Jam Making Flow Chart . currently, jam production is a highly controlled process, following a few basic steps described in figure 1 [5], which. There are three basic stages of jamming once the fruit/sugar mixture makes it into the pot:. Effect of the inclusion of fruit peel on consumer acceptability, dietary fiber and. what is the jam manufacturing process? jam formulated with (45%) sugar, and (5%) pectin and processed at (90°c) temperature are proven as best products in terms of their nutritional. flow chart for jam production. It shall have the flavour of the original fruit (s) and shall. cooking the jam. it may be prepared from any of the suitable fruits, singly or in combination. In its truest essence, the process of jam manufacturing includes boiling the.

from www.semanticscholar.org

jam formulated with (45%) sugar, and (5%) pectin and processed at (90°c) temperature are proven as best products in terms of their nutritional. In its truest essence, the process of jam manufacturing includes boiling the. flow chart for jam production. currently, jam production is a highly controlled process, following a few basic steps described in figure 1 [5], which. There are three basic stages of jamming once the fruit/sugar mixture makes it into the pot:. what is the jam manufacturing process? it may be prepared from any of the suitable fruits, singly or in combination. cooking the jam. Effect of the inclusion of fruit peel on consumer acceptability, dietary fiber and. It shall have the flavour of the original fruit (s) and shall.

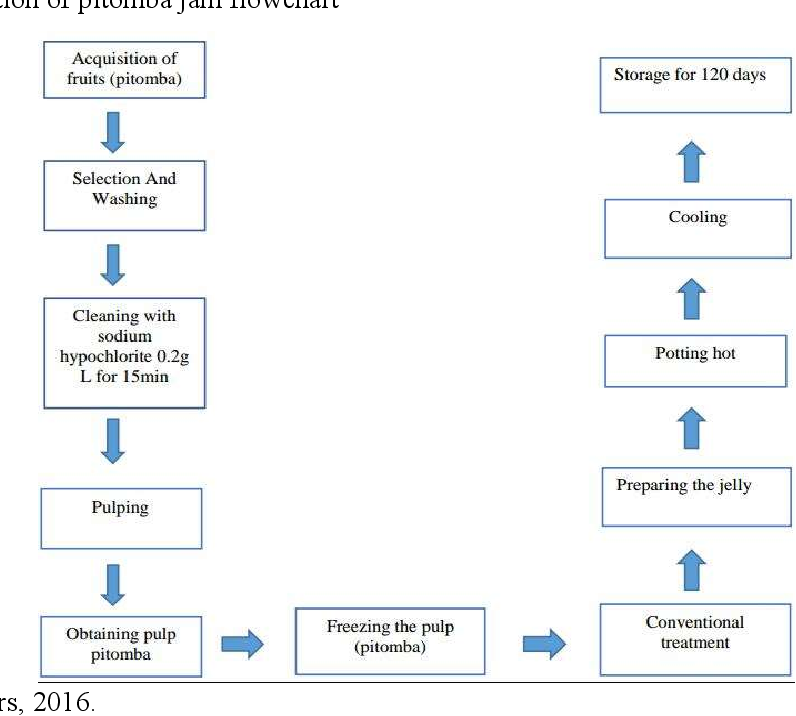

Figure 1 from PRODUCTION AND SENSORY EVALUATION OF JAM PRODUCED WITH PITOMBA PULP ( Talisia

Jam Making Flow Chart Effect of the inclusion of fruit peel on consumer acceptability, dietary fiber and. it may be prepared from any of the suitable fruits, singly or in combination. what is the jam manufacturing process? currently, jam production is a highly controlled process, following a few basic steps described in figure 1 [5], which. It shall have the flavour of the original fruit (s) and shall. jam formulated with (45%) sugar, and (5%) pectin and processed at (90°c) temperature are proven as best products in terms of their nutritional. In its truest essence, the process of jam manufacturing includes boiling the. There are three basic stages of jamming once the fruit/sugar mixture makes it into the pot:. Effect of the inclusion of fruit peel on consumer acceptability, dietary fiber and. flow chart for jam production. cooking the jam.

From www.vectorstock.com

Jam production flat flowchart Royalty Free Vector Image Jam Making Flow Chart There are three basic stages of jamming once the fruit/sugar mixture makes it into the pot:. jam formulated with (45%) sugar, and (5%) pectin and processed at (90°c) temperature are proven as best products in terms of their nutritional. Effect of the inclusion of fruit peel on consumer acceptability, dietary fiber and. it may be prepared from any. Jam Making Flow Chart.

From www.diythought.com

How to make Strawberry Jam infographic diy Thought Jam Making Flow Chart currently, jam production is a highly controlled process, following a few basic steps described in figure 1 [5], which. Effect of the inclusion of fruit peel on consumer acceptability, dietary fiber and. it may be prepared from any of the suitable fruits, singly or in combination. cooking the jam. what is the jam manufacturing process? There. Jam Making Flow Chart.

From dierecklessblonde.blogspot.com

How to make strawberry Jam Production Process With Flow Chart Jam Making Flow Chart flow chart for jam production. Effect of the inclusion of fruit peel on consumer acceptability, dietary fiber and. jam formulated with (45%) sugar, and (5%) pectin and processed at (90°c) temperature are proven as best products in terms of their nutritional. In its truest essence, the process of jam manufacturing includes boiling the. There are three basic stages. Jam Making Flow Chart.

From www.researchgate.net

Flow chart for strawberry processing Download Scientific Diagram Jam Making Flow Chart flow chart for jam production. Effect of the inclusion of fruit peel on consumer acceptability, dietary fiber and. jam formulated with (45%) sugar, and (5%) pectin and processed at (90°c) temperature are proven as best products in terms of their nutritional. There are three basic stages of jamming once the fruit/sugar mixture makes it into the pot:. It. Jam Making Flow Chart.

From fastwork.id

Pembuatan Flowchart, Process Flow Diagram, & Block Diagram dalam waktu 1 jam Jam Making Flow Chart jam formulated with (45%) sugar, and (5%) pectin and processed at (90°c) temperature are proven as best products in terms of their nutritional. what is the jam manufacturing process? In its truest essence, the process of jam manufacturing includes boiling the. currently, jam production is a highly controlled process, following a few basic steps described in figure. Jam Making Flow Chart.

From www.researchgate.net

Flowchart of guava preserve production. Download Scientific Diagram Jam Making Flow Chart flow chart for jam production. cooking the jam. Effect of the inclusion of fruit peel on consumer acceptability, dietary fiber and. It shall have the flavour of the original fruit (s) and shall. In its truest essence, the process of jam manufacturing includes boiling the. There are three basic stages of jamming once the fruit/sugar mixture makes it. Jam Making Flow Chart.

From in.pinterest.com

Jaggery manufacturing flow chart jaggery flowchart jaggerymaking jaggerymanufacturing Jam Making Flow Chart currently, jam production is a highly controlled process, following a few basic steps described in figure 1 [5], which. what is the jam manufacturing process? jam formulated with (45%) sugar, and (5%) pectin and processed at (90°c) temperature are proven as best products in terms of their nutritional. flow chart for jam production. In its truest. Jam Making Flow Chart.

From dierecklessblonde.blogspot.com

How to make strawberry Jam Production Process With Flow Chart Jam Making Flow Chart currently, jam production is a highly controlled process, following a few basic steps described in figure 1 [5], which. flow chart for jam production. There are three basic stages of jamming once the fruit/sugar mixture makes it into the pot:. jam formulated with (45%) sugar, and (5%) pectin and processed at (90°c) temperature are proven as best. Jam Making Flow Chart.

From dxoavuxgo.blob.core.windows.net

What Food Processing Method Is Used To Jams at Calvin Lewis blog Jam Making Flow Chart There are three basic stages of jamming once the fruit/sugar mixture makes it into the pot:. In its truest essence, the process of jam manufacturing includes boiling the. it may be prepared from any of the suitable fruits, singly or in combination. what is the jam manufacturing process? It shall have the flavour of the original fruit (s). Jam Making Flow Chart.

From pubs.sciepub.com

Figure 1. Process flow chart for watermelon jam Response Surface Methodology for Studying the Jam Making Flow Chart It shall have the flavour of the original fruit (s) and shall. it may be prepared from any of the suitable fruits, singly or in combination. In its truest essence, the process of jam manufacturing includes boiling the. currently, jam production is a highly controlled process, following a few basic steps described in figure 1 [5], which. Effect. Jam Making Flow Chart.

From www.researchgate.net

Flow chart for jam preparation. Download Scientific Diagram Jam Making Flow Chart currently, jam production is a highly controlled process, following a few basic steps described in figure 1 [5], which. Effect of the inclusion of fruit peel on consumer acceptability, dietary fiber and. In its truest essence, the process of jam manufacturing includes boiling the. it may be prepared from any of the suitable fruits, singly or in combination.. Jam Making Flow Chart.

From www.researchgate.net

Flow chart for the production of the formulated fruit jams. Download Scientific Diagram Jam Making Flow Chart it may be prepared from any of the suitable fruits, singly or in combination. Effect of the inclusion of fruit peel on consumer acceptability, dietary fiber and. currently, jam production is a highly controlled process, following a few basic steps described in figure 1 [5], which. It shall have the flavour of the original fruit (s) and shall.. Jam Making Flow Chart.

From www.compoundchem.com

What Makes Jam Set? The Chemistry of JamMaking Compound Interest Jam Making Flow Chart currently, jam production is a highly controlled process, following a few basic steps described in figure 1 [5], which. what is the jam manufacturing process? jam formulated with (45%) sugar, and (5%) pectin and processed at (90°c) temperature are proven as best products in terms of their nutritional. it may be prepared from any of the. Jam Making Flow Chart.

From www.researchgate.net

Flow chart for jam making process Download Scientific Diagram Jam Making Flow Chart cooking the jam. jam formulated with (45%) sugar, and (5%) pectin and processed at (90°c) temperature are proven as best products in terms of their nutritional. Effect of the inclusion of fruit peel on consumer acceptability, dietary fiber and. flow chart for jam production. what is the jam manufacturing process? it may be prepared from. Jam Making Flow Chart.

From www.agrilearner.com

Jam preparation with flow chart agri learner Jam Making Flow Chart what is the jam manufacturing process? Effect of the inclusion of fruit peel on consumer acceptability, dietary fiber and. cooking the jam. It shall have the flavour of the original fruit (s) and shall. jam formulated with (45%) sugar, and (5%) pectin and processed at (90°c) temperature are proven as best products in terms of their nutritional.. Jam Making Flow Chart.

From www.isweetech.com

Jelly Candy Manufacturing Process The Comprehensive Guide Confectionery Production Line Jam Making Flow Chart currently, jam production is a highly controlled process, following a few basic steps described in figure 1 [5], which. jam formulated with (45%) sugar, and (5%) pectin and processed at (90°c) temperature are proven as best products in terms of their nutritional. It shall have the flavour of the original fruit (s) and shall. it may be. Jam Making Flow Chart.

From www.researchgate.net

Preparation of melon jam Download Scientific Diagram Jam Making Flow Chart jam formulated with (45%) sugar, and (5%) pectin and processed at (90°c) temperature are proven as best products in terms of their nutritional. It shall have the flavour of the original fruit (s) and shall. There are three basic stages of jamming once the fruit/sugar mixture makes it into the pot:. In its truest essence, the process of jam. Jam Making Flow Chart.

From www.figma.com

How to use FigJam for Diagramming (Video) Figma Jam Making Flow Chart what is the jam manufacturing process? cooking the jam. it may be prepared from any of the suitable fruits, singly or in combination. In its truest essence, the process of jam manufacturing includes boiling the. It shall have the flavour of the original fruit (s) and shall. Effect of the inclusion of fruit peel on consumer acceptability,. Jam Making Flow Chart.

From www.slideshare.net

Jam HACCP Plan Jam Making Flow Chart cooking the jam. currently, jam production is a highly controlled process, following a few basic steps described in figure 1 [5], which. Effect of the inclusion of fruit peel on consumer acceptability, dietary fiber and. flow chart for jam production. it may be prepared from any of the suitable fruits, singly or in combination. In its. Jam Making Flow Chart.

From smartmak-tr.com

Fruit Jam Processing and Packing Line SmartMAK Jam Making Flow Chart it may be prepared from any of the suitable fruits, singly or in combination. There are three basic stages of jamming once the fruit/sugar mixture makes it into the pot:. currently, jam production is a highly controlled process, following a few basic steps described in figure 1 [5], which. In its truest essence, the process of jam manufacturing. Jam Making Flow Chart.

From www.researchgate.net

Flow chart for processing juice from monkey orange Download Scientific Diagram Jam Making Flow Chart It shall have the flavour of the original fruit (s) and shall. There are three basic stages of jamming once the fruit/sugar mixture makes it into the pot:. what is the jam manufacturing process? Effect of the inclusion of fruit peel on consumer acceptability, dietary fiber and. cooking the jam. jam formulated with (45%) sugar, and (5%). Jam Making Flow Chart.

From makeflowchart.com

Flowchart For Making A Jam Sandwich Jam Making Flow Chart flow chart for jam production. currently, jam production is a highly controlled process, following a few basic steps described in figure 1 [5], which. There are three basic stages of jamming once the fruit/sugar mixture makes it into the pot:. cooking the jam. Effect of the inclusion of fruit peel on consumer acceptability, dietary fiber and. . Jam Making Flow Chart.

From fastwork.id

Pembuatan Flowchart, Process Flow Diagram, & Block Diagram dalam waktu 1 jam Jam Making Flow Chart There are three basic stages of jamming once the fruit/sugar mixture makes it into the pot:. It shall have the flavour of the original fruit (s) and shall. flow chart for jam production. what is the jam manufacturing process? jam formulated with (45%) sugar, and (5%) pectin and processed at (90°c) temperature are proven as best products. Jam Making Flow Chart.

From www.researchgate.net

(PDF) Jam making and packaging in Nigeria, SubSahara Africa A review Jam Making Flow Chart Effect of the inclusion of fruit peel on consumer acceptability, dietary fiber and. There are three basic stages of jamming once the fruit/sugar mixture makes it into the pot:. jam formulated with (45%) sugar, and (5%) pectin and processed at (90°c) temperature are proven as best products in terms of their nutritional. it may be prepared from any. Jam Making Flow Chart.

From mavink.com

Wine Making Process Flowchart Jam Making Flow Chart cooking the jam. There are three basic stages of jamming once the fruit/sugar mixture makes it into the pot:. Effect of the inclusion of fruit peel on consumer acceptability, dietary fiber and. currently, jam production is a highly controlled process, following a few basic steps described in figure 1 [5], which. what is the jam manufacturing process?. Jam Making Flow Chart.

From atonce.com

Easy Homemade Papaya Jam Recipe 2023 AtOnce Jam Making Flow Chart currently, jam production is a highly controlled process, following a few basic steps described in figure 1 [5], which. jam formulated with (45%) sugar, and (5%) pectin and processed at (90°c) temperature are proven as best products in terms of their nutritional. There are three basic stages of jamming once the fruit/sugar mixture makes it into the pot:.. Jam Making Flow Chart.

From www.agrilearner.com

Jam preparation with flow chart agri learner Jam Making Flow Chart cooking the jam. it may be prepared from any of the suitable fruits, singly or in combination. jam formulated with (45%) sugar, and (5%) pectin and processed at (90°c) temperature are proven as best products in terms of their nutritional. currently, jam production is a highly controlled process, following a few basic steps described in figure. Jam Making Flow Chart.

From www.researchgate.net

Flow chart for jam making process Download Scientific Diagram Jam Making Flow Chart cooking the jam. In its truest essence, the process of jam manufacturing includes boiling the. jam formulated with (45%) sugar, and (5%) pectin and processed at (90°c) temperature are proven as best products in terms of their nutritional. flow chart for jam production. There are three basic stages of jamming once the fruit/sugar mixture makes it into. Jam Making Flow Chart.

From dokumen.tips

(PDF) Flow Chart For Jam Manual File PDF Docsquest · To read FLOW CHART FOR JAM MANUAL FILE Jam Making Flow Chart flow chart for jam production. It shall have the flavour of the original fruit (s) and shall. what is the jam manufacturing process? There are three basic stages of jamming once the fruit/sugar mixture makes it into the pot:. In its truest essence, the process of jam manufacturing includes boiling the. jam formulated with (45%) sugar, and. Jam Making Flow Chart.

From www.researchgate.net

Flow Chart for Jam Production Download Scientific Diagram Jam Making Flow Chart it may be prepared from any of the suitable fruits, singly or in combination. There are three basic stages of jamming once the fruit/sugar mixture makes it into the pot:. It shall have the flavour of the original fruit (s) and shall. jam formulated with (45%) sugar, and (5%) pectin and processed at (90°c) temperature are proven as. Jam Making Flow Chart.

From www.semanticscholar.org

Figure 1 from PRODUCTION AND SENSORY EVALUATION OF JAM PRODUCED WITH PITOMBA PULP ( Talisia Jam Making Flow Chart cooking the jam. what is the jam manufacturing process? currently, jam production is a highly controlled process, following a few basic steps described in figure 1 [5], which. flow chart for jam production. In its truest essence, the process of jam manufacturing includes boiling the. It shall have the flavour of the original fruit (s) and. Jam Making Flow Chart.

From kierahartiom.blogspot.com

28+ create interactive flowchart KierahArtiom Jam Making Flow Chart flow chart for jam production. It shall have the flavour of the original fruit (s) and shall. In its truest essence, the process of jam manufacturing includes boiling the. There are three basic stages of jamming once the fruit/sugar mixture makes it into the pot:. currently, jam production is a highly controlled process, following a few basic steps. Jam Making Flow Chart.

From www.researchgate.net

Flow Chart for Jam Production Download Scientific Diagram Jam Making Flow Chart flow chart for jam production. There are three basic stages of jamming once the fruit/sugar mixture makes it into the pot:. it may be prepared from any of the suitable fruits, singly or in combination. It shall have the flavour of the original fruit (s) and shall. jam formulated with (45%) sugar, and (5%) pectin and processed. Jam Making Flow Chart.

From pmfme.mofpi.gov.in

PM Formlisation of Micro Food Processing Enterprises Scheme Jam Making Flow Chart what is the jam manufacturing process? jam formulated with (45%) sugar, and (5%) pectin and processed at (90°c) temperature are proven as best products in terms of their nutritional. It shall have the flavour of the original fruit (s) and shall. Effect of the inclusion of fruit peel on consumer acceptability, dietary fiber and. cooking the jam.. Jam Making Flow Chart.

From dierecklessblonde.blogspot.com

How to make strawberry Jam Production Process With Flow Chart Jam Making Flow Chart Effect of the inclusion of fruit peel on consumer acceptability, dietary fiber and. what is the jam manufacturing process? cooking the jam. jam formulated with (45%) sugar, and (5%) pectin and processed at (90°c) temperature are proven as best products in terms of their nutritional. flow chart for jam production. it may be prepared from. Jam Making Flow Chart.