Type Of Aluminum Engine Block . The ls blocks were made in both iron and aluminum for nearly every size, however, the aluminum blocks were produced in generations 3 and 4 of the ls engine platform. Gen iii was simply a starting place for truck engines, ls engines, and more. Cast aluminum engine blocks are not only suitable for vehicles just because of their lightweight, but their excellent electrical and thermal conductivity ensures lesser wear and tear on vehicles and other associated components. The best engine block material for repairing an engine depends on a variety of factors, including the type of engine, the intended use of the engine, and the budget for repairs. Cast iron is a traditional and reliable material that is still commonly used for engine blocks, aluminum is a softer metal and can be machined more easily. Learn about the advantages, differences, alloys, and tips for honing and sizing in this detailed guide. Aluminum engine blocks have revolutionized the automotive industry with their blend of lightness and strength. Modern aluminum blocks are pretty strong, but a properly built iron block is still ultimately going to be stronger, and that strength offers some benefits that might be less obvious. For instance, if you have a catastrophic engine failure, an iron block is usually going to hold up better to it.

from www.enginelabs.com

Modern aluminum blocks are pretty strong, but a properly built iron block is still ultimately going to be stronger, and that strength offers some benefits that might be less obvious. Learn about the advantages, differences, alloys, and tips for honing and sizing in this detailed guide. For instance, if you have a catastrophic engine failure, an iron block is usually going to hold up better to it. The best engine block material for repairing an engine depends on a variety of factors, including the type of engine, the intended use of the engine, and the budget for repairs. Cast aluminum engine blocks are not only suitable for vehicles just because of their lightweight, but their excellent electrical and thermal conductivity ensures lesser wear and tear on vehicles and other associated components. Gen iii was simply a starting place for truck engines, ls engines, and more. The ls blocks were made in both iron and aluminum for nearly every size, however, the aluminum blocks were produced in generations 3 and 4 of the ls engine platform. Aluminum engine blocks have revolutionized the automotive industry with their blend of lightness and strength. Cast iron is a traditional and reliable material that is still commonly used for engine blocks, aluminum is a softer metal and can be machined more easily.

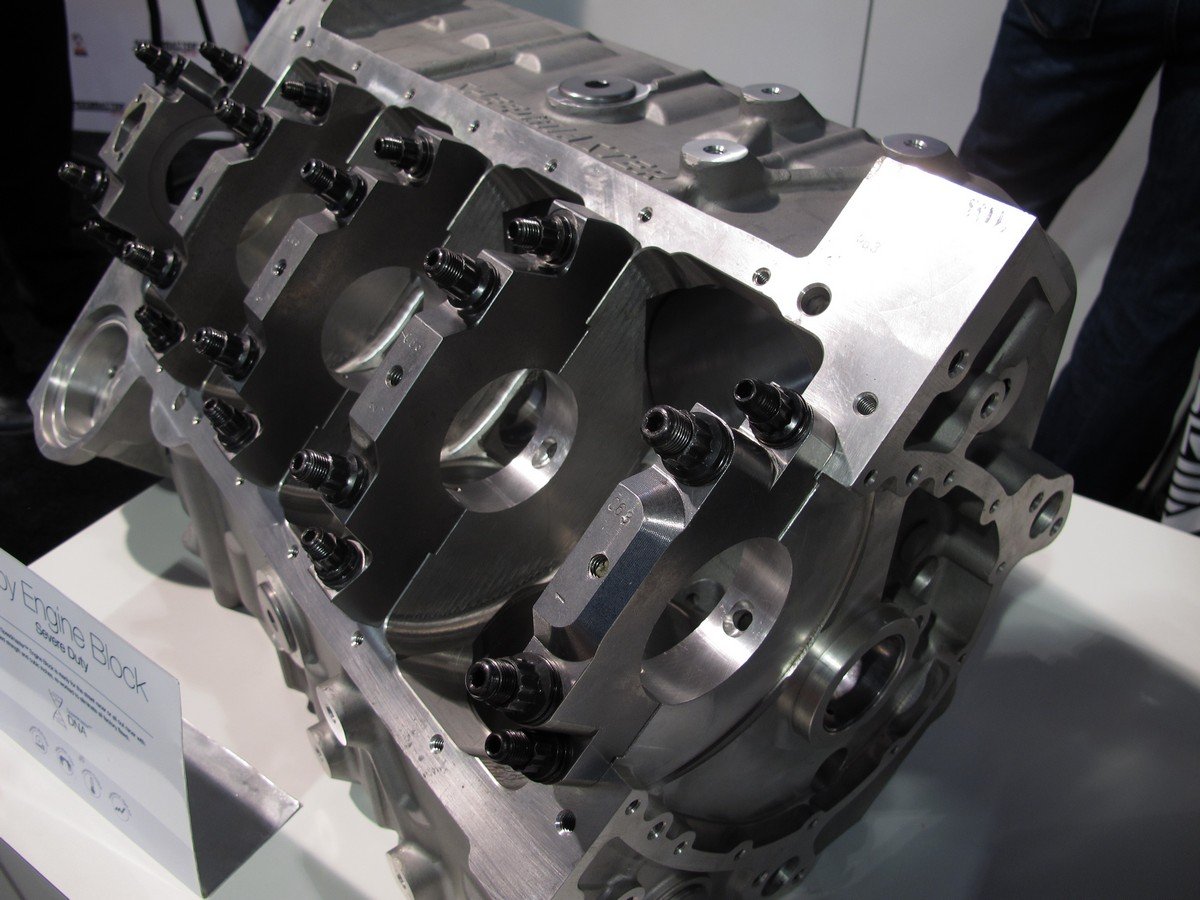

Speedmaster's Aluminum SmallBlock Chevy Engine Block

Type Of Aluminum Engine Block The best engine block material for repairing an engine depends on a variety of factors, including the type of engine, the intended use of the engine, and the budget for repairs. For instance, if you have a catastrophic engine failure, an iron block is usually going to hold up better to it. The ls blocks were made in both iron and aluminum for nearly every size, however, the aluminum blocks were produced in generations 3 and 4 of the ls engine platform. Cast iron is a traditional and reliable material that is still commonly used for engine blocks, aluminum is a softer metal and can be machined more easily. Aluminum engine blocks have revolutionized the automotive industry with their blend of lightness and strength. The best engine block material for repairing an engine depends on a variety of factors, including the type of engine, the intended use of the engine, and the budget for repairs. Modern aluminum blocks are pretty strong, but a properly built iron block is still ultimately going to be stronger, and that strength offers some benefits that might be less obvious. Cast aluminum engine blocks are not only suitable for vehicles just because of their lightweight, but their excellent electrical and thermal conductivity ensures lesser wear and tear on vehicles and other associated components. Learn about the advantages, differences, alloys, and tips for honing and sizing in this detailed guide. Gen iii was simply a starting place for truck engines, ls engines, and more.

From www.amedm.co.uk

Aluminium Engine Blocks A&M Type Of Aluminum Engine Block The ls blocks were made in both iron and aluminum for nearly every size, however, the aluminum blocks were produced in generations 3 and 4 of the ls engine platform. The best engine block material for repairing an engine depends on a variety of factors, including the type of engine, the intended use of the engine, and the budget for. Type Of Aluminum Engine Block.

From billmitchellproducts.com

SB Ford Aluminum Bill Mitchell Products Type Of Aluminum Engine Block Modern aluminum blocks are pretty strong, but a properly built iron block is still ultimately going to be stronger, and that strength offers some benefits that might be less obvious. Cast aluminum engine blocks are not only suitable for vehicles just because of their lightweight, but their excellent electrical and thermal conductivity ensures lesser wear and tear on vehicles and. Type Of Aluminum Engine Block.

From www.summitracing.com

Chevrolet Performance 12623969 Chevrolet Performance 6.2L LS9 Aluminum Type Of Aluminum Engine Block Learn about the advantages, differences, alloys, and tips for honing and sizing in this detailed guide. Gen iii was simply a starting place for truck engines, ls engines, and more. Cast iron is a traditional and reliable material that is still commonly used for engine blocks, aluminum is a softer metal and can be machined more easily. The ls blocks. Type Of Aluminum Engine Block.

From www.amedm.co.uk

Aluminium Engine Blocks A&M Type Of Aluminum Engine Block Modern aluminum blocks are pretty strong, but a properly built iron block is still ultimately going to be stronger, and that strength offers some benefits that might be less obvious. For instance, if you have a catastrophic engine failure, an iron block is usually going to hold up better to it. Aluminum engine blocks have revolutionized the automotive industry with. Type Of Aluminum Engine Block.

From www.ibuyautoparts.com

OEM Customized Aluminum Alloy Automatic CNC Engine Block Type Of Aluminum Engine Block The ls blocks were made in both iron and aluminum for nearly every size, however, the aluminum blocks were produced in generations 3 and 4 of the ls engine platform. Cast iron is a traditional and reliable material that is still commonly used for engine blocks, aluminum is a softer metal and can be machined more easily. Modern aluminum blocks. Type Of Aluminum Engine Block.

From www.motorcycle-cylinder.com

Modern Design Aluminum Alloy Cylinder Motorcycle Engine Block / Honda Type Of Aluminum Engine Block Cast aluminum engine blocks are not only suitable for vehicles just because of their lightweight, but their excellent electrical and thermal conductivity ensures lesser wear and tear on vehicles and other associated components. Aluminum engine blocks have revolutionized the automotive industry with their blend of lightness and strength. Cast iron is a traditional and reliable material that is still commonly. Type Of Aluminum Engine Block.

From www.lsxceleration.com

DART LS Next Gen III Aluminum Engine Block 31937212 Raised Cam, 9.240 Type Of Aluminum Engine Block The best engine block material for repairing an engine depends on a variety of factors, including the type of engine, the intended use of the engine, and the budget for repairs. Gen iii was simply a starting place for truck engines, ls engines, and more. Learn about the advantages, differences, alloys, and tips for honing and sizing in this detailed. Type Of Aluminum Engine Block.

From www.donovanengines.com

Donovan Aluminum Engine Blocks Donovan 417 Hemi Aluminum Blocks Type Of Aluminum Engine Block Modern aluminum blocks are pretty strong, but a properly built iron block is still ultimately going to be stronger, and that strength offers some benefits that might be less obvious. Cast aluminum engine blocks are not only suitable for vehicles just because of their lightweight, but their excellent electrical and thermal conductivity ensures lesser wear and tear on vehicles and. Type Of Aluminum Engine Block.

From www.cncmetalparts.com

Full CNC machining Aluminum Engine Block Besturn Industry Co.,Ltd Type Of Aluminum Engine Block Learn about the advantages, differences, alloys, and tips for honing and sizing in this detailed guide. Cast aluminum engine blocks are not only suitable for vehicles just because of their lightweight, but their excellent electrical and thermal conductivity ensures lesser wear and tear on vehicles and other associated components. Gen iii was simply a starting place for truck engines, ls. Type Of Aluminum Engine Block.

From www.enginebuildermag.com

Machining Aluminum Engine Blocks Engine Builder Magazine Type Of Aluminum Engine Block Gen iii was simply a starting place for truck engines, ls engines, and more. The best engine block material for repairing an engine depends on a variety of factors, including the type of engine, the intended use of the engine, and the budget for repairs. Cast aluminum engine blocks are not only suitable for vehicles just because of their lightweight,. Type Of Aluminum Engine Block.

From donovanengines.com

Donovan Aluminum Engine Blocks Donovan Engineering Aluminum Big Block Type Of Aluminum Engine Block Aluminum engine blocks have revolutionized the automotive industry with their blend of lightness and strength. Learn about the advantages, differences, alloys, and tips for honing and sizing in this detailed guide. Modern aluminum blocks are pretty strong, but a properly built iron block is still ultimately going to be stronger, and that strength offers some benefits that might be less. Type Of Aluminum Engine Block.

From www.autozone.com

Speedmaster Aluminum Engine Block PCE286.1045 Type Of Aluminum Engine Block Cast iron is a traditional and reliable material that is still commonly used for engine blocks, aluminum is a softer metal and can be machined more easily. The best engine block material for repairing an engine depends on a variety of factors, including the type of engine, the intended use of the engine, and the budget for repairs. Aluminum engine. Type Of Aluminum Engine Block.

From donovanengines.com

Donovan Aluminum Engine Blocks About Donovan Engineering Donovan Type Of Aluminum Engine Block For instance, if you have a catastrophic engine failure, an iron block is usually going to hold up better to it. The best engine block material for repairing an engine depends on a variety of factors, including the type of engine, the intended use of the engine, and the budget for repairs. Gen iii was simply a starting place for. Type Of Aluminum Engine Block.

From www.hotcars.com

Pros And Cons Of Iron Vs Aluminum Engine Blocks Type Of Aluminum Engine Block Learn about the advantages, differences, alloys, and tips for honing and sizing in this detailed guide. Gen iii was simply a starting place for truck engines, ls engines, and more. The ls blocks were made in both iron and aluminum for nearly every size, however, the aluminum blocks were produced in generations 3 and 4 of the ls engine platform.. Type Of Aluminum Engine Block.

From wtmsolutions.com

CNC Aluminum Engine Block WTM SOLUTIONS Type Of Aluminum Engine Block Cast aluminum engine blocks are not only suitable for vehicles just because of their lightweight, but their excellent electrical and thermal conductivity ensures lesser wear and tear on vehicles and other associated components. Learn about the advantages, differences, alloys, and tips for honing and sizing in this detailed guide. Cast iron is a traditional and reliable material that is still. Type Of Aluminum Engine Block.

From www.summitracing.com

Chevrolet Performance 5.7L LS1/LS6 Aluminum Engine Blocks 12561166 Type Of Aluminum Engine Block Cast iron is a traditional and reliable material that is still commonly used for engine blocks, aluminum is a softer metal and can be machined more easily. Aluminum engine blocks have revolutionized the automotive industry with their blend of lightness and strength. The best engine block material for repairing an engine depends on a variety of factors, including the type. Type Of Aluminum Engine Block.

From borowskirace.com

RHS Aluminum LS Engine Block Borowski Race Engines Type Of Aluminum Engine Block Gen iii was simply a starting place for truck engines, ls engines, and more. The ls blocks were made in both iron and aluminum for nearly every size, however, the aluminum blocks were produced in generations 3 and 4 of the ls engine platform. The best engine block material for repairing an engine depends on a variety of factors, including. Type Of Aluminum Engine Block.

From www.chevyhardcore.com

Speedmaster's Aluminum SmallBlock Chevy Engine Block Type Of Aluminum Engine Block Cast aluminum engine blocks are not only suitable for vehicles just because of their lightweight, but their excellent electrical and thermal conductivity ensures lesser wear and tear on vehicles and other associated components. Aluminum engine blocks have revolutionized the automotive industry with their blend of lightness and strength. Cast iron is a traditional and reliable material that is still commonly. Type Of Aluminum Engine Block.

From www.donovanengines.com

Donovan Aluminum Engine Blocks Donovan 417 Hemi Aluminum Blocks Type Of Aluminum Engine Block Gen iii was simply a starting place for truck engines, ls engines, and more. The best engine block material for repairing an engine depends on a variety of factors, including the type of engine, the intended use of the engine, and the budget for repairs. The ls blocks were made in both iron and aluminum for nearly every size, however,. Type Of Aluminum Engine Block.

From www.researchgate.net

An aluminum engine block with horned cylinder bores coated by EJPO Type Of Aluminum Engine Block Cast iron is a traditional and reliable material that is still commonly used for engine blocks, aluminum is a softer metal and can be machined more easily. The ls blocks were made in both iron and aluminum for nearly every size, however, the aluminum blocks were produced in generations 3 and 4 of the ls engine platform. Gen iii was. Type Of Aluminum Engine Block.

From www.youtube.com

ENGINE BLOCKS Aluminum vs. Iron YouTube Type Of Aluminum Engine Block For instance, if you have a catastrophic engine failure, an iron block is usually going to hold up better to it. The best engine block material for repairing an engine depends on a variety of factors, including the type of engine, the intended use of the engine, and the budget for repairs. Gen iii was simply a starting place for. Type Of Aluminum Engine Block.

From donovanengines.com

Donovan Aluminum Engine Blocks Donovan Chevy Style Small Block Type Of Aluminum Engine Block Aluminum engine blocks have revolutionized the automotive industry with their blend of lightness and strength. Learn about the advantages, differences, alloys, and tips for honing and sizing in this detailed guide. Gen iii was simply a starting place for truck engines, ls engines, and more. Modern aluminum blocks are pretty strong, but a properly built iron block is still ultimately. Type Of Aluminum Engine Block.

From jonkaaseracingengines.com

Kaase / Bear Billet Aluminum Blocks Jon Kaase Racing Engines Type Of Aluminum Engine Block Cast iron is a traditional and reliable material that is still commonly used for engine blocks, aluminum is a softer metal and can be machined more easily. The best engine block material for repairing an engine depends on a variety of factors, including the type of engine, the intended use of the engine, and the budget for repairs. Aluminum engine. Type Of Aluminum Engine Block.

From wiredatastella.z19.web.core.windows.net

Chevy Aluminum Block Engines Type Of Aluminum Engine Block Modern aluminum blocks are pretty strong, but a properly built iron block is still ultimately going to be stronger, and that strength offers some benefits that might be less obvious. Cast iron is a traditional and reliable material that is still commonly used for engine blocks, aluminum is a softer metal and can be machined more easily. Cast aluminum engine. Type Of Aluminum Engine Block.

From borowskirace.com

RHS Aluminum LS Engine Block Borowski Race Engines Type Of Aluminum Engine Block The best engine block material for repairing an engine depends on a variety of factors, including the type of engine, the intended use of the engine, and the budget for repairs. Cast iron is a traditional and reliable material that is still commonly used for engine blocks, aluminum is a softer metal and can be machined more easily. Modern aluminum. Type Of Aluminum Engine Block.

From www.dreamstime.com

Aluminum Blocks of Cylinders of an Automobile Engine. the Cylinder Type Of Aluminum Engine Block Aluminum engine blocks have revolutionized the automotive industry with their blend of lightness and strength. Cast iron is a traditional and reliable material that is still commonly used for engine blocks, aluminum is a softer metal and can be machined more easily. Cast aluminum engine blocks are not only suitable for vehicles just because of their lightweight, but their excellent. Type Of Aluminum Engine Block.

From www.enginelabs.com

Speedmaster's Aluminum SmallBlock Chevy Engine Block Type Of Aluminum Engine Block The best engine block material for repairing an engine depends on a variety of factors, including the type of engine, the intended use of the engine, and the budget for repairs. For instance, if you have a catastrophic engine failure, an iron block is usually going to hold up better to it. The ls blocks were made in both iron. Type Of Aluminum Engine Block.

From www.carid.com

Speedmaster® PCE286.1049 Bare Billet Aluminum Engine Block Type Of Aluminum Engine Block Cast iron is a traditional and reliable material that is still commonly used for engine blocks, aluminum is a softer metal and can be machined more easily. Aluminum engine blocks have revolutionized the automotive industry with their blend of lightness and strength. Gen iii was simply a starting place for truck engines, ls engines, and more. Modern aluminum blocks are. Type Of Aluminum Engine Block.

From wtmsolutions.com

CNC Aluminum Engine Block WTM SOLUTIONS Type Of Aluminum Engine Block The ls blocks were made in both iron and aluminum for nearly every size, however, the aluminum blocks were produced in generations 3 and 4 of the ls engine platform. Cast aluminum engine blocks are not only suitable for vehicles just because of their lightweight, but their excellent electrical and thermal conductivity ensures lesser wear and tear on vehicles and. Type Of Aluminum Engine Block.

From donovanengines.com

Donovan Aluminum Engine Blocks Donovan 417 Hemi Aluminum Blocks Type Of Aluminum Engine Block Cast iron is a traditional and reliable material that is still commonly used for engine blocks, aluminum is a softer metal and can be machined more easily. For instance, if you have a catastrophic engine failure, an iron block is usually going to hold up better to it. Learn about the advantages, differences, alloys, and tips for honing and sizing. Type Of Aluminum Engine Block.

From borowskirace.com

RHS Aluminum LS Engine Block Borowski Race Engines Type Of Aluminum Engine Block The best engine block material for repairing an engine depends on a variety of factors, including the type of engine, the intended use of the engine, and the budget for repairs. Modern aluminum blocks are pretty strong, but a properly built iron block is still ultimately going to be stronger, and that strength offers some benefits that might be less. Type Of Aluminum Engine Block.

From www.equipment-news.com

Aluminium engine block Asia Pacific Metalworking Equipment News Type Of Aluminum Engine Block Modern aluminum blocks are pretty strong, but a properly built iron block is still ultimately going to be stronger, and that strength offers some benefits that might be less obvious. The ls blocks were made in both iron and aluminum for nearly every size, however, the aluminum blocks were produced in generations 3 and 4 of the ls engine platform.. Type Of Aluminum Engine Block.

From qix.owj.mybluehost.me

Donovan Aluminum Engine Blocks Donovan D500 Big Block Donovan Type Of Aluminum Engine Block The ls blocks were made in both iron and aluminum for nearly every size, however, the aluminum blocks were produced in generations 3 and 4 of the ls engine platform. Gen iii was simply a starting place for truck engines, ls engines, and more. Aluminum engine blocks have revolutionized the automotive industry with their blend of lightness and strength. For. Type Of Aluminum Engine Block.

From www.alamy.com

Aluminum blocks of cylinders of an automobile engine. The cylinder Type Of Aluminum Engine Block Learn about the advantages, differences, alloys, and tips for honing and sizing in this detailed guide. Modern aluminum blocks are pretty strong, but a properly built iron block is still ultimately going to be stronger, and that strength offers some benefits that might be less obvious. The best engine block material for repairing an engine depends on a variety of. Type Of Aluminum Engine Block.

From wtmsolutions.com

CNC Aluminum Engine Block WTM SOLUTIONS Type Of Aluminum Engine Block Aluminum engine blocks have revolutionized the automotive industry with their blend of lightness and strength. For instance, if you have a catastrophic engine failure, an iron block is usually going to hold up better to it. The best engine block material for repairing an engine depends on a variety of factors, including the type of engine, the intended use of. Type Of Aluminum Engine Block.