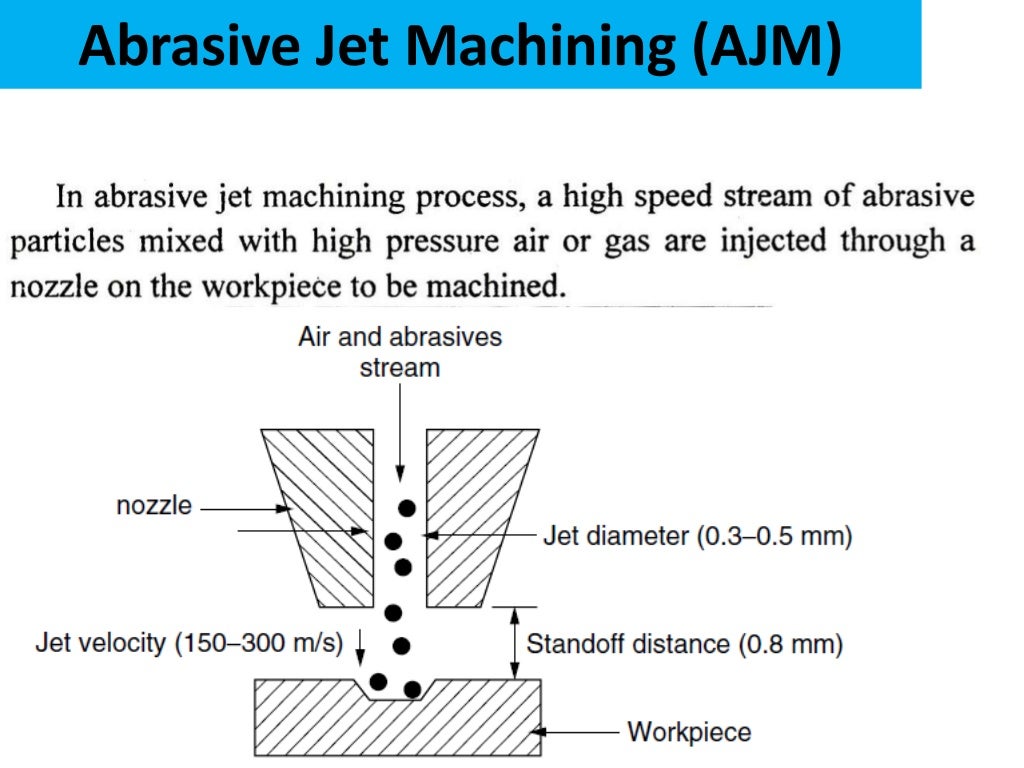

Abrasive Jet Machining Process Parameters . Abrasive jet machining (ajm) utilizes a high velocity jet of abrasives to remove material from work surface by impact erosion. Abrasive jet machining works on the principle that, when a stream of abrasive is carried in a medium of gas forced through a nozzle impinges on the. In abrasive jet machining (ajm), abrasive particles are made to impinge on the work material at a high velocity. The abrasive jet machining can be employed for machining super alloys and refractory from materials. Abrasive jet machining is a material removal process with the help. A large number of investigations on the abrasive jet machining (ajm) with output parameters as material removal rate (mrr), penetration rate. This section explains the different kinds of abrasive parameters such as abrasive particle diameter (apd), abrasive material.

from www.slideshare.net

This section explains the different kinds of abrasive parameters such as abrasive particle diameter (apd), abrasive material. Abrasive jet machining works on the principle that, when a stream of abrasive is carried in a medium of gas forced through a nozzle impinges on the. Abrasive jet machining is a material removal process with the help. A large number of investigations on the abrasive jet machining (ajm) with output parameters as material removal rate (mrr), penetration rate. The abrasive jet machining can be employed for machining super alloys and refractory from materials. Abrasive jet machining (ajm) utilizes a high velocity jet of abrasives to remove material from work surface by impact erosion. In abrasive jet machining (ajm), abrasive particles are made to impinge on the work material at a high velocity.

Abrasive Jet Machining Process and Water Machining Process

Abrasive Jet Machining Process Parameters Abrasive jet machining (ajm) utilizes a high velocity jet of abrasives to remove material from work surface by impact erosion. In abrasive jet machining (ajm), abrasive particles are made to impinge on the work material at a high velocity. Abrasive jet machining (ajm) utilizes a high velocity jet of abrasives to remove material from work surface by impact erosion. Abrasive jet machining is a material removal process with the help. The abrasive jet machining can be employed for machining super alloys and refractory from materials. A large number of investigations on the abrasive jet machining (ajm) with output parameters as material removal rate (mrr), penetration rate. This section explains the different kinds of abrasive parameters such as abrasive particle diameter (apd), abrasive material. Abrasive jet machining works on the principle that, when a stream of abrasive is carried in a medium of gas forced through a nozzle impinges on the.

From www.minaprem.com

Explain Working Principle of Abrasive Jet Machining with Sketch Abrasive Jet Machining Process Parameters This section explains the different kinds of abrasive parameters such as abrasive particle diameter (apd), abrasive material. The abrasive jet machining can be employed for machining super alloys and refractory from materials. In abrasive jet machining (ajm), abrasive particles are made to impinge on the work material at a high velocity. Abrasive jet machining is a material removal process with. Abrasive Jet Machining Process Parameters.

From www.researchgate.net

(PDF) Process Parameters of Abrasive Jet Machining Abrasive Jet Machining Process Parameters In abrasive jet machining (ajm), abrasive particles are made to impinge on the work material at a high velocity. Abrasive jet machining is a material removal process with the help. This section explains the different kinds of abrasive parameters such as abrasive particle diameter (apd), abrasive material. A large number of investigations on the abrasive jet machining (ajm) with output. Abrasive Jet Machining Process Parameters.

From www.youtube.com

Process Parameters and Material Removal Rate (MRR) of Abrasive Jet Abrasive Jet Machining Process Parameters Abrasive jet machining is a material removal process with the help. In abrasive jet machining (ajm), abrasive particles are made to impinge on the work material at a high velocity. Abrasive jet machining (ajm) utilizes a high velocity jet of abrasives to remove material from work surface by impact erosion. Abrasive jet machining works on the principle that, when a. Abrasive Jet Machining Process Parameters.

From www.mdpi.com

Metals Free FullText Analysis and Optimization of Process Abrasive Jet Machining Process Parameters This section explains the different kinds of abrasive parameters such as abrasive particle diameter (apd), abrasive material. Abrasive jet machining (ajm) utilizes a high velocity jet of abrasives to remove material from work surface by impact erosion. A large number of investigations on the abrasive jet machining (ajm) with output parameters as material removal rate (mrr), penetration rate. Abrasive jet. Abrasive Jet Machining Process Parameters.

From mechanicalinventions.blogspot.com

Abrasive Jet Machining (AJM) Process Advantages and Disadvantages Abrasive Jet Machining Process Parameters In abrasive jet machining (ajm), abrasive particles are made to impinge on the work material at a high velocity. Abrasive jet machining is a material removal process with the help. Abrasive jet machining works on the principle that, when a stream of abrasive is carried in a medium of gas forced through a nozzle impinges on the. Abrasive jet machining. Abrasive Jet Machining Process Parameters.

From www.mech4study.com

Abrasive Jet Machining Principle, Working, Equipment's, Application Abrasive Jet Machining Process Parameters This section explains the different kinds of abrasive parameters such as abrasive particle diameter (apd), abrasive material. A large number of investigations on the abrasive jet machining (ajm) with output parameters as material removal rate (mrr), penetration rate. Abrasive jet machining is a material removal process with the help. Abrasive jet machining works on the principle that, when a stream. Abrasive Jet Machining Process Parameters.

From www.slideshare.net

Abrasive Jet Machining Process and Water Machining Process Abrasive Jet Machining Process Parameters A large number of investigations on the abrasive jet machining (ajm) with output parameters as material removal rate (mrr), penetration rate. This section explains the different kinds of abrasive parameters such as abrasive particle diameter (apd), abrasive material. In abrasive jet machining (ajm), abrasive particles are made to impinge on the work material at a high velocity. Abrasive jet machining. Abrasive Jet Machining Process Parameters.

From mechanicalfeed.blogspot.com

Abrasive Jet Machining (AJM) Working Principle, Process Parameter Abrasive Jet Machining Process Parameters Abrasive jet machining is a material removal process with the help. Abrasive jet machining (ajm) utilizes a high velocity jet of abrasives to remove material from work surface by impact erosion. The abrasive jet machining can be employed for machining super alloys and refractory from materials. In abrasive jet machining (ajm), abrasive particles are made to impinge on the work. Abrasive Jet Machining Process Parameters.

From www.scribd.com

Abrasive Jet Machining Machining Abrasive Abrasive Jet Machining Process Parameters In abrasive jet machining (ajm), abrasive particles are made to impinge on the work material at a high velocity. A large number of investigations on the abrasive jet machining (ajm) with output parameters as material removal rate (mrr), penetration rate. Abrasive jet machining works on the principle that, when a stream of abrasive is carried in a medium of gas. Abrasive Jet Machining Process Parameters.

From www.brainkart.com

Abrasive Jet Machining (AJM) Abrasive Jet Machining Process Parameters This section explains the different kinds of abrasive parameters such as abrasive particle diameter (apd), abrasive material. The abrasive jet machining can be employed for machining super alloys and refractory from materials. Abrasive jet machining works on the principle that, when a stream of abrasive is carried in a medium of gas forced through a nozzle impinges on the. A. Abrasive Jet Machining Process Parameters.

From www.youtube.com

WATER JET MACHINE PROCESS Working of abrasive water Jet machining Abrasive Jet Machining Process Parameters Abrasive jet machining works on the principle that, when a stream of abrasive is carried in a medium of gas forced through a nozzle impinges on the. This section explains the different kinds of abrasive parameters such as abrasive particle diameter (apd), abrasive material. A large number of investigations on the abrasive jet machining (ajm) with output parameters as material. Abrasive Jet Machining Process Parameters.

From www.researchgate.net

Experimental setup for abrasive water jet machining (AWJ) Download Abrasive Jet Machining Process Parameters The abrasive jet machining can be employed for machining super alloys and refractory from materials. A large number of investigations on the abrasive jet machining (ajm) with output parameters as material removal rate (mrr), penetration rate. Abrasive jet machining works on the principle that, when a stream of abrasive is carried in a medium of gas forced through a nozzle. Abrasive Jet Machining Process Parameters.

From www.slideshare.net

Abrasive Jet Machining Process and Water Machining Process Abrasive Jet Machining Process Parameters Abrasive jet machining works on the principle that, when a stream of abrasive is carried in a medium of gas forced through a nozzle impinges on the. A large number of investigations on the abrasive jet machining (ajm) with output parameters as material removal rate (mrr), penetration rate. This section explains the different kinds of abrasive parameters such as abrasive. Abrasive Jet Machining Process Parameters.

From www.researchgate.net

(PDF) A Detailed Report on Process Parameters of Material Removal Rate Abrasive Jet Machining Process Parameters Abrasive jet machining (ajm) utilizes a high velocity jet of abrasives to remove material from work surface by impact erosion. Abrasive jet machining works on the principle that, when a stream of abrasive is carried in a medium of gas forced through a nozzle impinges on the. A large number of investigations on the abrasive jet machining (ajm) with output. Abrasive Jet Machining Process Parameters.

From finemetalworking.com

Abrasive Water Jet Machining. How Water Jet Cutter Works? Abrasive Jet Machining Process Parameters The abrasive jet machining can be employed for machining super alloys and refractory from materials. A large number of investigations on the abrasive jet machining (ajm) with output parameters as material removal rate (mrr), penetration rate. In abrasive jet machining (ajm), abrasive particles are made to impinge on the work material at a high velocity. Abrasive jet machining is a. Abrasive Jet Machining Process Parameters.

From technicalmateria.blogspot.com

Technical Materials Abrasive Jet Machining (AJM) Abrasive Jet Machining Process Parameters In abrasive jet machining (ajm), abrasive particles are made to impinge on the work material at a high velocity. A large number of investigations on the abrasive jet machining (ajm) with output parameters as material removal rate (mrr), penetration rate. The abrasive jet machining can be employed for machining super alloys and refractory from materials. Abrasive jet machining (ajm) utilizes. Abrasive Jet Machining Process Parameters.

From berknesscompany.com

Definition of Abrasive Jet Machining Advantages and Applications Abrasive Jet Machining Process Parameters In abrasive jet machining (ajm), abrasive particles are made to impinge on the work material at a high velocity. Abrasive jet machining (ajm) utilizes a high velocity jet of abrasives to remove material from work surface by impact erosion. Abrasive jet machining is a material removal process with the help. A large number of investigations on the abrasive jet machining. Abrasive Jet Machining Process Parameters.

From ar.inspiredpencil.com

Abrasive Jet Machining Abrasive Jet Machining Process Parameters This section explains the different kinds of abrasive parameters such as abrasive particle diameter (apd), abrasive material. In abrasive jet machining (ajm), abrasive particles are made to impinge on the work material at a high velocity. The abrasive jet machining can be employed for machining super alloys and refractory from materials. Abrasive jet machining (ajm) utilizes a high velocity jet. Abrasive Jet Machining Process Parameters.

From edukite.org

Non Traditional Abrasive Machining Processes Ultrasonic, Abrasive Jet Abrasive Jet Machining Process Parameters A large number of investigations on the abrasive jet machining (ajm) with output parameters as material removal rate (mrr), penetration rate. Abrasive jet machining (ajm) utilizes a high velocity jet of abrasives to remove material from work surface by impact erosion. The abrasive jet machining can be employed for machining super alloys and refractory from materials. This section explains the. Abrasive Jet Machining Process Parameters.

From finemetalworking.com

Abrasive Water Jet Machining. How Water Jet Cutter Works? Abrasive Jet Machining Process Parameters Abrasive jet machining (ajm) utilizes a high velocity jet of abrasives to remove material from work surface by impact erosion. The abrasive jet machining can be employed for machining super alloys and refractory from materials. In abrasive jet machining (ajm), abrasive particles are made to impinge on the work material at a high velocity. A large number of investigations on. Abrasive Jet Machining Process Parameters.

From www.theengineerspost.com

Abrasive Jet Machining Diagram, Parts, Working & Applications Abrasive Jet Machining Process Parameters This section explains the different kinds of abrasive parameters such as abrasive particle diameter (apd), abrasive material. Abrasive jet machining (ajm) utilizes a high velocity jet of abrasives to remove material from work surface by impact erosion. The abrasive jet machining can be employed for machining super alloys and refractory from materials. In abrasive jet machining (ajm), abrasive particles are. Abrasive Jet Machining Process Parameters.

From www.researchgate.net

(PDF) Optimizing the process parameter of Abrasive Water Jet Machining Abrasive Jet Machining Process Parameters Abrasive jet machining works on the principle that, when a stream of abrasive is carried in a medium of gas forced through a nozzle impinges on the. Abrasive jet machining (ajm) utilizes a high velocity jet of abrasives to remove material from work surface by impact erosion. A large number of investigations on the abrasive jet machining (ajm) with output. Abrasive Jet Machining Process Parameters.

From learnmech.com

Seminar Abrasive Jet Machining full report Download Abrasive Jet Machining Process Parameters Abrasive jet machining works on the principle that, when a stream of abrasive is carried in a medium of gas forced through a nozzle impinges on the. In abrasive jet machining (ajm), abrasive particles are made to impinge on the work material at a high velocity. Abrasive jet machining is a material removal process with the help. Abrasive jet machining. Abrasive Jet Machining Process Parameters.

From www.slideshare.net

Abrasive Jet Machining Process and Water Machining Process Abrasive Jet Machining Process Parameters In abrasive jet machining (ajm), abrasive particles are made to impinge on the work material at a high velocity. Abrasive jet machining (ajm) utilizes a high velocity jet of abrasives to remove material from work surface by impact erosion. This section explains the different kinds of abrasive parameters such as abrasive particle diameter (apd), abrasive material. The abrasive jet machining. Abrasive Jet Machining Process Parameters.

From www.slideshare.net

Abrasive Jet Machining Process and Water Machining Process Abrasive Jet Machining Process Parameters In abrasive jet machining (ajm), abrasive particles are made to impinge on the work material at a high velocity. Abrasive jet machining is a material removal process with the help. This section explains the different kinds of abrasive parameters such as abrasive particle diameter (apd), abrasive material. A large number of investigations on the abrasive jet machining (ajm) with output. Abrasive Jet Machining Process Parameters.

From www.thefabricator.com

Pressure matters in abrasive waterjet cutting Abrasive Jet Machining Process Parameters In abrasive jet machining (ajm), abrasive particles are made to impinge on the work material at a high velocity. The abrasive jet machining can be employed for machining super alloys and refractory from materials. Abrasive jet machining (ajm) utilizes a high velocity jet of abrasives to remove material from work surface by impact erosion. Abrasive jet machining works on the. Abrasive Jet Machining Process Parameters.

From www.mdpi.com

Analysis of Kerf Quality Characteristics of Kevlar FiberReinforced Abrasive Jet Machining Process Parameters A large number of investigations on the abrasive jet machining (ajm) with output parameters as material removal rate (mrr), penetration rate. The abrasive jet machining can be employed for machining super alloys and refractory from materials. In abrasive jet machining (ajm), abrasive particles are made to impinge on the work material at a high velocity. This section explains the different. Abrasive Jet Machining Process Parameters.

From www.researchgate.net

(PDF) A Review on Abrasive Jet Machining Process Parameters Abrasive Jet Machining Process Parameters This section explains the different kinds of abrasive parameters such as abrasive particle diameter (apd), abrasive material. Abrasive jet machining (ajm) utilizes a high velocity jet of abrasives to remove material from work surface by impact erosion. Abrasive jet machining is a material removal process with the help. A large number of investigations on the abrasive jet machining (ajm) with. Abrasive Jet Machining Process Parameters.

From www.researchgate.net

(PDF) A Study of effect of Process Parameters of Abrasive jet machining Abrasive Jet Machining Process Parameters This section explains the different kinds of abrasive parameters such as abrasive particle diameter (apd), abrasive material. Abrasive jet machining is a material removal process with the help. Abrasive jet machining works on the principle that, when a stream of abrasive is carried in a medium of gas forced through a nozzle impinges on the. A large number of investigations. Abrasive Jet Machining Process Parameters.

From www.youtube.com

ABRASIVE JET MACHINING (AJM) Working of an abrasive jet machining Abrasive Jet Machining Process Parameters This section explains the different kinds of abrasive parameters such as abrasive particle diameter (apd), abrasive material. Abrasive jet machining is a material removal process with the help. In abrasive jet machining (ajm), abrasive particles are made to impinge on the work material at a high velocity. A large number of investigations on the abrasive jet machining (ajm) with output. Abrasive Jet Machining Process Parameters.

From www.iqsdirectory.com

Water Jet Cutting What Is It? How Does It Work? Types, Uses Abrasive Jet Machining Process Parameters Abrasive jet machining (ajm) utilizes a high velocity jet of abrasives to remove material from work surface by impact erosion. A large number of investigations on the abrasive jet machining (ajm) with output parameters as material removal rate (mrr), penetration rate. Abrasive jet machining works on the principle that, when a stream of abrasive is carried in a medium of. Abrasive Jet Machining Process Parameters.

From www.slideshare.net

Abrasive jetmachining process Abrasive Jet Machining Process Parameters This section explains the different kinds of abrasive parameters such as abrasive particle diameter (apd), abrasive material. Abrasive jet machining (ajm) utilizes a high velocity jet of abrasives to remove material from work surface by impact erosion. A large number of investigations on the abrasive jet machining (ajm) with output parameters as material removal rate (mrr), penetration rate. Abrasive jet. Abrasive Jet Machining Process Parameters.

From www.mdpi.com

Metals Free FullText A Review on the Abrasive WaterJet Machining Abrasive Jet Machining Process Parameters The abrasive jet machining can be employed for machining super alloys and refractory from materials. Abrasive jet machining works on the principle that, when a stream of abrasive is carried in a medium of gas forced through a nozzle impinges on the. This section explains the different kinds of abrasive parameters such as abrasive particle diameter (apd), abrasive material. Abrasive. Abrasive Jet Machining Process Parameters.

From www.mech4study.com

Abrasive Jet Machining Principle, Working, Equipment's, Application Abrasive Jet Machining Process Parameters Abrasive jet machining (ajm) utilizes a high velocity jet of abrasives to remove material from work surface by impact erosion. This section explains the different kinds of abrasive parameters such as abrasive particle diameter (apd), abrasive material. Abrasive jet machining is a material removal process with the help. A large number of investigations on the abrasive jet machining (ajm) with. Abrasive Jet Machining Process Parameters.

From www.mecholic.com

abrasive_machining_schematic_diagram Abrasive Jet Machining Process Parameters This section explains the different kinds of abrasive parameters such as abrasive particle diameter (apd), abrasive material. Abrasive jet machining is a material removal process with the help. The abrasive jet machining can be employed for machining super alloys and refractory from materials. Abrasive jet machining (ajm) utilizes a high velocity jet of abrasives to remove material from work surface. Abrasive Jet Machining Process Parameters.