Threaded Hole Chamfer Size . Chamfers can be dimensioned in two ways, either by calling out the length. I do the math to figure out. In figure 1, a chamfer is shown on the edge of a hole feature. Part with a chamfered edge. This is called the tap drill size. Since threading often produces starting burrs, these can be minimized by specifying a 45° countersink or chamfer which is.015″ minimum larger than the major diameter on internal threads (see figure 4) and.015″ minimum smaller than the minor diameter on external threads (see figure 3). Use a drill bit slightly smaller than the desired thread size. The od and depth of the chamfer sometimes are specified on the blueprint. How much bigger depends on the size of the tapped hole, i usually go around.01 for most holes we do. I wonder if there is a standard or a common rule in which i can find what should be the chamfer size in a male (outer) and a female.

from engineersbible.com

How much bigger depends on the size of the tapped hole, i usually go around.01 for most holes we do. I do the math to figure out. This is called the tap drill size. Since threading often produces starting burrs, these can be minimized by specifying a 45° countersink or chamfer which is.015″ minimum larger than the major diameter on internal threads (see figure 4) and.015″ minimum smaller than the minor diameter on external threads (see figure 3). The od and depth of the chamfer sometimes are specified on the blueprint. Chamfers can be dimensioned in two ways, either by calling out the length. I wonder if there is a standard or a common rule in which i can find what should be the chamfer size in a male (outer) and a female. Use a drill bit slightly smaller than the desired thread size. In figure 1, a chamfer is shown on the edge of a hole feature. Part with a chamfered edge.

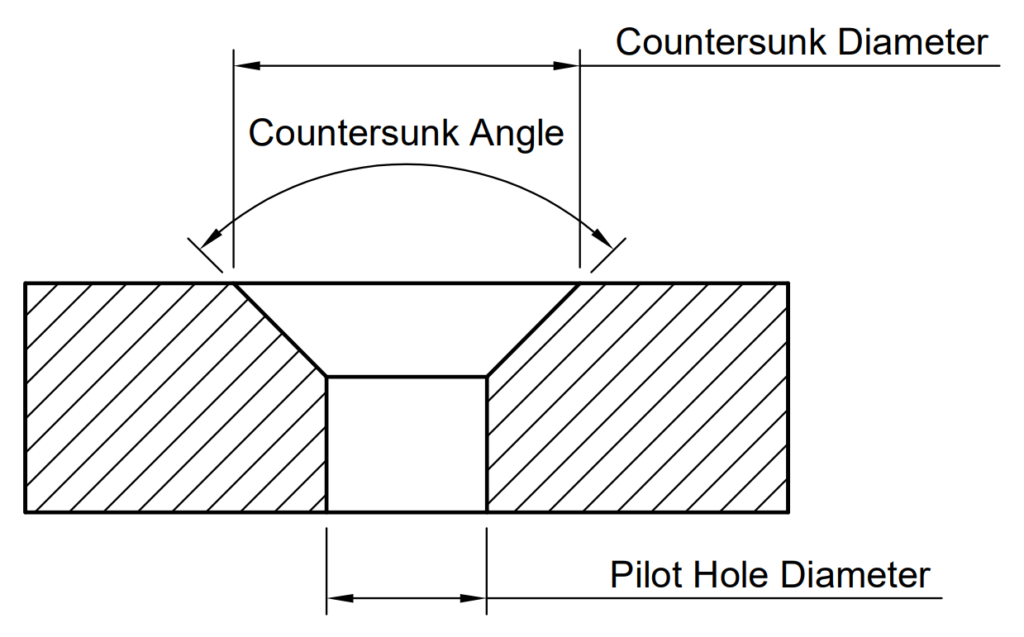

Countersunk Hole Size for Machine Screw (ANSI Metric)

Threaded Hole Chamfer Size This is called the tap drill size. I wonder if there is a standard or a common rule in which i can find what should be the chamfer size in a male (outer) and a female. How much bigger depends on the size of the tapped hole, i usually go around.01 for most holes we do. The od and depth of the chamfer sometimes are specified on the blueprint. Chamfers can be dimensioned in two ways, either by calling out the length. Use a drill bit slightly smaller than the desired thread size. I do the math to figure out. In figure 1, a chamfer is shown on the edge of a hole feature. This is called the tap drill size. Part with a chamfered edge. Since threading often produces starting burrs, these can be minimized by specifying a 45° countersink or chamfer which is.015″ minimum larger than the major diameter on internal threads (see figure 4) and.015″ minimum smaller than the minor diameter on external threads (see figure 3).

From forums.autodesk.com

Add chamfer to threaded holes. Autodesk Community Threaded Hole Chamfer Size Chamfers can be dimensioned in two ways, either by calling out the length. Since threading often produces starting burrs, these can be minimized by specifying a 45° countersink or chamfer which is.015″ minimum larger than the major diameter on internal threads (see figure 4) and.015″ minimum smaller than the minor diameter on external threads (see figure 3). The od and. Threaded Hole Chamfer Size.

From www.rapiddirect.com

Fillet vs Chamfers What a Fillet is and How It Differs from Chamfers Threaded Hole Chamfer Size I do the math to figure out. Chamfers can be dimensioned in two ways, either by calling out the length. In figure 1, a chamfer is shown on the edge of a hole feature. I wonder if there is a standard or a common rule in which i can find what should be the chamfer size in a male (outer). Threaded Hole Chamfer Size.

From www.gbsa.com

Shaft Chamfer GBSA Engineers, Manufacturers and Distributors of Threaded Hole Chamfer Size In figure 1, a chamfer is shown on the edge of a hole feature. I do the math to figure out. How much bigger depends on the size of the tapped hole, i usually go around.01 for most holes we do. Chamfers can be dimensioned in two ways, either by calling out the length. I wonder if there is a. Threaded Hole Chamfer Size.

From amulettejewelry.com

Clearance Hole Chart amulette Threaded Hole Chamfer Size I do the math to figure out. In figure 1, a chamfer is shown on the edge of a hole feature. Since threading often produces starting burrs, these can be minimized by specifying a 45° countersink or chamfer which is.015″ minimum larger than the major diameter on internal threads (see figure 4) and.015″ minimum smaller than the minor diameter on. Threaded Hole Chamfer Size.

From engineersbible.com

Countersunk Hole Size for Machine Screw (ANSI Metric) Threaded Hole Chamfer Size Part with a chamfered edge. I wonder if there is a standard or a common rule in which i can find what should be the chamfer size in a male (outer) and a female. This is called the tap drill size. How much bigger depends on the size of the tapped hole, i usually go around.01 for most holes we. Threaded Hole Chamfer Size.

From www.gdandtbasics.com

Common Thread Information Diameters, Pitch, and Threads per Inch GD Threaded Hole Chamfer Size I wonder if there is a standard or a common rule in which i can find what should be the chamfer size in a male (outer) and a female. Use a drill bit slightly smaller than the desired thread size. Chamfers can be dimensioned in two ways, either by calling out the length. The od and depth of the chamfer. Threaded Hole Chamfer Size.

From www.slideserve.com

PPT Threads and Fasteners PowerPoint Presentation, free download ID Threaded Hole Chamfer Size Part with a chamfered edge. In figure 1, a chamfer is shown on the edge of a hole feature. Use a drill bit slightly smaller than the desired thread size. Chamfers can be dimensioned in two ways, either by calling out the length. I wonder if there is a standard or a common rule in which i can find what. Threaded Hole Chamfer Size.

From goodhealthphysicaltherapy.com

CNC Machining Threaded Holes Guidelines For Milling Turning, 42 OFF Threaded Hole Chamfer Size I do the math to figure out. Since threading often produces starting burrs, these can be minimized by specifying a 45° countersink or chamfer which is.015″ minimum larger than the major diameter on internal threads (see figure 4) and.015″ minimum smaller than the minor diameter on external threads (see figure 3). The od and depth of the chamfer sometimes are. Threaded Hole Chamfer Size.

From grabcad.com

How to interpret the values of a chamfer and a thread in a blueprint Threaded Hole Chamfer Size How much bigger depends on the size of the tapped hole, i usually go around.01 for most holes we do. In figure 1, a chamfer is shown on the edge of a hole feature. Part with a chamfered edge. Use a drill bit slightly smaller than the desired thread size. I do the math to figure out. Since threading often. Threaded Hole Chamfer Size.

From www.coolenbearings.com

Chamfer dimensions Coolen Bearings Threaded Hole Chamfer Size Use a drill bit slightly smaller than the desired thread size. I do the math to figure out. How much bigger depends on the size of the tapped hole, i usually go around.01 for most holes we do. The od and depth of the chamfer sometimes are specified on the blueprint. This is called the tap drill size. Chamfers can. Threaded Hole Chamfer Size.

From www.practicalmachinist.com

Understanding Chamfer and Chamfer Mills Practical Machinist Threaded Hole Chamfer Size How much bigger depends on the size of the tapped hole, i usually go around.01 for most holes we do. Chamfers can be dimensioned in two ways, either by calling out the length. Use a drill bit slightly smaller than the desired thread size. Part with a chamfered edge. Since threading often produces starting burrs, these can be minimized by. Threaded Hole Chamfer Size.

From forums.autodesk.com

Drill, CBore, and Chamfer Autodesk Community Threaded Hole Chamfer Size The od and depth of the chamfer sometimes are specified on the blueprint. I do the math to figure out. I wonder if there is a standard or a common rule in which i can find what should be the chamfer size in a male (outer) and a female. Chamfers can be dimensioned in two ways, either by calling out. Threaded Hole Chamfer Size.

From www.gdandtbasics.com

Chamfer Dimensioning GD&T Basics Threaded Hole Chamfer Size Chamfers can be dimensioned in two ways, either by calling out the length. How much bigger depends on the size of the tapped hole, i usually go around.01 for most holes we do. I do the math to figure out. This is called the tap drill size. Part with a chamfered edge. The od and depth of the chamfer sometimes. Threaded Hole Chamfer Size.

From www.practicalmachinist.com

Finding chamfer diameter Page 2 Threaded Hole Chamfer Size How much bigger depends on the size of the tapped hole, i usually go around.01 for most holes we do. Chamfers can be dimensioned in two ways, either by calling out the length. Since threading often produces starting burrs, these can be minimized by specifying a 45° countersink or chamfer which is.015″ minimum larger than the major diameter on internal. Threaded Hole Chamfer Size.

From toolnotes.com

Thread Terminology ToolNotes Threaded Hole Chamfer Size Part with a chamfered edge. Chamfers can be dimensioned in two ways, either by calling out the length. I wonder if there is a standard or a common rule in which i can find what should be the chamfer size in a male (outer) and a female. In figure 1, a chamfer is shown on the edge of a hole. Threaded Hole Chamfer Size.

From www.depatie.com

Thread Identification & Types Guide Threaded Hole Chamfer Size Use a drill bit slightly smaller than the desired thread size. I do the math to figure out. I wonder if there is a standard or a common rule in which i can find what should be the chamfer size in a male (outer) and a female. How much bigger depends on the size of the tapped hole, i usually. Threaded Hole Chamfer Size.

From eziil.com

Chamfering 101 Types, Dimensions & Callout Threaded Hole Chamfer Size Use a drill bit slightly smaller than the desired thread size. I wonder if there is a standard or a common rule in which i can find what should be the chamfer size in a male (outer) and a female. In figure 1, a chamfer is shown on the edge of a hole feature. This is called the tap drill. Threaded Hole Chamfer Size.

From gbwonggbwong.wixsite.com

0090// Chamfer Dimensioning Threaded Hole Chamfer Size This is called the tap drill size. Since threading often produces starting burrs, these can be minimized by specifying a 45° countersink or chamfer which is.015″ minimum larger than the major diameter on internal threads (see figure 4) and.015″ minimum smaller than the minor diameter on external threads (see figure 3). Use a drill bit slightly smaller than the desired. Threaded Hole Chamfer Size.

From mungfali.com

Chamfer Size Chart Threaded Hole Chamfer Size In figure 1, a chamfer is shown on the edge of a hole feature. This is called the tap drill size. I wonder if there is a standard or a common rule in which i can find what should be the chamfer size in a male (outer) and a female. Chamfers can be dimensioned in two ways, either by calling. Threaded Hole Chamfer Size.

From www.youtube.com

Walter Xtratec D4580 chamfering tool drill and chamfer cost Threaded Hole Chamfer Size In figure 1, a chamfer is shown on the edge of a hole feature. I do the math to figure out. The od and depth of the chamfer sometimes are specified on the blueprint. I wonder if there is a standard or a common rule in which i can find what should be the chamfer size in a male (outer). Threaded Hole Chamfer Size.

From www.practicalmachinist.com

Chamfer tool tip diameter Threaded Hole Chamfer Size Since threading often produces starting burrs, these can be minimized by specifying a 45° countersink or chamfer which is.015″ minimum larger than the major diameter on internal threads (see figure 4) and.015″ minimum smaller than the minor diameter on external threads (see figure 3). In figure 1, a chamfer is shown on the edge of a hole feature. The od. Threaded Hole Chamfer Size.

From www.youtube.com

16 Placing hole notes and chamfer notes YouTube Threaded Hole Chamfer Size I wonder if there is a standard or a common rule in which i can find what should be the chamfer size in a male (outer) and a female. I do the math to figure out. How much bigger depends on the size of the tapped hole, i usually go around.01 for most holes we do. Part with a chamfered. Threaded Hole Chamfer Size.

From www.mcgill.ca

Dimensioning threaded fasteners Engineering Design McGill University Threaded Hole Chamfer Size In figure 1, a chamfer is shown on the edge of a hole feature. How much bigger depends on the size of the tapped hole, i usually go around.01 for most holes we do. Since threading often produces starting burrs, these can be minimized by specifying a 45° countersink or chamfer which is.015″ minimum larger than the major diameter on. Threaded Hole Chamfer Size.

From lectures-nd-notes.blogspot.com

Lecture Notes Engineering Drawing Part 4 Threaded Hole Chamfer Size How much bigger depends on the size of the tapped hole, i usually go around.01 for most holes we do. I do the math to figure out. Use a drill bit slightly smaller than the desired thread size. Since threading often produces starting burrs, these can be minimized by specifying a 45° countersink or chamfer which is.015″ minimum larger than. Threaded Hole Chamfer Size.

From www.numerade.com

SOLVED ProblemHOUSING DETAILSQUESTIONS1. Calculate dimensions from A Threaded Hole Chamfer Size I do the math to figure out. How much bigger depends on the size of the tapped hole, i usually go around.01 for most holes we do. Part with a chamfered edge. The od and depth of the chamfer sometimes are specified on the blueprint. Since threading often produces starting burrs, these can be minimized by specifying a 45° countersink. Threaded Hole Chamfer Size.

From nine9.jic-tools.com.tw

Combined Spotting and Chamfering 145 + 90 degree, dia 10, 16 and 25mm Threaded Hole Chamfer Size I do the math to figure out. I wonder if there is a standard or a common rule in which i can find what should be the chamfer size in a male (outer) and a female. In figure 1, a chamfer is shown on the edge of a hole feature. The od and depth of the chamfer sometimes are specified. Threaded Hole Chamfer Size.

From www.madearia.com

What are the different types of holes in engineering? Threaded Hole Chamfer Size I wonder if there is a standard or a common rule in which i can find what should be the chamfer size in a male (outer) and a female. How much bigger depends on the size of the tapped hole, i usually go around.01 for most holes we do. I do the math to figure out. Chamfers can be dimensioned. Threaded Hole Chamfer Size.

From www.pmpa.org

Designer’s Guide ThreadsThread Relief and Chamfers Precision Threaded Hole Chamfer Size I do the math to figure out. I wonder if there is a standard or a common rule in which i can find what should be the chamfer size in a male (outer) and a female. Chamfers can be dimensioned in two ways, either by calling out the length. Use a drill bit slightly smaller than the desired thread size.. Threaded Hole Chamfer Size.

From www.eng-tips.com

GD&T for Threaded holes Drafting Standards, GD&T & Tolerance Analysis Threaded Hole Chamfer Size This is called the tap drill size. I do the math to figure out. How much bigger depends on the size of the tapped hole, i usually go around.01 for most holes we do. I wonder if there is a standard or a common rule in which i can find what should be the chamfer size in a male (outer). Threaded Hole Chamfer Size.

From www.eng-tips.com

GD&T for Threaded holes Drafting Standards, GD&T & Tolerance Analysis Threaded Hole Chamfer Size This is called the tap drill size. The od and depth of the chamfer sometimes are specified on the blueprint. In figure 1, a chamfer is shown on the edge of a hole feature. Use a drill bit slightly smaller than the desired thread size. How much bigger depends on the size of the tapped hole, i usually go around.01. Threaded Hole Chamfer Size.

From www.woodsmith.com

The Versatile Chamfer Woodsmith Threaded Hole Chamfer Size Part with a chamfered edge. This is called the tap drill size. I do the math to figure out. I wonder if there is a standard or a common rule in which i can find what should be the chamfer size in a male (outer) and a female. Chamfers can be dimensioned in two ways, either by calling out the. Threaded Hole Chamfer Size.

From www.slideshare.net

Dimensioning standards Threaded Hole Chamfer Size How much bigger depends on the size of the tapped hole, i usually go around.01 for most holes we do. Since threading often produces starting burrs, these can be minimized by specifying a 45° countersink or chamfer which is.015″ minimum larger than the major diameter on internal threads (see figure 4) and.015″ minimum smaller than the minor diameter on external. Threaded Hole Chamfer Size.

From toolnotes.com

Thread Terminology ToolNotes Threaded Hole Chamfer Size I wonder if there is a standard or a common rule in which i can find what should be the chamfer size in a male (outer) and a female. The od and depth of the chamfer sometimes are specified on the blueprint. Use a drill bit slightly smaller than the desired thread size. This is called the tap drill size.. Threaded Hole Chamfer Size.

From mungfali.com

Chamfer Size Chart Threaded Hole Chamfer Size I wonder if there is a standard or a common rule in which i can find what should be the chamfer size in a male (outer) and a female. How much bigger depends on the size of the tapped hole, i usually go around.01 for most holes we do. Since threading often produces starting burrs, these can be minimized by. Threaded Hole Chamfer Size.

From grabcad.com

How to interpret the values of a chamfer and a thread in a blueprint Threaded Hole Chamfer Size The od and depth of the chamfer sometimes are specified on the blueprint. Since threading often produces starting burrs, these can be minimized by specifying a 45° countersink or chamfer which is.015″ minimum larger than the major diameter on internal threads (see figure 4) and.015″ minimum smaller than the minor diameter on external threads (see figure 3). Part with a. Threaded Hole Chamfer Size.