Mig Welding Tip Angle . Lets go over some mig welding tips that will help you get. Mig welding is more tolerant of minor surface. Mig welding beginners should learn safety protocols, choose the right gas and wire, practice on scrap metal, maintain proper torch angle, control travel speed and wire feed, keep a. Overhead mig welding requires the mig gun tilted 5 to 35 degrees toward the direction of the weld. These mig welding tips cover gas metal arc welding techniques which improves your welds. The key with mig is to not go too extreme in either direction. You want the heat to be on the hot side. Why is clean metal essential? Ideally, you will be almost at 90° with the workpiece with a very slight push angle, maybe 5°. But dragging is acceptable, and some people prefer it since it creates better joint penetration. The material needs to be clean to get a good weld; Remove any grease or oil before using abrasives. Finding the right stickout length.

from joimkmton.blob.core.windows.net

Remove any grease or oil before using abrasives. The key with mig is to not go too extreme in either direction. Ideally, you will be almost at 90° with the workpiece with a very slight push angle, maybe 5°. You want the heat to be on the hot side. Overhead mig welding requires the mig gun tilted 5 to 35 degrees toward the direction of the weld. Why is clean metal essential? The material needs to be clean to get a good weld; These mig welding tips cover gas metal arc welding techniques which improves your welds. Mig welding is more tolerant of minor surface. But dragging is acceptable, and some people prefer it since it creates better joint penetration.

Mig Welding Wire Distance at Kevin Faulkner blog

Mig Welding Tip Angle Mig welding is more tolerant of minor surface. Mig welding beginners should learn safety protocols, choose the right gas and wire, practice on scrap metal, maintain proper torch angle, control travel speed and wire feed, keep a. You want the heat to be on the hot side. The key with mig is to not go too extreme in either direction. These mig welding tips cover gas metal arc welding techniques which improves your welds. Why is clean metal essential? The material needs to be clean to get a good weld; Remove any grease or oil before using abrasives. Finding the right stickout length. Overhead mig welding requires the mig gun tilted 5 to 35 degrees toward the direction of the weld. But dragging is acceptable, and some people prefer it since it creates better joint penetration. Ideally, you will be almost at 90° with the workpiece with a very slight push angle, maybe 5°. Mig welding is more tolerant of minor surface. Lets go over some mig welding tips that will help you get.

From joimkmton.blob.core.windows.net

Mig Welding Wire Distance at Kevin Faulkner blog Mig Welding Tip Angle Lets go over some mig welding tips that will help you get. You want the heat to be on the hot side. Finding the right stickout length. But dragging is acceptable, and some people prefer it since it creates better joint penetration. These mig welding tips cover gas metal arc welding techniques which improves your welds. Overhead mig welding requires. Mig Welding Tip Angle.

From www.wcwelding.com

MIG Welding Tips and Tricks! Mig Welding Tip Angle Mig welding is more tolerant of minor surface. Mig welding beginners should learn safety protocols, choose the right gas and wire, practice on scrap metal, maintain proper torch angle, control travel speed and wire feed, keep a. You want the heat to be on the hot side. These mig welding tips cover gas metal arc welding techniques which improves your. Mig Welding Tip Angle.

From www.familyhandyman.com

Learn MIG Welding Tips From a Pro Family Handyman Mig Welding Tip Angle Lets go over some mig welding tips that will help you get. You want the heat to be on the hot side. Why is clean metal essential? Mig welding beginners should learn safety protocols, choose the right gas and wire, practice on scrap metal, maintain proper torch angle, control travel speed and wire feed, keep a. The material needs to. Mig Welding Tip Angle.

From www.westermans.com

How to Weld Square Tube Step by Step! Westermans Blog Mig Welding Tip Angle You want the heat to be on the hot side. These mig welding tips cover gas metal arc welding techniques which improves your welds. Why is clean metal essential? The material needs to be clean to get a good weld; The key with mig is to not go too extreme in either direction. Mig welding is more tolerant of minor. Mig Welding Tip Angle.

From www.instructables.com

Beginning to MIG Weld 11 Steps Instructables Mig Welding Tip Angle The material needs to be clean to get a good weld; These mig welding tips cover gas metal arc welding techniques which improves your welds. Overhead mig welding requires the mig gun tilted 5 to 35 degrees toward the direction of the weld. Finding the right stickout length. Mig welding is more tolerant of minor surface. Lets go over some. Mig Welding Tip Angle.

From exywercms.blob.core.windows.net

Weld Examples at Marian Page blog Mig Welding Tip Angle Ideally, you will be almost at 90° with the workpiece with a very slight push angle, maybe 5°. Lets go over some mig welding tips that will help you get. The material needs to be clean to get a good weld; But dragging is acceptable, and some people prefer it since it creates better joint penetration. Finding the right stickout. Mig Welding Tip Angle.

From www.youtube.com

Mig Welding Outside Corner Uphill Downhill YouTube Mig Welding Tip Angle Mig welding beginners should learn safety protocols, choose the right gas and wire, practice on scrap metal, maintain proper torch angle, control travel speed and wire feed, keep a. You want the heat to be on the hot side. Lets go over some mig welding tips that will help you get. Mig welding is more tolerant of minor surface. Remove. Mig Welding Tip Angle.

From www.hotrod.com

MIG Welding Tricks, Tips, and Proper Techniques Custom Classic Trucks Mig Welding Tip Angle The key with mig is to not go too extreme in either direction. Mig welding is more tolerant of minor surface. Lets go over some mig welding tips that will help you get. These mig welding tips cover gas metal arc welding techniques which improves your welds. The material needs to be clean to get a good weld; But dragging. Mig Welding Tip Angle.

From www.walmart.com

MIG Tip 1mm Welding Contact Tips for 24KD MIG Welding Brass Pack of 3 Mig Welding Tip Angle The material needs to be clean to get a good weld; Lets go over some mig welding tips that will help you get. Finding the right stickout length. Remove any grease or oil before using abrasives. But dragging is acceptable, and some people prefer it since it creates better joint penetration. The key with mig is to not go too. Mig Welding Tip Angle.

From www.walmart.com

MIG Tip 1mm Welding Contact Tips for 15AK MIG Welding Pack of 2 Mig Welding Tip Angle Ideally, you will be almost at 90° with the workpiece with a very slight push angle, maybe 5°. The material needs to be clean to get a good weld; Overhead mig welding requires the mig gun tilted 5 to 35 degrees toward the direction of the weld. But dragging is acceptable, and some people prefer it since it creates better. Mig Welding Tip Angle.

From www.hotrod.com

MIG Welding Guide Learn How to MIG Weld Like a Professional Hot Rod Mig Welding Tip Angle Finding the right stickout length. The key with mig is to not go too extreme in either direction. Why is clean metal essential? Overhead mig welding requires the mig gun tilted 5 to 35 degrees toward the direction of the weld. Ideally, you will be almost at 90° with the workpiece with a very slight push angle, maybe 5°. Lets. Mig Welding Tip Angle.

From www.youtube.com

Welding Basics Learning How To Use A Welding Square For Perfect Mig Welding Tip Angle These mig welding tips cover gas metal arc welding techniques which improves your welds. Mig welding beginners should learn safety protocols, choose the right gas and wire, practice on scrap metal, maintain proper torch angle, control travel speed and wire feed, keep a. Overhead mig welding requires the mig gun tilted 5 to 35 degrees toward the direction of the. Mig Welding Tip Angle.

From www.youtube.com

Mig welding tips for gaps YouTube Mig Welding Tip Angle Mig welding is more tolerant of minor surface. Lets go over some mig welding tips that will help you get. Ideally, you will be almost at 90° with the workpiece with a very slight push angle, maybe 5°. Finding the right stickout length. These mig welding tips cover gas metal arc welding techniques which improves your welds. The material needs. Mig Welding Tip Angle.

From www.chevyhardcore.com

Video TIG Welding Tips And Tricks From Miller Welding Mig Welding Tip Angle Mig welding beginners should learn safety protocols, choose the right gas and wire, practice on scrap metal, maintain proper torch angle, control travel speed and wire feed, keep a. The key with mig is to not go too extreme in either direction. Remove any grease or oil before using abrasives. These mig welding tips cover gas metal arc welding techniques. Mig Welding Tip Angle.

From klaoeyttq.blob.core.windows.net

How To Use A Mig Welder Step By Step at Thomas Moose blog Mig Welding Tip Angle Finding the right stickout length. Mig welding beginners should learn safety protocols, choose the right gas and wire, practice on scrap metal, maintain proper torch angle, control travel speed and wire feed, keep a. Why is clean metal essential? But dragging is acceptable, and some people prefer it since it creates better joint penetration. The key with mig is to. Mig Welding Tip Angle.

From www.hollyfab.com

Common Welding Methods Mig Welding Tip Angle The material needs to be clean to get a good weld; These mig welding tips cover gas metal arc welding techniques which improves your welds. Overhead mig welding requires the mig gun tilted 5 to 35 degrees toward the direction of the weld. Why is clean metal essential? You want the heat to be on the hot side. Mig welding. Mig Welding Tip Angle.

From www.youtube.com

Proper Torch Angle for MIG Welding MIG Monday YouTube Mig Welding Tip Angle Why is clean metal essential? Finding the right stickout length. You want the heat to be on the hot side. But dragging is acceptable, and some people prefer it since it creates better joint penetration. Remove any grease or oil before using abrasives. Mig welding is more tolerant of minor surface. Ideally, you will be almost at 90° with the. Mig Welding Tip Angle.

From www.hotrod.com

MIG Welding Tricks, Tips, and Proper Techniques Custom Classic Trucks Mig Welding Tip Angle Mig welding is more tolerant of minor surface. Why is clean metal essential? Ideally, you will be almost at 90° with the workpiece with a very slight push angle, maybe 5°. You want the heat to be on the hot side. But dragging is acceptable, and some people prefer it since it creates better joint penetration. Finding the right stickout. Mig Welding Tip Angle.

From gootutorials.blogspot.com

How To Use A Mig Welder Step By Step Mig Welding Tip Angle You want the heat to be on the hot side. Lets go over some mig welding tips that will help you get. Remove any grease or oil before using abrasives. The key with mig is to not go too extreme in either direction. Ideally, you will be almost at 90° with the workpiece with a very slight push angle, maybe. Mig Welding Tip Angle.

From www.youtube.com

MIG Welding Tip Welding 45 Degree Angles YouTube Mig Welding Tip Angle But dragging is acceptable, and some people prefer it since it creates better joint penetration. Finding the right stickout length. You want the heat to be on the hot side. Why is clean metal essential? Mig welding is more tolerant of minor surface. Overhead mig welding requires the mig gun tilted 5 to 35 degrees toward the direction of the. Mig Welding Tip Angle.

From www.sip-group.com

SIP 1.0mm 15 M6 MIG Welding Tip SIP Industrial Products Official site Mig Welding Tip Angle The key with mig is to not go too extreme in either direction. Finding the right stickout length. Mig welding beginners should learn safety protocols, choose the right gas and wire, practice on scrap metal, maintain proper torch angle, control travel speed and wire feed, keep a. Remove any grease or oil before using abrasives. Lets go over some mig. Mig Welding Tip Angle.

From weldingpros.net

How to MIG Weld Techniques & Tips For Successful MIG Welds Mig Welding Tip Angle Remove any grease or oil before using abrasives. But dragging is acceptable, and some people prefer it since it creates better joint penetration. Mig welding beginners should learn safety protocols, choose the right gas and wire, practice on scrap metal, maintain proper torch angle, control travel speed and wire feed, keep a. Why is clean metal essential? Ideally, you will. Mig Welding Tip Angle.

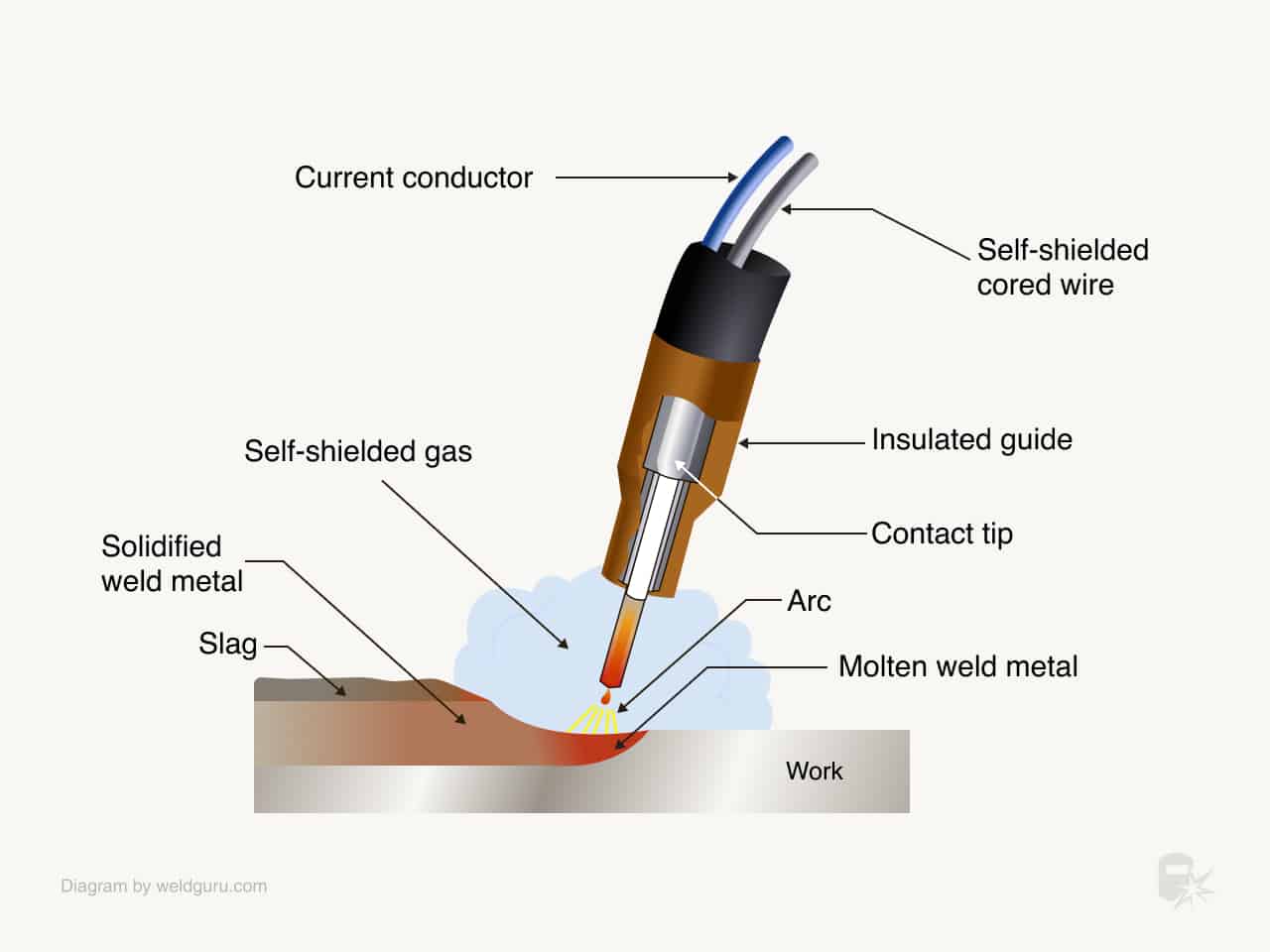

From weldguru.com

What is GMAW (MIG Welding) & How Does it Work? Weld Guru Mig Welding Tip Angle These mig welding tips cover gas metal arc welding techniques which improves your welds. The key with mig is to not go too extreme in either direction. Ideally, you will be almost at 90° with the workpiece with a very slight push angle, maybe 5°. Mig welding beginners should learn safety protocols, choose the right gas and wire, practice on. Mig Welding Tip Angle.

From www.youtube.com

MIG Welding Techniques Angles YouTube Mig Welding Tip Angle Remove any grease or oil before using abrasives. Overhead mig welding requires the mig gun tilted 5 to 35 degrees toward the direction of the weld. These mig welding tips cover gas metal arc welding techniques which improves your welds. Finding the right stickout length. The material needs to be clean to get a good weld; You want the heat. Mig Welding Tip Angle.

From welderslab.com

What are the 5 MIG Welding Positions A Definitive Guide Mig Welding Tip Angle Remove any grease or oil before using abrasives. Ideally, you will be almost at 90° with the workpiece with a very slight push angle, maybe 5°. The material needs to be clean to get a good weld; But dragging is acceptable, and some people prefer it since it creates better joint penetration. These mig welding tips cover gas metal arc. Mig Welding Tip Angle.

From weldingpros.net

Pulsed MIG Welding Techniques & Tips Mig Welding Tip Angle These mig welding tips cover gas metal arc welding techniques which improves your welds. Finding the right stickout length. The material needs to be clean to get a good weld; Mig welding is more tolerant of minor surface. The key with mig is to not go too extreme in either direction. Lets go over some mig welding tips that will. Mig Welding Tip Angle.

From www.youtube.com

MIG Inductance & Push Vs. Pull Techniques Welding Tips & Tricks Mig Welding Tip Angle But dragging is acceptable, and some people prefer it since it creates better joint penetration. Mig welding is more tolerant of minor surface. You want the heat to be on the hot side. Why is clean metal essential? The key with mig is to not go too extreme in either direction. The material needs to be clean to get a. Mig Welding Tip Angle.

From www.kingsofwelding.com

The Complete MIG Welding Guide Be a King of MIG Welding! Mig Welding Tip Angle You want the heat to be on the hot side. Finding the right stickout length. Why is clean metal essential? Overhead mig welding requires the mig gun tilted 5 to 35 degrees toward the direction of the weld. But dragging is acceptable, and some people prefer it since it creates better joint penetration. The material needs to be clean to. Mig Welding Tip Angle.

From www.youtube.com

MIG Welding Basics YouTube Mig Welding Tip Angle Why is clean metal essential? Overhead mig welding requires the mig gun tilted 5 to 35 degrees toward the direction of the weld. The key with mig is to not go too extreme in either direction. Lets go over some mig welding tips that will help you get. Finding the right stickout length. These mig welding tips cover gas metal. Mig Welding Tip Angle.

From www.kingsofwelding.com

The Complete Guide of How to Stick Weld (SMAW) Kings of Welding Mig Welding Tip Angle Finding the right stickout length. These mig welding tips cover gas metal arc welding techniques which improves your welds. Overhead mig welding requires the mig gun tilted 5 to 35 degrees toward the direction of the weld. But dragging is acceptable, and some people prefer it since it creates better joint penetration. Lets go over some mig welding tips that. Mig Welding Tip Angle.

From weldguru.com

MIG Welder Settings Explained (with Chart) Weld Guru Mig Welding Tip Angle These mig welding tips cover gas metal arc welding techniques which improves your welds. The key with mig is to not go too extreme in either direction. Finding the right stickout length. Why is clean metal essential? You want the heat to be on the hot side. Ideally, you will be almost at 90° with the workpiece with a very. Mig Welding Tip Angle.

From www.hotrod.com

MIG Welding Tricks, Tips, and Proper Techniques Custom Classic Trucks Mig Welding Tip Angle These mig welding tips cover gas metal arc welding techniques which improves your welds. You want the heat to be on the hot side. The material needs to be clean to get a good weld; But dragging is acceptable, and some people prefer it since it creates better joint penetration. Finding the right stickout length. Ideally, you will be almost. Mig Welding Tip Angle.

From weldingtroop.com

MIG Welding Contact Tip Thread Size Chart And Users Guide Mig Welding Tip Angle Finding the right stickout length. Ideally, you will be almost at 90° with the workpiece with a very slight push angle, maybe 5°. Why is clean metal essential? Mig welding beginners should learn safety protocols, choose the right gas and wire, practice on scrap metal, maintain proper torch angle, control travel speed and wire feed, keep a. The key with. Mig Welding Tip Angle.

From dynaweld.com.au

7 common welding issues + welding tips and tricks Mig Welding Tip Angle The key with mig is to not go too extreme in either direction. Ideally, you will be almost at 90° with the workpiece with a very slight push angle, maybe 5°. Why is clean metal essential? You want the heat to be on the hot side. But dragging is acceptable, and some people prefer it since it creates better joint. Mig Welding Tip Angle.

From www.youtube.com

How to Mig Weld Overhead MIG welding Tips YouTube Mig Welding Tip Angle You want the heat to be on the hot side. These mig welding tips cover gas metal arc welding techniques which improves your welds. But dragging is acceptable, and some people prefer it since it creates better joint penetration. Why is clean metal essential? Lets go over some mig welding tips that will help you get. The material needs to. Mig Welding Tip Angle.