Best Plastic For Forming . Pressure forming and vacuum forming are the most common thermoforming techniques. At ssi, we specialize in thermoforming and vacuum forming services, but in this. Thermoforming is a manufacturing process that empowers manufacturers with a versatile solution for processing plastic sheets. In this comprehensive guide, learn about the various thermoforming processes, materials, equipment, and how you can create molds for thermoforming, including advanced processes like 3d printing. First, a plastic sheet is heated to a temperature at which it becomes pliable. Vacuum forming involves molding plastic by heating it until soft and then shaping it over a mold using suction. Then, the malleable plastic is cooled so it can harden into the desired shape. There are a range of different vacuum forming plastics used within the vacuum forming process, such as acrylic (pmma), polyethylene (hdpe), polystyrene (hips), and many more. Plastic manufacturers use a process called thermoforming. Here is a quick guide to the plastics most commonly used in vacuum forming. Plastic forming can be done in various ways depending on your constraints and needs.

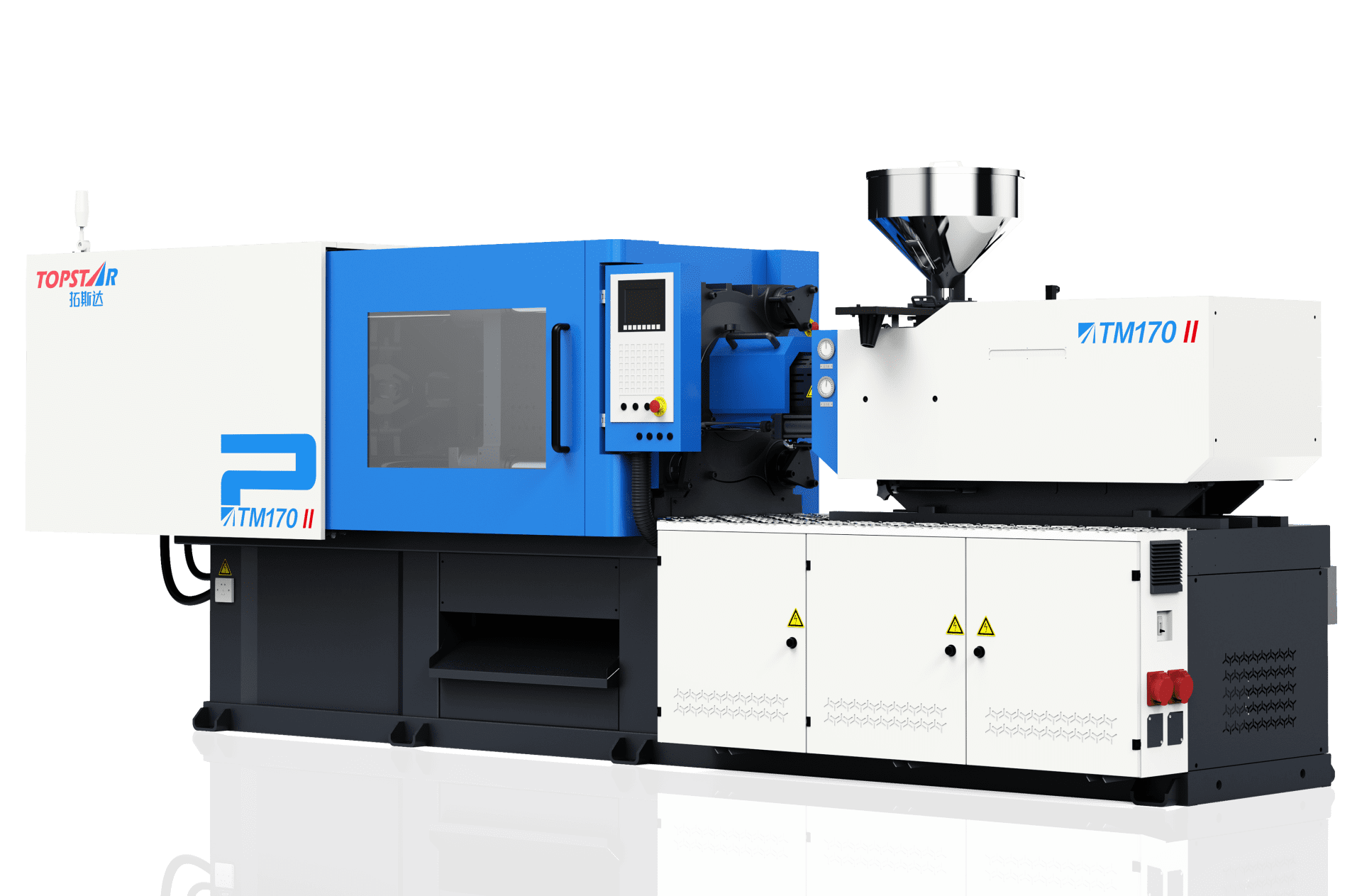

from www.topstarmachine.com

Thermoforming is a manufacturing process that empowers manufacturers with a versatile solution for processing plastic sheets. Plastic forming can be done in various ways depending on your constraints and needs. Pressure forming and vacuum forming are the most common thermoforming techniques. First, a plastic sheet is heated to a temperature at which it becomes pliable. Plastic manufacturers use a process called thermoforming. In this comprehensive guide, learn about the various thermoforming processes, materials, equipment, and how you can create molds for thermoforming, including advanced processes like 3d printing. There are a range of different vacuum forming plastics used within the vacuum forming process, such as acrylic (pmma), polyethylene (hdpe), polystyrene (hips), and many more. Here is a quick guide to the plastics most commonly used in vacuum forming. Vacuum forming involves molding plastic by heating it until soft and then shaping it over a mold using suction. Then, the malleable plastic is cooled so it can harden into the desired shape.

Plastic Forming The Future of Plastic Forming Equipment TopStar

Best Plastic For Forming At ssi, we specialize in thermoforming and vacuum forming services, but in this. Then, the malleable plastic is cooled so it can harden into the desired shape. First, a plastic sheet is heated to a temperature at which it becomes pliable. Thermoforming is a manufacturing process that empowers manufacturers with a versatile solution for processing plastic sheets. Vacuum forming involves molding plastic by heating it until soft and then shaping it over a mold using suction. Here is a quick guide to the plastics most commonly used in vacuum forming. Pressure forming and vacuum forming are the most common thermoforming techniques. There are a range of different vacuum forming plastics used within the vacuum forming process, such as acrylic (pmma), polyethylene (hdpe), polystyrene (hips), and many more. At ssi, we specialize in thermoforming and vacuum forming services, but in this. In this comprehensive guide, learn about the various thermoforming processes, materials, equipment, and how you can create molds for thermoforming, including advanced processes like 3d printing. Plastic forming can be done in various ways depending on your constraints and needs. Plastic manufacturers use a process called thermoforming.

From robersontool.com

What Are the Best Plastics For CNC Machining? Roberson Tool Best Plastic For Forming Vacuum forming involves molding plastic by heating it until soft and then shaping it over a mold using suction. In this comprehensive guide, learn about the various thermoforming processes, materials, equipment, and how you can create molds for thermoforming, including advanced processes like 3d printing. Then, the malleable plastic is cooled so it can harden into the desired shape. Plastic. Best Plastic For Forming.

From www.ebay.com

PETG Plastic Sheet Clear 0.5mm 1.5mm Thick A6 A4 Moulding Vacuum Best Plastic For Forming Thermoforming is a manufacturing process that empowers manufacturers with a versatile solution for processing plastic sheets. In this comprehensive guide, learn about the various thermoforming processes, materials, equipment, and how you can create molds for thermoforming, including advanced processes like 3d printing. There are a range of different vacuum forming plastics used within the vacuum forming process, such as acrylic. Best Plastic For Forming.

From www.designdevelopmenttoday.com

The Top 8 Methods for Forming Plastics Design and Development Today Best Plastic For Forming In this comprehensive guide, learn about the various thermoforming processes, materials, equipment, and how you can create molds for thermoforming, including advanced processes like 3d printing. Pressure forming and vacuum forming are the most common thermoforming techniques. Plastic manufacturers use a process called thermoforming. Here is a quick guide to the plastics most commonly used in vacuum forming. Thermoforming is. Best Plastic For Forming.

From www.topstarmachine.com

Plastic Forming The Future of Plastic Forming Equipment TopStar Best Plastic For Forming In this comprehensive guide, learn about the various thermoforming processes, materials, equipment, and how you can create molds for thermoforming, including advanced processes like 3d printing. Thermoforming is a manufacturing process that empowers manufacturers with a versatile solution for processing plastic sheets. First, a plastic sheet is heated to a temperature at which it becomes pliable. Vacuum forming involves molding. Best Plastic For Forming.

From dgfonorheco.blob.core.windows.net

Vacuum Forming Plastic Bottles at Joanna Elias blog Best Plastic For Forming First, a plastic sheet is heated to a temperature at which it becomes pliable. There are a range of different vacuum forming plastics used within the vacuum forming process, such as acrylic (pmma), polyethylene (hdpe), polystyrene (hips), and many more. Plastic manufacturers use a process called thermoforming. Vacuum forming involves molding plastic by heating it until soft and then shaping. Best Plastic For Forming.

From sme-machine.blogspot.com

SME Group Corp Dedicated Plastic Forming Plastic Thermoforming Best Plastic For Forming Pressure forming and vacuum forming are the most common thermoforming techniques. There are a range of different vacuum forming plastics used within the vacuum forming process, such as acrylic (pmma), polyethylene (hdpe), polystyrene (hips), and many more. Vacuum forming involves molding plastic by heating it until soft and then shaping it over a mold using suction. In this comprehensive guide,. Best Plastic For Forming.

From www.ccmiplastics.com

CCMI Plastics Custom Plastics Thermoforming and Vacuum Forming Best Plastic For Forming Then, the malleable plastic is cooled so it can harden into the desired shape. Plastic manufacturers use a process called thermoforming. Here is a quick guide to the plastics most commonly used in vacuum forming. In this comprehensive guide, learn about the various thermoforming processes, materials, equipment, and how you can create molds for thermoforming, including advanced processes like 3d. Best Plastic For Forming.

From oczami-gonczego.blogspot.com

Diy Vacuum Forming Abs Plastic / Make A Good Cheap Upgradeable Sheet Best Plastic For Forming In this comprehensive guide, learn about the various thermoforming processes, materials, equipment, and how you can create molds for thermoforming, including advanced processes like 3d printing. Plastic forming can be done in various ways depending on your constraints and needs. There are a range of different vacuum forming plastics used within the vacuum forming process, such as acrylic (pmma), polyethylene. Best Plastic For Forming.

From www.weetect.com

Plastic Fabrication The Complete Guide In 2018 Wee Tect Best Plastic For Forming First, a plastic sheet is heated to a temperature at which it becomes pliable. Plastic manufacturers use a process called thermoforming. There are a range of different vacuum forming plastics used within the vacuum forming process, such as acrylic (pmma), polyethylene (hdpe), polystyrene (hips), and many more. In this comprehensive guide, learn about the various thermoforming processes, materials, equipment, and. Best Plastic For Forming.

From www.royalcase.com

Custom Vacuum Forming Manufacturing Plastics Made in the USA Texas Best Plastic For Forming Pressure forming and vacuum forming are the most common thermoforming techniques. Plastic forming can be done in various ways depending on your constraints and needs. Then, the malleable plastic is cooled so it can harden into the desired shape. First, a plastic sheet is heated to a temperature at which it becomes pliable. At ssi, we specialize in thermoforming and. Best Plastic For Forming.

From www.singhalglobal.com

Vacuum Form Plastic Sheets Thermoforming Sheets Manufacturer Best Plastic For Forming Pressure forming and vacuum forming are the most common thermoforming techniques. Here is a quick guide to the plastics most commonly used in vacuum forming. Then, the malleable plastic is cooled so it can harden into the desired shape. In this comprehensive guide, learn about the various thermoforming processes, materials, equipment, and how you can create molds for thermoforming, including. Best Plastic For Forming.

From bcjplastics.com.au

Vacuum Forming Plastic BCJ Plastic Products Best Plastic For Forming First, a plastic sheet is heated to a temperature at which it becomes pliable. Pressure forming and vacuum forming are the most common thermoforming techniques. There are a range of different vacuum forming plastics used within the vacuum forming process, such as acrylic (pmma), polyethylene (hdpe), polystyrene (hips), and many more. Plastic forming can be done in various ways depending. Best Plastic For Forming.

From plasticmouldingsnorthern.co.uk

Best Plastics for Vacuum Forming Your Complete Guide Plastic Best Plastic For Forming Pressure forming and vacuum forming are the most common thermoforming techniques. There are a range of different vacuum forming plastics used within the vacuum forming process, such as acrylic (pmma), polyethylene (hdpe), polystyrene (hips), and many more. At ssi, we specialize in thermoforming and vacuum forming services, but in this. Then, the malleable plastic is cooled so it can harden. Best Plastic For Forming.

From predictabledesigns.com

How to Choose the Production Plastic for Your New Product Best Plastic For Forming Here is a quick guide to the plastics most commonly used in vacuum forming. At ssi, we specialize in thermoforming and vacuum forming services, but in this. Vacuum forming involves molding plastic by heating it until soft and then shaping it over a mold using suction. First, a plastic sheet is heated to a temperature at which it becomes pliable.. Best Plastic For Forming.

From foammolders.com

Vacuum Forming The Processes Foam Molders Uses To Create HighQuality Best Plastic For Forming At ssi, we specialize in thermoforming and vacuum forming services, but in this. Pressure forming and vacuum forming are the most common thermoforming techniques. There are a range of different vacuum forming plastics used within the vacuum forming process, such as acrylic (pmma), polyethylene (hdpe), polystyrene (hips), and many more. Vacuum forming involves molding plastic by heating it until soft. Best Plastic For Forming.

From plastifaboftexas.com

Vacuum Forming / Thermoforming Plastic Sheet Fabrication Manufacturing Best Plastic For Forming Plastic forming can be done in various ways depending on your constraints and needs. First, a plastic sheet is heated to a temperature at which it becomes pliable. Then, the malleable plastic is cooled so it can harden into the desired shape. In this comprehensive guide, learn about the various thermoforming processes, materials, equipment, and how you can create molds. Best Plastic For Forming.

From racheldebarros.com

Choosing the Best Plastics for your Vacuum Forming Project Best Plastic For Forming Plastic manufacturers use a process called thermoforming. Then, the malleable plastic is cooled so it can harden into the desired shape. Here is a quick guide to the plastics most commonly used in vacuum forming. Vacuum forming involves molding plastic by heating it until soft and then shaping it over a mold using suction. There are a range of different. Best Plastic For Forming.

From www.hotrod.com

How to build a vacuum forming mold to make your own plastic parts Best Plastic For Forming In this comprehensive guide, learn about the various thermoforming processes, materials, equipment, and how you can create molds for thermoforming, including advanced processes like 3d printing. Plastic manufacturers use a process called thermoforming. At ssi, we specialize in thermoforming and vacuum forming services, but in this. Vacuum forming involves molding plastic by heating it until soft and then shaping it. Best Plastic For Forming.

From www.plasticsunlimited.com

Thermoforming Products Plastics Unlimited Best Plastic For Forming Vacuum forming involves molding plastic by heating it until soft and then shaping it over a mold using suction. There are a range of different vacuum forming plastics used within the vacuum forming process, such as acrylic (pmma), polyethylene (hdpe), polystyrene (hips), and many more. Then, the malleable plastic is cooled so it can harden into the desired shape. In. Best Plastic For Forming.

From borkemold.com

A primer on six methods for forming plastics • Borke Mold Specialists, Inc. Best Plastic For Forming Vacuum forming involves molding plastic by heating it until soft and then shaping it over a mold using suction. First, a plastic sheet is heated to a temperature at which it becomes pliable. Plastic manufacturers use a process called thermoforming. At ssi, we specialize in thermoforming and vacuum forming services, but in this. Here is a quick guide to the. Best Plastic For Forming.

From www.plasticmoulds.net

Various Plastic Molding Process Best Plastic For Forming Here is a quick guide to the plastics most commonly used in vacuum forming. Pressure forming and vacuum forming are the most common thermoforming techniques. Then, the malleable plastic is cooled so it can harden into the desired shape. Thermoforming is a manufacturing process that empowers manufacturers with a versatile solution for processing plastic sheets. Plastic forming can be done. Best Plastic For Forming.

From trueformplastics.co.uk

Vacuum Forming, Drape Forming and Blow Moulding. Trueform Plastics Best Plastic For Forming There are a range of different vacuum forming plastics used within the vacuum forming process, such as acrylic (pmma), polyethylene (hdpe), polystyrene (hips), and many more. Then, the malleable plastic is cooled so it can harden into the desired shape. First, a plastic sheet is heated to a temperature at which it becomes pliable. Plastic forming can be done in. Best Plastic For Forming.

From steelefreeman.com

Plastic Forming Manufacturing Steele & Freeman, Inc. Best Plastic For Forming Plastic manufacturers use a process called thermoforming. First, a plastic sheet is heated to a temperature at which it becomes pliable. There are a range of different vacuum forming plastics used within the vacuum forming process, such as acrylic (pmma), polyethylene (hdpe), polystyrene (hips), and many more. Thermoforming is a manufacturing process that empowers manufacturers with a versatile solution for. Best Plastic For Forming.

From www.la-plastic.com

What is the Best Clear Plastic for Vacuum Forming? Best Plastic For Forming In this comprehensive guide, learn about the various thermoforming processes, materials, equipment, and how you can create molds for thermoforming, including advanced processes like 3d printing. At ssi, we specialize in thermoforming and vacuum forming services, but in this. Here is a quick guide to the plastics most commonly used in vacuum forming. First, a plastic sheet is heated to. Best Plastic For Forming.

From racheldebarros.com

Choosing the Best Plastics for your Vacuum Forming Project Best Plastic For Forming Plastic forming can be done in various ways depending on your constraints and needs. Plastic manufacturers use a process called thermoforming. There are a range of different vacuum forming plastics used within the vacuum forming process, such as acrylic (pmma), polyethylene (hdpe), polystyrene (hips), and many more. Pressure forming and vacuum forming are the most common thermoforming techniques. Here is. Best Plastic For Forming.

From www.weprofab.com

Plastic Vacuum Forming Manufacturer in China WeProFab Best Plastic For Forming Plastic forming can be done in various ways depending on your constraints and needs. Then, the malleable plastic is cooled so it can harden into the desired shape. First, a plastic sheet is heated to a temperature at which it becomes pliable. There are a range of different vacuum forming plastics used within the vacuum forming process, such as acrylic. Best Plastic For Forming.

From www.productiveplastics.com

Vacuum Forming Services, Custom Plastic Vacuum Thermoforming Best Plastic For Forming Plastic manufacturers use a process called thermoforming. Thermoforming is a manufacturing process that empowers manufacturers with a versatile solution for processing plastic sheets. At ssi, we specialize in thermoforming and vacuum forming services, but in this. First, a plastic sheet is heated to a temperature at which it becomes pliable. Pressure forming and vacuum forming are the most common thermoforming. Best Plastic For Forming.

From apporello.com

Vacuum forming v injection moulding Best Plastic For Forming There are a range of different vacuum forming plastics used within the vacuum forming process, such as acrylic (pmma), polyethylene (hdpe), polystyrene (hips), and many more. In this comprehensive guide, learn about the various thermoforming processes, materials, equipment, and how you can create molds for thermoforming, including advanced processes like 3d printing. First, a plastic sheet is heated to a. Best Plastic For Forming.

From www.rohrer.com

How to Choose the Right Plastic for Your Thermoformed Packaging Best Plastic For Forming At ssi, we specialize in thermoforming and vacuum forming services, but in this. Here is a quick guide to the plastics most commonly used in vacuum forming. There are a range of different vacuum forming plastics used within the vacuum forming process, such as acrylic (pmma), polyethylene (hdpe), polystyrene (hips), and many more. In this comprehensive guide, learn about the. Best Plastic For Forming.

From www.productiveplastics.com

Plastic Thermoforming, Pressure Forming, Vacuum Forming What's the Best Plastic For Forming Plastic manufacturers use a process called thermoforming. There are a range of different vacuum forming plastics used within the vacuum forming process, such as acrylic (pmma), polyethylene (hdpe), polystyrene (hips), and many more. First, a plastic sheet is heated to a temperature at which it becomes pliable. At ssi, we specialize in thermoforming and vacuum forming services, but in this.. Best Plastic For Forming.

From progardplastics.com.au

Thermoforming Progard Plastics Best Plastic For Forming Then, the malleable plastic is cooled so it can harden into the desired shape. In this comprehensive guide, learn about the various thermoforming processes, materials, equipment, and how you can create molds for thermoforming, including advanced processes like 3d printing. Thermoforming is a manufacturing process that empowers manufacturers with a versatile solution for processing plastic sheets. Plastic forming can be. Best Plastic For Forming.

From resource.download.wjec.co.uk.s3.amazonaws.com

Design and Technology Best Plastic For Forming First, a plastic sheet is heated to a temperature at which it becomes pliable. There are a range of different vacuum forming plastics used within the vacuum forming process, such as acrylic (pmma), polyethylene (hdpe), polystyrene (hips), and many more. In this comprehensive guide, learn about the various thermoforming processes, materials, equipment, and how you can create molds for thermoforming,. Best Plastic For Forming.

From globalvacuumpresses.com

Thermoplastic industry Thermoforming of plastic sheets and foils Best Plastic For Forming Thermoforming is a manufacturing process that empowers manufacturers with a versatile solution for processing plastic sheets. Pressure forming and vacuum forming are the most common thermoforming techniques. Vacuum forming involves molding plastic by heating it until soft and then shaping it over a mold using suction. Then, the malleable plastic is cooled so it can harden into the desired shape.. Best Plastic For Forming.

From paulmurphyplastics.com

Ultimate Guide to The Plastic Extrusion Process • Paul Murphy Plastics Best Plastic For Forming First, a plastic sheet is heated to a temperature at which it becomes pliable. Here is a quick guide to the plastics most commonly used in vacuum forming. Vacuum forming involves molding plastic by heating it until soft and then shaping it over a mold using suction. Plastic manufacturers use a process called thermoforming. Pressure forming and vacuum forming are. Best Plastic For Forming.

From www.kemalmfg.com

Discover the Top 9 Techniques of Plastic Forming and Manufacturing Best Plastic For Forming First, a plastic sheet is heated to a temperature at which it becomes pliable. Then, the malleable plastic is cooled so it can harden into the desired shape. Here is a quick guide to the plastics most commonly used in vacuum forming. In this comprehensive guide, learn about the various thermoforming processes, materials, equipment, and how you can create molds. Best Plastic For Forming.