Push Vs Pull Solenoid . The first type, push/pull or monostable, is used to displace an object by energizing and de. A push solenoid is a pull solenoid with an added shaft that extends out the bottom of the solenoid plunger to provide a pushing function. They are widely used in various applications, ranging from industrial machinery to consumer electronics. The push type solenoid takes the pull solenoid and incorporates a pushrod attached to the plunger, which passes through the polepiece. This is the mechanical difference providing a mechanical ‘push’ force at the other end of the A solenoid with its axis sticking out at boths ends is usable as push or pull solenoid, no real difference. This makes them ideally suited for heavy duty applications, and those demanding low The solenoid will be used such that it will be mounted in the floor and when a stick is put over it, it will start vibration. The direction opposite of the direction the spring extends is the one. There are three main categories of solenoids;

from robu.in

The direction opposite of the direction the spring extends is the one. This is the mechanical difference providing a mechanical ‘push’ force at the other end of the The solenoid will be used such that it will be mounted in the floor and when a stick is put over it, it will start vibration. The first type, push/pull or monostable, is used to displace an object by energizing and de. This makes them ideally suited for heavy duty applications, and those demanding low A push solenoid is a pull solenoid with an added shaft that extends out the bottom of the solenoid plunger to provide a pushing function. They are widely used in various applications, ranging from industrial machinery to consumer electronics. There are three main categories of solenoids; The push type solenoid takes the pull solenoid and incorporates a pushrod attached to the plunger, which passes through the polepiece. A solenoid with its axis sticking out at boths ends is usable as push or pull solenoid, no real difference.

Buy DC12V 0.3N 10mm Push Pull Solenoid Online at Robu.in

Push Vs Pull Solenoid This makes them ideally suited for heavy duty applications, and those demanding low They are widely used in various applications, ranging from industrial machinery to consumer electronics. The direction opposite of the direction the spring extends is the one. The push type solenoid takes the pull solenoid and incorporates a pushrod attached to the plunger, which passes through the polepiece. A solenoid with its axis sticking out at boths ends is usable as push or pull solenoid, no real difference. The first type, push/pull or monostable, is used to displace an object by energizing and de. This is the mechanical difference providing a mechanical ‘push’ force at the other end of the This makes them ideally suited for heavy duty applications, and those demanding low There are three main categories of solenoids; The solenoid will be used such that it will be mounted in the floor and when a stick is put over it, it will start vibration. A push solenoid is a pull solenoid with an added shaft that extends out the bottom of the solenoid plunger to provide a pushing function.

From www.amazon.co.uk

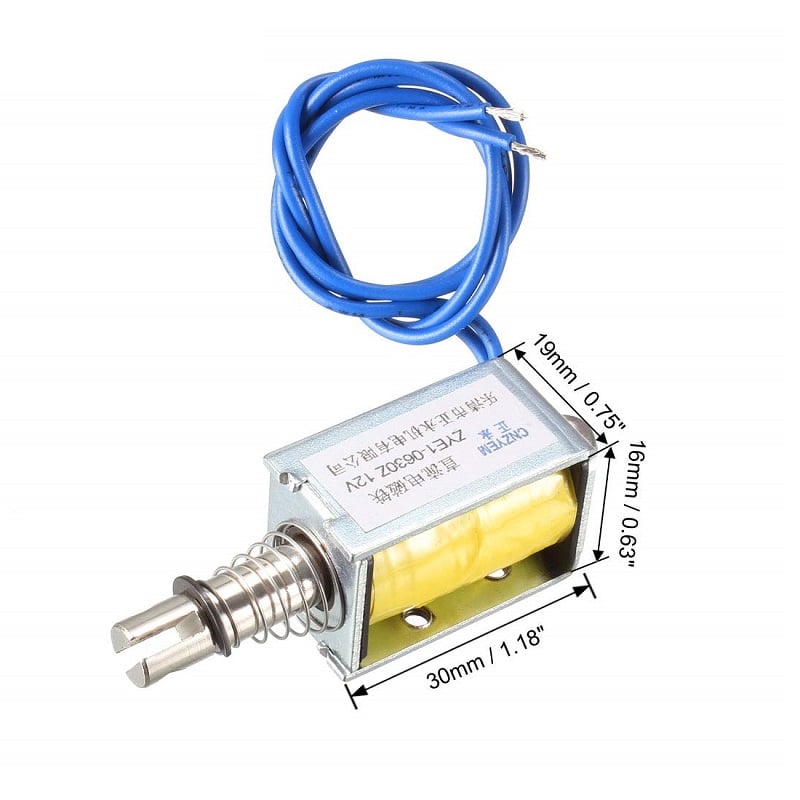

sourcing map DC 12V 0.42A 30g 3mm Mini Solenoid Lock Push Vs Pull Solenoid A push solenoid is a pull solenoid with an added shaft that extends out the bottom of the solenoid plunger to provide a pushing function. The direction opposite of the direction the spring extends is the one. The push type solenoid takes the pull solenoid and incorporates a pushrod attached to the plunger, which passes through the polepiece. The first. Push Vs Pull Solenoid.

From www.youtube.com

Mini Solenoid PushPull 5V Arduino and Electronics Projects YouTube Push Vs Pull Solenoid The first type, push/pull or monostable, is used to displace an object by energizing and de. There are three main categories of solenoids; A solenoid with its axis sticking out at boths ends is usable as push or pull solenoid, no real difference. A push solenoid is a pull solenoid with an added shaft that extends out the bottom of. Push Vs Pull Solenoid.

From www.murcal.com

RP2308B 24 Volt Push/Pull DC Solenoid Push Vs Pull Solenoid This is the mechanical difference providing a mechanical ‘push’ force at the other end of the The direction opposite of the direction the spring extends is the one. There are three main categories of solenoids; A solenoid with its axis sticking out at boths ends is usable as push or pull solenoid, no real difference. A push solenoid is a. Push Vs Pull Solenoid.

From www.micro-airpumps.com

Safe Lock DC 9V Push Pull Solenoid 300mmHg Electric Push Vs Pull Solenoid This is the mechanical difference providing a mechanical ‘push’ force at the other end of the The push type solenoid takes the pull solenoid and incorporates a pushrod attached to the plunger, which passes through the polepiece. The solenoid will be used such that it will be mounted in the floor and when a stick is put over it, it. Push Vs Pull Solenoid.

From shopee.co.id

Jual Actu Solenoid Micro 6V Push Pull Type Linear Push Vs Pull Solenoid This makes them ideally suited for heavy duty applications, and those demanding low There are three main categories of solenoids; The direction opposite of the direction the spring extends is the one. The push type solenoid takes the pull solenoid and incorporates a pushrod attached to the plunger, which passes through the polepiece. A solenoid with its axis sticking out. Push Vs Pull Solenoid.

From www.dozuki.com

Push vs. Pull System in Manufacturing A Complete Overview for Push Vs Pull Solenoid The push type solenoid takes the pull solenoid and incorporates a pushrod attached to the plunger, which passes through the polepiece. A solenoid with its axis sticking out at boths ends is usable as push or pull solenoid, no real difference. This makes them ideally suited for heavy duty applications, and those demanding low There are three main categories of. Push Vs Pull Solenoid.

From www.adafruit.com

Large pushpull solenoid ID 413 14.95 Adafruit Industries Push Vs Pull Solenoid This makes them ideally suited for heavy duty applications, and those demanding low The solenoid will be used such that it will be mounted in the floor and when a stick is put over it, it will start vibration. A solenoid with its axis sticking out at boths ends is usable as push or pull solenoid, no real difference. The. Push Vs Pull Solenoid.

From auspowers.com

Fielect DC 24V 42N 10mm Stroke Push Pull Solenoid 0.45A Push Vs Pull Solenoid This is the mechanical difference providing a mechanical ‘push’ force at the other end of the There are three main categories of solenoids; A solenoid with its axis sticking out at boths ends is usable as push or pull solenoid, no real difference. They are widely used in various applications, ranging from industrial machinery to consumer electronics. The direction opposite. Push Vs Pull Solenoid.

From www.adafruit.com

Small PushPull Solenoid 12VDC ID 412 7.50 Adafruit Industries Push Vs Pull Solenoid The push type solenoid takes the pull solenoid and incorporates a pushrod attached to the plunger, which passes through the polepiece. A solenoid with its axis sticking out at boths ends is usable as push or pull solenoid, no real difference. The direction opposite of the direction the spring extends is the one. There are three main categories of solenoids;. Push Vs Pull Solenoid.

From www.adafruit.com

Large pushpull solenoid ID 413 14.95 Adafruit Industries Push Vs Pull Solenoid The push type solenoid takes the pull solenoid and incorporates a pushrod attached to the plunger, which passes through the polepiece. They are widely used in various applications, ranging from industrial machinery to consumer electronics. The solenoid will be used such that it will be mounted in the floor and when a stick is put over it, it will start. Push Vs Pull Solenoid.

From probots.co.in

Probots 12V Solenoid Push Pull Linear Actuator Motor Push Vs Pull Solenoid The first type, push/pull or monostable, is used to displace an object by energizing and de. This makes them ideally suited for heavy duty applications, and those demanding low The direction opposite of the direction the spring extends is the one. They are widely used in various applications, ranging from industrial machinery to consumer electronics. A push solenoid is a. Push Vs Pull Solenoid.

From www.geeplus.com

Mini PushPull Solenoids From Geeplus Offer High Force Using Low Power Push Vs Pull Solenoid There are three main categories of solenoids; The push type solenoid takes the pull solenoid and incorporates a pushrod attached to the plunger, which passes through the polepiece. A push solenoid is a pull solenoid with an added shaft that extends out the bottom of the solenoid plunger to provide a pushing function. The solenoid will be used such that. Push Vs Pull Solenoid.

From www.murcal.com

RP2309B 12 Volt Push/Pull DC Solenoid Push Vs Pull Solenoid This makes them ideally suited for heavy duty applications, and those demanding low The solenoid will be used such that it will be mounted in the floor and when a stick is put over it, it will start vibration. A solenoid with its axis sticking out at boths ends is usable as push or pull solenoid, no real difference. There. Push Vs Pull Solenoid.

From robu.in

Buy DC12V 0.3N 10mm Push Pull Solenoid Online at Robu.in Push Vs Pull Solenoid There are three main categories of solenoids; They are widely used in various applications, ranging from industrial machinery to consumer electronics. This is the mechanical difference providing a mechanical ‘push’ force at the other end of the A push solenoid is a pull solenoid with an added shaft that extends out the bottom of the solenoid plunger to provide a. Push Vs Pull Solenoid.

From murcal.com

D513A33V24 Dual Coil Pull Solenoid, 24 Volt Push Vs Pull Solenoid The solenoid will be used such that it will be mounted in the floor and when a stick is put over it, it will start vibration. This is the mechanical difference providing a mechanical ‘push’ force at the other end of the The first type, push/pull or monostable, is used to displace an object by energizing and de. There are. Push Vs Pull Solenoid.

From www.pinterest.com

Push Pull Electric Solenoid Actuator Actuator, Control, Mechanic Push Vs Pull Solenoid There are three main categories of solenoids; The solenoid will be used such that it will be mounted in the floor and when a stick is put over it, it will start vibration. This is the mechanical difference providing a mechanical ‘push’ force at the other end of the The first type, push/pull or monostable, is used to displace an. Push Vs Pull Solenoid.

From www.researchgate.net

The pullin and pushout functions of a solenoid are shown. End A of Push Vs Pull Solenoid This is the mechanical difference providing a mechanical ‘push’ force at the other end of the The solenoid will be used such that it will be mounted in the floor and when a stick is put over it, it will start vibration. The push type solenoid takes the pull solenoid and incorporates a pushrod attached to the plunger, which passes. Push Vs Pull Solenoid.

From www.dc-solenoid.com

6V DC Push Pull Solenoid Push Vs Pull Solenoid A solenoid with its axis sticking out at boths ends is usable as push or pull solenoid, no real difference. The direction opposite of the direction the spring extends is the one. This is the mechanical difference providing a mechanical ‘push’ force at the other end of the There are three main categories of solenoids; A push solenoid is a. Push Vs Pull Solenoid.

From udvabony.com

Mini PushPull Solenoid 5V Electronics, Sensors Push Vs Pull Solenoid The direction opposite of the direction the spring extends is the one. This is the mechanical difference providing a mechanical ‘push’ force at the other end of the The first type, push/pull or monostable, is used to displace an object by energizing and de. A solenoid with its axis sticking out at boths ends is usable as push or pull. Push Vs Pull Solenoid.

From nsfcontrols.co.uk

PushPull Solenoids High Force, Short Stroke Application Push Vs Pull Solenoid This is the mechanical difference providing a mechanical ‘push’ force at the other end of the A push solenoid is a pull solenoid with an added shaft that extends out the bottom of the solenoid plunger to provide a pushing function. This makes them ideally suited for heavy duty applications, and those demanding low There are three main categories of. Push Vs Pull Solenoid.

From www.amazon.in

TAKAHA Push Pull Solenoid DC 24v Stroke 35mm Force 450g Duty Cycle 50 Push Vs Pull Solenoid The direction opposite of the direction the spring extends is the one. They are widely used in various applications, ranging from industrial machinery to consumer electronics. A solenoid with its axis sticking out at boths ends is usable as push or pull solenoid, no real difference. A push solenoid is a pull solenoid with an added shaft that extends out. Push Vs Pull Solenoid.

From store.shopping.yahoo.co.jp

uxcell DCソレノイドバルブ 電磁石 プッシュプル型 DC12V0.6A 2mm 500g 10mm 100g 1個入り Push Vs Pull Solenoid A push solenoid is a pull solenoid with an added shaft that extends out the bottom of the solenoid plunger to provide a pushing function. The first type, push/pull or monostable, is used to displace an object by energizing and de. There are three main categories of solenoids; This is the mechanical difference providing a mechanical ‘push’ force at the. Push Vs Pull Solenoid.

From probots.co.in

Probots 0826B 24V Solenoid 2kg Push Pull Linear Actuator Motor Push Vs Pull Solenoid The push type solenoid takes the pull solenoid and incorporates a pushrod attached to the plunger, which passes through the polepiece. They are widely used in various applications, ranging from industrial machinery to consumer electronics. This is the mechanical difference providing a mechanical ‘push’ force at the other end of the A solenoid with its axis sticking out at boths. Push Vs Pull Solenoid.

From solenoid-ninja.com

Square Push Pull Solenoid, Linear Solenoid LHP035053 Solenoid Ninja Push Vs Pull Solenoid A push solenoid is a pull solenoid with an added shaft that extends out the bottom of the solenoid plunger to provide a pushing function. The push type solenoid takes the pull solenoid and incorporates a pushrod attached to the plunger, which passes through the polepiece. There are three main categories of solenoids; A solenoid with its axis sticking out. Push Vs Pull Solenoid.

From www.murcal.com

RP2307B 12 Volt Push/Pull DC Solenoid Push Vs Pull Solenoid The push type solenoid takes the pull solenoid and incorporates a pushrod attached to the plunger, which passes through the polepiece. There are three main categories of solenoids; They are widely used in various applications, ranging from industrial machinery to consumer electronics. The solenoid will be used such that it will be mounted in the floor and when a stick. Push Vs Pull Solenoid.

From www.deskera.com

Push System vs. Pull System in Manufacturing Management Push Vs Pull Solenoid The push type solenoid takes the pull solenoid and incorporates a pushrod attached to the plunger, which passes through the polepiece. This makes them ideally suited for heavy duty applications, and those demanding low This is the mechanical difference providing a mechanical ‘push’ force at the other end of the A solenoid with its axis sticking out at boths ends. Push Vs Pull Solenoid.

From solenoid-ninja.com

Push Pull Solenoid, 24V DC, 10mm LHP035MI900 Solenoid Ninja Push Vs Pull Solenoid There are three main categories of solenoids; This makes them ideally suited for heavy duty applications, and those demanding low The direction opposite of the direction the spring extends is the one. They are widely used in various applications, ranging from industrial machinery to consumer electronics. A solenoid with its axis sticking out at boths ends is usable as push. Push Vs Pull Solenoid.

From www.murcal.com

RP2308B 24 Volt Push/Pull DC Solenoid Push Vs Pull Solenoid They are widely used in various applications, ranging from industrial machinery to consumer electronics. A push solenoid is a pull solenoid with an added shaft that extends out the bottom of the solenoid plunger to provide a pushing function. The direction opposite of the direction the spring extends is the one. This makes them ideally suited for heavy duty applications,. Push Vs Pull Solenoid.

From www.indiamart.com

Push Pull Solenoid Coil, Single Phase Three Phase, 220vac,415vac at Rs Push Vs Pull Solenoid The first type, push/pull or monostable, is used to displace an object by energizing and de. A push solenoid is a pull solenoid with an added shaft that extends out the bottom of the solenoid plunger to provide a pushing function. The direction opposite of the direction the spring extends is the one. This is the mechanical difference providing a. Push Vs Pull Solenoid.

From probots.co.in

Probots DC 24V 0.8KG 0837S Solenoid PushPull Linear Actuator Motor Push Vs Pull Solenoid The solenoid will be used such that it will be mounted in the floor and when a stick is put over it, it will start vibration. The first type, push/pull or monostable, is used to displace an object by energizing and de. The push type solenoid takes the pull solenoid and incorporates a pushrod attached to the plunger, which passes. Push Vs Pull Solenoid.

From www.geeplus.com

Solenoids 101 Push vs Pull Solenoids vs Push Pull Solenoids Push Vs Pull Solenoid There are three main categories of solenoids; This is the mechanical difference providing a mechanical ‘push’ force at the other end of the This makes them ideally suited for heavy duty applications, and those demanding low A solenoid with its axis sticking out at boths ends is usable as push or pull solenoid, no real difference. The push type solenoid. Push Vs Pull Solenoid.

From www.geeplus.com

Linear Solenoids Push Pull Solenoids Push Vs Pull Solenoid A solenoid with its axis sticking out at boths ends is usable as push or pull solenoid, no real difference. The solenoid will be used such that it will be mounted in the floor and when a stick is put over it, it will start vibration. The first type, push/pull or monostable, is used to displace an object by energizing. Push Vs Pull Solenoid.

From redditfavorites.com

Reddit compares 3V12V DC 80mA350mA Micro Solenoid Push Push Vs Pull Solenoid The first type, push/pull or monostable, is used to displace an object by energizing and de. A solenoid with its axis sticking out at boths ends is usable as push or pull solenoid, no real difference. This is the mechanical difference providing a mechanical ‘push’ force at the other end of the There are three main categories of solenoids; The. Push Vs Pull Solenoid.

From www.walmart.com

DC Push Pull Type Solenoid DC 9V 0.8N 10mm, Open Frame Push Vs Pull Solenoid This makes them ideally suited for heavy duty applications, and those demanding low A solenoid with its axis sticking out at boths ends is usable as push or pull solenoid, no real difference. The push type solenoid takes the pull solenoid and incorporates a pushrod attached to the plunger, which passes through the polepiece. This is the mechanical difference providing. Push Vs Pull Solenoid.

From www.aliexpress.com

Solenoid electric solenoid type push / pull 10 mm DC 12 V 2.1 kg force Push Vs Pull Solenoid The first type, push/pull or monostable, is used to displace an object by energizing and de. A push solenoid is a pull solenoid with an added shaft that extends out the bottom of the solenoid plunger to provide a pushing function. A solenoid with its axis sticking out at boths ends is usable as push or pull solenoid, no real. Push Vs Pull Solenoid.