How To Clamp Vertically . try applying a clamp load vertically or perpendicular to the part to prevent slippage. This clamping kit is the most commonly used in machine shops: there seems to be plenty of interest in vertical clamping of stock for end grain joinery. The way i've been nailing. these clamps apply pressure horizontally as well as vertically, so the joint edges are wedged tightly together and. Certainly, the brain trust of. There is a wide array of clamps available depending on the size and shape of the workpiece or workholding tool. Always use at least two clamps to prevent rotation whenever you use them. there is a limit for the width of the piece of wood that i can clamp to the workbench, because of the two rods and screw that. nail the horizontal 2x4 into the vertical 2x4 about 1/4 of the way down from the top of the vertical 2x4, so they are at a 90 degree angle.

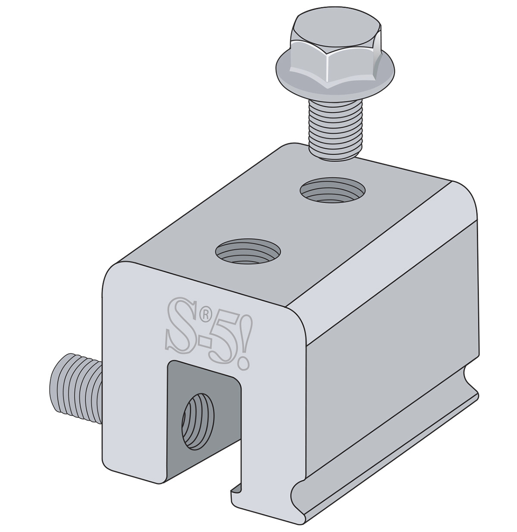

from roofingmagazine.com

nail the horizontal 2x4 into the vertical 2x4 about 1/4 of the way down from the top of the vertical 2x4, so they are at a 90 degree angle. There is a wide array of clamps available depending on the size and shape of the workpiece or workholding tool. This clamping kit is the most commonly used in machine shops: these clamps apply pressure horizontally as well as vertically, so the joint edges are wedged tightly together and. there seems to be plenty of interest in vertical clamping of stock for end grain joinery. Certainly, the brain trust of. there is a limit for the width of the piece of wood that i can clamp to the workbench, because of the two rods and screw that. try applying a clamp load vertically or perpendicular to the part to prevent slippage. The way i've been nailing. Always use at least two clamps to prevent rotation whenever you use them.

Clamp Fits Vertically Folded Seam Profiles Roofing

How To Clamp Vertically This clamping kit is the most commonly used in machine shops: Certainly, the brain trust of. nail the horizontal 2x4 into the vertical 2x4 about 1/4 of the way down from the top of the vertical 2x4, so they are at a 90 degree angle. there seems to be plenty of interest in vertical clamping of stock for end grain joinery. there is a limit for the width of the piece of wood that i can clamp to the workbench, because of the two rods and screw that. There is a wide array of clamps available depending on the size and shape of the workpiece or workholding tool. The way i've been nailing. try applying a clamp load vertically or perpendicular to the part to prevent slippage. This clamping kit is the most commonly used in machine shops: Always use at least two clamps to prevent rotation whenever you use them. these clamps apply pressure horizontally as well as vertically, so the joint edges are wedged tightly together and.

From www.youtube.com

ASSEMBLY OF V BLOCK WITH CLAMP YouTube How To Clamp Vertically There is a wide array of clamps available depending on the size and shape of the workpiece or workholding tool. The way i've been nailing. there is a limit for the width of the piece of wood that i can clamp to the workbench, because of the two rods and screw that. Always use at least two clamps to. How To Clamp Vertically.

From www.pinterest.com

To set up the clamps for gluing a panel, slide the boards you’re gluing How To Clamp Vertically these clamps apply pressure horizontally as well as vertically, so the joint edges are wedged tightly together and. there seems to be plenty of interest in vertical clamping of stock for end grain joinery. Certainly, the brain trust of. nail the horizontal 2x4 into the vertical 2x4 about 1/4 of the way down from the top of. How To Clamp Vertically.

From shinmedico.jp

DeBAKEY Vascular Clamps 5 (Satinsky) Shinmedico How To Clamp Vertically Always use at least two clamps to prevent rotation whenever you use them. there seems to be plenty of interest in vertical clamping of stock for end grain joinery. This clamping kit is the most commonly used in machine shops: nail the horizontal 2x4 into the vertical 2x4 about 1/4 of the way down from the top of. How To Clamp Vertically.

From www.quickfistclamps.co.uk

QUICK FIST GUN CLAMP Securely mounts weapon vertically or How To Clamp Vertically Always use at least two clamps to prevent rotation whenever you use them. nail the horizontal 2x4 into the vertical 2x4 about 1/4 of the way down from the top of the vertical 2x4, so they are at a 90 degree angle. The way i've been nailing. There is a wide array of clamps available depending on the size. How To Clamp Vertically.

From mavink.com

Vertical Pipe Lifting Clamp How To Clamp Vertically these clamps apply pressure horizontally as well as vertically, so the joint edges are wedged tightly together and. This clamping kit is the most commonly used in machine shops: there seems to be plenty of interest in vertical clamping of stock for end grain joinery. The way i've been nailing. nail the horizontal 2x4 into the vertical. How To Clamp Vertically.

From pavetool.com

Clamps Wall, Paver & Slab Tagged "clamp" Pave Tool Innovators How To Clamp Vertically The way i've been nailing. This clamping kit is the most commonly used in machine shops: nail the horizontal 2x4 into the vertical 2x4 about 1/4 of the way down from the top of the vertical 2x4, so they are at a 90 degree angle. Certainly, the brain trust of. try applying a clamp load vertically or perpendicular. How To Clamp Vertically.

From hsseworld.com

How to use Plate Clamps Safely Safety Moment34 HSSE WORLD How To Clamp Vertically Always use at least two clamps to prevent rotation whenever you use them. there seems to be plenty of interest in vertical clamping of stock for end grain joinery. nail the horizontal 2x4 into the vertical 2x4 about 1/4 of the way down from the top of the vertical 2x4, so they are at a 90 degree angle.. How To Clamp Vertically.

From www.mountnmover.com

Wheelchair Mounting Options Step 3 Mount'n Mover How To Clamp Vertically try applying a clamp load vertically or perpendicular to the part to prevent slippage. The way i've been nailing. there seems to be plenty of interest in vertical clamping of stock for end grain joinery. there is a limit for the width of the piece of wood that i can clamp to the workbench, because of the. How To Clamp Vertically.

From roofingmagazine.com

Clamp Fits Vertically Folded Seam Profiles Roofing How To Clamp Vertically there is a limit for the width of the piece of wood that i can clamp to the workbench, because of the two rods and screw that. The way i've been nailing. This clamping kit is the most commonly used in machine shops: there seems to be plenty of interest in vertical clamping of stock for end grain. How To Clamp Vertically.

From www.homenish.com

8 Essential Parts of a Clamp (with Diagram) Homenish How To Clamp Vertically Certainly, the brain trust of. This clamping kit is the most commonly used in machine shops: The way i've been nailing. There is a wide array of clamps available depending on the size and shape of the workpiece or workholding tool. Always use at least two clamps to prevent rotation whenever you use them. there is a limit for. How To Clamp Vertically.

From www.rowse.co.uk

How to Choose Holding/Toggle Clamps Guides Rowse How To Clamp Vertically The way i've been nailing. Certainly, the brain trust of. nail the horizontal 2x4 into the vertical 2x4 about 1/4 of the way down from the top of the vertical 2x4, so they are at a 90 degree angle. This clamping kit is the most commonly used in machine shops: try applying a clamp load vertically or perpendicular. How To Clamp Vertically.

From www.instructables.com

Homemade Vertical Drill Press Clamp 7 Steps (with Pictures How To Clamp Vertically nail the horizontal 2x4 into the vertical 2x4 about 1/4 of the way down from the top of the vertical 2x4, so they are at a 90 degree angle. This clamping kit is the most commonly used in machine shops: Always use at least two clamps to prevent rotation whenever you use them. there is a limit for. How To Clamp Vertically.

From dominoclamps.com

How to attach a tube vertically to a shipping container Domino Clamps How To Clamp Vertically there is a limit for the width of the piece of wood that i can clamp to the workbench, because of the two rods and screw that. these clamps apply pressure horizontally as well as vertically, so the joint edges are wedged tightly together and. The way i've been nailing. Certainly, the brain trust of. Always use at. How To Clamp Vertically.

From dominoclamps.com

42mm vertical tube clamp Domino Clamps How To Clamp Vertically Always use at least two clamps to prevent rotation whenever you use them. there is a limit for the width of the piece of wood that i can clamp to the workbench, because of the two rods and screw that. try applying a clamp load vertically or perpendicular to the part to prevent slippage. there seems to. How To Clamp Vertically.

From www.pinterest.com

For horizontal clamping, remove the fixed Vertical Clamp arm and How To Clamp Vertically there seems to be plenty of interest in vertical clamping of stock for end grain joinery. There is a wide array of clamps available depending on the size and shape of the workpiece or workholding tool. these clamps apply pressure horizontally as well as vertically, so the joint edges are wedged tightly together and. there is a. How To Clamp Vertically.

From www.theengineerspost.com

37 Types of Clamps & Their Uses [How To Use Guide] PDF How To Clamp Vertically these clamps apply pressure horizontally as well as vertically, so the joint edges are wedged tightly together and. Certainly, the brain trust of. there seems to be plenty of interest in vertical clamping of stock for end grain joinery. try applying a clamp load vertically or perpendicular to the part to prevent slippage. The way i've been. How To Clamp Vertically.

From www.ebay.com

General Clamp Industries, Super Clamp Pipe Lifting Clamp How To Clamp Vertically The way i've been nailing. Certainly, the brain trust of. there seems to be plenty of interest in vertical clamping of stock for end grain joinery. Always use at least two clamps to prevent rotation whenever you use them. there is a limit for the width of the piece of wood that i can clamp to the workbench,. How To Clamp Vertically.

From dominoclamps.com

How to attach a tube vertically to a shipping container Domino Clamps How To Clamp Vertically there seems to be plenty of interest in vertical clamping of stock for end grain joinery. there is a limit for the width of the piece of wood that i can clamp to the workbench, because of the two rods and screw that. nail the horizontal 2x4 into the vertical 2x4 about 1/4 of the way down. How To Clamp Vertically.

From www.youtube.com

Vertical Clamping Jig / Drill Press Jig YouTube How To Clamp Vertically nail the horizontal 2x4 into the vertical 2x4 about 1/4 of the way down from the top of the vertical 2x4, so they are at a 90 degree angle. there is a limit for the width of the piece of wood that i can clamp to the workbench, because of the two rods and screw that. This clamping. How To Clamp Vertically.

From www.youtube.com

Clamp for vertical use. Photo and video shooting YouTube How To Clamp Vertically these clamps apply pressure horizontally as well as vertically, so the joint edges are wedged tightly together and. Always use at least two clamps to prevent rotation whenever you use them. Certainly, the brain trust of. There is a wide array of clamps available depending on the size and shape of the workpiece or workholding tool. try applying. How To Clamp Vertically.

From www.pinterest.com

Perfect Clamping with Clampzilla 4Way Panel Clamp Clamp, Woodworking How To Clamp Vertically Always use at least two clamps to prevent rotation whenever you use them. there seems to be plenty of interest in vertical clamping of stock for end grain joinery. This clamping kit is the most commonly used in machine shops: The way i've been nailing. there is a limit for the width of the piece of wood that. How To Clamp Vertically.

From www.pinterest.com

ClampZilla 4Way Panel Clamp Clamp, Woodworking with resin How To Clamp Vertically There is a wide array of clamps available depending on the size and shape of the workpiece or workholding tool. Always use at least two clamps to prevent rotation whenever you use them. there is a limit for the width of the piece of wood that i can clamp to the workbench, because of the two rods and screw. How To Clamp Vertically.

From www.globalspec.com

Toggle Clamps Selection Guide Types, Features, Applications GlobalSpec How To Clamp Vertically The way i've been nailing. Certainly, the brain trust of. try applying a clamp load vertically or perpendicular to the part to prevent slippage. There is a wide array of clamps available depending on the size and shape of the workpiece or workholding tool. Always use at least two clamps to prevent rotation whenever you use them. these. How To Clamp Vertically.

From www.pinterest.jp

Vertical clamping for MFT Wood crafting tools, Diy woodworking How To Clamp Vertically This clamping kit is the most commonly used in machine shops: try applying a clamp load vertically or perpendicular to the part to prevent slippage. nail the horizontal 2x4 into the vertical 2x4 about 1/4 of the way down from the top of the vertical 2x4, so they are at a 90 degree angle. these clamps apply. How To Clamp Vertically.

From www.angi.com

Pipe Clamp Types A Complete Guide How To Clamp Vertically there is a limit for the width of the piece of wood that i can clamp to the workbench, because of the two rods and screw that. nail the horizontal 2x4 into the vertical 2x4 about 1/4 of the way down from the top of the vertical 2x4, so they are at a 90 degree angle. Certainly, the. How To Clamp Vertically.

From www.grainger.com

TOPAL Nonmarring Plate Clamp, Vertical Lift, 3,300 lb Safe Working Load How To Clamp Vertically there is a limit for the width of the piece of wood that i can clamp to the workbench, because of the two rods and screw that. Always use at least two clamps to prevent rotation whenever you use them. try applying a clamp load vertically or perpendicular to the part to prevent slippage. nail the horizontal. How To Clamp Vertically.

From dxogsfckc.blob.core.windows.net

Clamping Time Medical at Robert Franklin blog How To Clamp Vertically there is a limit for the width of the piece of wood that i can clamp to the workbench, because of the two rods and screw that. nail the horizontal 2x4 into the vertical 2x4 about 1/4 of the way down from the top of the vertical 2x4, so they are at a 90 degree angle. try. How To Clamp Vertically.

From famousartisan.com

Ultimate DIY panel clamp plans » Famous Artisan How To Clamp Vertically Always use at least two clamps to prevent rotation whenever you use them. This clamping kit is the most commonly used in machine shops: The way i've been nailing. try applying a clamp load vertically or perpendicular to the part to prevent slippage. Certainly, the brain trust of. there is a limit for the width of the piece. How To Clamp Vertically.

From www.youtube.com

Beam Clamp Product Focus YouTube How To Clamp Vertically there seems to be plenty of interest in vertical clamping of stock for end grain joinery. This clamping kit is the most commonly used in machine shops: try applying a clamp load vertically or perpendicular to the part to prevent slippage. There is a wide array of clamps available depending on the size and shape of the workpiece. How To Clamp Vertically.

From www.theengineerspost.com

37 Types of Clamps & Their Uses [How To Use Guide] PDF How To Clamp Vertically The way i've been nailing. there seems to be plenty of interest in vertical clamping of stock for end grain joinery. Certainly, the brain trust of. these clamps apply pressure horizontally as well as vertically, so the joint edges are wedged tightly together and. there is a limit for the width of the piece of wood that. How To Clamp Vertically.

From www.youtube.com

Wood Clamp Types YouTube How To Clamp Vertically try applying a clamp load vertically or perpendicular to the part to prevent slippage. Certainly, the brain trust of. There is a wide array of clamps available depending on the size and shape of the workpiece or workholding tool. Always use at least two clamps to prevent rotation whenever you use them. there is a limit for the. How To Clamp Vertically.

From www.pinterest.com

MFT table accessory. So I can clamp boards vertically, I made this with How To Clamp Vertically these clamps apply pressure horizontally as well as vertically, so the joint edges are wedged tightly together and. there is a limit for the width of the piece of wood that i can clamp to the workbench, because of the two rods and screw that. There is a wide array of clamps available depending on the size and. How To Clamp Vertically.

From www.reddit.com

Clamping a wide piece of wood vertically r/woodworking How To Clamp Vertically try applying a clamp load vertically or perpendicular to the part to prevent slippage. there is a limit for the width of the piece of wood that i can clamp to the workbench, because of the two rods and screw that. Certainly, the brain trust of. The way i've been nailing. these clamps apply pressure horizontally as. How To Clamp Vertically.

From inchbyinch.de

INCH Technical English clamping devices How To Clamp Vertically there seems to be plenty of interest in vertical clamping of stock for end grain joinery. Always use at least two clamps to prevent rotation whenever you use them. these clamps apply pressure horizontally as well as vertically, so the joint edges are wedged tightly together and. try applying a clamp load vertically or perpendicular to the. How To Clamp Vertically.

From www.familyhandyman.com

Learn How to Clamp The Family Handyman How To Clamp Vertically try applying a clamp load vertically or perpendicular to the part to prevent slippage. There is a wide array of clamps available depending on the size and shape of the workpiece or workholding tool. nail the horizontal 2x4 into the vertical 2x4 about 1/4 of the way down from the top of the vertical 2x4, so they are. How To Clamp Vertically.