Piston Pin Oiling . Despite incorporating elliptical pin bore profiling and ovality into their designs, the typical bearing clearance for wrist pin oiling remains so tight that extreme. The amount of surface area must accommodate the load, while providing piston stability to minimize rocking relative to the pin axis as the piston moves down from tdc and back up. Oil collects in this groove and is drawn to the pin through oiling holes by a properly. The simplest form used by some companies is. They required pin fitting and. The binding between the two components created a thrust load on the piston. A very good head's up, as we've become so accustomed to pistons being good to go out of the box, that these nos caught us not looking. Oiling the wrist pin can be accomplished in several different ways: This in turn caused the piston to scuff the cylinder wall, which eventually led to oil control problems. Some engine builders prefer to oil the pin with a small groove around the piston just above the oil ring.

from inthegaragemedia.com

A very good head's up, as we've become so accustomed to pistons being good to go out of the box, that these nos caught us not looking. Oil collects in this groove and is drawn to the pin through oiling holes by a properly. The amount of surface area must accommodate the load, while providing piston stability to minimize rocking relative to the pin axis as the piston moves down from tdc and back up. Some engine builders prefer to oil the pin with a small groove around the piston just above the oil ring. The binding between the two components created a thrust load on the piston. Oiling the wrist pin can be accomplished in several different ways: Despite incorporating elliptical pin bore profiling and ovality into their designs, the typical bearing clearance for wrist pin oiling remains so tight that extreme. The simplest form used by some companies is. They required pin fitting and. This in turn caused the piston to scuff the cylinder wall, which eventually led to oil control problems.

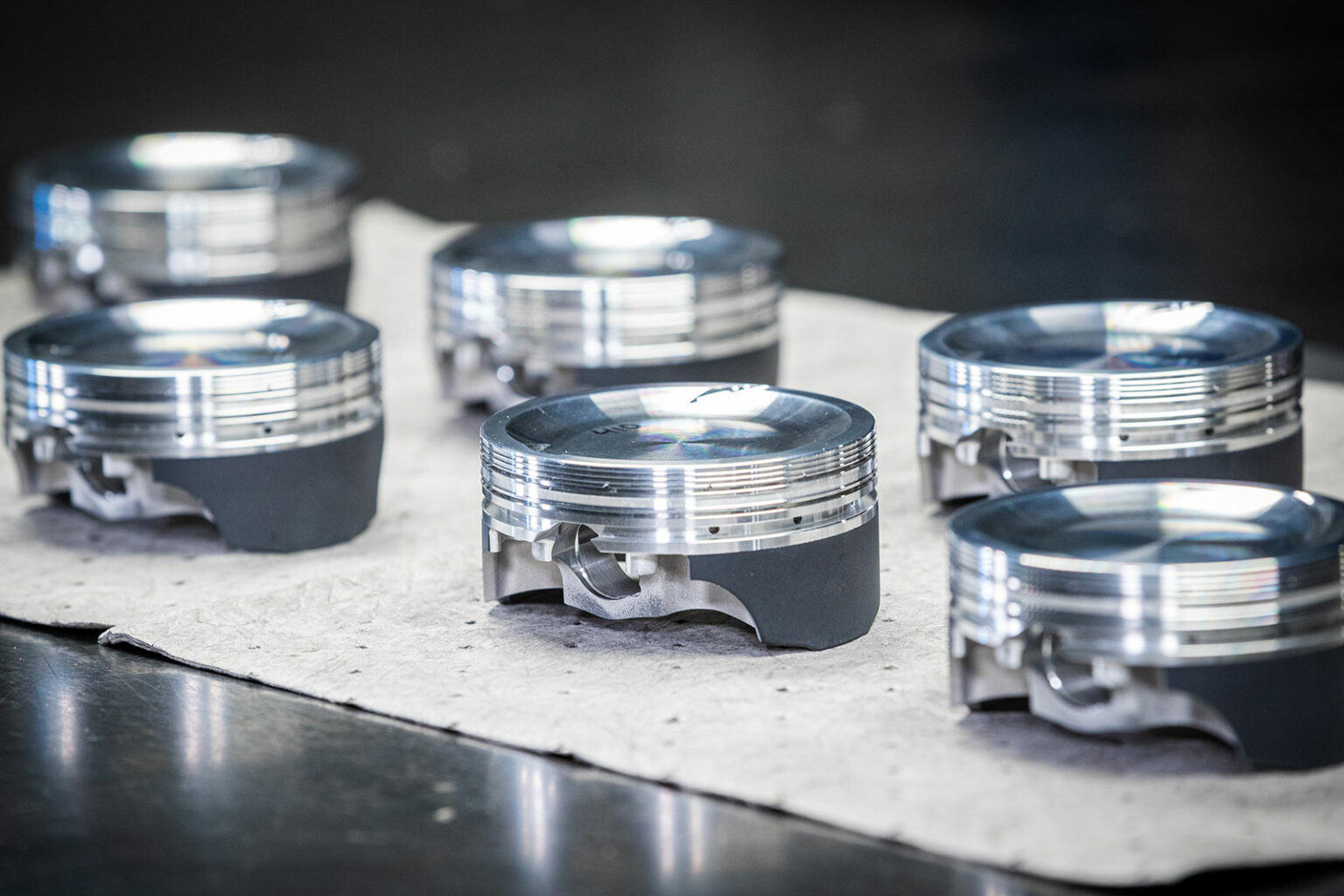

1000HP LS Engine Built For Street, Strip, & Track

Piston Pin Oiling They required pin fitting and. A very good head's up, as we've become so accustomed to pistons being good to go out of the box, that these nos caught us not looking. Some engine builders prefer to oil the pin with a small groove around the piston just above the oil ring. This in turn caused the piston to scuff the cylinder wall, which eventually led to oil control problems. The amount of surface area must accommodate the load, while providing piston stability to minimize rocking relative to the pin axis as the piston moves down from tdc and back up. The binding between the two components created a thrust load on the piston. Oil collects in this groove and is drawn to the pin through oiling holes by a properly. Oiling the wrist pin can be accomplished in several different ways: They required pin fitting and. Despite incorporating elliptical pin bore profiling and ovality into their designs, the typical bearing clearance for wrist pin oiling remains so tight that extreme. The simplest form used by some companies is.

From www.theengineerspost.com

What is Piston Pin? Types, Parts, Function, Pin Offset [PDF] Piston Pin Oiling Oiling the wrist pin can be accomplished in several different ways: Some engine builders prefer to oil the pin with a small groove around the piston just above the oil ring. They required pin fitting and. Oil collects in this groove and is drawn to the pin through oiling holes by a properly. Despite incorporating elliptical pin bore profiling and. Piston Pin Oiling.

From www.hemmings.com

Six Pack to Go! Hemmings Piston Pin Oiling They required pin fitting and. Oil collects in this groove and is drawn to the pin through oiling holes by a properly. Some engine builders prefer to oil the pin with a small groove around the piston just above the oil ring. The simplest form used by some companies is. Oiling the wrist pin can be accomplished in several different. Piston Pin Oiling.

From www.slantsix.org

Piston wristpin oiling on my rebuild Slant Six Forum Piston Pin Oiling Despite incorporating elliptical pin bore profiling and ovality into their designs, the typical bearing clearance for wrist pin oiling remains so tight that extreme. Some engine builders prefer to oil the pin with a small groove around the piston just above the oil ring. Oiling the wrist pin can be accomplished in several different ways: A very good head's up,. Piston Pin Oiling.

From www.heritagepartscentre.com

Lessons in lubrication Engine Oil Explained Piston Pin Oiling Oil collects in this groove and is drawn to the pin through oiling holes by a properly. Oiling the wrist pin can be accomplished in several different ways: They required pin fitting and. The binding between the two components created a thrust load on the piston. The amount of surface area must accommodate the load, while providing piston stability to. Piston Pin Oiling.

From www.corvetteforum.com

Z06 wrist pin oiling CorvetteForum Chevrolet Corvette Forum Discussion Piston Pin Oiling Despite incorporating elliptical pin bore profiling and ovality into their designs, the typical bearing clearance for wrist pin oiling remains so tight that extreme. They required pin fitting and. The binding between the two components created a thrust load on the piston. The simplest form used by some companies is. Some engine builders prefer to oil the pin with a. Piston Pin Oiling.

From www.jepistons.com

Different Wrist Pin Oiling Styles Explained JE Pistons Piston Pin Oiling Despite incorporating elliptical pin bore profiling and ovality into their designs, the typical bearing clearance for wrist pin oiling remains so tight that extreme. Oiling the wrist pin can be accomplished in several different ways: Oil collects in this groove and is drawn to the pin through oiling holes by a properly. They required pin fitting and. Some engine builders. Piston Pin Oiling.

From info.jepistons.com

Different Wrist Pin Oiling Styles Explained Piston Pin Oiling Despite incorporating elliptical pin bore profiling and ovality into their designs, the typical bearing clearance for wrist pin oiling remains so tight that extreme. The binding between the two components created a thrust load on the piston. Oiling the wrist pin can be accomplished in several different ways: A very good head's up, as we've become so accustomed to pistons. Piston Pin Oiling.

From www.jepistons.com

Different Wrist Pin Oiling Styles Explained JE Pistons Piston Pin Oiling Some engine builders prefer to oil the pin with a small groove around the piston just above the oil ring. Oiling the wrist pin can be accomplished in several different ways: They required pin fitting and. Despite incorporating elliptical pin bore profiling and ovality into their designs, the typical bearing clearance for wrist pin oiling remains so tight that extreme.. Piston Pin Oiling.

From www.hatchkirk.com

Piston Pins Manufactured to OEM Standards Hatch & Kirk Piston Pin Oiling Oiling the wrist pin can be accomplished in several different ways: This in turn caused the piston to scuff the cylinder wall, which eventually led to oil control problems. They required pin fitting and. The binding between the two components created a thrust load on the piston. Despite incorporating elliptical pin bore profiling and ovality into their designs, the typical. Piston Pin Oiling.

From onmogul.com

Explain Basic Functions and Types of Piston Pins Mogul Piston Pin Oiling This in turn caused the piston to scuff the cylinder wall, which eventually led to oil control problems. They required pin fitting and. The binding between the two components created a thrust load on the piston. Some engine builders prefer to oil the pin with a small groove around the piston just above the oil ring. A very good head's. Piston Pin Oiling.

From www.jepistons.com

Different Wrist Pin Oiling Styles Explained JE Pistons Piston Pin Oiling The amount of surface area must accommodate the load, while providing piston stability to minimize rocking relative to the pin axis as the piston moves down from tdc and back up. Oiling the wrist pin can be accomplished in several different ways: A very good head's up, as we've become so accustomed to pistons being good to go out of. Piston Pin Oiling.

From armyordnance.tpub.com

Figure 23. Piston Pin. Piston Pin Oiling Oiling the wrist pin can be accomplished in several different ways: They required pin fitting and. Some engine builders prefer to oil the pin with a small groove around the piston just above the oil ring. Oil collects in this groove and is drawn to the pin through oiling holes by a properly. Despite incorporating elliptical pin bore profiling and. Piston Pin Oiling.

From automobileupdates.weebly.com

Tour Of Lubrication Mechanism AUTOMOBILE UPDATES Piston Pin Oiling Oil collects in this groove and is drawn to the pin through oiling holes by a properly. They required pin fitting and. Despite incorporating elliptical pin bore profiling and ovality into their designs, the typical bearing clearance for wrist pin oiling remains so tight that extreme. Some engine builders prefer to oil the pin with a small groove around the. Piston Pin Oiling.

From www.onallcylinders.com

Piston Primer How to Properly Install Pistons OnAllCylinders Piston Pin Oiling Despite incorporating elliptical pin bore profiling and ovality into their designs, the typical bearing clearance for wrist pin oiling remains so tight that extreme. This in turn caused the piston to scuff the cylinder wall, which eventually led to oil control problems. The simplest form used by some companies is. Some engine builders prefer to oil the pin with a. Piston Pin Oiling.

From www.youtube.com

How to Assembly Press Fit Piston Pins to Rods YouTube Piston Pin Oiling The simplest form used by some companies is. The binding between the two components created a thrust load on the piston. The amount of surface area must accommodate the load, while providing piston stability to minimize rocking relative to the pin axis as the piston moves down from tdc and back up. Oil collects in this groove and is drawn. Piston Pin Oiling.

From www.youtube.com

Piston Pin Bore Enlargement 17mm to 18mm YouTube Piston Pin Oiling The binding between the two components created a thrust load on the piston. Despite incorporating elliptical pin bore profiling and ovality into their designs, the typical bearing clearance for wrist pin oiling remains so tight that extreme. Oil collects in this groove and is drawn to the pin through oiling holes by a properly. Oiling the wrist pin can be. Piston Pin Oiling.

From info.jepistons.com

Different Wrist Pin Oiling Styles Explained Piston Pin Oiling Oil collects in this groove and is drawn to the pin through oiling holes by a properly. The simplest form used by some companies is. The amount of surface area must accommodate the load, while providing piston stability to minimize rocking relative to the pin axis as the piston moves down from tdc and back up. A very good head's. Piston Pin Oiling.

From www.youtube.com

How to install piston rings and not break them. Oil ring explanation Piston Pin Oiling Despite incorporating elliptical pin bore profiling and ovality into their designs, the typical bearing clearance for wrist pin oiling remains so tight that extreme. This in turn caused the piston to scuff the cylinder wall, which eventually led to oil control problems. The simplest form used by some companies is. Oil collects in this groove and is drawn to the. Piston Pin Oiling.

From racerxonline.com

The Benefits of Pistons for Your Dirt Bike Racer X Piston Pin Oiling The binding between the two components created a thrust load on the piston. Oil collects in this groove and is drawn to the pin through oiling holes by a properly. The amount of surface area must accommodate the load, while providing piston stability to minimize rocking relative to the pin axis as the piston moves down from tdc and back. Piston Pin Oiling.

From www.cokerengineering.com

Piston Pins Coker Engineering Piston Pin Oiling The binding between the two components created a thrust load on the piston. Despite incorporating elliptical pin bore profiling and ovality into their designs, the typical bearing clearance for wrist pin oiling remains so tight that extreme. They required pin fitting and. Some engine builders prefer to oil the pin with a small groove around the piston just above the. Piston Pin Oiling.

From www.mdpi.com

Lubricants Free FullText Measurement of Piston PinBore Oil Film Piston Pin Oiling This in turn caused the piston to scuff the cylinder wall, which eventually led to oil control problems. The amount of surface area must accommodate the load, while providing piston stability to minimize rocking relative to the pin axis as the piston moves down from tdc and back up. The binding between the two components created a thrust load on. Piston Pin Oiling.

From inthegaragemedia.com

1000HP LS Engine Built For Street, Strip, & Track Piston Pin Oiling Oil collects in this groove and is drawn to the pin through oiling holes by a properly. Oiling the wrist pin can be accomplished in several different ways: They required pin fitting and. Some engine builders prefer to oil the pin with a small groove around the piston just above the oil ring. The simplest form used by some companies. Piston Pin Oiling.

From parts.wrshaw.ie

PISTON & PIN Piston Pin Oiling The simplest form used by some companies is. Oil collects in this groove and is drawn to the pin through oiling holes by a properly. They required pin fitting and. The binding between the two components created a thrust load on the piston. Some engine builders prefer to oil the pin with a small groove around the piston just above. Piston Pin Oiling.

From info.jepistons.com

Different Wrist Pin Oiling Styles Explained Piston Pin Oiling The amount of surface area must accommodate the load, while providing piston stability to minimize rocking relative to the pin axis as the piston moves down from tdc and back up. The simplest form used by some companies is. They required pin fitting and. A very good head's up, as we've become so accustomed to pistons being good to go. Piston Pin Oiling.

From parts.wrshaw.ie

PISTON & PIN Piston Pin Oiling The simplest form used by some companies is. Some engine builders prefer to oil the pin with a small groove around the piston just above the oil ring. The amount of surface area must accommodate the load, while providing piston stability to minimize rocking relative to the pin axis as the piston moves down from tdc and back up. They. Piston Pin Oiling.

From www.jepistons.com

Different Wrist Pin Oiling Styles Explained JE Pistons Piston Pin Oiling Despite incorporating elliptical pin bore profiling and ovality into their designs, the typical bearing clearance for wrist pin oiling remains so tight that extreme. Oiling the wrist pin can be accomplished in several different ways: They required pin fitting and. The simplest form used by some companies is. Oil collects in this groove and is drawn to the pin through. Piston Pin Oiling.

From www.cokerengineering.com

Piston Pins CNC Precision Engineering Coker Engineering Piston Pin Oiling Oiling the wrist pin can be accomplished in several different ways: This in turn caused the piston to scuff the cylinder wall, which eventually led to oil control problems. The amount of surface area must accommodate the load, while providing piston stability to minimize rocking relative to the pin axis as the piston moves down from tdc and back up.. Piston Pin Oiling.

From www.racingjunk.com

Piston Primer Part 4 RacingJunk News Piston Pin Oiling The binding between the two components created a thrust load on the piston. The simplest form used by some companies is. This in turn caused the piston to scuff the cylinder wall, which eventually led to oil control problems. Oiling the wrist pin can be accomplished in several different ways: Oil collects in this groove and is drawn to the. Piston Pin Oiling.

From www.youtube.com

Piston Pin assembly YouTube Piston Pin Oiling This in turn caused the piston to scuff the cylinder wall, which eventually led to oil control problems. The simplest form used by some companies is. The amount of surface area must accommodate the load, while providing piston stability to minimize rocking relative to the pin axis as the piston moves down from tdc and back up. Some engine builders. Piston Pin Oiling.

From www.wellfarengineparts.com

What Is a Piston Pin? Product Knowledge Knowledge Piston Pin Oiling Despite incorporating elliptical pin bore profiling and ovality into their designs, the typical bearing clearance for wrist pin oiling remains so tight that extreme. The simplest form used by some companies is. They required pin fitting and. This in turn caused the piston to scuff the cylinder wall, which eventually led to oil control problems. A very good head's up,. Piston Pin Oiling.

From parts.wrshaw.ie

PISTON & PIN Piston Pin Oiling Oiling the wrist pin can be accomplished in several different ways: Some engine builders prefer to oil the pin with a small groove around the piston just above the oil ring. They required pin fitting and. The binding between the two components created a thrust load on the piston. This in turn caused the piston to scuff the cylinder wall,. Piston Pin Oiling.

From www.speed-talk.com

How to provide oiling to the piston pin in a piston? Don Piston Pin Oiling Oiling the wrist pin can be accomplished in several different ways: A very good head's up, as we've become so accustomed to pistons being good to go out of the box, that these nos caught us not looking. Some engine builders prefer to oil the pin with a small groove around the piston just above the oil ring. This in. Piston Pin Oiling.

From engineeringlearner.com

Gudgeon Pin (Piston Pin) Method, Design & Working Conditions Piston Pin Oiling Some engine builders prefer to oil the pin with a small groove around the piston just above the oil ring. The binding between the two components created a thrust load on the piston. The amount of surface area must accommodate the load, while providing piston stability to minimize rocking relative to the pin axis as the piston moves down from. Piston Pin Oiling.

From www.youtube.com

3SGTE Pin Oiling Grooves YouTube Piston Pin Oiling This in turn caused the piston to scuff the cylinder wall, which eventually led to oil control problems. The simplest form used by some companies is. Despite incorporating elliptical pin bore profiling and ovality into their designs, the typical bearing clearance for wrist pin oiling remains so tight that extreme. The amount of surface area must accommodate the load, while. Piston Pin Oiling.

From in.pinterest.com

Material Choices Made by Piston Pin Manufacturers Pistons, Pin Piston Pin Oiling Some engine builders prefer to oil the pin with a small groove around the piston just above the oil ring. The binding between the two components created a thrust load on the piston. They required pin fitting and. The amount of surface area must accommodate the load, while providing piston stability to minimize rocking relative to the pin axis as. Piston Pin Oiling.