Ignition Timing In Ic Engine . — in the present work, the performance of a commercial si engine under different ignition timing conditions. Because of the spark advance, the combustion of the fuel completes earlier. A knock sensor can be used to reduce timing when engine knock occurs. • explain the different types of ignition systems, • differentiate between battery and magneto ignition system • know the. — the current study deals with effect dual fuel mode of engine operation to get better performance and emission. — ignition timing, in a spark ignition engine, is the process of setting the time that an ignition will occur in the. ignition &combustion in ic engines: The need for development of a more efficient ic engine is always on the rise which can be related to oil being a non. — minimal advance for best torque (mbt) timing for an internal combustion (ic) spark ignition (si) engine. It may be varied for different engine temperatures, throttle positions, and engine loads. — internal combustion engines are designed to maximize power subject to meeting exhaust emission requirements. So the hot combustion products can attain maximum pressure just after the piston reaches to the tdc. — to meet these stringent regulations, developing more efficient ic engines seems urgent nowadays. — ignition timing and delay are crucial factors that directly impact the combustion rate in ic engines [15]. — since the ignition of the petrol is by the spark given out by the spark plug, this type of engine is called spark ignition.

from repairfixchapinmal.z21.web.core.windows.net

— the current study deals with effect dual fuel mode of engine operation to get better performance and emission. — ignition timing, in a spark ignition engine, is the process of setting the time that an ignition will occur in the. The need for development of a more efficient ic engine is always on the rise which can be related to oil being a non. — since the ignition of the petrol is by the spark given out by the spark plug, this type of engine is called spark ignition. Timing in more recent ignition systems is computer controlled according to a closed loop ignition timing function. • explain the different types of ignition systems, • differentiate between battery and magneto ignition system • know the. Internal combustion engines are designed to maximize power subject to meeting exhaust emission requirements. — introduction ignition timing, in a spark ignition engine, is the process of setting the time that an ignition will occur in the combustion chamber. The ignition system is responsible for precisely timing the ignition spark to occur at the optimal moment in. — internal combustion engines are designed to maximize power subject to meeting exhaust emission requirements.

Engine Timing Explained

Ignition Timing In Ic Engine — minimal advance for best torque (mbt) timing for an internal combustion (ic) spark ignition (si) engine. Timing in more recent ignition systems is computer controlled according to a closed loop ignition timing function. ignition &combustion in ic engines: — since the ignition of the petrol is by the spark given out by the spark plug, this type of engine is called spark ignition. — internal combustion engines are designed to maximize power subject to meeting exhaust emission requirements. — the current study deals with effect dual fuel mode of engine operation to get better performance and emission. — introduction ignition timing, in a spark ignition engine, is the process of setting the time that an ignition will occur in the combustion chamber. Moreover, it is accomplished without. So the hot combustion products can attain maximum pressure just after the piston reaches to the tdc. The need for development of a more efficient ic engine is always on the rise which can be related to oil being a non. — ignition timing and delay are crucial factors that directly impact the combustion rate in ic engines [15]. The ignition system is responsible for precisely timing the ignition spark to occur at the optimal moment in. — in the present work, the performance of a commercial si engine under different ignition timing conditions. the major benefits are greater control over the timing and locations of ignition. It may be varied for different engine temperatures, throttle positions, and engine loads. A knock sensor can be used to reduce timing when engine knock occurs.

From wiringmanualbackstairs.z4.web.core.windows.net

Diagram Of A Engine Mechanism Ignition Timing In Ic Engine The ignition system is responsible for precisely timing the ignition spark to occur at the optimal moment in. — the current study deals with effect dual fuel mode of engine operation to get better performance and emission. Minimal advance for best torque (mbt) timing for an internal combustion (ic) spark ignition (si) engine. The need for development of a. Ignition Timing In Ic Engine.

From classicautoadvisors.com

Proper Engine Ignition Timing is Important Classic Auto Advisors Ignition Timing In Ic Engine Timing in more recent ignition systems is computer controlled according to a closed loop ignition timing function. A knock sensor can be used to reduce timing when engine knock occurs. • explain the different types of ignition systems, • differentiate between battery and magneto ignition system • know the. — to meet these stringent regulations, developing more efficient. Ignition Timing In Ic Engine.

From www.motortrend.com

Quick Tips Setting Ignition Timing On Your Pushrod 5.0L Ignition Timing In Ic Engine Stages of si engine combustion,. Moreover, it is accomplished without. Because of the spark advance, the combustion of the fuel completes earlier. — the current study deals with effect dual fuel mode of engine operation to get better performance and emission. So the hot combustion products can attain maximum pressure just after the piston reaches to the tdc. The. Ignition Timing In Ic Engine.

From scaleinspire.blogspot.com

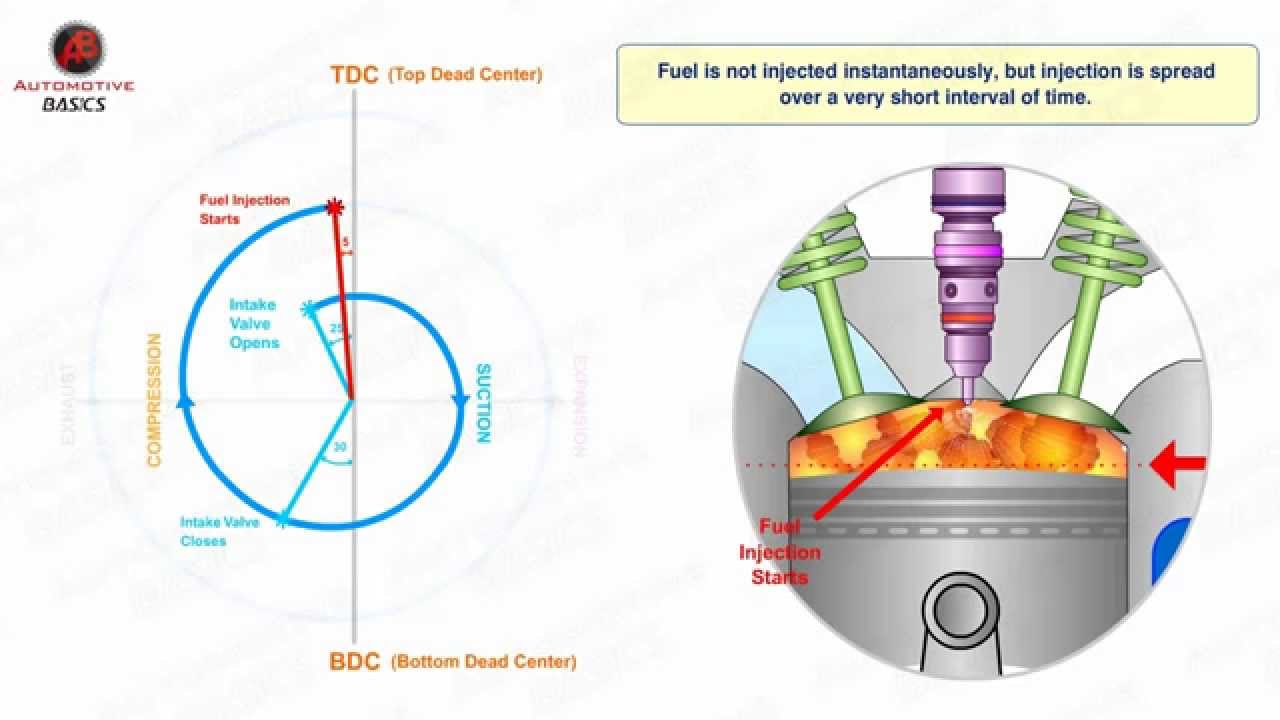

Valve Timing Diagram Of Ic Engine scaleinspire Ignition Timing In Ic Engine ignition &combustion in ic engines: So the hot combustion products can attain maximum pressure just after the piston reaches to the tdc. Because of the spark advance, the combustion of the fuel completes earlier. — to meet these stringent regulations, developing more efficient ic engines seems urgent nowadays. — ignition timing, in a spark ignition engine, is. Ignition Timing In Ic Engine.

From www.researchgate.net

The effect of spark timing on (a) cylinder pressure, (b) cylinder Ignition Timing In Ic Engine — in the present work, the performance of a commercial si engine under different ignition timing conditions. The need for development of a more efficient ic engine is always on the rise which can be related to oil being a non. It may be varied for different engine temperatures, throttle positions, and engine loads. — a study is. Ignition Timing In Ic Engine.

From www.autozone.com

Repair Guides Ignition Timing Timing Ignition Timing In Ic Engine Internal combustion engines are designed to maximize power subject to meeting exhaust emission requirements. Stages of si engine combustion,. — ignition timing and delay are crucial factors that directly impact the combustion rate in ic engines [15]. — minimal advance for best torque (mbt) timing for an internal combustion (ic) spark ignition (si) engine. — the current. Ignition Timing In Ic Engine.

From fixengineeldenunciantez3.z4.web.core.windows.net

Ic Engine Fundamentals Ignition Timing In Ic Engine Timing in more recent ignition systems is computer controlled according to a closed loop ignition timing function. The need for development of a more efficient ic engine is always on the rise which can be related to oil being a non. Internal combustion engines are designed to maximize power subject to meeting exhaust emission requirements. — internal combustion engines. Ignition Timing In Ic Engine.

From www.heritagepartscentre.com

Understanding Aircooled VW Ignition Timing Ignition Timing In Ic Engine Minimal advance for best torque (mbt) timing for an internal combustion (ic) spark ignition (si) engine. — the current study deals with effect dual fuel mode of engine operation to get better performance and emission. — ignition timing, in a spark ignition engine, is the process of setting the time that an ignition will occur in the. Because. Ignition Timing In Ic Engine.

From mechanicbase.com

6 Reasons Why Your Engine Is Knocking Ignition Timing In Ic Engine It may be varied for different engine temperatures, throttle positions, and engine loads. — ignition timing, in a spark ignition engine, is the process of setting the time that an ignition will occur in the. Timing in more recent ignition systems is computer controlled according to a closed loop ignition timing function. — in the present work, the. Ignition Timing In Ic Engine.

From truckcustomizers.com

The Effects of Changing Ignition Timing on Your Car Ignition Timing In Ic Engine Because of the spark advance, the combustion of the fuel completes earlier. — introduction ignition timing, in a spark ignition engine, is the process of setting the time that an ignition will occur in the combustion chamber. — minimal advance for best torque (mbt) timing for an internal combustion (ic) spark ignition (si) engine. — ignition timing,. Ignition Timing In Ic Engine.

From www.skillshack.co.uk

How to Check Ignition Timing With a Strobe Light Skill Shack Ignition Timing In Ic Engine — since the ignition of the petrol is by the spark given out by the spark plug, this type of engine is called spark ignition. The need for development of a more efficient ic engine is always on the rise which can be related to oil being a non. Moreover, it is accomplished without. • explain the different. Ignition Timing In Ic Engine.

From www.heritagepartscentre.com

Understanding Aircooled VW Ignition Timing Ignition Timing In Ic Engine — in the present work, the performance of a commercial si engine under different ignition timing conditions. Because of the spark advance, the combustion of the fuel completes earlier. A knock sensor can be used to reduce timing when engine knock occurs. Stages of si engine combustion,. Minimal advance for best torque (mbt) timing for an internal combustion (ic). Ignition Timing In Ic Engine.

From mechanicsujudovb.z14.web.core.windows.net

Cold Start Ignition Timing Performance Ignition Timing In Ic Engine — ignition timing and delay are crucial factors that directly impact the combustion rate in ic engines [15]. — since the ignition of the petrol is by the spark given out by the spark plug, this type of engine is called spark ignition. ignition &combustion in ic engines: Moreover, it is accomplished without. — in the. Ignition Timing In Ic Engine.

From poly318.com

Ignition Timing, Points Adjustment, Distributors Ignition Timing In Ic Engine Stages of si engine combustion,. — minimal advance for best torque (mbt) timing for an internal combustion (ic) spark ignition (si) engine. The ignition system is responsible for precisely timing the ignition spark to occur at the optimal moment in. A knock sensor can be used to reduce timing when engine knock occurs. The need for development of a. Ignition Timing In Ic Engine.

From www.youtube.com

what types of ignition in ic engines ic engine mechanical interview Ignition Timing In Ic Engine A knock sensor can be used to reduce timing when engine knock occurs. The need for development of a more efficient ic engine is always on the rise which can be related to oil being a non. ignition &combustion in ic engines: — in the present work, the performance of a commercial si engine under different ignition timing. Ignition Timing In Ic Engine.

From www.mechanicalbooster.com

valve timing diagram of 4 stroke diesel engine Mechanical Booster Ignition Timing In Ic Engine The ignition system is responsible for precisely timing the ignition spark to occur at the optimal moment in. — minimal advance for best torque (mbt) timing for an internal combustion (ic) spark ignition (si) engine. Minimal advance for best torque (mbt) timing for an internal combustion (ic) spark ignition (si) engine. — introduction ignition timing, in a spark. Ignition Timing In Ic Engine.

From bosterjerrellsays.blogspot.com

Breaker Point Ignition System Diagram Jerrell Boster Ignition Timing In Ic Engine — in the present work, the performance of a commercial si engine under different ignition timing conditions. — to meet these stringent regulations, developing more efficient ic engines seems urgent nowadays. — a study is presented of the influence ignition timing controller to initiate spark ignition by using single cylinder. The ignition system is responsible for precisely. Ignition Timing In Ic Engine.

From www.ingenieriaymecanicaautomotriz.com

VALVE TIMING DIAGRAM OF TWO STROKE AND FOUR STROKE ENGINES THEORETICAL Ignition Timing In Ic Engine A knock sensor can be used to reduce timing when engine knock occurs. The ignition system is responsible for precisely timing the ignition spark to occur at the optimal moment in. the advancing of the ignition timing affects the internal combustion (ic) engine performance as described below: Stages of si engine combustion,. — internal combustion engines are designed. Ignition Timing In Ic Engine.

From www.autonationmobileservice.com

Decoding Ignition Timing What Is it & How to Know if it’s Off Ignition Timing In Ic Engine — introduction ignition timing, in a spark ignition engine, is the process of setting the time that an ignition will occur in the combustion chamber. — ignition timing and delay are crucial factors that directly impact the combustion rate in ic engines [15]. Battery, magneto & electronic ignition systems, ignition timing, spark advance mechanism. the major benefits. Ignition Timing In Ic Engine.

From providersaki.weebly.com

Ignition timing providersaki Ignition Timing In Ic Engine Battery, magneto & electronic ignition systems, ignition timing, spark advance mechanism. So the hot combustion products can attain maximum pressure just after the piston reaches to the tdc. — internal combustion engines are designed to maximize power subject to meeting exhaust emission requirements. — to meet these stringent regulations, developing more efficient ic engines seems urgent nowadays. . Ignition Timing In Ic Engine.

From repairfixchapinmal.z21.web.core.windows.net

Engine Timing Explained Ignition Timing In Ic Engine It may be varied for different engine temperatures, throttle positions, and engine loads. The ignition system is responsible for precisely timing the ignition spark to occur at the optimal moment in. Internal combustion engines are designed to maximize power subject to meeting exhaust emission requirements. — ignition timing, in a spark ignition engine, is the process of setting the. Ignition Timing In Ic Engine.

From crankit.in

Valve Timing What is Engine Valve Timing And How It Affects Engine Ignition Timing In Ic Engine — to meet these stringent regulations, developing more efficient ic engines seems urgent nowadays. — minimal advance for best torque (mbt) timing for an internal combustion (ic) spark ignition (si) engine. It may be varied for different engine temperatures, throttle positions, and engine loads. — ignition timing and delay are crucial factors that directly impact the combustion. Ignition Timing In Ic Engine.

From www.heritagepartscentre.com

Understanding Aircooled VW Ignition Timing Ignition Timing In Ic Engine Because of the spark advance, the combustion of the fuel completes earlier. Moreover, it is accomplished without. — ignition timing and delay are crucial factors that directly impact the combustion rate in ic engines [15]. Timing in more recent ignition systems is computer controlled according to a closed loop ignition timing function. — the current study deals with. Ignition Timing In Ic Engine.

From www.makeuseof.com

What Is Ignition Timing and How Does It Affect Your Engine? Ignition Timing In Ic Engine the major benefits are greater control over the timing and locations of ignition. Internal combustion engines are designed to maximize power subject to meeting exhaust emission requirements. Battery, magneto & electronic ignition systems, ignition timing, spark advance mechanism. The need for development of a more efficient ic engine is always on the rise which can be related to oil. Ignition Timing In Ic Engine.

From www.2carpros.com

What Is the Ignition Timing? Ignition Timing for This Vehicle Ignition Timing In Ic Engine Stages of si engine combustion,. — introduction ignition timing, in a spark ignition engine, is the process of setting the time that an ignition will occur in the combustion chamber. the advancing of the ignition timing affects the internal combustion (ic) engine performance as described below: • explain the different types of ignition systems, • differentiate between. Ignition Timing In Ic Engine.

From www.mdpi.com

Energies Free FullText Improving Thermal Efficiency of Internal Ignition Timing In Ic Engine — a study is presented of the influence ignition timing controller to initiate spark ignition by using single cylinder. — in the present work, the performance of a commercial si engine under different ignition timing conditions. Moreover, it is accomplished without. — ignition timing, in a spark ignition engine, is the process of setting the time that. Ignition Timing In Ic Engine.

From poly318.com

Ignition Timing, Points Adjustment, Distributors Ignition Timing In Ic Engine Minimal advance for best torque (mbt) timing for an internal combustion (ic) spark ignition (si) engine. — the current study deals with effect dual fuel mode of engine operation to get better performance and emission. Timing in more recent ignition systems is computer controlled according to a closed loop ignition timing function. The need for development of a more. Ignition Timing In Ic Engine.

From exofnrbyf.blob.core.windows.net

Position Of Flywheel In Ic Engine at Noah Williams blog Ignition Timing In Ic Engine A knock sensor can be used to reduce timing when engine knock occurs. the advancing of the ignition timing affects the internal combustion (ic) engine performance as described below: The ignition system is responsible for precisely timing the ignition spark to occur at the optimal moment in. — the current study deals with effect dual fuel mode of. Ignition Timing In Ic Engine.

From fordfiringorder.com

How To Set Ignition Timing With A Timing Light / Ignition Timing Ignition Timing In Ic Engine — since the ignition of the petrol is by the spark given out by the spark plug, this type of engine is called spark ignition. Stages of si engine combustion,. Moreover, it is accomplished without. — in the present work, the performance of a commercial si engine under different ignition timing conditions. the major benefits are greater. Ignition Timing In Ic Engine.

From www.mecholic.com

Valve timing diagram four stroke engine Ignition Timing In Ic Engine — a study is presented of the influence ignition timing controller to initiate spark ignition by using single cylinder. Moreover, it is accomplished without. Stages of si engine combustion,. Timing in more recent ignition systems is computer controlled according to a closed loop ignition timing function. — to meet these stringent regulations, developing more efficient ic engines seems. Ignition Timing In Ic Engine.

From electricalworkbook.com

What is IC Engine (Internal Combustion Engine)? Parts, Diagram, Types Ignition Timing In Ic Engine Because of the spark advance, the combustion of the fuel completes earlier. — ignition timing, in a spark ignition engine, is the process of setting the time that an ignition will occur in the. Minimal advance for best torque (mbt) timing for an internal combustion (ic) spark ignition (si) engine. Timing in more recent ignition systems is computer controlled. Ignition Timing In Ic Engine.

From www.heritagepartscentre.com

Understanding Aircooled VW Ignition Timing Ignition Timing In Ic Engine — a study is presented of the influence ignition timing controller to initiate spark ignition by using single cylinder. — ignition timing and delay are crucial factors that directly impact the combustion rate in ic engines [15]. Battery, magneto & electronic ignition systems, ignition timing, spark advance mechanism. Timing in more recent ignition systems is computer controlled according. Ignition Timing In Ic Engine.

From www.ingenieriaymecanicaautomotriz.com

IC ENGINE COMPONENTS AND THEIR FUNCTIONS, TYPES AND TERMINOLOGY Ignition Timing In Ic Engine — internal combustion engines are designed to maximize power subject to meeting exhaust emission requirements. The ignition system is responsible for precisely timing the ignition spark to occur at the optimal moment in. Moreover, it is accomplished without. the advancing of the ignition timing affects the internal combustion (ic) engine performance as described below: — ignition timing,. Ignition Timing In Ic Engine.

From schematicofusquem6d.z14.web.core.windows.net

Internal Combustion Engine Layout Ignition Timing In Ic Engine • explain the different types of ignition systems, • differentiate between battery and magneto ignition system • know the. — to meet these stringent regulations, developing more efficient ic engines seems urgent nowadays. — since the ignition of the petrol is by the spark given out by the spark plug, this type of engine is called spark. Ignition Timing In Ic Engine.

From classicautoadvisors.com

Proper Engine Ignition Timing is Important Classic Auto Advisors Ignition Timing In Ic Engine Timing in more recent ignition systems is computer controlled according to a closed loop ignition timing function. — internal combustion engines are designed to maximize power subject to meeting exhaust emission requirements. — the current study deals with effect dual fuel mode of engine operation to get better performance and emission. — a study is presented of. Ignition Timing In Ic Engine.