Insert Wear Chart . Locate the diagram of the. Plus, all the related charts. Detailed information on turning inserts identification. Normal flank wear normal flank wear,. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. Check your inserts every week to maintain optimal performance. Worn tips can diminish your scaling efficiency. Detailed information on tool wear. Fitting the grooving insert before inserting the cutting insert, you should check to ensure that the insert seat is free from dirt and damage to. Learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best possible way to.

from sumicarbide.com

Plus, all the related charts. Fitting the grooving insert before inserting the cutting insert, you should check to ensure that the insert seat is free from dirt and damage to. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. Detailed information on turning inserts identification. Worn tips can diminish your scaling efficiency. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. Normal flank wear normal flank wear,. Learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best possible way to. Check your inserts every week to maintain optimal performance. Detailed information on tool wear.

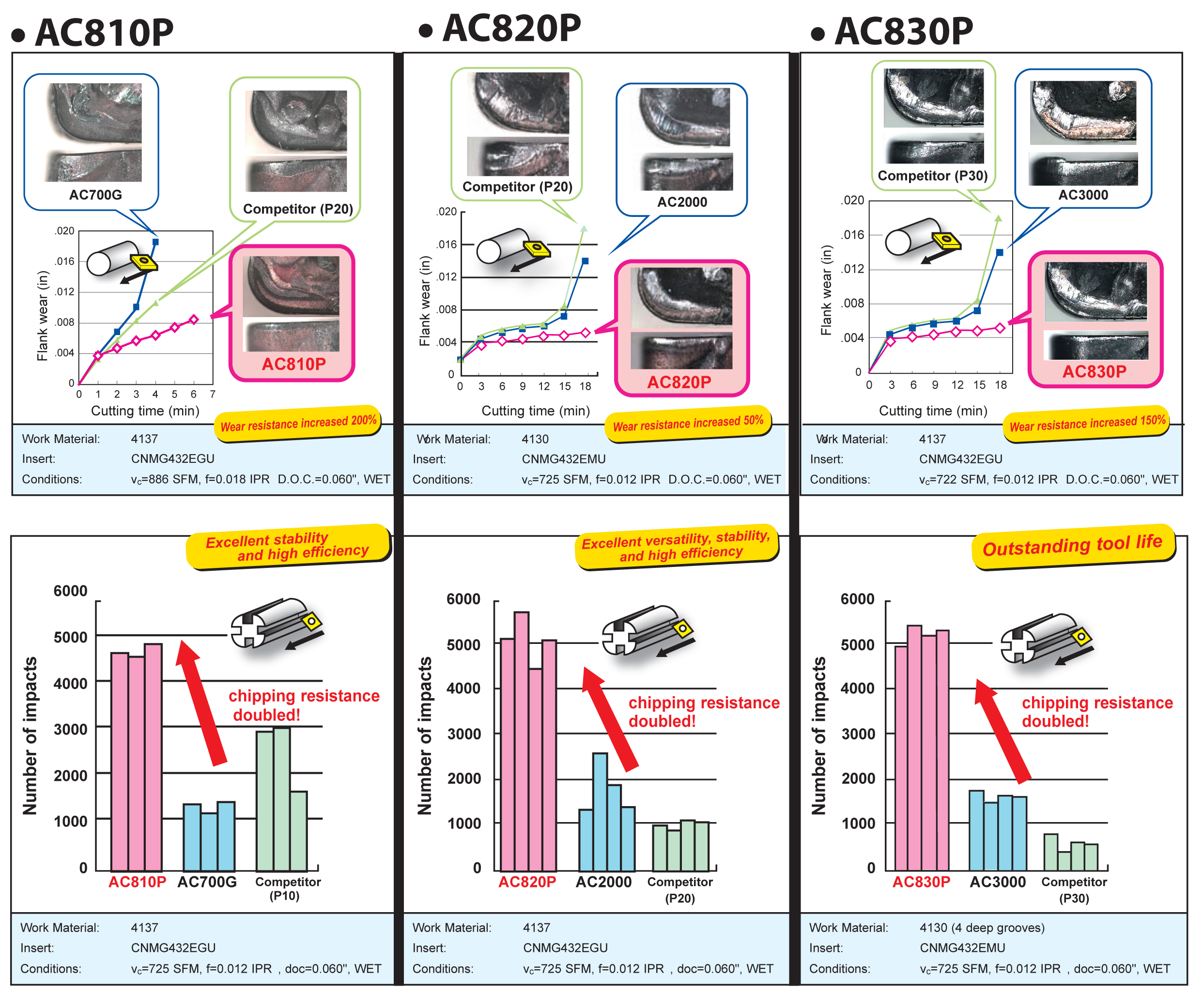

AC800P Series Turning Tools Sumitomo Electric Carbide, Inc.

Insert Wear Chart Locate the diagram of the. Worn tips can diminish your scaling efficiency. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. Check your inserts every week to maintain optimal performance. Normal flank wear normal flank wear,. Learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best possible way to. Detailed information on turning inserts identification. Plus, all the related charts. Detailed information on tool wear. Fitting the grooving insert before inserting the cutting insert, you should check to ensure that the insert seat is free from dirt and damage to. Locate the diagram of the.

From www.todaysrdh.com

INFOGRAPHIC Monitor Insert Wear to Ensure Optimal Performance Today Insert Wear Chart Fitting the grooving insert before inserting the cutting insert, you should check to ensure that the insert seat is free from dirt and damage to. Worn tips can diminish your scaling efficiency. Normal flank wear normal flank wear,. Detailed information on turning inserts identification. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades,. Insert Wear Chart.

From www.researchgate.net

Wear mechanisms developed on the cutting tools. Download Scientific Insert Wear Chart Worn tips can diminish your scaling efficiency. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. Detailed information on turning inserts identification. Detailed information on tool wear. Fitting the grooving insert before inserting the cutting insert, you should check to ensure that the insert seat is free from dirt and damage. Insert Wear Chart.

From www.researchgate.net

Typical tool inserts wear patterns [5]. Download Scientific Diagram Insert Wear Chart In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. Detailed information on turning inserts identification. Learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best possible way to. Detailed information on tool wear. In addition to an overview. Insert Wear Chart.

From www.researchgate.net

Typical wear patterns according to ISO 3685 [2]. Download Scientific Insert Wear Chart In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. Fitting the grooving insert before inserting the cutting insert, you should check to ensure that the insert seat is free from dirt and damage to. Learn how to identify the most common tool wear patterns in machining, common causes, and what to do. Insert Wear Chart.

From www.mdpi.com

Materials Free FullText Simple Discriminatory Methodology for Wear Insert Wear Chart Normal flank wear normal flank wear,. Locate the diagram of the. Plus, all the related charts. Check your inserts every week to maintain optimal performance. Fitting the grooving insert before inserting the cutting insert, you should check to ensure that the insert seat is free from dirt and damage to. Detailed information on tool wear. Detailed information on turning inserts. Insert Wear Chart.

From www.researchgate.net

10. Types wear on cutting tools (adapted from Sandvik® [12]) Download Insert Wear Chart Worn tips can diminish your scaling efficiency. Learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best possible way to. Plus, all the related charts. Detailed information on turning inserts identification. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades,. Insert Wear Chart.

From aprontodental.com

Dental Equipment, Dental supplies and Replacement Part Apronto Dental Insert Wear Chart Check your inserts every week to maintain optimal performance. Detailed information on tool wear. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. Detailed information on turning inserts identification. Normal flank wear normal flank wear,. Learn how to identify the most common tool wear patterns in machining, common causes, and what to. Insert Wear Chart.

From www.mdpi.com

Symmetry Free FullText Methodology for Measuring the Cutting Insert Wear Chart Check your inserts every week to maintain optimal performance. Plus, all the related charts. Worn tips can diminish your scaling efficiency. Detailed information on tool wear. Locate the diagram of the. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. Normal flank wear normal flank wear,. In addition to an overview of. Insert Wear Chart.

From www.mdpi.com

Symmetry Free FullText Methodology for Measuring the Cutting Insert Wear Chart Normal flank wear normal flank wear,. Fitting the grooving insert before inserting the cutting insert, you should check to ensure that the insert seat is free from dirt and damage to. Plus, all the related charts. Learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best possible. Insert Wear Chart.

From www.mdpi.com

Symmetry Free FullText Methodology for Measuring the Cutting Insert Wear Chart In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. Worn tips can diminish your scaling efficiency. Normal flank wear normal flank wear,. Locate the diagram of the. Detailed information on turning inserts identification. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. Plus,. Insert Wear Chart.

From www.mdpi.com

Symmetry Free FullText Methodology for Measuring the Cutting Insert Wear Chart Detailed information on tool wear. Locate the diagram of the. Normal flank wear normal flank wear,. Detailed information on turning inserts identification. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. Learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them. Insert Wear Chart.

From www.youtube.com

2018 02 23 Online Training Series Insert wear YouTube Insert Wear Chart Normal flank wear normal flank wear,. Check your inserts every week to maintain optimal performance. Plus, all the related charts. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. Learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best. Insert Wear Chart.

From huanatools.com

How to choose the right carbide turning insert Huana Tools Insert Wear Chart Check your inserts every week to maintain optimal performance. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. Normal flank wear normal flank wear,. Worn tips can diminish your scaling efficiency. Learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control. Insert Wear Chart.

From www.practicalmachinist.com

Parting Off Part 3 Feeds, Speeds and Chamfering Considerations Insert Wear Chart Plus, all the related charts. Detailed information on turning inserts identification. Worn tips can diminish your scaling efficiency. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. Normal flank wear normal flank wear,. Learn. Insert Wear Chart.

From clinetool.com

Insert Wear Pattern Cause & Remedy Chart Cline Tool Insert Wear Chart Check your inserts every week to maintain optimal performance. Detailed information on tool wear. Learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best possible way to. Plus, all the related charts. Detailed information on turning inserts identification. Fitting the grooving insert before inserting the cutting insert,. Insert Wear Chart.

From www.researchgate.net

Wear morphology from test of the cutting insert Download Scientific Insert Wear Chart Locate the diagram of the. Normal flank wear normal flank wear,. Learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best possible way to. Detailed information on turning inserts identification. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product.. Insert Wear Chart.

From www.mmc-carbide.com

Tool wear Technical Info / Cutting Formula MITSUBISHI MATERIALS Insert Wear Chart Normal flank wear normal flank wear,. Learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best possible way to. Check your inserts every week to maintain optimal performance. Plus, all the related charts. Locate the diagram of the. Detailed information on tool wear. Worn tips can diminish. Insert Wear Chart.

From www.shangintool.com

ISO Designations For Insert|Hon Jan Cutting Tools Co., LTD. Insert Wear Chart Detailed information on tool wear. Worn tips can diminish your scaling efficiency. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. Plus, all the related charts. Check your inserts every week to maintain optimal performance. Learn how to identify the most common tool wear patterns in machining, common causes, and what to. Insert Wear Chart.

From www.researchgate.net

The wear morphology of the insert at different conditions after Insert Wear Chart Fitting the grooving insert before inserting the cutting insert, you should check to ensure that the insert seat is free from dirt and damage to. Detailed information on turning inserts identification. Learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best possible way to. Plus, all the. Insert Wear Chart.

From www.mscdirect.com

Turning Inserts MSC Industrial Supply Insert Wear Chart Check your inserts every week to maintain optimal performance. Normal flank wear normal flank wear,. Worn tips can diminish your scaling efficiency. Learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best possible way to. In addition to an overview of cutting tools, safety and precautions, information. Insert Wear Chart.

From www.scribd.com

Carbide Inserts Wear Failure Modes PDF Wear Machining Insert Wear Chart In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. Fitting the grooving insert before inserting the cutting insert, you should check to ensure that the insert seat is free from dirt and damage to.. Insert Wear Chart.

From www.researchgate.net

Different types of wornout tool inserts. Download Scientific Diagram Insert Wear Chart In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. Worn tips can diminish your scaling efficiency. Check your inserts every week to maintain optimal performance. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. Learn how to identify the most common tool wear. Insert Wear Chart.

From www.researchgate.net

Typical wear patterns according to ISO 3685 [2]. Download Scientific Insert Wear Chart In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. Detailed information on turning inserts identification. Worn tips can diminish your scaling efficiency. Normal flank wear normal flank wear,. Check your inserts every week to maintain optimal performance. Detailed information on tool wear. Learn how to identify the most common tool wear. Insert Wear Chart.

From exoenvecm.blob.core.windows.net

Orthopedic Shoe Inserts Vancouver at Olivia Kruse blog Insert Wear Chart Detailed information on turning inserts identification. Learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best possible way to. Worn tips can diminish your scaling efficiency. Locate the diagram of the. Check your inserts every week to maintain optimal performance. In addition to an overview of cutting. Insert Wear Chart.

From www.zzyftools.com

carbide turning inserts APMT1135 CNC indexable inserts Insert Wear Chart Worn tips can diminish your scaling efficiency. Check your inserts every week to maintain optimal performance. Plus, all the related charts. Detailed information on turning inserts identification. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. Normal flank wear normal flank wear,. Detailed information on tool wear. Fitting the grooving insert. Insert Wear Chart.

From aic-plastico.com

“P2000R” 4Piece/High Abrasion PlastiCo Insert Wear Chart Detailed information on turning inserts identification. Learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best possible way to. Plus, all the related charts. Fitting the grooving insert before inserting the cutting insert, you should check to ensure that the insert seat is free from dirt and. Insert Wear Chart.

From www.researchgate.net

Flank wear land on a single point turning cutting edge according to the Insert Wear Chart Worn tips can diminish your scaling efficiency. Normal flank wear normal flank wear,. Detailed information on turning inserts identification. Plus, all the related charts. Check your inserts every week to maintain optimal performance. Fitting the grooving insert before inserting the cutting insert, you should check to ensure that the insert seat is free from dirt and damage to. Learn how. Insert Wear Chart.

From www.researchgate.net

Microphotos of CBN insert wear both on flank face and rake face (Zf Insert Wear Chart Check your inserts every week to maintain optimal performance. Normal flank wear normal flank wear,. Detailed information on turning inserts identification. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. Locate the diagram of the. Fitting the grooving insert before inserting the cutting insert, you should check to ensure that the. Insert Wear Chart.

From www.offthecusp.com

Ensure Efficiency with an Insert Wear Guide Insert Wear Chart Normal flank wear normal flank wear,. Worn tips can diminish your scaling efficiency. Fitting the grooving insert before inserting the cutting insert, you should check to ensure that the insert seat is free from dirt and damage to. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. Locate the diagram of. Insert Wear Chart.

From www.machinemetrics.com

How to Identify and Reduce Tool Wear to Improve Quality Insert Wear Chart Learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best possible way to. Fitting the grooving insert before inserting the cutting insert, you should check to ensure that the insert seat is free from dirt and damage to. In addition to an overview of cutting tools, safety. Insert Wear Chart.

From sumicarbide.com

AC800P Series Turning Tools Sumitomo Electric Carbide, Inc. Insert Wear Chart In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. Detailed information on turning inserts identification. Check your inserts every week to maintain optimal performance. Plus, all the related charts. Detailed information on tool wear.. Insert Wear Chart.

From ponasa.condesan-ecoandes.org

Carbide Insert Identification Chart Ponasa Insert Wear Chart In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. Learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best possible way to. Fitting the grooving insert before inserting the cutting insert, you should check to ensure that the. Insert Wear Chart.

From journals.sagepub.com

Effect of cutting speed on chip formation and wear mechanisms of coated Insert Wear Chart Fitting the grooving insert before inserting the cutting insert, you should check to ensure that the insert seat is free from dirt and damage to. Normal flank wear normal flank wear,. Learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best possible way to. Worn tips can. Insert Wear Chart.

From www.zestdent.com

Insert Strength Color Code Guide for Locator Zest Dental Zest Insert Wear Chart Check your inserts every week to maintain optimal performance. Detailed information on tool wear. Locate the diagram of the. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. Worn tips can diminish your scaling efficiency. Normal flank wear normal flank wear,. Fitting the grooving insert before inserting the cutting insert, you should. Insert Wear Chart.

From www.mdpi.com

Symmetry Free FullText Methodology for Measuring the Cutting Insert Wear Chart Check your inserts every week to maintain optimal performance. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. Normal flank wear normal flank wear,. Detailed information on tool wear. Plus, all the related charts. Locate the diagram of the. Worn tips can diminish your scaling efficiency. Detailed information on turning inserts identification.. Insert Wear Chart.