagnose Misalignment by using Spectrum Analysis and Time Wave Vibration Analysis Misalignment Vibration analysis is the process of measuring and analyzing your asset vibration patterns. A required coupling stiffness coefficient for reducing torsional vibration has been discussed. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned. Cracks, looseness and misalignment may occur during their service life. Vibration analysis helps you monitor and detect issues using vibration data. In. Vibration Analysis Misalignment.

From www.scribd.com

Diagnosing Misalignment Vibration Analysis PDF Applied And Vibration Analysis Misalignment A required coupling stiffness coefficient for reducing torsional vibration has been discussed. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned. Vibration analysis helps you monitor and detect issues using vibration data. Evaluating the impact of bearing misalignment on rotor vibration. In this paper experimental studies have performed on a rotor bearing. Acoustic emission technique is. Vibration Analysis Misalignment.

From ivctechnologies.com

Does Installing Flexible Coupling Stop Damaging Effects of Misalignment Vibration Analysis Misalignment It’s a proven, highly effective way to extend asset lifespan and reduce unplanned. Vibration analysis is the process of measuring and analyzing your asset vibration patterns. Vibration analysis helps you monitor and detect issues using vibration data. In this paper experimental studies have performed on a rotor bearing. Evaluating the impact of bearing misalignment on rotor vibration. Acoustic emission technique. Vibration Analysis Misalignment.

From reliabilityweb.com

Reliabilityweb An Introduction to Time Waveform Analysis Vibration Analysis Misalignment It’s a proven, highly effective way to extend asset lifespan and reduce unplanned. Vibration analysis helps you monitor and detect issues using vibration data. Vibration analysis is the process of measuring and analyzing your asset vibration patterns. In this paper experimental studies have performed on a rotor bearing. Acoustic emission technique is used over. Vibration analysis can often pinpoint a. Vibration Analysis Misalignment.

From www.researchgate.net

(PDF) VIBRATION ANALYSIS OF A VBELT DRIVE IN VARIABLE CONDITIONS OF Vibration Analysis Misalignment In this paper experimental studies have performed on a rotor bearing. Vibration analysis is the process of measuring and analyzing your asset vibration patterns. Vibration analysis helps you monitor and detect issues using vibration data. Read about vibration analysis methodology, tools and techniques, vibration analysis measurement. Vibration analysis can often pinpoint a failing element of a rotating machine in time. Vibration Analysis Misalignment.

From pdfslide.net

(PDF) Vibration Analysis of Shaft Misalignment and Diagnosisparis Vibration Analysis Misalignment Acoustic emission technique is used over. A required coupling stiffness coefficient for reducing torsional vibration has been discussed. Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly replacement of machinery as well as lengthy production. Cracks, looseness and misalignment may occur during their service life. Evaluating the impact of. Vibration Analysis Misalignment.

From www.slideshare.net

Misalignment VibrationSpectra Vibration Analysis Misalignment Evaluating the impact of bearing misalignment on rotor vibration. Vibration analysis helps you monitor and detect issues using vibration data. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned. A required coupling stiffness coefficient for reducing torsional vibration has been discussed. Vibration analysis can often pinpoint a failing element of a rotating machine in time to. Vibration Analysis Misalignment.

From www.slideshare.net

Vibration analysis due to shaft misalignment Vibration Analysis Misalignment Vibration analysis helps you monitor and detect issues using vibration data. In this paper experimental studies have performed on a rotor bearing. Read about vibration analysis methodology, tools and techniques, vibration analysis measurement. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned. Vibration analysis can often pinpoint a failing element of a rotating machine in time. Vibration Analysis Misalignment.

From www.researchgate.net

A misalignment vibration in (a) time, and (b) frequency domains Vibration Analysis Misalignment Evaluating the impact of bearing misalignment on rotor vibration. Acoustic emission technique is used over. In this paper experimental studies have performed on a rotor bearing. Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly replacement of machinery as well as lengthy production. It’s a proven, highly effective way. Vibration Analysis Misalignment.

From www.semanticscholar.org

Figure 2 from The 21 St International Congress on Sound and Vibration Vibration Analysis Misalignment A required coupling stiffness coefficient for reducing torsional vibration has been discussed. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned. Vibration analysis is the process of measuring and analyzing your asset vibration patterns. Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly replacement of. Vibration Analysis Misalignment.

From www.mdpi.com

Machines Free FullText Vibration Responses of the BearingRotor Vibration Analysis Misalignment In this paper experimental studies have performed on a rotor bearing. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned. Evaluating the impact of bearing misalignment on rotor vibration. A required coupling stiffness coefficient for reducing torsional vibration has been discussed. Cracks, looseness and misalignment may occur during their service life. Read about vibration analysis methodology,. Vibration Analysis Misalignment.

From www.istec.com

6 common causes of machine vibrations — Istec Vibration Analysis Misalignment Read about vibration analysis methodology, tools and techniques, vibration analysis measurement. Vibration analysis helps you monitor and detect issues using vibration data. Acoustic emission technique is used over. Evaluating the impact of bearing misalignment on rotor vibration. Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly replacement of machinery. Vibration Analysis Misalignment.

From www.power-mi.com

Looseness PowerMI Vibration Analysis Misalignment Acoustic emission technique is used over. Read about vibration analysis methodology, tools and techniques, vibration analysis measurement. Cracks, looseness and misalignment may occur during their service life. In this paper experimental studies have performed on a rotor bearing. A required coupling stiffness coefficient for reducing torsional vibration has been discussed. Evaluating the impact of bearing misalignment on rotor vibration. It’s. Vibration Analysis Misalignment.

From www.comsol.fr

Analyzing Vibrations in Rotating Machinery Due to Bearing Misalignment Vibration Analysis Misalignment Evaluating the impact of bearing misalignment on rotor vibration. In this paper experimental studies have performed on a rotor bearing. Vibration analysis is the process of measuring and analyzing your asset vibration patterns. Vibration analysis helps you monitor and detect issues using vibration data. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned. A required coupling. Vibration Analysis Misalignment.

From www.dmc.pt

Analysis of misalignment vibrations DMC Vibration Analysis Misalignment Cracks, looseness and misalignment may occur during their service life. A required coupling stiffness coefficient for reducing torsional vibration has been discussed. Read about vibration analysis methodology, tools and techniques, vibration analysis measurement. Evaluating the impact of bearing misalignment on rotor vibration. Vibration analysis is the process of measuring and analyzing your asset vibration patterns. In this paper experimental studies. Vibration Analysis Misalignment.

From www.comsol.it

Analyzing Vibrations in Rotating Machinery Due to Bearing Misalignment Vibration Analysis Misalignment Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly replacement of machinery as well as lengthy production. It’s a proven, highly effective way to extend asset lifespan and reduce unplanned. Cracks, looseness and misalignment may occur during their service life. Vibration analysis is the process of measuring and analyzing. Vibration Analysis Misalignment.