Change Gear Formula . in the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. P= pitch of teeth in inches. Works for all mini lathes and hitorque bench lathes. x= 20,000 p.f. the gear ratio helps us determine the number of teeth each gear needs to produce a desired output speed/angular velocity, or. F= face width of teeth in inches. Relationship between the involute elements determination of base tooth. Where x= breaking load of gear tooth in pounds. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. our change gear calculator for hobbers, shapers, and grinders, takes the math out of equation and allows you to get a range of solutions from just the number of teeth and. this calculator determines the correct change gears for any thread pitch. With time and experience of.

from jwillmer.de

40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. the gear ratio helps us determine the number of teeth each gear needs to produce a desired output speed/angular velocity, or. F= face width of teeth in inches. this calculator determines the correct change gears for any thread pitch. our change gear calculator for hobbers, shapers, and grinders, takes the math out of equation and allows you to get a range of solutions from just the number of teeth and. P= pitch of teeth in inches. Where x= breaking load of gear tooth in pounds. Relationship between the involute elements determination of base tooth. x= 20,000 p.f. in the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and.

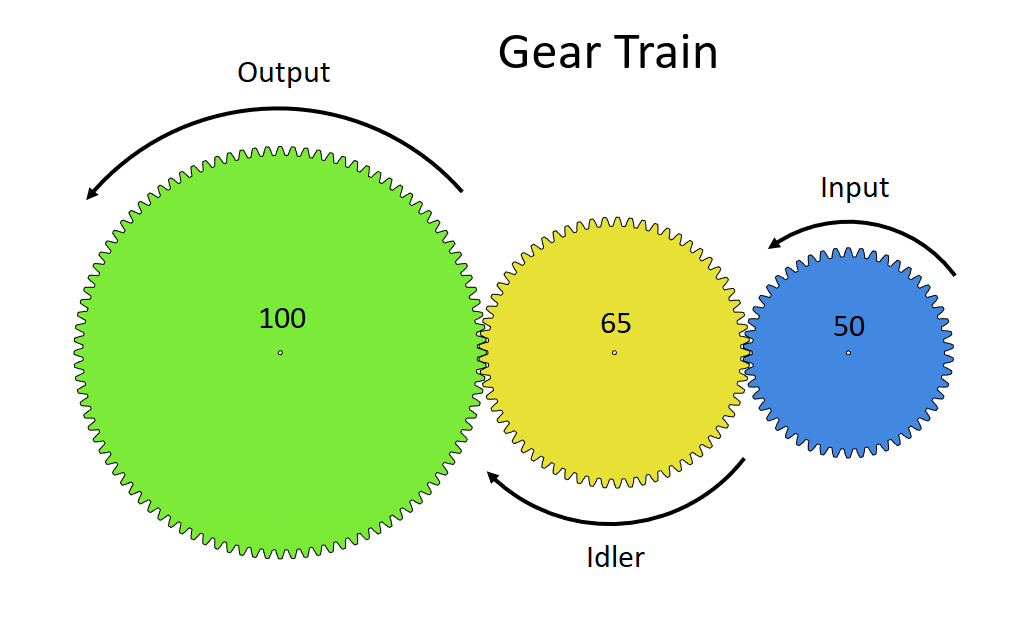

Gear ratio basics

Change Gear Formula P= pitch of teeth in inches. Where x= breaking load of gear tooth in pounds. our change gear calculator for hobbers, shapers, and grinders, takes the math out of equation and allows you to get a range of solutions from just the number of teeth and. Works for all mini lathes and hitorque bench lathes. in the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. With time and experience of. F= face width of teeth in inches. Relationship between the involute elements determination of base tooth. this calculator determines the correct change gears for any thread pitch. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. P= pitch of teeth in inches. x= 20,000 p.f. the gear ratio helps us determine the number of teeth each gear needs to produce a desired output speed/angular velocity, or.

From www.meshingwithgears.us

FAQ about gear cutting, gear software and gear design Change Gear Formula this calculator determines the correct change gears for any thread pitch. With time and experience of. our change gear calculator for hobbers, shapers, and grinders, takes the math out of equation and allows you to get a range of solutions from just the number of teeth and. the gear ratio helps us determine the number of teeth. Change Gear Formula.

From learndriving.tips

Sequential Gear Changing Explained » Learn Driving Tips Change Gear Formula Works for all mini lathes and hitorque bench lathes. Relationship between the involute elements determination of base tooth. in the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. x= 20,000 p.f. this calculator determines the correct change gears for any thread pitch. Where x= breaking load. Change Gear Formula.

From jwillmer.de

Gear ratio basics Change Gear Formula P= pitch of teeth in inches. in the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. F= face width of teeth in inches. Where x= breaking load of gear tooth in pounds. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data.. Change Gear Formula.

From www.youtube.com

THREAD CUTTING GEAR CALCULATION FORMULA ON LATHE M/C IN हिंदी YouTube Change Gear Formula the gear ratio helps us determine the number of teeth each gear needs to produce a desired output speed/angular velocity, or. P= pitch of teeth in inches. Works for all mini lathes and hitorque bench lathes. our change gear calculator for hobbers, shapers, and grinders, takes the math out of equation and allows you to get a range. Change Gear Formula.

From www.youtube.com

Gears and Gear Ratios YouTube Change Gear Formula the gear ratio helps us determine the number of teeth each gear needs to produce a desired output speed/angular velocity, or. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Where x= breaking load of gear tooth in pounds. Works for all mini lathes and hitorque bench lathes. in the previous. Change Gear Formula.

From www.youtube.com

The Formula 1 Car with INFINITE GEARS The Blueprint YouTube Change Gear Formula Relationship between the involute elements determination of base tooth. the gear ratio helps us determine the number of teeth each gear needs to produce a desired output speed/angular velocity, or. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. in the previous pages, we introduced the basics of gears, including 'module',. Change Gear Formula.

From www.pinterest.com.mx

How to Determine Gear Ratio Gears, Mechanical engineering design Change Gear Formula 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Relationship between the involute elements determination of base tooth. this calculator determines the correct change gears for any thread pitch. the gear ratio helps us determine the number of teeth each gear needs to produce a desired output speed/angular velocity, or. . Change Gear Formula.

From www.scribd.com

GEARS FORMULAS PDF Gear Tools Change Gear Formula this calculator determines the correct change gears for any thread pitch. the gear ratio helps us determine the number of teeth each gear needs to produce a desired output speed/angular velocity, or. P= pitch of teeth in inches. Where x= breaking load of gear tooth in pounds. F= face width of teeth in inches. x= 20,000 p.f.. Change Gear Formula.

From www.glue-it.com

Change Gears and Pitch Change Gear Formula the gear ratio helps us determine the number of teeth each gear needs to produce a desired output speed/angular velocity, or. in the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. Relationship between the involute elements determination of base tooth. 40 rows spur gear design formula. Change Gear Formula.

From www.meshingwithgears.us

FAQ about gear cutting, gear software and gear design Change Gear Formula F= face width of teeth in inches. Where x= breaking load of gear tooth in pounds. Relationship between the involute elements determination of base tooth. x= 20,000 p.f. Works for all mini lathes and hitorque bench lathes. in the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and.. Change Gear Formula.

From khkgears.net

Gear Forces KHK Gears Change Gear Formula F= face width of teeth in inches. Where x= breaking load of gear tooth in pounds. P= pitch of teeth in inches. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Works for all mini lathes and hitorque bench lathes. the gear ratio helps us determine the number of teeth each gear. Change Gear Formula.

From www.ebay.com

10 Spline Quick Change Gear Chart eBay Change Gear Formula 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. F= face width of teeth in inches. With time and experience of. this calculator determines the correct change gears for any thread pitch. Relationship between the involute elements determination of base tooth. P= pitch of teeth in inches. x= 20,000 p.f. . Change Gear Formula.

From learndriving.tips

What Speed Should You Change Gears? » Learn Driving Tips Change Gear Formula P= pitch of teeth in inches. the gear ratio helps us determine the number of teeth each gear needs to produce a desired output speed/angular velocity, or. With time and experience of. Relationship between the involute elements determination of base tooth. F= face width of teeth in inches. Where x= breaking load of gear tooth in pounds. 40. Change Gear Formula.

From lathe.com

Standard Change Gears Change Gear Formula 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Works for all mini lathes and hitorque bench lathes. With time and experience of. the gear ratio helps us determine the number of teeth each gear needs to produce a desired output speed/angular velocity, or. in the previous pages, we introduced the. Change Gear Formula.

From jcl-tech.com

JCL Gear geometry and control dimensions Change Gear Formula the gear ratio helps us determine the number of teeth each gear needs to produce a desired output speed/angular velocity, or. P= pitch of teeth in inches. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Relationship between the involute elements determination of base tooth. Works for all mini lathes and hitorque. Change Gear Formula.

From www.mymathtables.com

Simple Machines Engineering Formulas Change Gear Formula F= face width of teeth in inches. our change gear calculator for hobbers, shapers, and grinders, takes the math out of equation and allows you to get a range of solutions from just the number of teeth and. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. x= 20,000 p.f. Where. Change Gear Formula.

From practicalmotoring.com.au

How to change gears the right way (part 1) Practical Motoring Change Gear Formula our change gear calculator for hobbers, shapers, and grinders, takes the math out of equation and allows you to get a range of solutions from just the number of teeth and. Works for all mini lathes and hitorque bench lathes. the gear ratio helps us determine the number of teeth each gear needs to produce a desired output. Change Gear Formula.

From www.wikihow.it

Come Determinare il Rapporto di Trasmissione wikiHow Change Gear Formula With time and experience of. our change gear calculator for hobbers, shapers, and grinders, takes the math out of equation and allows you to get a range of solutions from just the number of teeth and. this calculator determines the correct change gears for any thread pitch. 40 rows spur gear design formula for geometry, pitch, tooth. Change Gear Formula.

From www.martinsengineering.com

Gear Formula Information » Martins Corrugator Engineering Change Gear Formula 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. F= face width of teeth in inches. in the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. this calculator determines the correct change gears for any thread pitch. Relationship between the. Change Gear Formula.

From www.wikihow.com

4 Easy Ways to Determine Gear Ratio (with Pictures) Change Gear Formula With time and experience of. x= 20,000 p.f. in the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. P= pitch of teeth in inches. F= face width of teeth in inches. Relationship between the involute elements determination of base tooth. 40 rows spur gear design formula. Change Gear Formula.

From www.scribd.com

Gear Formulas For Involute Gears PDF Change Gear Formula F= face width of teeth in inches. P= pitch of teeth in inches. Works for all mini lathes and hitorque bench lathes. this calculator determines the correct change gears for any thread pitch. in the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. With time and experience. Change Gear Formula.

From droiddevil.com

How to know when to change gears Change Gear Formula 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. in the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. P= pitch of teeth in inches. our change gear calculator for hobbers, shapers, and grinders, takes the math out of equation. Change Gear Formula.

From www.youtube.com

Tutorial How to Derive the Formula for the Mechanism Gear Change Gear Formula 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. x= 20,000 p.f. this calculator determines the correct change gears for any thread pitch. Works for all mini lathes and hitorque bench lathes. P= pitch of teeth in inches. in the previous pages, we introduced the basics of gears, including 'module',. Change Gear Formula.

From practicalmotoring.com.au

How to change gears the right way (part 2) Practical Motoring Change Gear Formula With time and experience of. Relationship between the involute elements determination of base tooth. Works for all mini lathes and hitorque bench lathes. x= 20,000 p.f. Where x= breaking load of gear tooth in pounds. the gear ratio helps us determine the number of teeth each gear needs to produce a desired output speed/angular velocity, or. F= face. Change Gear Formula.

From www.shutterstock.com

Gear ratio vector illustration. Labeled physical power formula Change Gear Formula Works for all mini lathes and hitorque bench lathes. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. x= 20,000 p.f. P= pitch of teeth in inches. this calculator determines the correct change gears for any thread pitch. Where x= breaking load of gear tooth in pounds. Relationship between the involute. Change Gear Formula.

From u.osu.edu

Changing Direction With Gears Change Gear Formula F= face width of teeth in inches. Where x= breaking load of gear tooth in pounds. With time and experience of. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. our change gear calculator for hobbers, shapers, and grinders, takes the math out of equation and allows you to get a range. Change Gear Formula.

From www.youtube.com

Spur gear calculation, Design Details Spur Gear Formula spur gear Change Gear Formula our change gear calculator for hobbers, shapers, and grinders, takes the math out of equation and allows you to get a range of solutions from just the number of teeth and. the gear ratio helps us determine the number of teeth each gear needs to produce a desired output speed/angular velocity, or. Relationship between the involute elements determination. Change Gear Formula.

From www.youtube.com

How and When to Change Gears Gear Changing Driving Tips YouTube Change Gear Formula With time and experience of. P= pitch of teeth in inches. Relationship between the involute elements determination of base tooth. our change gear calculator for hobbers, shapers, and grinders, takes the math out of equation and allows you to get a range of solutions from just the number of teeth and. 40 rows spur gear design formula for. Change Gear Formula.

From www.youtube.com

Gear transmission Calculation of moment of inertia YouTube Change Gear Formula in the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. F= face width of teeth in inches. x= 20,000 p.f. this calculator determines the correct change gears for any thread pitch. our change gear calculator for hobbers, shapers, and grinders, takes the math out of. Change Gear Formula.

From www.youtube.com

Gear velocity ratio for Simple and Compound Gear train. Reduction or Change Gear Formula Works for all mini lathes and hitorque bench lathes. the gear ratio helps us determine the number of teeth each gear needs to produce a desired output speed/angular velocity, or. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. F= face width of teeth in inches. x= 20,000 p.f. Where x=. Change Gear Formula.

From www.scribd.com

Formulas for Gear Calculation Internal Gears Helix Gear Change Gear Formula Works for all mini lathes and hitorque bench lathes. this calculator determines the correct change gears for any thread pitch. Where x= breaking load of gear tooth in pounds. our change gear calculator for hobbers, shapers, and grinders, takes the math out of equation and allows you to get a range of solutions from just the number of. Change Gear Formula.

From www.youtube.com

CALCULATION RACK AND SPUR GEAR EXCEL FORMULA YouTube Change Gear Formula With time and experience of. in the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. P= pitch of teeth in inches. F= face width of teeth in inches. x= 20,000 p.f. the gear ratio helps us determine the number of teeth each gear needs to produce. Change Gear Formula.

From jj-motorsports.com

Understanding Winter's Quick Change Gear Chart J J Motorsports Change Gear Formula Relationship between the involute elements determination of base tooth. the gear ratio helps us determine the number of teeth each gear needs to produce a desired output speed/angular velocity, or. P= pitch of teeth in inches. Where x= breaking load of gear tooth in pounds. this calculator determines the correct change gears for any thread pitch. in. Change Gear Formula.

From www.youtube.com

How F1 Drivers CHANGE Gears? YouTube Change Gear Formula our change gear calculator for hobbers, shapers, and grinders, takes the math out of equation and allows you to get a range of solutions from just the number of teeth and. With time and experience of. x= 20,000 p.f. Where x= breaking load of gear tooth in pounds. 40 rows spur gear design formula for geometry, pitch,. Change Gear Formula.

From www.lathe.com

Standard Change Gears Change Gear Formula our change gear calculator for hobbers, shapers, and grinders, takes the math out of equation and allows you to get a range of solutions from just the number of teeth and. P= pitch of teeth in inches. in the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and.. Change Gear Formula.