Cleaning Process Gas . This review highlighted the advantages and disadvantages of different gas cleaning methods including physical filtration,. The gas cleaning requirements for fts are rigorous; Practically all the contaminants produced during the gasification process must. In recent studies, in situ plasma cleaning with different types of sources, feedstock gases, (partial) gas pressures as well as other. Gas cleaning requirements for downstream applications such as fts, methanol, and other chemicals are indispensable, hence. By varying the process gas, plasma processing may be used for chemical and mechanical contamination removal, oxidation, activation,.

from www.uky.edu

By varying the process gas, plasma processing may be used for chemical and mechanical contamination removal, oxidation, activation,. This review highlighted the advantages and disadvantages of different gas cleaning methods including physical filtration,. Gas cleaning requirements for downstream applications such as fts, methanol, and other chemicals are indispensable, hence. Practically all the contaminants produced during the gasification process must. In recent studies, in situ plasma cleaning with different types of sources, feedstock gases, (partial) gas pressures as well as other. The gas cleaning requirements for fts are rigorous;

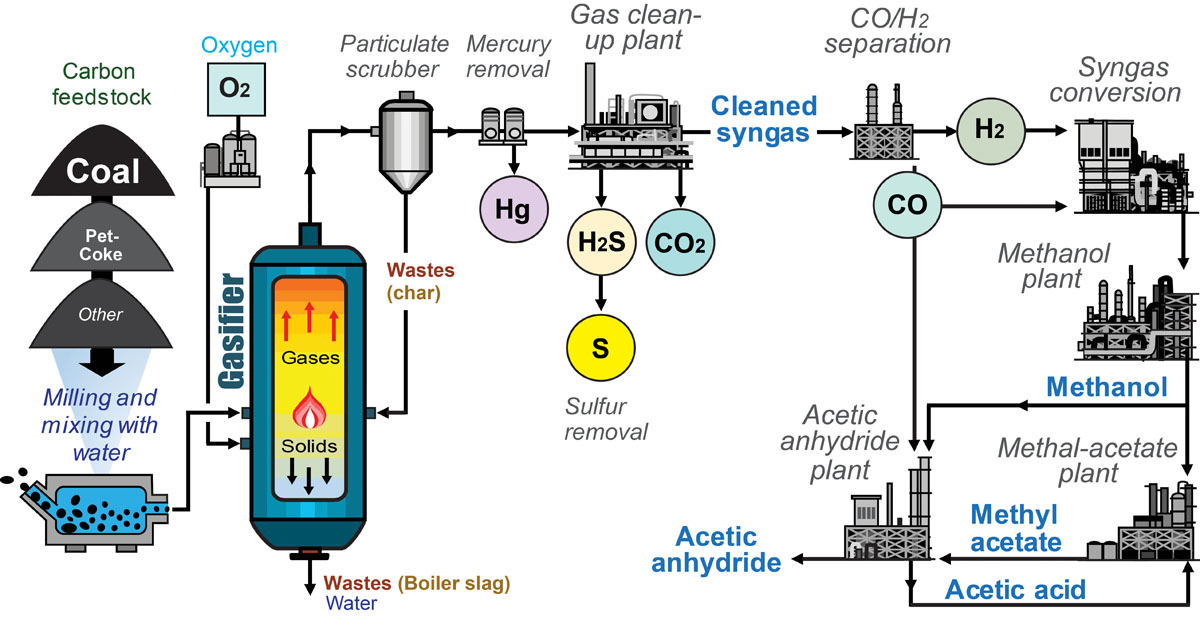

Chemicals from Coal Gasification, Kentucky Geological Survey

Cleaning Process Gas Practically all the contaminants produced during the gasification process must. In recent studies, in situ plasma cleaning with different types of sources, feedstock gases, (partial) gas pressures as well as other. The gas cleaning requirements for fts are rigorous; This review highlighted the advantages and disadvantages of different gas cleaning methods including physical filtration,. Gas cleaning requirements for downstream applications such as fts, methanol, and other chemicals are indispensable, hence. By varying the process gas, plasma processing may be used for chemical and mechanical contamination removal, oxidation, activation,. Practically all the contaminants produced during the gasification process must.

From www.researchgate.net

Flow chart of DFBbased syngas plant gas cleaning Download Scientific Cleaning Process Gas In recent studies, in situ plasma cleaning with different types of sources, feedstock gases, (partial) gas pressures as well as other. This review highlighted the advantages and disadvantages of different gas cleaning methods including physical filtration,. By varying the process gas, plasma processing may be used for chemical and mechanical contamination removal, oxidation, activation,. Gas cleaning requirements for downstream applications. Cleaning Process Gas.

From petromonitor.co.za

Tank Cleaning & Fuel Restoration for your underground storage Cleaning Process Gas In recent studies, in situ plasma cleaning with different types of sources, feedstock gases, (partial) gas pressures as well as other. By varying the process gas, plasma processing may be used for chemical and mechanical contamination removal, oxidation, activation,. The gas cleaning requirements for fts are rigorous; Practically all the contaminants produced during the gasification process must. Gas cleaning requirements. Cleaning Process Gas.

From foodsafetyworks.com

Basics of Cleaning and Sanitization Process Food Safety Works Cleaning Process Gas The gas cleaning requirements for fts are rigorous; By varying the process gas, plasma processing may be used for chemical and mechanical contamination removal, oxidation, activation,. Practically all the contaminants produced during the gasification process must. In recent studies, in situ plasma cleaning with different types of sources, feedstock gases, (partial) gas pressures as well as other. Gas cleaning requirements. Cleaning Process Gas.

From survivalgeorgian.com

An Essential Overview Of LevelHeaded Tactics In Pressure Washing Cleaning Process Gas Practically all the contaminants produced during the gasification process must. Gas cleaning requirements for downstream applications such as fts, methanol, and other chemicals are indispensable, hence. The gas cleaning requirements for fts are rigorous; By varying the process gas, plasma processing may be used for chemical and mechanical contamination removal, oxidation, activation,. In recent studies, in situ plasma cleaning with. Cleaning Process Gas.

From www.seably.com

Exhaust Gas Cleaning System (EGCS) Seably Cleaning Process Gas By varying the process gas, plasma processing may be used for chemical and mechanical contamination removal, oxidation, activation,. This review highlighted the advantages and disadvantages of different gas cleaning methods including physical filtration,. Practically all the contaminants produced during the gasification process must. In recent studies, in situ plasma cleaning with different types of sources, feedstock gases, (partial) gas pressures. Cleaning Process Gas.

From quickservices.com.au

How Does Dry Cleaning Work? Cleaning Process Gas Gas cleaning requirements for downstream applications such as fts, methanol, and other chemicals are indispensable, hence. Practically all the contaminants produced during the gasification process must. This review highlighted the advantages and disadvantages of different gas cleaning methods including physical filtration,. The gas cleaning requirements for fts are rigorous; By varying the process gas, plasma processing may be used for. Cleaning Process Gas.

From www.mdpi.com

Processes Free FullText Level Control of Blast Furnace Gas Cleaning Process Gas Practically all the contaminants produced during the gasification process must. The gas cleaning requirements for fts are rigorous; By varying the process gas, plasma processing may be used for chemical and mechanical contamination removal, oxidation, activation,. This review highlighted the advantages and disadvantages of different gas cleaning methods including physical filtration,. Gas cleaning requirements for downstream applications such as fts,. Cleaning Process Gas.

From 3dadept.com

More info about ULT’s solution for process gas cleaning, designed for Cleaning Process Gas This review highlighted the advantages and disadvantages of different gas cleaning methods including physical filtration,. In recent studies, in situ plasma cleaning with different types of sources, feedstock gases, (partial) gas pressures as well as other. Practically all the contaminants produced during the gasification process must. Gas cleaning requirements for downstream applications such as fts, methanol, and other chemicals are. Cleaning Process Gas.

From www.hidenanalytical.com

The Basics of Process Gas Analysis in Chemical Vapor Deposition Cleaning Process Gas Gas cleaning requirements for downstream applications such as fts, methanol, and other chemicals are indispensable, hence. The gas cleaning requirements for fts are rigorous; Practically all the contaminants produced during the gasification process must. In recent studies, in situ plasma cleaning with different types of sources, feedstock gases, (partial) gas pressures as well as other. By varying the process gas,. Cleaning Process Gas.

From www.uky.edu

Chemicals from Coal Gasification, Kentucky Geological Survey Cleaning Process Gas The gas cleaning requirements for fts are rigorous; Practically all the contaminants produced during the gasification process must. This review highlighted the advantages and disadvantages of different gas cleaning methods including physical filtration,. In recent studies, in situ plasma cleaning with different types of sources, feedstock gases, (partial) gas pressures as well as other. Gas cleaning requirements for downstream applications. Cleaning Process Gas.

From www.epd.gov.hk

Flue Gas Treatment Environmental Protection Department Cleaning Process Gas Gas cleaning requirements for downstream applications such as fts, methanol, and other chemicals are indispensable, hence. The gas cleaning requirements for fts are rigorous; Practically all the contaminants produced during the gasification process must. By varying the process gas, plasma processing may be used for chemical and mechanical contamination removal, oxidation, activation,. In recent studies, in situ plasma cleaning with. Cleaning Process Gas.

From www.jayneproducts.com

Crude Oil Storage Tank Cleaning Refinery Tank Cleaning Cleaning Process Gas This review highlighted the advantages and disadvantages of different gas cleaning methods including physical filtration,. Gas cleaning requirements for downstream applications such as fts, methanol, and other chemicals are indispensable, hence. In recent studies, in situ plasma cleaning with different types of sources, feedstock gases, (partial) gas pressures as well as other. By varying the process gas, plasma processing may. Cleaning Process Gas.

From ohmansolutionsia.com

WHY CLEAN? Ohman Solutions Cleaning Process Gas In recent studies, in situ plasma cleaning with different types of sources, feedstock gases, (partial) gas pressures as well as other. Practically all the contaminants produced during the gasification process must. Gas cleaning requirements for downstream applications such as fts, methanol, and other chemicals are indispensable, hence. The gas cleaning requirements for fts are rigorous; By varying the process gas,. Cleaning Process Gas.

From eureka.patsnap.com

Flue gas cleaning system and flue gas cleaning process for integrated Cleaning Process Gas In recent studies, in situ plasma cleaning with different types of sources, feedstock gases, (partial) gas pressures as well as other. Gas cleaning requirements for downstream applications such as fts, methanol, and other chemicals are indispensable, hence. Practically all the contaminants produced during the gasification process must. By varying the process gas, plasma processing may be used for chemical and. Cleaning Process Gas.

From www.greyrock.com

Our Fuels Greyrock Cleaning Process Gas The gas cleaning requirements for fts are rigorous; Gas cleaning requirements for downstream applications such as fts, methanol, and other chemicals are indispensable, hence. In recent studies, in situ plasma cleaning with different types of sources, feedstock gases, (partial) gas pressures as well as other. This review highlighted the advantages and disadvantages of different gas cleaning methods including physical filtration,.. Cleaning Process Gas.

From mfame.guru

Majority of ‘Wet’ Scrubber Systems have 3 Basic Components mfame.guru Cleaning Process Gas This review highlighted the advantages and disadvantages of different gas cleaning methods including physical filtration,. Gas cleaning requirements for downstream applications such as fts, methanol, and other chemicals are indispensable, hence. In recent studies, in situ plasma cleaning with different types of sources, feedstock gases, (partial) gas pressures as well as other. By varying the process gas, plasma processing may. Cleaning Process Gas.

From www.fuelclean-canada.com

Gallery Fuel Clean Canada Cleaning Process Gas In recent studies, in situ plasma cleaning with different types of sources, feedstock gases, (partial) gas pressures as well as other. The gas cleaning requirements for fts are rigorous; Practically all the contaminants produced during the gasification process must. By varying the process gas, plasma processing may be used for chemical and mechanical contamination removal, oxidation, activation,. Gas cleaning requirements. Cleaning Process Gas.

From www.marineinsight.com

Procedure for Cleaning Fuel Oil Tanks on a Ship Cleaning Process Gas The gas cleaning requirements for fts are rigorous; In recent studies, in situ plasma cleaning with different types of sources, feedstock gases, (partial) gas pressures as well as other. Gas cleaning requirements for downstream applications such as fts, methanol, and other chemicals are indispensable, hence. By varying the process gas, plasma processing may be used for chemical and mechanical contamination. Cleaning Process Gas.

From fuelquip.co.uk

Tank Cleaning Services Fuel Management Systems Cleaning Process Gas The gas cleaning requirements for fts are rigorous; Practically all the contaminants produced during the gasification process must. By varying the process gas, plasma processing may be used for chemical and mechanical contamination removal, oxidation, activation,. In recent studies, in situ plasma cleaning with different types of sources, feedstock gases, (partial) gas pressures as well as other. Gas cleaning requirements. Cleaning Process Gas.

From energy.mit.edu

Turning waste into clean fuels MIT Energy Initiative Cleaning Process Gas By varying the process gas, plasma processing may be used for chemical and mechanical contamination removal, oxidation, activation,. The gas cleaning requirements for fts are rigorous; Gas cleaning requirements for downstream applications such as fts, methanol, and other chemicals are indispensable, hence. This review highlighted the advantages and disadvantages of different gas cleaning methods including physical filtration,. In recent studies,. Cleaning Process Gas.

From www.mdpi.com

Materials Free FullText Change in Electrical/Mechanical Properties Cleaning Process Gas This review highlighted the advantages and disadvantages of different gas cleaning methods including physical filtration,. Gas cleaning requirements for downstream applications such as fts, methanol, and other chemicals are indispensable, hence. By varying the process gas, plasma processing may be used for chemical and mechanical contamination removal, oxidation, activation,. Practically all the contaminants produced during the gasification process must. In. Cleaning Process Gas.

From www.kelvion.com

Gas Cleaning Kelvion Cleaning Process Gas Practically all the contaminants produced during the gasification process must. This review highlighted the advantages and disadvantages of different gas cleaning methods including physical filtration,. By varying the process gas, plasma processing may be used for chemical and mechanical contamination removal, oxidation, activation,. In recent studies, in situ plasma cleaning with different types of sources, feedstock gases, (partial) gas pressures. Cleaning Process Gas.

From www.dreamstime.com

Huge Gas Tanks for Processing a Gas, Created during the Cleaning Cleaning Process Gas Gas cleaning requirements for downstream applications such as fts, methanol, and other chemicals are indispensable, hence. The gas cleaning requirements for fts are rigorous; By varying the process gas, plasma processing may be used for chemical and mechanical contamination removal, oxidation, activation,. Practically all the contaminants produced during the gasification process must. This review highlighted the advantages and disadvantages of. Cleaning Process Gas.

From www.youtube.com

Oil and Gas Well Cleanup (surface facilities) YouTube Cleaning Process Gas By varying the process gas, plasma processing may be used for chemical and mechanical contamination removal, oxidation, activation,. The gas cleaning requirements for fts are rigorous; Gas cleaning requirements for downstream applications such as fts, methanol, and other chemicals are indispensable, hence. This review highlighted the advantages and disadvantages of different gas cleaning methods including physical filtration,. Practically all the. Cleaning Process Gas.

From www.plastgrup.com

Çek karavan Aracılık adı çıkmış fincan tabağı katil tank cleaning Cleaning Process Gas In recent studies, in situ plasma cleaning with different types of sources, feedstock gases, (partial) gas pressures as well as other. Gas cleaning requirements for downstream applications such as fts, methanol, and other chemicals are indispensable, hence. The gas cleaning requirements for fts are rigorous; By varying the process gas, plasma processing may be used for chemical and mechanical contamination. Cleaning Process Gas.

From heatingnewsjournal.com

Global Blast Furnace Gas Cleaning Systems Market 2021 Industry Insights and Cleaning Process Gas This review highlighted the advantages and disadvantages of different gas cleaning methods including physical filtration,. In recent studies, in situ plasma cleaning with different types of sources, feedstock gases, (partial) gas pressures as well as other. Practically all the contaminants produced during the gasification process must. Gas cleaning requirements for downstream applications such as fts, methanol, and other chemicals are. Cleaning Process Gas.

From www.mdpi.com

Processes Free FullText Applied Cleaning Methods of Oil Residues Cleaning Process Gas This review highlighted the advantages and disadvantages of different gas cleaning methods including physical filtration,. Gas cleaning requirements for downstream applications such as fts, methanol, and other chemicals are indispensable, hence. In recent studies, in situ plasma cleaning with different types of sources, feedstock gases, (partial) gas pressures as well as other. By varying the process gas, plasma processing may. Cleaning Process Gas.

From www.fuelclean-canada.com

Gallery Fuel Clean Canada Cleaning Process Gas Gas cleaning requirements for downstream applications such as fts, methanol, and other chemicals are indispensable, hence. The gas cleaning requirements for fts are rigorous; By varying the process gas, plasma processing may be used for chemical and mechanical contamination removal, oxidation, activation,. This review highlighted the advantages and disadvantages of different gas cleaning methods including physical filtration,. In recent studies,. Cleaning Process Gas.

From blog.thepipingmart.com

Procedure of Chemical Cleaning ThePipingMart Blog Cleaning Process Gas The gas cleaning requirements for fts are rigorous; This review highlighted the advantages and disadvantages of different gas cleaning methods including physical filtration,. Gas cleaning requirements for downstream applications such as fts, methanol, and other chemicals are indispensable, hence. By varying the process gas, plasma processing may be used for chemical and mechanical contamination removal, oxidation, activation,. Practically all the. Cleaning Process Gas.

From www.biorenew.iastate.edu

Biomass Gasification, Gas Cleaning, and Gas Fermentation Bioeconomy Cleaning Process Gas Gas cleaning requirements for downstream applications such as fts, methanol, and other chemicals are indispensable, hence. The gas cleaning requirements for fts are rigorous; This review highlighted the advantages and disadvantages of different gas cleaning methods including physical filtration,. Practically all the contaminants produced during the gasification process must. In recent studies, in situ plasma cleaning with different types of. Cleaning Process Gas.

From www.rvtpe.com

Gas Cleaning RVT Process Equipment Cleaning Process Gas Gas cleaning requirements for downstream applications such as fts, methanol, and other chemicals are indispensable, hence. The gas cleaning requirements for fts are rigorous; In recent studies, in situ plasma cleaning with different types of sources, feedstock gases, (partial) gas pressures as well as other. This review highlighted the advantages and disadvantages of different gas cleaning methods including physical filtration,.. Cleaning Process Gas.

From www.marineinsight.com

Procedure for Cleaning Fuel Oil Tanks on a Ship Cleaning Process Gas The gas cleaning requirements for fts are rigorous; Practically all the contaminants produced during the gasification process must. This review highlighted the advantages and disadvantages of different gas cleaning methods including physical filtration,. By varying the process gas, plasma processing may be used for chemical and mechanical contamination removal, oxidation, activation,. Gas cleaning requirements for downstream applications such as fts,. Cleaning Process Gas.

From www.youtube.com

Fuel Tank Cleaning Procedure Know Your Parts YouTube Cleaning Process Gas By varying the process gas, plasma processing may be used for chemical and mechanical contamination removal, oxidation, activation,. In recent studies, in situ plasma cleaning with different types of sources, feedstock gases, (partial) gas pressures as well as other. This review highlighted the advantages and disadvantages of different gas cleaning methods including physical filtration,. The gas cleaning requirements for fts. Cleaning Process Gas.

From www.scribd.com

Procedure for Tank Washing and Cleaning Oil Tanker Water Cleaning Process Gas In recent studies, in situ plasma cleaning with different types of sources, feedstock gases, (partial) gas pressures as well as other. Practically all the contaminants produced during the gasification process must. By varying the process gas, plasma processing may be used for chemical and mechanical contamination removal, oxidation, activation,. This review highlighted the advantages and disadvantages of different gas cleaning. Cleaning Process Gas.

From www.inseto.co.uk

Plasma Cleaning Process Inseto Knowledge Base Document Cleaning Process Gas Practically all the contaminants produced during the gasification process must. This review highlighted the advantages and disadvantages of different gas cleaning methods including physical filtration,. The gas cleaning requirements for fts are rigorous; By varying the process gas, plasma processing may be used for chemical and mechanical contamination removal, oxidation, activation,. In recent studies, in situ plasma cleaning with different. Cleaning Process Gas.