Eddy Current Testing Thickness . Eddy current techniques are used to measure the thickness of hot sheet, strip and foil in rolling mills, and to measure the amount of metal. Eddy current array (eca) technology offers major advantages over conventional eddy current inspection methods when it comes to corrosion. Eddy current testing (ect) is an ndt method that employs electromagnetic induction to detect flaws, measure material thickness, and assess the properties of conductive. Understanding the ect process can help you determine if it’s the appropriate ndt method for your inspection needs. Thicker materials may require an advanced probe with a deep penetration feature. Difficult to detect flaws may be parallel. The thickness of the metal workpiece can affect the test results.

from www.semanticscholar.org

Understanding the ect process can help you determine if it’s the appropriate ndt method for your inspection needs. Difficult to detect flaws may be parallel. Thicker materials may require an advanced probe with a deep penetration feature. The thickness of the metal workpiece can affect the test results. Eddy current techniques are used to measure the thickness of hot sheet, strip and foil in rolling mills, and to measure the amount of metal. Eddy current testing (ect) is an ndt method that employs electromagnetic induction to detect flaws, measure material thickness, and assess the properties of conductive. Eddy current array (eca) technology offers major advantages over conventional eddy current inspection methods when it comes to corrosion.

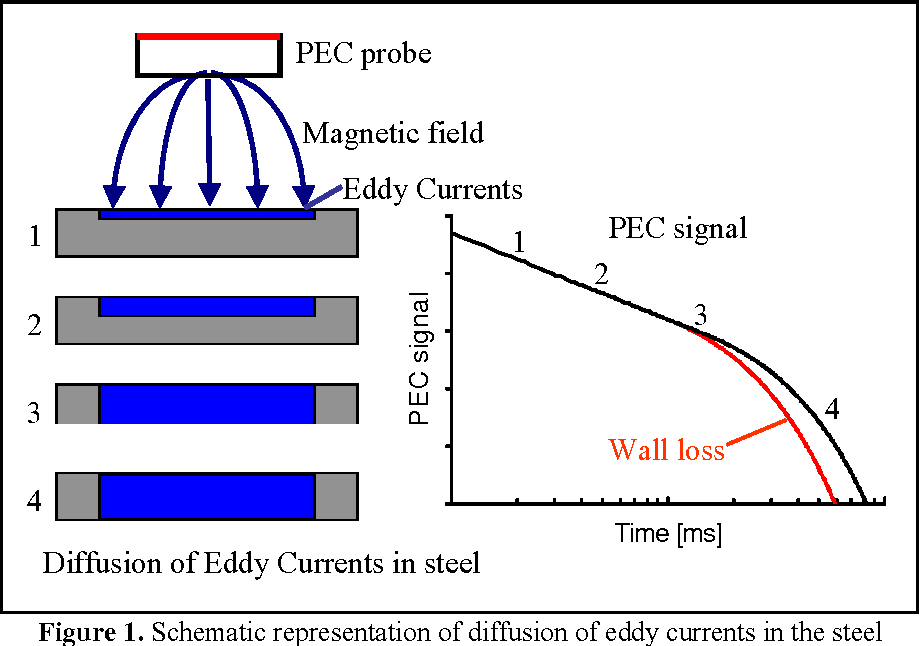

Figure 1 from Pulsed Eddy Current Corrosion Monitoring in Refineries

Eddy Current Testing Thickness Eddy current techniques are used to measure the thickness of hot sheet, strip and foil in rolling mills, and to measure the amount of metal. The thickness of the metal workpiece can affect the test results. Thicker materials may require an advanced probe with a deep penetration feature. Understanding the ect process can help you determine if it’s the appropriate ndt method for your inspection needs. Eddy current testing (ect) is an ndt method that employs electromagnetic induction to detect flaws, measure material thickness, and assess the properties of conductive. Difficult to detect flaws may be parallel. Eddy current techniques are used to measure the thickness of hot sheet, strip and foil in rolling mills, and to measure the amount of metal. Eddy current array (eca) technology offers major advantages over conventional eddy current inspection methods when it comes to corrosion.

From www.suragus.com

SURAGUS Technology of Eddy Current Testing Eddy Current Testing Thickness Eddy current testing (ect) is an ndt method that employs electromagnetic induction to detect flaws, measure material thickness, and assess the properties of conductive. Difficult to detect flaws may be parallel. Eddy current techniques are used to measure the thickness of hot sheet, strip and foil in rolling mills, and to measure the amount of metal. Eddy current array (eca). Eddy Current Testing Thickness.

From www.aliexpress.com

CM 8823 Portable Eddy Current N Probe Coating Thickness Gauge Meter Eddy Current Testing Thickness Eddy current techniques are used to measure the thickness of hot sheet, strip and foil in rolling mills, and to measure the amount of metal. Thicker materials may require an advanced probe with a deep penetration feature. Eddy current testing (ect) is an ndt method that employs electromagnetic induction to detect flaws, measure material thickness, and assess the properties of. Eddy Current Testing Thickness.

From www.wermac.org

Non Destructive Testing Eddy Current testing, (Wirbelstrom) Eddy Current Testing Thickness Thicker materials may require an advanced probe with a deep penetration feature. Eddy current techniques are used to measure the thickness of hot sheet, strip and foil in rolling mills, and to measure the amount of metal. Eddy current testing (ect) is an ndt method that employs electromagnetic induction to detect flaws, measure material thickness, and assess the properties of. Eddy Current Testing Thickness.

From www.researchgate.net

Eddy Current Probe geometry. The coil windings (blue) together with the Eddy Current Testing Thickness The thickness of the metal workpiece can affect the test results. Eddy current testing (ect) is an ndt method that employs electromagnetic induction to detect flaws, measure material thickness, and assess the properties of conductive. Understanding the ect process can help you determine if it’s the appropriate ndt method for your inspection needs. Eddy current techniques are used to measure. Eddy Current Testing Thickness.

From www.huatecgroup.com

Portable Eddy Current Micro Coating Thickness Tester Gauge Bluetooth Eddy Current Testing Thickness Eddy current array (eca) technology offers major advantages over conventional eddy current inspection methods when it comes to corrosion. Eddy current testing (ect) is an ndt method that employs electromagnetic induction to detect flaws, measure material thickness, and assess the properties of conductive. Eddy current techniques are used to measure the thickness of hot sheet, strip and foil in rolling. Eddy Current Testing Thickness.

From www.atozndt.com

Eddy Current Testing Course A TO Z NDT SOLUTIONS PVT LTD Eddy Current Testing Thickness The thickness of the metal workpiece can affect the test results. Difficult to detect flaws may be parallel. Thicker materials may require an advanced probe with a deep penetration feature. Eddy current array (eca) technology offers major advantages over conventional eddy current inspection methods when it comes to corrosion. Understanding the ect process can help you determine if it’s the. Eddy Current Testing Thickness.

From ndtblog-us.fujifilm.com

Complete Guide to Eddy Current Testing Fujifilm NDT Eddy Current Testing Thickness Eddy current array (eca) technology offers major advantages over conventional eddy current inspection methods when it comes to corrosion. Understanding the ect process can help you determine if it’s the appropriate ndt method for your inspection needs. Difficult to detect flaws may be parallel. The thickness of the metal workpiece can affect the test results. Eddy current techniques are used. Eddy Current Testing Thickness.

From www.innerspec.com

Eddy Current Technology Eddy Current Testing Thickness Thicker materials may require an advanced probe with a deep penetration feature. The thickness of the metal workpiece can affect the test results. Eddy current testing (ect) is an ndt method that employs electromagnetic induction to detect flaws, measure material thickness, and assess the properties of conductive. Difficult to detect flaws may be parallel. Understanding the ect process can help. Eddy Current Testing Thickness.

From www.mdpi.com

Metals Free FullText Relative Density Measurement of PBF Eddy Current Testing Thickness Eddy current techniques are used to measure the thickness of hot sheet, strip and foil in rolling mills, and to measure the amount of metal. Thicker materials may require an advanced probe with a deep penetration feature. Difficult to detect flaws may be parallel. Eddy current testing (ect) is an ndt method that employs electromagnetic induction to detect flaws, measure. Eddy Current Testing Thickness.

From oktanta-ndt.ru

Eddy current nondestructive testing Oktanta NDT Eddy Current Testing Thickness Eddy current array (eca) technology offers major advantages over conventional eddy current inspection methods when it comes to corrosion. Difficult to detect flaws may be parallel. Understanding the ect process can help you determine if it’s the appropriate ndt method for your inspection needs. Eddy current testing (ect) is an ndt method that employs electromagnetic induction to detect flaws, measure. Eddy Current Testing Thickness.

From www.slideshare.net

Introduction_to_NDT Eddy Current Testing Thickness Understanding the ect process can help you determine if it’s the appropriate ndt method for your inspection needs. The thickness of the metal workpiece can affect the test results. Eddy current techniques are used to measure the thickness of hot sheet, strip and foil in rolling mills, and to measure the amount of metal. Difficult to detect flaws may be. Eddy Current Testing Thickness.

From www.youtube.com

Eddy current test of heat exchanger tube. Thickness measurements of Eddy Current Testing Thickness Eddy current array (eca) technology offers major advantages over conventional eddy current inspection methods when it comes to corrosion. Understanding the ect process can help you determine if it’s the appropriate ndt method for your inspection needs. Eddy current techniques are used to measure the thickness of hot sheet, strip and foil in rolling mills, and to measure the amount. Eddy Current Testing Thickness.

From www.qualitymag.com

What Is Eddy Current Testing? 20161101 Quality Magazine Eddy Current Testing Thickness Eddy current techniques are used to measure the thickness of hot sheet, strip and foil in rolling mills, and to measure the amount of metal. Eddy current array (eca) technology offers major advantages over conventional eddy current inspection methods when it comes to corrosion. Thicker materials may require an advanced probe with a deep penetration feature. The thickness of the. Eddy Current Testing Thickness.

From eurotubi.it

Eddy Current Testing of Tubes Eurotubi Eddy Current Testing Thickness Eddy current testing (ect) is an ndt method that employs electromagnetic induction to detect flaws, measure material thickness, and assess the properties of conductive. Eddy current array (eca) technology offers major advantages over conventional eddy current inspection methods when it comes to corrosion. Eddy current techniques are used to measure the thickness of hot sheet, strip and foil in rolling. Eddy Current Testing Thickness.

From fyodiqroi.blob.core.windows.net

Eddy Current Testing For Thickness Measurement at Jeremy Donahue blog Eddy Current Testing Thickness Eddy current array (eca) technology offers major advantages over conventional eddy current inspection methods when it comes to corrosion. Eddy current techniques are used to measure the thickness of hot sheet, strip and foil in rolling mills, and to measure the amount of metal. Eddy current testing (ect) is an ndt method that employs electromagnetic induction to detect flaws, measure. Eddy Current Testing Thickness.

From www.suragus.com

SURAGUS Technology of Eddy Current Testing Eddy Current Testing Thickness Eddy current testing (ect) is an ndt method that employs electromagnetic induction to detect flaws, measure material thickness, and assess the properties of conductive. Understanding the ect process can help you determine if it’s the appropriate ndt method for your inspection needs. Difficult to detect flaws may be parallel. The thickness of the metal workpiece can affect the test results.. Eddy Current Testing Thickness.

From www.sumico.com.pk

Eddy Current Testing Service Eddy Current Testing Thickness The thickness of the metal workpiece can affect the test results. Difficult to detect flaws may be parallel. Understanding the ect process can help you determine if it’s the appropriate ndt method for your inspection needs. Eddy current techniques are used to measure the thickness of hot sheet, strip and foil in rolling mills, and to measure the amount of. Eddy Current Testing Thickness.

From www.semanticscholar.org

Figure 1 from Pulsed Eddy Current Corrosion Monitoring in Refineries Eddy Current Testing Thickness Understanding the ect process can help you determine if it’s the appropriate ndt method for your inspection needs. Eddy current array (eca) technology offers major advantages over conventional eddy current inspection methods when it comes to corrosion. Eddy current techniques are used to measure the thickness of hot sheet, strip and foil in rolling mills, and to measure the amount. Eddy Current Testing Thickness.

From www.tec-science.com

Eddy current testing (ECT) tecscience Eddy Current Testing Thickness Thicker materials may require an advanced probe with a deep penetration feature. The thickness of the metal workpiece can affect the test results. Difficult to detect flaws may be parallel. Eddy current array (eca) technology offers major advantages over conventional eddy current inspection methods when it comes to corrosion. Understanding the ect process can help you determine if it’s the. Eddy Current Testing Thickness.

From www.sciensoria.fr

Advantages of the eddy current technique for thickness measurement Eddy Current Testing Thickness Understanding the ect process can help you determine if it’s the appropriate ndt method for your inspection needs. Difficult to detect flaws may be parallel. Eddy current techniques are used to measure the thickness of hot sheet, strip and foil in rolling mills, and to measure the amount of metal. Thicker materials may require an advanced probe with a deep. Eddy Current Testing Thickness.

From www.elcometer.com

Electronic Coating Thickness Gauges Eddy Current Testing Thickness Eddy current techniques are used to measure the thickness of hot sheet, strip and foil in rolling mills, and to measure the amount of metal. The thickness of the metal workpiece can affect the test results. Difficult to detect flaws may be parallel. Understanding the ect process can help you determine if it’s the appropriate ndt method for your inspection. Eddy Current Testing Thickness.

From www.tmteck-ndt.com

Digital Portable Eddy Current Flaw Detector Filter Coating Thickness Eddy Current Testing Thickness Eddy current testing (ect) is an ndt method that employs electromagnetic induction to detect flaws, measure material thickness, and assess the properties of conductive. The thickness of the metal workpiece can affect the test results. Thicker materials may require an advanced probe with a deep penetration feature. Eddy current techniques are used to measure the thickness of hot sheet, strip. Eddy Current Testing Thickness.

From www.twi-global.com

Eddy Current Testing A Definitive Guide (Includes Eddy Current Array Eddy Current Testing Thickness Difficult to detect flaws may be parallel. The thickness of the metal workpiece can affect the test results. Eddy current testing (ect) is an ndt method that employs electromagnetic induction to detect flaws, measure material thickness, and assess the properties of conductive. Eddy current techniques are used to measure the thickness of hot sheet, strip and foil in rolling mills,. Eddy Current Testing Thickness.

From qclabs.net

Eddy Current Testing QC Laboratories, Inc. Eddy Current Testing Thickness Eddy current testing (ect) is an ndt method that employs electromagnetic induction to detect flaws, measure material thickness, and assess the properties of conductive. Understanding the ect process can help you determine if it’s the appropriate ndt method for your inspection needs. Difficult to detect flaws may be parallel. Eddy current array (eca) technology offers major advantages over conventional eddy. Eddy Current Testing Thickness.

From www.mdpi.com

Sensors Free FullText A Study of Quantifying Thickness of Eddy Current Testing Thickness Eddy current techniques are used to measure the thickness of hot sheet, strip and foil in rolling mills, and to measure the amount of metal. Eddy current testing (ect) is an ndt method that employs electromagnetic induction to detect flaws, measure material thickness, and assess the properties of conductive. Understanding the ect process can help you determine if it’s the. Eddy Current Testing Thickness.

From www.huatecgroup.com

Eddy Current Good Stability 0.1um / 1um Coating Thickness Gauge TG8830N Eddy Current Testing Thickness Eddy current array (eca) technology offers major advantages over conventional eddy current inspection methods when it comes to corrosion. Eddy current testing (ect) is an ndt method that employs electromagnetic induction to detect flaws, measure material thickness, and assess the properties of conductive. Thicker materials may require an advanced probe with a deep penetration feature. Difficult to detect flaws may. Eddy Current Testing Thickness.

From www.ndtcorner.com

NDT Corner Eddy Current Testing Thickness Eddy current techniques are used to measure the thickness of hot sheet, strip and foil in rolling mills, and to measure the amount of metal. Thicker materials may require an advanced probe with a deep penetration feature. Understanding the ect process can help you determine if it’s the appropriate ndt method for your inspection needs. Eddy current array (eca) technology. Eddy Current Testing Thickness.

From tiat.nl

Eddy Current Testing Tiat Europe B.V. Eddy Current Testing Thickness Understanding the ect process can help you determine if it’s the appropriate ndt method for your inspection needs. Difficult to detect flaws may be parallel. The thickness of the metal workpiece can affect the test results. Thicker materials may require an advanced probe with a deep penetration feature. Eddy current testing (ect) is an ndt method that employs electromagnetic induction. Eddy Current Testing Thickness.

From www.enggstudy.com

Eddy current testing Principle, Applications, Advantages, Limitations Eddy Current Testing Thickness The thickness of the metal workpiece can affect the test results. Eddy current techniques are used to measure the thickness of hot sheet, strip and foil in rolling mills, and to measure the amount of metal. Thicker materials may require an advanced probe with a deep penetration feature. Understanding the ect process can help you determine if it’s the appropriate. Eddy Current Testing Thickness.

From www.eddyfi.com

Pulsed Eddy Current (PEC) Eddy Current Testing Thickness Eddy current testing (ect) is an ndt method that employs electromagnetic induction to detect flaws, measure material thickness, and assess the properties of conductive. The thickness of the metal workpiece can affect the test results. Understanding the ect process can help you determine if it’s the appropriate ndt method for your inspection needs. Eddy current techniques are used to measure. Eddy Current Testing Thickness.

From fyodiqroi.blob.core.windows.net

Eddy Current Testing For Thickness Measurement at Jeremy Donahue blog Eddy Current Testing Thickness Eddy current techniques are used to measure the thickness of hot sheet, strip and foil in rolling mills, and to measure the amount of metal. Eddy current array (eca) technology offers major advantages over conventional eddy current inspection methods when it comes to corrosion. The thickness of the metal workpiece can affect the test results. Difficult to detect flaws may. Eddy Current Testing Thickness.

From www.aliexpress.com

ED400 Eddy current testing equipment with aluminum coating thickness Eddy Current Testing Thickness Eddy current techniques are used to measure the thickness of hot sheet, strip and foil in rolling mills, and to measure the amount of metal. Eddy current testing (ect) is an ndt method that employs electromagnetic induction to detect flaws, measure material thickness, and assess the properties of conductive. Understanding the ect process can help you determine if it’s the. Eddy Current Testing Thickness.

From www.asseteng.com.au

Eddy Current Testing (ECT) Explained » NDT Method AME Eddy Current Testing Thickness Difficult to detect flaws may be parallel. The thickness of the metal workpiece can affect the test results. Eddy current techniques are used to measure the thickness of hot sheet, strip and foil in rolling mills, and to measure the amount of metal. Understanding the ect process can help you determine if it’s the appropriate ndt method for your inspection. Eddy Current Testing Thickness.

From lmats.com.au

Pulsed EddyCurrent (PEC) LMATS LMATS Eddy Current Testing Thickness Difficult to detect flaws may be parallel. Eddy current techniques are used to measure the thickness of hot sheet, strip and foil in rolling mills, and to measure the amount of metal. Eddy current array (eca) technology offers major advantages over conventional eddy current inspection methods when it comes to corrosion. Thicker materials may require an advanced probe with a. Eddy Current Testing Thickness.

From www.theseverngroup.com

Eddy Current Testing 101 The Severn Group Eddy Current Testing Thickness Difficult to detect flaws may be parallel. Eddy current techniques are used to measure the thickness of hot sheet, strip and foil in rolling mills, and to measure the amount of metal. The thickness of the metal workpiece can affect the test results. Eddy current array (eca) technology offers major advantages over conventional eddy current inspection methods when it comes. Eddy Current Testing Thickness.