Car Assembly Line Time . the production time for a single car dropped from over 12 hours to just 93 minutes due to the introduction of the assembly line. the original assembly line was 150 feet long, and cars were initially moved along it using a rope. because each worker had one task and worked on just one car at a time, it meant that hundreds of cars were being built simultaneously. This ingenious revolution changed the world, as it transformed how people worked and lived their lives. did you know that when henry ford introduced the automotive assembly line in 1913, the time it took to produce a car was slashed from 12 hours to 93 minutes? Ford’s 1914 production rate of 308,162 eclipsed the number of cars produced by all other automobile manufacturers combined. With the implementation of the assembly line, the time required to build a car dropped dramatically to just 3 hours. Parts installed in one vehicle on the assembly line.

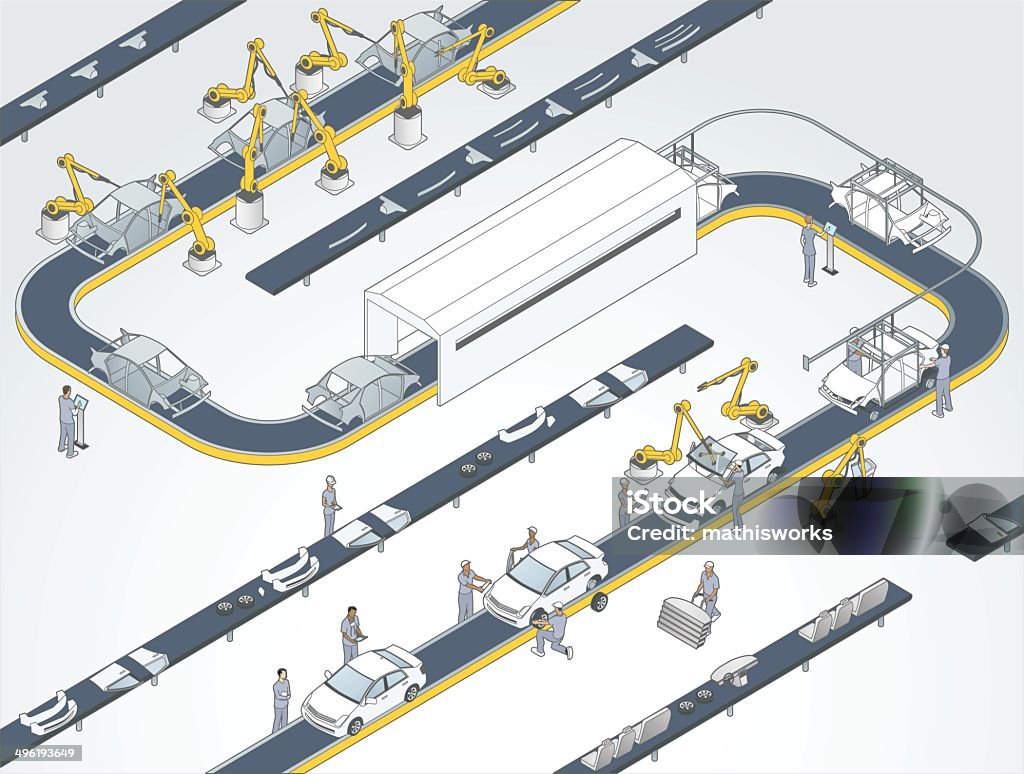

from www.istockphoto.com

the original assembly line was 150 feet long, and cars were initially moved along it using a rope. Parts installed in one vehicle on the assembly line. Ford’s 1914 production rate of 308,162 eclipsed the number of cars produced by all other automobile manufacturers combined. did you know that when henry ford introduced the automotive assembly line in 1913, the time it took to produce a car was slashed from 12 hours to 93 minutes? because each worker had one task and worked on just one car at a time, it meant that hundreds of cars were being built simultaneously. the production time for a single car dropped from over 12 hours to just 93 minutes due to the introduction of the assembly line. This ingenious revolution changed the world, as it transformed how people worked and lived their lives. With the implementation of the assembly line, the time required to build a car dropped dramatically to just 3 hours.

Auto Assembly Line Illustration Stock Illustration Download Image Now

Car Assembly Line Time the original assembly line was 150 feet long, and cars were initially moved along it using a rope. This ingenious revolution changed the world, as it transformed how people worked and lived their lives. Parts installed in one vehicle on the assembly line. With the implementation of the assembly line, the time required to build a car dropped dramatically to just 3 hours. the production time for a single car dropped from over 12 hours to just 93 minutes due to the introduction of the assembly line. did you know that when henry ford introduced the automotive assembly line in 1913, the time it took to produce a car was slashed from 12 hours to 93 minutes? the original assembly line was 150 feet long, and cars were initially moved along it using a rope. Ford’s 1914 production rate of 308,162 eclipsed the number of cars produced by all other automobile manufacturers combined. because each worker had one task and worked on just one car at a time, it meant that hundreds of cars were being built simultaneously.

From www.dreamstime.com

Automotive Production Line. Welding Car Body. Modern Car Assembly Plant Car Assembly Line Time This ingenious revolution changed the world, as it transformed how people worked and lived their lives. the production time for a single car dropped from over 12 hours to just 93 minutes due to the introduction of the assembly line. the original assembly line was 150 feet long, and cars were initially moved along it using a rope.. Car Assembly Line Time.

From www.dreamstime.com

Workers Assemble a Car on Assembly Line in Car Factory Editorial Stock Car Assembly Line Time With the implementation of the assembly line, the time required to build a car dropped dramatically to just 3 hours. This ingenious revolution changed the world, as it transformed how people worked and lived their lives. Ford’s 1914 production rate of 308,162 eclipsed the number of cars produced by all other automobile manufacturers combined. did you know that when. Car Assembly Line Time.

From www.dreamstime.com

Car Production Line Stock Images Image 14745174 Car Assembly Line Time With the implementation of the assembly line, the time required to build a car dropped dramatically to just 3 hours. did you know that when henry ford introduced the automotive assembly line in 1913, the time it took to produce a car was slashed from 12 hours to 93 minutes? Ford’s 1914 production rate of 308,162 eclipsed the number. Car Assembly Line Time.

From buntyllc.com

The Ultimate Guide to Car Production Lines Car Assembly Line Time Parts installed in one vehicle on the assembly line. the original assembly line was 150 feet long, and cars were initially moved along it using a rope. With the implementation of the assembly line, the time required to build a car dropped dramatically to just 3 hours. did you know that when henry ford introduced the automotive assembly. Car Assembly Line Time.

From www.youtube.com

Vehicle assembly line time lapse YouTube Car Assembly Line Time the production time for a single car dropped from over 12 hours to just 93 minutes due to the introduction of the assembly line. because each worker had one task and worked on just one car at a time, it meant that hundreds of cars were being built simultaneously. With the implementation of the assembly line, the time. Car Assembly Line Time.

From datamyte.com

What is an Automotive Production Line Checklist? DataMyte Car Assembly Line Time the original assembly line was 150 feet long, and cars were initially moved along it using a rope. This ingenious revolution changed the world, as it transformed how people worked and lived their lives. did you know that when henry ford introduced the automotive assembly line in 1913, the time it took to produce a car was slashed. Car Assembly Line Time.

From www.dreamstime.com

Automotive Mechanical Assembly, Engine, Transmission, Suspension and Car Assembly Line Time because each worker had one task and worked on just one car at a time, it meant that hundreds of cars were being built simultaneously. This ingenious revolution changed the world, as it transformed how people worked and lived their lives. the original assembly line was 150 feet long, and cars were initially moved along it using a. Car Assembly Line Time.

From www.dreamstime.com

Photo of a Car Production Line. Modern Car Assembly Plant Editorial Car Assembly Line Time This ingenious revolution changed the world, as it transformed how people worked and lived their lives. Parts installed in one vehicle on the assembly line. because each worker had one task and worked on just one car at a time, it meant that hundreds of cars were being built simultaneously. did you know that when henry ford introduced. Car Assembly Line Time.

From www.automobilemag.com

First Opel Insignia Flagship Rolls off Assembly Line Automobile Magazine Car Assembly Line Time Ford’s 1914 production rate of 308,162 eclipsed the number of cars produced by all other automobile manufacturers combined. did you know that when henry ford introduced the automotive assembly line in 1913, the time it took to produce a car was slashed from 12 hours to 93 minutes? Parts installed in one vehicle on the assembly line. the. Car Assembly Line Time.

From www.dreamstime.com

Automotive Production Line. Welding Car Body. Modern Car Assembly Plant Car Assembly Line Time the production time for a single car dropped from over 12 hours to just 93 minutes due to the introduction of the assembly line. did you know that when henry ford introduced the automotive assembly line in 1913, the time it took to produce a car was slashed from 12 hours to 93 minutes? the original assembly. Car Assembly Line Time.

From www.dreamstime.com

Workers Assembles Cars at Automobile Assembly Line Production Plant Car Assembly Line Time did you know that when henry ford introduced the automotive assembly line in 1913, the time it took to produce a car was slashed from 12 hours to 93 minutes? the production time for a single car dropped from over 12 hours to just 93 minutes due to the introduction of the assembly line. the original assembly. Car Assembly Line Time.

From www.dreamstime.com

Photo of Automobile Production Line. Welding Car Body. Modern Car Car Assembly Line Time Parts installed in one vehicle on the assembly line. did you know that when henry ford introduced the automotive assembly line in 1913, the time it took to produce a car was slashed from 12 hours to 93 minutes? With the implementation of the assembly line, the time required to build a car dropped dramatically to just 3 hours.. Car Assembly Line Time.

From www.dreamstime.com

Car assembly line stock photo. Image of assembly, plant 46458140 Car Assembly Line Time did you know that when henry ford introduced the automotive assembly line in 1913, the time it took to produce a car was slashed from 12 hours to 93 minutes? because each worker had one task and worked on just one car at a time, it meant that hundreds of cars were being built simultaneously. the original. Car Assembly Line Time.

From www.dreamstime.com

Car assembly line stock image. Image of assemble, carcass 46458075 Car Assembly Line Time Ford’s 1914 production rate of 308,162 eclipsed the number of cars produced by all other automobile manufacturers combined. because each worker had one task and worked on just one car at a time, it meant that hundreds of cars were being built simultaneously. This ingenious revolution changed the world, as it transformed how people worked and lived their lives.. Car Assembly Line Time.

From www.dreamstime.com

Car Assembly Line Stock Vector Image 60346604 Car Assembly Line Time Ford’s 1914 production rate of 308,162 eclipsed the number of cars produced by all other automobile manufacturers combined. the production time for a single car dropped from over 12 hours to just 93 minutes due to the introduction of the assembly line. With the implementation of the assembly line, the time required to build a car dropped dramatically to. Car Assembly Line Time.

From www.dreamstime.com

Photo of a Car Production Line. Modern Car Assembly Plant Stock Image Car Assembly Line Time Parts installed in one vehicle on the assembly line. because each worker had one task and worked on just one car at a time, it meant that hundreds of cars were being built simultaneously. This ingenious revolution changed the world, as it transformed how people worked and lived their lives. With the implementation of the assembly line, the time. Car Assembly Line Time.

From cevkscsc.blob.core.windows.net

Auto Factory Photos at Tommie Edwards blog Car Assembly Line Time because each worker had one task and worked on just one car at a time, it meant that hundreds of cars were being built simultaneously. did you know that when henry ford introduced the automotive assembly line in 1913, the time it took to produce a car was slashed from 12 hours to 93 minutes? This ingenious revolution. Car Assembly Line Time.

From www.dubizzle.com

Car Assembly Components, Processes & More Car Assembly Line Time Parts installed in one vehicle on the assembly line. the production time for a single car dropped from over 12 hours to just 93 minutes due to the introduction of the assembly line. This ingenious revolution changed the world, as it transformed how people worked and lived their lives. because each worker had one task and worked on. Car Assembly Line Time.

From www.istockphoto.com

Auto Assembly Line Illustration Stock Illustration Download Image Now Car Assembly Line Time because each worker had one task and worked on just one car at a time, it meant that hundreds of cars were being built simultaneously. With the implementation of the assembly line, the time required to build a car dropped dramatically to just 3 hours. Ford’s 1914 production rate of 308,162 eclipsed the number of cars produced by all. Car Assembly Line Time.

From www.dreamstime.com

Car assembly line stock image. Image of chassis, machinery 31860045 Car Assembly Line Time This ingenious revolution changed the world, as it transformed how people worked and lived their lives. With the implementation of the assembly line, the time required to build a car dropped dramatically to just 3 hours. the original assembly line was 150 feet long, and cars were initially moved along it using a rope. because each worker had. Car Assembly Line Time.

From www.dreamstime.com

Car assembly line stock photo. Image of equipment, factory 46458354 Car Assembly Line Time Ford’s 1914 production rate of 308,162 eclipsed the number of cars produced by all other automobile manufacturers combined. because each worker had one task and worked on just one car at a time, it meant that hundreds of cars were being built simultaneously. did you know that when henry ford introduced the automotive assembly line in 1913, the. Car Assembly Line Time.

From www.dreamstime.com

Car factory assembly line stock image. Image of crane 31660527 Car Assembly Line Time Parts installed in one vehicle on the assembly line. the original assembly line was 150 feet long, and cars were initially moved along it using a rope. Ford’s 1914 production rate of 308,162 eclipsed the number of cars produced by all other automobile manufacturers combined. the production time for a single car dropped from over 12 hours to. Car Assembly Line Time.

From www.dreamstime.com

Workers Assemble a Car on Assembly Line in Car Factory Editorial Stock Car Assembly Line Time Ford’s 1914 production rate of 308,162 eclipsed the number of cars produced by all other automobile manufacturers combined. the production time for a single car dropped from over 12 hours to just 93 minutes due to the introduction of the assembly line. Parts installed in one vehicle on the assembly line. did you know that when henry ford. Car Assembly Line Time.

From guidelibrarymarco.z13.web.core.windows.net

Car Production Line Diagram Car Assembly Line Time the production time for a single car dropped from over 12 hours to just 93 minutes due to the introduction of the assembly line. Ford’s 1914 production rate of 308,162 eclipsed the number of cars produced by all other automobile manufacturers combined. This ingenious revolution changed the world, as it transformed how people worked and lived their lives. . Car Assembly Line Time.

From buntyllc.com

The Ultimate Guide to Car Production Lines Car Assembly Line Time Parts installed in one vehicle on the assembly line. because each worker had one task and worked on just one car at a time, it meant that hundreds of cars were being built simultaneously. the original assembly line was 150 feet long, and cars were initially moved along it using a rope. the production time for a. Car Assembly Line Time.

From maycointernational.com

Understanding How the Automotive Assembly Line Works A Closer Look Car Assembly Line Time Parts installed in one vehicle on the assembly line. With the implementation of the assembly line, the time required to build a car dropped dramatically to just 3 hours. Ford’s 1914 production rate of 308,162 eclipsed the number of cars produced by all other automobile manufacturers combined. because each worker had one task and worked on just one car. Car Assembly Line Time.

From www.dreamstime.com

Photo of Car Bodies are on Assembly Line. Factory for Production of Car Assembly Line Time did you know that when henry ford introduced the automotive assembly line in 1913, the time it took to produce a car was slashed from 12 hours to 93 minutes? the production time for a single car dropped from over 12 hours to just 93 minutes due to the introduction of the assembly line. Parts installed in one. Car Assembly Line Time.

From www.trifive.com

How long to biuld a 567 on assembly line. Chevy Tri Five Forum Car Assembly Line Time Ford’s 1914 production rate of 308,162 eclipsed the number of cars produced by all other automobile manufacturers combined. This ingenious revolution changed the world, as it transformed how people worked and lived their lives. because each worker had one task and worked on just one car at a time, it meant that hundreds of cars were being built simultaneously.. Car Assembly Line Time.

From www.dreamstime.com

Car Assembly Line Editorial Image Image 26078565 Car Assembly Line Time Ford’s 1914 production rate of 308,162 eclipsed the number of cars produced by all other automobile manufacturers combined. With the implementation of the assembly line, the time required to build a car dropped dramatically to just 3 hours. the original assembly line was 150 feet long, and cars were initially moved along it using a rope. did you. Car Assembly Line Time.

From www.toyotauk.com

Toyota Production System Car Assembly Line Time the original assembly line was 150 feet long, and cars were initially moved along it using a rope. because each worker had one task and worked on just one car at a time, it meant that hundreds of cars were being built simultaneously. Parts installed in one vehicle on the assembly line. Ford’s 1914 production rate of 308,162. Car Assembly Line Time.

From www.dreamstime.com

Photo of a Car Production Line. Modern Car Assembly Plant Stock Photo Car Assembly Line Time Parts installed in one vehicle on the assembly line. because each worker had one task and worked on just one car at a time, it meant that hundreds of cars were being built simultaneously. the production time for a single car dropped from over 12 hours to just 93 minutes due to the introduction of the assembly line.. Car Assembly Line Time.

From www.stoneacre.co.uk

What is a Car Assembly Line? Stoneacre Motor Group Car Assembly Line Time Ford’s 1914 production rate of 308,162 eclipsed the number of cars produced by all other automobile manufacturers combined. Parts installed in one vehicle on the assembly line. because each worker had one task and worked on just one car at a time, it meant that hundreds of cars were being built simultaneously. the production time for a single. Car Assembly Line Time.

From clickamericana.com

See Ford assembly lines from 100 years ago, massproducing Model T cars Car Assembly Line Time This ingenious revolution changed the world, as it transformed how people worked and lived their lives. Ford’s 1914 production rate of 308,162 eclipsed the number of cars produced by all other automobile manufacturers combined. the original assembly line was 150 feet long, and cars were initially moved along it using a rope. the production time for a single. Car Assembly Line Time.

From www.dreamstime.com

Car assembly line editorial image. Image of heavy, building 26078565 Car Assembly Line Time Parts installed in one vehicle on the assembly line. the production time for a single car dropped from over 12 hours to just 93 minutes due to the introduction of the assembly line. because each worker had one task and worked on just one car at a time, it meant that hundreds of cars were being built simultaneously.. Car Assembly Line Time.

From www.alamy.com

Car Assembly Line High Resolution Stock Photography and Images Alamy Car Assembly Line Time Ford’s 1914 production rate of 308,162 eclipsed the number of cars produced by all other automobile manufacturers combined. Parts installed in one vehicle on the assembly line. did you know that when henry ford introduced the automotive assembly line in 1913, the time it took to produce a car was slashed from 12 hours to 93 minutes? With the. Car Assembly Line Time.