Cosmetic Defects In Manufacturing . Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken. Often in injection molding it is assumed. Understanding and addressing these issues is essential for any manufacturer aiming to foster customer loyalty and maintain a positive brand. Quality control in cosmetics refers to the systematic processes and procedures that manufacturers implement to ensure their. Like all manufacturing defects, cosmetic blemishes can occur anywhere in the product development process — from initial planning,. Cosmetics manufacturing is a critical process where the main goal is to produce cosmetics products that are safe, reliable, and. Rigorous adherence to good manufacturing practice minimizes the risk of adulteration or misbranding of cosmetics. The iso 22716 good manufacturing practices (gmp) for cosmetics was introduced to provide guidelines for the production, control, storage.

from perfectwerks.com

Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken. Understanding and addressing these issues is essential for any manufacturer aiming to foster customer loyalty and maintain a positive brand. Rigorous adherence to good manufacturing practice minimizes the risk of adulteration or misbranding of cosmetics. Quality control in cosmetics refers to the systematic processes and procedures that manufacturers implement to ensure their. Like all manufacturing defects, cosmetic blemishes can occur anywhere in the product development process — from initial planning,. Often in injection molding it is assumed. The iso 22716 good manufacturing practices (gmp) for cosmetics was introduced to provide guidelines for the production, control, storage. Cosmetics manufacturing is a critical process where the main goal is to produce cosmetics products that are safe, reliable, and.

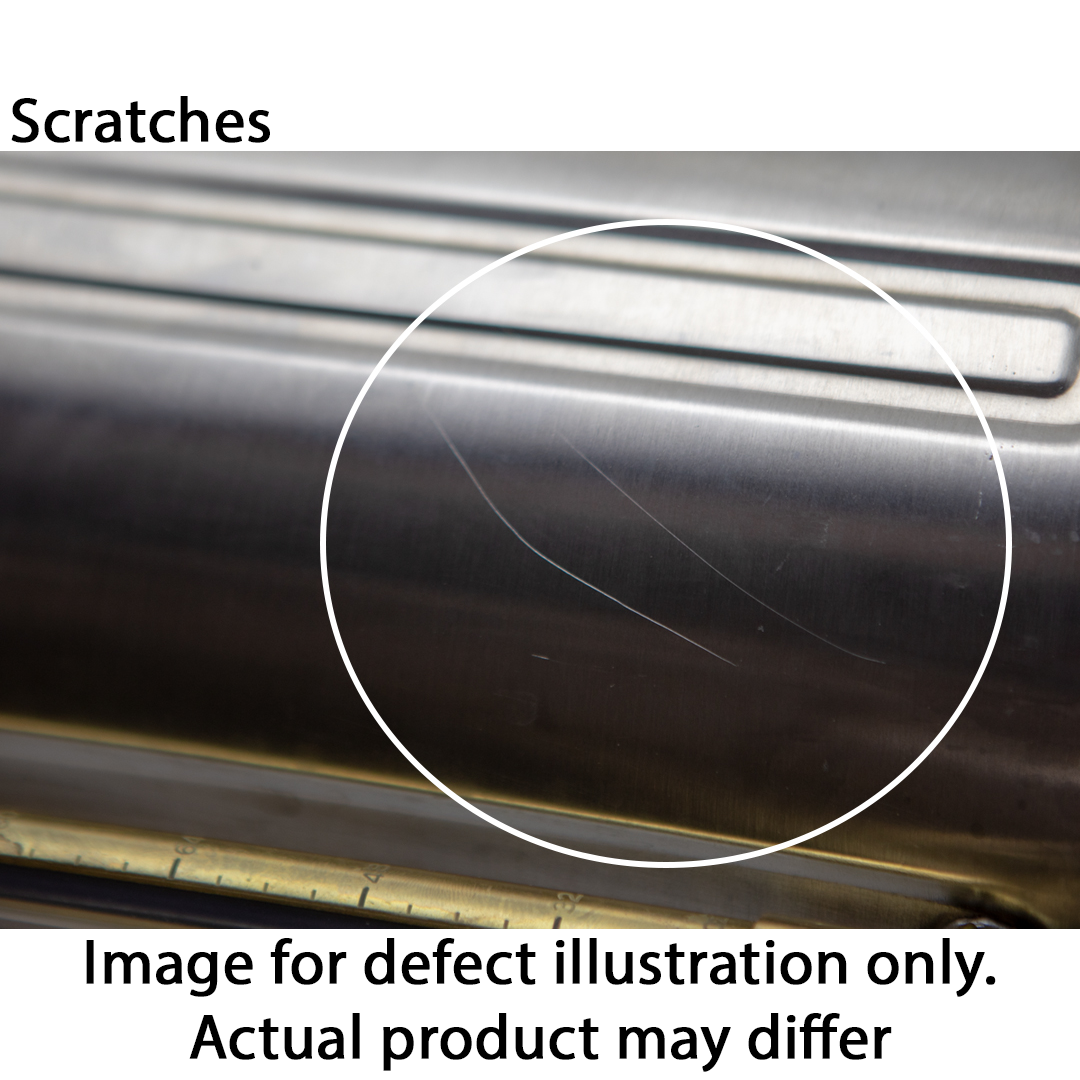

uKeg 128 Stainless Refurb with Minor Cosmetic Defects

Cosmetic Defects In Manufacturing Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken. Like all manufacturing defects, cosmetic blemishes can occur anywhere in the product development process — from initial planning,. Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken. Cosmetics manufacturing is a critical process where the main goal is to produce cosmetics products that are safe, reliable, and. Often in injection molding it is assumed. The iso 22716 good manufacturing practices (gmp) for cosmetics was introduced to provide guidelines for the production, control, storage. Quality control in cosmetics refers to the systematic processes and procedures that manufacturers implement to ensure their. Understanding and addressing these issues is essential for any manufacturer aiming to foster customer loyalty and maintain a positive brand. Rigorous adherence to good manufacturing practice minimizes the risk of adulteration or misbranding of cosmetics.

From kaass.com

Defective Skin Cosmetics KAASS LAW Cosmetic Defects In Manufacturing Quality control in cosmetics refers to the systematic processes and procedures that manufacturers implement to ensure their. Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken. Rigorous adherence to good manufacturing practice minimizes the risk of adulteration or misbranding of cosmetics. Often in injection. Cosmetic Defects In Manufacturing.

From discussions.apple.com

Cosmetic defect in the case, defect or no… Apple Community Cosmetic Defects In Manufacturing Cosmetics manufacturing is a critical process where the main goal is to produce cosmetics products that are safe, reliable, and. Quality control in cosmetics refers to the systematic processes and procedures that manufacturers implement to ensure their. Understanding and addressing these issues is essential for any manufacturer aiming to foster customer loyalty and maintain a positive brand. The iso 22716. Cosmetic Defects In Manufacturing.

From www.plasticmoulds.net

Troubleshooting Product Defects In Injection Moldingflash,short Shot Cosmetic Defects In Manufacturing The iso 22716 good manufacturing practices (gmp) for cosmetics was introduced to provide guidelines for the production, control, storage. Rigorous adherence to good manufacturing practice minimizes the risk of adulteration or misbranding of cosmetics. Often in injection molding it is assumed. Cosmetics manufacturing is a critical process where the main goal is to produce cosmetics products that are safe, reliable,. Cosmetic Defects In Manufacturing.

From www.mrpeasy.com

Manufacturing Defects Types, Examples, and Tips MRPeasy Cosmetic Defects In Manufacturing Like all manufacturing defects, cosmetic blemishes can occur anywhere in the product development process — from initial planning,. Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken. The iso 22716 good manufacturing practices (gmp) for cosmetics was introduced to provide guidelines for the production,. Cosmetic Defects In Manufacturing.

From www.minaprem.com

Substitutional Defect Point Defect Defects in Solid Materials Science Cosmetic Defects In Manufacturing Cosmetics manufacturing is a critical process where the main goal is to produce cosmetics products that are safe, reliable, and. Understanding and addressing these issues is essential for any manufacturer aiming to foster customer loyalty and maintain a positive brand. Quality control in cosmetics refers to the systematic processes and procedures that manufacturers implement to ensure their. Like all manufacturing. Cosmetic Defects In Manufacturing.

From www.mdpi.com

Cosmetics Free FullText Lipsticks History, Formulations, and Cosmetic Defects In Manufacturing Often in injection molding it is assumed. Quality control in cosmetics refers to the systematic processes and procedures that manufacturers implement to ensure their. Like all manufacturing defects, cosmetic blemishes can occur anywhere in the product development process — from initial planning,. The iso 22716 good manufacturing practices (gmp) for cosmetics was introduced to provide guidelines for the production, control,. Cosmetic Defects In Manufacturing.

From componentsbydesign.com

What Are Manufacturing Defects? Components By Design Cosmetic Defects In Manufacturing Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken. Rigorous adherence to good manufacturing practice minimizes the risk of adulteration or misbranding of cosmetics. Cosmetics manufacturing is a critical process where the main goal is to produce cosmetics products that are safe, reliable, and.. Cosmetic Defects In Manufacturing.

From www.researchgate.net

(PDF) Automatic Detection and Classification of Manufacturing Defects Cosmetic Defects In Manufacturing Often in injection molding it is assumed. Cosmetics manufacturing is a critical process where the main goal is to produce cosmetics products that are safe, reliable, and. Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken. Like all manufacturing defects, cosmetic blemishes can occur. Cosmetic Defects In Manufacturing.

From onthepulsenews.com

Ways To Reduce Defects in the Metal Manufacturing Process On the PULSE Cosmetic Defects In Manufacturing Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken. Quality control in cosmetics refers to the systematic processes and procedures that manufacturers implement to ensure their. The iso 22716 good manufacturing practices (gmp) for cosmetics was introduced to provide guidelines for the production, control,. Cosmetic Defects In Manufacturing.

From www.slideserve.com

PPT Ch. 8 Liability for Defective Products A. Introduction Cosmetic Defects In Manufacturing Quality control in cosmetics refers to the systematic processes and procedures that manufacturers implement to ensure their. Often in injection molding it is assumed. Understanding and addressing these issues is essential for any manufacturer aiming to foster customer loyalty and maintain a positive brand. Taking a step back and identifying the root cause of a cosmetic flaw can help molders. Cosmetic Defects In Manufacturing.

From encyclopedia.pub

Defect Synthesis for Automated Visual Inspection Encyclopedia MDPI Cosmetic Defects In Manufacturing Often in injection molding it is assumed. Rigorous adherence to good manufacturing practice minimizes the risk of adulteration or misbranding of cosmetics. Understanding and addressing these issues is essential for any manufacturer aiming to foster customer loyalty and maintain a positive brand. Quality control in cosmetics refers to the systematic processes and procedures that manufacturers implement to ensure their. Like. Cosmetic Defects In Manufacturing.

From protolabs.madeinthemidlands.com

Made in the Midlands 9 Cosmetic Defects and How to Avoid Them Cosmetic Defects In Manufacturing The iso 22716 good manufacturing practices (gmp) for cosmetics was introduced to provide guidelines for the production, control, storage. Quality control in cosmetics refers to the systematic processes and procedures that manufacturers implement to ensure their. Understanding and addressing these issues is essential for any manufacturer aiming to foster customer loyalty and maintain a positive brand. Like all manufacturing defects,. Cosmetic Defects In Manufacturing.

From www.mdpi.com

Metals Free FullText InSitu Defect Detection in Laser Powder Bed Cosmetic Defects In Manufacturing Like all manufacturing defects, cosmetic blemishes can occur anywhere in the product development process — from initial planning,. Quality control in cosmetics refers to the systematic processes and procedures that manufacturers implement to ensure their. Rigorous adherence to good manufacturing practice minimizes the risk of adulteration or misbranding of cosmetics. Taking a step back and identifying the root cause of. Cosmetic Defects In Manufacturing.

From www.fastradius.com

7 Injection Molding Defects and How to Avoid Cosmetic Defects In Manufacturing The iso 22716 good manufacturing practices (gmp) for cosmetics was introduced to provide guidelines for the production, control, storage. Often in injection molding it is assumed. Like all manufacturing defects, cosmetic blemishes can occur anywhere in the product development process — from initial planning,. Cosmetics manufacturing is a critical process where the main goal is to produce cosmetics products that. Cosmetic Defects In Manufacturing.

From www.mdpi.com

Applied Sciences Free FullText DualKernelBased Aggregated Cosmetic Defects In Manufacturing Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken. The iso 22716 good manufacturing practices (gmp) for cosmetics was introduced to provide guidelines for the production, control, storage. Understanding and addressing these issues is essential for any manufacturer aiming to foster customer loyalty and. Cosmetic Defects In Manufacturing.

From www.researchgate.net

Surface defects of steel plate. Download Scientific Diagram Cosmetic Defects In Manufacturing Cosmetics manufacturing is a critical process where the main goal is to produce cosmetics products that are safe, reliable, and. Rigorous adherence to good manufacturing practice minimizes the risk of adulteration or misbranding of cosmetics. Quality control in cosmetics refers to the systematic processes and procedures that manufacturers implement to ensure their. The iso 22716 good manufacturing practices (gmp) for. Cosmetic Defects In Manufacturing.

From www.slideserve.com

PPT CCDs PowerPoint Presentation, free download ID5731230 Cosmetic Defects In Manufacturing Like all manufacturing defects, cosmetic blemishes can occur anywhere in the product development process — from initial planning,. Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken. Understanding and addressing these issues is essential for any manufacturer aiming to foster customer loyalty and maintain. Cosmetic Defects In Manufacturing.

From bexchange.bonfiglioliengineering.com

Guide to defects detected by Visual Inspection Cosmetic Defects In Manufacturing Often in injection molding it is assumed. Understanding and addressing these issues is essential for any manufacturer aiming to foster customer loyalty and maintain a positive brand. Quality control in cosmetics refers to the systematic processes and procedures that manufacturers implement to ensure their. Like all manufacturing defects, cosmetic blemishes can occur anywhere in the product development process — from. Cosmetic Defects In Manufacturing.

From www.pioneerplastics.com

Injection Molding Defects and How to Avoid Them Cosmetic Defects In Manufacturing Rigorous adherence to good manufacturing practice minimizes the risk of adulteration or misbranding of cosmetics. Quality control in cosmetics refers to the systematic processes and procedures that manufacturers implement to ensure their. Understanding and addressing these issues is essential for any manufacturer aiming to foster customer loyalty and maintain a positive brand. Often in injection molding it is assumed. Taking. Cosmetic Defects In Manufacturing.

From www.optofidelity.com

Machine visionbased cosmetic defect detection enhanced with AI Make Cosmetic Defects In Manufacturing Understanding and addressing these issues is essential for any manufacturer aiming to foster customer loyalty and maintain a positive brand. Like all manufacturing defects, cosmetic blemishes can occur anywhere in the product development process — from initial planning,. Cosmetics manufacturing is a critical process where the main goal is to produce cosmetics products that are safe, reliable, and. Taking a. Cosmetic Defects In Manufacturing.

From www.hqts.com

How to Prevent Garment Defects in Apparel and Textile Industry HQTS Cosmetic Defects In Manufacturing Like all manufacturing defects, cosmetic blemishes can occur anywhere in the product development process — from initial planning,. Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken. Cosmetics manufacturing is a critical process where the main goal is to produce cosmetics products that are. Cosmetic Defects In Manufacturing.

From www.bestpracticesconstructionlaw.com

Cosmetic Defects Found to Be Basis for Termination of Contractor for Cosmetic Defects In Manufacturing Like all manufacturing defects, cosmetic blemishes can occur anywhere in the product development process — from initial planning,. Understanding and addressing these issues is essential for any manufacturer aiming to foster customer loyalty and maintain a positive brand. Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need. Cosmetic Defects In Manufacturing.

From perfectwerks.com

uKeg 128 Stainless Refurb with Minor Cosmetic Defects Cosmetic Defects In Manufacturing Often in injection molding it is assumed. Like all manufacturing defects, cosmetic blemishes can occur anywhere in the product development process — from initial planning,. The iso 22716 good manufacturing practices (gmp) for cosmetics was introduced to provide guidelines for the production, control, storage. Cosmetics manufacturing is a critical process where the main goal is to produce cosmetics products that. Cosmetic Defects In Manufacturing.

From www.youtube.com

Common Defects in Film Coating Process with Causes and Possible Cosmetic Defects In Manufacturing Cosmetics manufacturing is a critical process where the main goal is to produce cosmetics products that are safe, reliable, and. Understanding and addressing these issues is essential for any manufacturer aiming to foster customer loyalty and maintain a positive brand. Quality control in cosmetics refers to the systematic processes and procedures that manufacturers implement to ensure their. Rigorous adherence to. Cosmetic Defects In Manufacturing.

From www.mechanicalbooster.com

What is Casting Defects Types, Causes and Remedies? Mechanical Booster Cosmetic Defects In Manufacturing Rigorous adherence to good manufacturing practice minimizes the risk of adulteration or misbranding of cosmetics. Quality control in cosmetics refers to the systematic processes and procedures that manufacturers implement to ensure their. Like all manufacturing defects, cosmetic blemishes can occur anywhere in the product development process — from initial planning,. Cosmetics manufacturing is a critical process where the main goal. Cosmetic Defects In Manufacturing.

From slidetodoc.com

DEFECT IN PLASTIC INJECTION MOULDING PROCESS DEFECT IN Cosmetic Defects In Manufacturing Rigorous adherence to good manufacturing practice minimizes the risk of adulteration or misbranding of cosmetics. Cosmetics manufacturing is a critical process where the main goal is to produce cosmetics products that are safe, reliable, and. Quality control in cosmetics refers to the systematic processes and procedures that manufacturers implement to ensure their. Like all manufacturing defects, cosmetic blemishes can occur. Cosmetic Defects In Manufacturing.

From www.slideserve.com

PPT Product Liability PowerPoint Presentation ID4000481 Cosmetic Defects In Manufacturing Often in injection molding it is assumed. The iso 22716 good manufacturing practices (gmp) for cosmetics was introduced to provide guidelines for the production, control, storage. Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken. Like all manufacturing defects, cosmetic blemishes can occur anywhere. Cosmetic Defects In Manufacturing.

From slidetodoc.com

DEFECT IN PLASTIC INJECTION MOULDING PROCESS DEFECT IN Cosmetic Defects In Manufacturing Like all manufacturing defects, cosmetic blemishes can occur anywhere in the product development process — from initial planning,. Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken. Rigorous adherence to good manufacturing practice minimizes the risk of adulteration or misbranding of cosmetics. Quality control. Cosmetic Defects In Manufacturing.

From mungfali.com

Manufacturing Defect Detection Cosmetic Defects In Manufacturing Understanding and addressing these issues is essential for any manufacturer aiming to foster customer loyalty and maintain a positive brand. Cosmetics manufacturing is a critical process where the main goal is to produce cosmetics products that are safe, reliable, and. Often in injection molding it is assumed. Quality control in cosmetics refers to the systematic processes and procedures that manufacturers. Cosmetic Defects In Manufacturing.

From perfectwerks.com

uKeg 128 Stainless Refurb with Minor Cosmetic Defects Cosmetic Defects In Manufacturing Understanding and addressing these issues is essential for any manufacturer aiming to foster customer loyalty and maintain a positive brand. Cosmetics manufacturing is a critical process where the main goal is to produce cosmetics products that are safe, reliable, and. Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective. Cosmetic Defects In Manufacturing.

From smith-law.org

Defective Products/Cosmetics The Smith Law Firm, PLLC Cosmetic Defects In Manufacturing Quality control in cosmetics refers to the systematic processes and procedures that manufacturers implement to ensure their. Often in injection molding it is assumed. Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken. Cosmetics manufacturing is a critical process where the main goal is. Cosmetic Defects In Manufacturing.

From www.drugplastics.com

Recognizing Defects in Plastic Packaging Drug Plastics & Glass Cosmetic Defects In Manufacturing Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken. Cosmetics manufacturing is a critical process where the main goal is to produce cosmetics products that are safe, reliable, and. The iso 22716 good manufacturing practices (gmp) for cosmetics was introduced to provide guidelines for. Cosmetic Defects In Manufacturing.

From www.iotforall.com

AI Visual Inspection For Defect Detection in Manufacturing Cosmetic Defects In Manufacturing Cosmetics manufacturing is a critical process where the main goal is to produce cosmetics products that are safe, reliable, and. The iso 22716 good manufacturing practices (gmp) for cosmetics was introduced to provide guidelines for the production, control, storage. Rigorous adherence to good manufacturing practice minimizes the risk of adulteration or misbranding of cosmetics. Understanding and addressing these issues is. Cosmetic Defects In Manufacturing.

From www.forbes.com

Manufacturing Defect Definition, Types & Examples Forbes Advisor Cosmetic Defects In Manufacturing Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken. Like all manufacturing defects, cosmetic blemishes can occur anywhere in the product development process — from initial planning,. Rigorous adherence to good manufacturing practice minimizes the risk of adulteration or misbranding of cosmetics. Cosmetics manufacturing. Cosmetic Defects In Manufacturing.

From www.dozuki.com

How To Reduce Defects in Manufacturing in 2022 Cosmetic Defects In Manufacturing Understanding and addressing these issues is essential for any manufacturer aiming to foster customer loyalty and maintain a positive brand. Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken. Rigorous adherence to good manufacturing practice minimizes the risk of adulteration or misbranding of cosmetics.. Cosmetic Defects In Manufacturing.