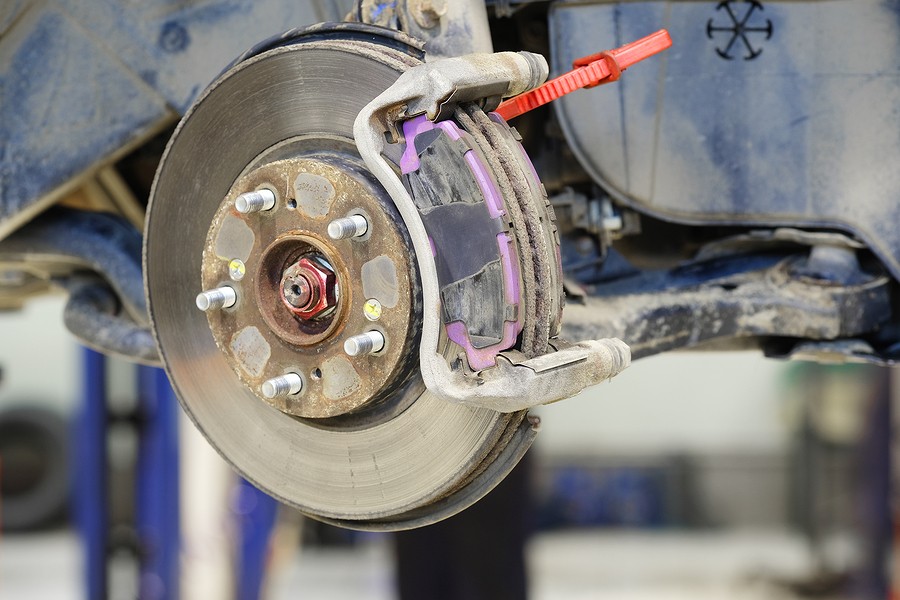

Rotors Turning . Remove any grooves or gouges. Shops usually quote about 2 hours of labor for turning brake rotors. It is then spun around by the lathe while the bits remove the material from the surface of both sides to true up the rotor, essentially removing the embedded. This is because of a thickness variance in one or both front rotors, sometimes considered to be warped. Car parts avoid filling the landfill. This includes placing the vehicle on a lift, removing the wheels, and unbolting the brake calipers to free the rotors. Advantages of resurfacing brake rotors. A steering wheel vibration when you press the brake pedal, especially at high speed. Smooth out the rotor surface. Most types of minimal to moderate damage can be corrected in about 30 minutes per pair. Turning the brake rotors is a process done to the rotors to extend their lifespan. I ordered aftermarket rotors (which cost less than the exorbitant $125 they wanted to resurface them) and when i took the wheels off,. Shimmying or shaking in the vehicle body, often felt through the seat or brake pedal. Usually, the rotor is mounted on a lathe where two bits of steel are placed on either side of the rotor. Signs that rotor resurfacing is needed include:

from www.cashcarsbuyer.com

Most types of minimal to moderate damage can be corrected in about 30 minutes per pair. This includes placing the vehicle on a lift, removing the wheels, and unbolting the brake calipers to free the rotors. It is then spun around by the lathe while the bits remove the material from the surface of both sides to true up the rotor, essentially removing the embedded. Shimmying or shaking in the vehicle body, often felt through the seat or brake pedal. Resurfacing your rotors is the practice of using a brake lathe to shave off a small layer of the rotor’s surface. Advantages of resurfacing brake rotors. A brake lathe spins the rotor as it machines a thin layer off the rotor surface. Car parts avoid filling the landfill. Remove any grooves or gouges. A steering wheel vibration when you press the brake pedal, especially at high speed.

Turning Rotors What Are They and How Does The Process Work?

Rotors Turning Smooth out the rotor surface. A brake lathe spins the rotor as it machines a thin layer off the rotor surface. Signs that rotor resurfacing is needed include: Shimmying or shaking in the vehicle body, often felt through the seat or brake pedal. A steering wheel vibration when you press the brake pedal, especially at high speed. Turning the brake rotors is a process done to the rotors to extend their lifespan. Shops usually quote about 2 hours of labor for turning brake rotors. I ordered aftermarket rotors (which cost less than the exorbitant $125 they wanted to resurface them) and when i took the wheels off,. Advantages of resurfacing brake rotors. Usually, the rotor is mounted on a lathe where two bits of steel are placed on either side of the rotor. Remove any grooves or gouges. Car parts avoid filling the landfill. Most types of minimal to moderate damage can be corrected in about 30 minutes per pair. This is because of a thickness variance in one or both front rotors, sometimes considered to be warped. It is then spun around by the lathe while the bits remove the material from the surface of both sides to true up the rotor, essentially removing the embedded. Smooth out the rotor surface.

From www.youtube.com

TURNING ROTOR PART 3 YouTube Rotors Turning Turning the brake rotors is a process done to the rotors to extend their lifespan. A brake lathe spins the rotor as it machines a thin layer off the rotor surface. Remove any grooves or gouges. It is then spun around by the lathe while the bits remove the material from the surface of both sides to true up the. Rotors Turning.

From www.wikov.com

Rotor turning devices in our testing lab Wikov Rotors Turning I ordered aftermarket rotors (which cost less than the exorbitant $125 they wanted to resurface them) and when i took the wheels off,. This is because of a thickness variance in one or both front rotors, sometimes considered to be warped. Most types of minimal to moderate damage can be corrected in about 30 minutes per pair. Shimmying or shaking. Rotors Turning.

From carfromjapan.com

When Is the Right Time for Brake Rotors Turning? Rotors Turning Resurfacing your rotors is the practice of using a brake lathe to shave off a small layer of the rotor’s surface. Advantages of resurfacing brake rotors. Usually, the rotor is mounted on a lathe where two bits of steel are placed on either side of the rotor. Remove any grooves or gouges. Smooth out the rotor surface. This is because. Rotors Turning.

From www.myg37.com

Turning Rotors MyG37 Rotors Turning This is because of a thickness variance in one or both front rotors, sometimes considered to be warped. This includes placing the vehicle on a lift, removing the wheels, and unbolting the brake calipers to free the rotors. Turning the brake rotors is a process done to the rotors to extend their lifespan. I ordered aftermarket rotors (which cost less. Rotors Turning.

From www.youtube.com

Hunter Brake Lathe Turning a Brake Rotor YouTube Rotors Turning Shops usually quote about 2 hours of labor for turning brake rotors. Most types of minimal to moderate damage can be corrected in about 30 minutes per pair. A brake lathe spins the rotor as it machines a thin layer off the rotor surface. Signs that rotor resurfacing is needed include: It is then spun around by the lathe while. Rotors Turning.

From www.youtube.com

Resurfacing rotors for free Part 2 YouTube Rotors Turning It is then spun around by the lathe while the bits remove the material from the surface of both sides to true up the rotor, essentially removing the embedded. A steering wheel vibration when you press the brake pedal, especially at high speed. Resurfacing your rotors is the practice of using a brake lathe to shave off a small layer. Rotors Turning.

From joihpotjc.blob.core.windows.net

Autozone Brake Rotor Turning at Daniel Lucero blog Rotors Turning Smooth out the rotor surface. A steering wheel vibration when you press the brake pedal, especially at high speed. A brake lathe spins the rotor as it machines a thin layer off the rotor surface. It is then spun around by the lathe while the bits remove the material from the surface of both sides to true up the rotor,. Rotors Turning.

From www.tacomaworld.com

do you turn your rotors on a lathe? World Rotors Turning A steering wheel vibration when you press the brake pedal, especially at high speed. Shops usually quote about 2 hours of labor for turning brake rotors. It is then spun around by the lathe while the bits remove the material from the surface of both sides to true up the rotor, essentially removing the embedded. Resurfacing your rotors is the. Rotors Turning.

From www.pointmeby.com

Using Flex Hone to Resurface and Turn Rotors Point Me By Rotors Turning Turning the brake rotors is a process done to the rotors to extend their lifespan. Smooth out the rotor surface. This is because of a thickness variance in one or both front rotors, sometimes considered to be warped. Shops usually quote about 2 hours of labor for turning brake rotors. Most types of minimal to moderate damage can be corrected. Rotors Turning.

From jangirengineers.com

Rotor Turning Machine Rotors Turning Advantages of resurfacing brake rotors. I ordered aftermarket rotors (which cost less than the exorbitant $125 they wanted to resurface them) and when i took the wheels off,. A steering wheel vibration when you press the brake pedal, especially at high speed. Most types of minimal to moderate damage can be corrected in about 30 minutes per pair. Resurfacing your. Rotors Turning.

From www.youtube.com

How to Mount a Rotor on the AccuTurn Brake Lathe YouTube Rotors Turning Most types of minimal to moderate damage can be corrected in about 30 minutes per pair. Smooth out the rotor surface. Turning the brake rotors is a process done to the rotors to extend their lifespan. Usually, the rotor is mounted on a lathe where two bits of steel are placed on either side of the rotor. Shops usually quote. Rotors Turning.

From www.myg37.com

Turning Rotors MyG37 Rotors Turning Signs that rotor resurfacing is needed include: Remove any grooves or gouges. Car parts avoid filling the landfill. A brake lathe spins the rotor as it machines a thin layer off the rotor surface. Resurfacing your rotors is the practice of using a brake lathe to shave off a small layer of the rotor’s surface. This is because of a. Rotors Turning.

From www.youtube.com

AMMCO Brake Lathe Turning Rotors Fast !!! YouTube Rotors Turning This includes placing the vehicle on a lift, removing the wheels, and unbolting the brake calipers to free the rotors. Car parts avoid filling the landfill. Most types of minimal to moderate damage can be corrected in about 30 minutes per pair. Remove any grooves or gouges. Resurfacing your rotors is the practice of using a brake lathe to shave. Rotors Turning.

From www.powerstop.com

Drilled vs Slotted Rotors, Which is Better for You? PowerStop Brakes Rotors Turning A steering wheel vibration when you press the brake pedal, especially at high speed. Advantages of resurfacing brake rotors. This is because of a thickness variance in one or both front rotors, sometimes considered to be warped. Usually, the rotor is mounted on a lathe where two bits of steel are placed on either side of the rotor. This includes. Rotors Turning.

From www.xs400.com

Turning brake rotor. Yamaha XS400 Forum Rotors Turning Advantages of resurfacing brake rotors. It is then spun around by the lathe while the bits remove the material from the surface of both sides to true up the rotor, essentially removing the embedded. I ordered aftermarket rotors (which cost less than the exorbitant $125 they wanted to resurface them) and when i took the wheels off,. Shops usually quote. Rotors Turning.

From www.alibaba.com

C9370 Brake Rotor Turning Machine For Drum And Disc Buy C9370 Brake Rotors Turning Smooth out the rotor surface. It is then spun around by the lathe while the bits remove the material from the surface of both sides to true up the rotor, essentially removing the embedded. I ordered aftermarket rotors (which cost less than the exorbitant $125 they wanted to resurface them) and when i took the wheels off,. Resurfacing your rotors. Rotors Turning.

From www.cashcarsbuyer.com

Turning Rotors What Are They and How Does The Process Work? Rotors Turning Signs that rotor resurfacing is needed include: Usually, the rotor is mounted on a lathe where two bits of steel are placed on either side of the rotor. Remove any grooves or gouges. Car parts avoid filling the landfill. Turning the brake rotors is a process done to the rotors to extend their lifespan. This includes placing the vehicle on. Rotors Turning.

From pilotteacher.com

How Do Helicopters Turn? A Pilot Explains Pilot Teacher Rotors Turning Signs that rotor resurfacing is needed include: Smooth out the rotor surface. Advantages of resurfacing brake rotors. Car parts avoid filling the landfill. Turning the brake rotors is a process done to the rotors to extend their lifespan. This includes placing the vehicle on a lift, removing the wheels, and unbolting the brake calipers to free the rotors. Shimmying or. Rotors Turning.

From knowhow.napaonline.com

KnowHow Notes All About Flywheel and Brake Rotor Turning » NAPA Blog Rotors Turning Most types of minimal to moderate damage can be corrected in about 30 minutes per pair. It is then spun around by the lathe while the bits remove the material from the surface of both sides to true up the rotor, essentially removing the embedded. Signs that rotor resurfacing is needed include: Advantages of resurfacing brake rotors. This is because. Rotors Turning.

From www.youtube.com

Rotors Turning! YouTube Rotors Turning A steering wheel vibration when you press the brake pedal, especially at high speed. A brake lathe spins the rotor as it machines a thin layer off the rotor surface. Turning the brake rotors is a process done to the rotors to extend their lifespan. Most types of minimal to moderate damage can be corrected in about 30 minutes per. Rotors Turning.

From www.r1concepts.com

Should I Buy New Rotors Or Simply Turn Them? R1 Concepts Rotors Turning Smooth out the rotor surface. Most types of minimal to moderate damage can be corrected in about 30 minutes per pair. Usually, the rotor is mounted on a lathe where two bits of steel are placed on either side of the rotor. Advantages of resurfacing brake rotors. Signs that rotor resurfacing is needed include: A steering wheel vibration when you. Rotors Turning.

From www.youtube.com

Turning brake rotors YouTube Rotors Turning This is because of a thickness variance in one or both front rotors, sometimes considered to be warped. A brake lathe spins the rotor as it machines a thin layer off the rotor surface. Most types of minimal to moderate damage can be corrected in about 30 minutes per pair. Turning the brake rotors is a process done to the. Rotors Turning.

From www.indiamart.com

Automatic Rotor Turning Machine at Rs 290000 Hyderabad ID 23397346830 Rotors Turning It is then spun around by the lathe while the bits remove the material from the surface of both sides to true up the rotor, essentially removing the embedded. Most types of minimal to moderate damage can be corrected in about 30 minutes per pair. This is because of a thickness variance in one or both front rotors, sometimes considered. Rotors Turning.

From www.youtube.com

Turning a Brake ROTOR Disc on a Small Lathe Mill Drill YouTube Rotors Turning Car parts avoid filling the landfill. Most types of minimal to moderate damage can be corrected in about 30 minutes per pair. This is because of a thickness variance in one or both front rotors, sometimes considered to be warped. Smooth out the rotor surface. It is then spun around by the lathe while the bits remove the material from. Rotors Turning.

From motormission.com

Brake Rotor and Drum Turning and Machining Motor Mission Machine and Rotors Turning Most types of minimal to moderate damage can be corrected in about 30 minutes per pair. This is because of a thickness variance in one or both front rotors, sometimes considered to be warped. A brake lathe spins the rotor as it machines a thin layer off the rotor surface. A steering wheel vibration when you press the brake pedal,. Rotors Turning.

From carfromjapan.com

When Is the Right Time for Brake Rotors Turning? CAR FROM JAPAN Rotors Turning Turning the brake rotors is a process done to the rotors to extend their lifespan. I ordered aftermarket rotors (which cost less than the exorbitant $125 they wanted to resurface them) and when i took the wheels off,. Usually, the rotor is mounted on a lathe where two bits of steel are placed on either side of the rotor. A. Rotors Turning.

From knowhow.napaonline.com

KnowHow Notes All About Flywheel and Brake Rotor Turning » NAPA Blog Rotors Turning Usually, the rotor is mounted on a lathe where two bits of steel are placed on either side of the rotor. Smooth out the rotor surface. A brake lathe spins the rotor as it machines a thin layer off the rotor surface. Shimmying or shaking in the vehicle body, often felt through the seat or brake pedal. Most types of. Rotors Turning.

From www.youtube.com

TURNING BRAKE ROTORS YouTube Rotors Turning A steering wheel vibration when you press the brake pedal, especially at high speed. This is because of a thickness variance in one or both front rotors, sometimes considered to be warped. I ordered aftermarket rotors (which cost less than the exorbitant $125 they wanted to resurface them) and when i took the wheels off,. Usually, the rotor is mounted. Rotors Turning.

From www.youtube.com

Cutting a Brake Disc/Rotor with an OnCar Lathe Machine YouTube Rotors Turning Turning the brake rotors is a process done to the rotors to extend their lifespan. Signs that rotor resurfacing is needed include: Resurfacing your rotors is the practice of using a brake lathe to shave off a small layer of the rotor’s surface. Usually, the rotor is mounted on a lathe where two bits of steel are placed on either. Rotors Turning.

From www.youtube.com

What does that mean? "Turning Rotors" YouTube Rotors Turning A steering wheel vibration when you press the brake pedal, especially at high speed. Usually, the rotor is mounted on a lathe where two bits of steel are placed on either side of the rotor. Remove any grooves or gouges. Turning the brake rotors is a process done to the rotors to extend their lifespan. This includes placing the vehicle. Rotors Turning.

From www.myg37.com

Turning Rotors MyG37 Rotors Turning Shops usually quote about 2 hours of labor for turning brake rotors. A steering wheel vibration when you press the brake pedal, especially at high speed. Car parts avoid filling the landfill. This is because of a thickness variance in one or both front rotors, sometimes considered to be warped. Resurfacing your rotors is the practice of using a brake. Rotors Turning.

From www.youtube.com

Semi automatic rotor turning machine assembly line_Motor Rotor Rotors Turning A brake lathe spins the rotor as it machines a thin layer off the rotor surface. Signs that rotor resurfacing is needed include: It is then spun around by the lathe while the bits remove the material from the surface of both sides to true up the rotor, essentially removing the embedded. Advantages of resurfacing brake rotors. Resurfacing your rotors. Rotors Turning.

From www.youtube.com

How To Turn / Cut A Rotor on a Brake Lathe Machine YouTube Rotors Turning It is then spun around by the lathe while the bits remove the material from the surface of both sides to true up the rotor, essentially removing the embedded. This includes placing the vehicle on a lift, removing the wheels, and unbolting the brake calipers to free the rotors. A steering wheel vibration when you press the brake pedal, especially. Rotors Turning.

From motormission.com

Brake Rotor and Drum Turning and Machining Motor Mission Machine and Rotors Turning Most types of minimal to moderate damage can be corrected in about 30 minutes per pair. This is because of a thickness variance in one or both front rotors, sometimes considered to be warped. Usually, the rotor is mounted on a lathe where two bits of steel are placed on either side of the rotor. A brake lathe spins the. Rotors Turning.

From www.wikov.com

Rotor turning devices in our testing lab Wikov Rotors Turning Advantages of resurfacing brake rotors. This includes placing the vehicle on a lift, removing the wheels, and unbolting the brake calipers to free the rotors. Resurfacing your rotors is the practice of using a brake lathe to shave off a small layer of the rotor’s surface. Shops usually quote about 2 hours of labor for turning brake rotors. Most types. Rotors Turning.