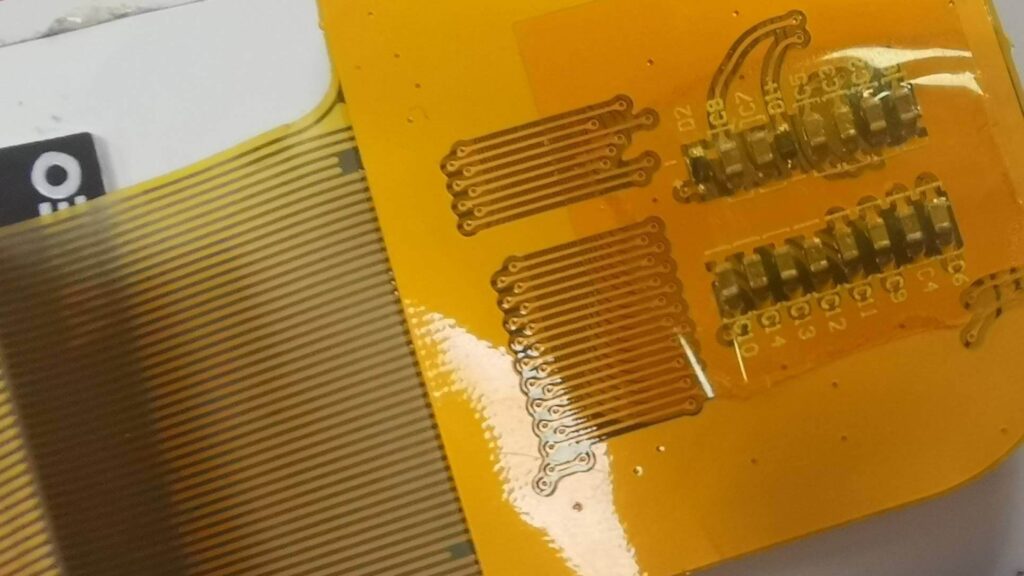

Soldering Flex Cable To Pcb . A second soldering option is to have pads on the bottom of the flex, not quite at the end of the board, and top of the rigid pcb. In addition, the arrangement of conductors on the flexible pcb eliminates mounting errors. Repairing broken flexible cables, image is oversized to show detail. Proper flex pcb soldering technique is critical to creating reliable solder joints that can withstand flexing without cracking or failing over time. In this case, the flexible printed circuit board is a profitable and reliable substrate. The video shows the repair of both a volume flex cable and power button flex cable on a single pcb. I am repairing a pcb (first photo), but the white flex cable with 12 pins spaced 0.5mm apart was directly soldered to the tracks on the. Solder paste, scissors, soldering iron,. First the damaged volume/power flex cables. Rather than buy an expensive replacement part, he shows us how to repair a soldered ribbon wire connection. Then the pads are joined with solder sandwiched.

from titoma.com

I am repairing a pcb (first photo), but the white flex cable with 12 pins spaced 0.5mm apart was directly soldered to the tracks on the. Then the pads are joined with solder sandwiched. The video shows the repair of both a volume flex cable and power button flex cable on a single pcb. In addition, the arrangement of conductors on the flexible pcb eliminates mounting errors. First the damaged volume/power flex cables. Solder paste, scissors, soldering iron,. In this case, the flexible printed circuit board is a profitable and reliable substrate. A second soldering option is to have pads on the bottom of the flex, not quite at the end of the board, and top of the rigid pcb. Proper flex pcb soldering technique is critical to creating reliable solder joints that can withstand flexing without cracking or failing over time. Repairing broken flexible cables, image is oversized to show detail.

Avoid Mistakes with These 7 Expert Flex Soldering Rules Titoma

Soldering Flex Cable To Pcb In this case, the flexible printed circuit board is a profitable and reliable substrate. Proper flex pcb soldering technique is critical to creating reliable solder joints that can withstand flexing without cracking or failing over time. Repairing broken flexible cables, image is oversized to show detail. I am repairing a pcb (first photo), but the white flex cable with 12 pins spaced 0.5mm apart was directly soldered to the tracks on the. Rather than buy an expensive replacement part, he shows us how to repair a soldered ribbon wire connection. Solder paste, scissors, soldering iron,. The video shows the repair of both a volume flex cable and power button flex cable on a single pcb. Then the pads are joined with solder sandwiched. First the damaged volume/power flex cables. A second soldering option is to have pads on the bottom of the flex, not quite at the end of the board, and top of the rigid pcb. In addition, the arrangement of conductors on the flexible pcb eliminates mounting errors. In this case, the flexible printed circuit board is a profitable and reliable substrate.

From titoma.com

Avoid Mistakes with These 7 Expert Flex Soldering Rules Titoma Soldering Flex Cable To Pcb Then the pads are joined with solder sandwiched. Rather than buy an expensive replacement part, he shows us how to repair a soldered ribbon wire connection. In addition, the arrangement of conductors on the flexible pcb eliminates mounting errors. The video shows the repair of both a volume flex cable and power button flex cable on a single pcb. I. Soldering Flex Cable To Pcb.

From hillmancurtis.com

How to Solder Wire to PCB Soldering Flex Cable To Pcb The video shows the repair of both a volume flex cable and power button flex cable on a single pcb. Solder paste, scissors, soldering iron,. In addition, the arrangement of conductors on the flexible pcb eliminates mounting errors. In this case, the flexible printed circuit board is a profitable and reliable substrate. First the damaged volume/power flex cables. A second. Soldering Flex Cable To Pcb.

From respuestas.me

El cable flexible plano soldado a PCB está desarrollando un Soldering Flex Cable To Pcb In addition, the arrangement of conductors on the flexible pcb eliminates mounting errors. In this case, the flexible printed circuit board is a profitable and reliable substrate. Repairing broken flexible cables, image is oversized to show detail. Then the pads are joined with solder sandwiched. Rather than buy an expensive replacement part, he shows us how to repair a soldered. Soldering Flex Cable To Pcb.

From www.pcbelec.com

How to Solder On Flex PCB? Flex PCB Assembly Guidelines JHYPCB Soldering Flex Cable To Pcb Repairing broken flexible cables, image is oversized to show detail. I am repairing a pcb (first photo), but the white flex cable with 12 pins spaced 0.5mm apart was directly soldered to the tracks on the. The video shows the repair of both a volume flex cable and power button flex cable on a single pcb. Solder paste, scissors, soldering. Soldering Flex Cable To Pcb.

From hilelectronic.com

5 Things You Need To Pay Attention To When Flex PCB Soldering Soldering Flex Cable To Pcb First the damaged volume/power flex cables. In addition, the arrangement of conductors on the flexible pcb eliminates mounting errors. Proper flex pcb soldering technique is critical to creating reliable solder joints that can withstand flexing without cracking or failing over time. In this case, the flexible printed circuit board is a profitable and reliable substrate. The video shows the repair. Soldering Flex Cable To Pcb.

From oliver.st

Flexible PCB connections Oliver's Blog Soldering Flex Cable To Pcb I am repairing a pcb (first photo), but the white flex cable with 12 pins spaced 0.5mm apart was directly soldered to the tracks on the. In addition, the arrangement of conductors on the flexible pcb eliminates mounting errors. Solder paste, scissors, soldering iron,. Proper flex pcb soldering technique is critical to creating reliable solder joints that can withstand flexing. Soldering Flex Cable To Pcb.

From www.alibaba.com

Fpc To Pcb Hsc To Fpc Flexible Circuit Board Hot Press Soldering Acf Soldering Flex Cable To Pcb I am repairing a pcb (first photo), but the white flex cable with 12 pins spaced 0.5mm apart was directly soldered to the tracks on the. In addition, the arrangement of conductors on the flexible pcb eliminates mounting errors. A second soldering option is to have pads on the bottom of the flex, not quite at the end of the. Soldering Flex Cable To Pcb.

From titoma.com

Avoid Mistakes with These 7 Expert Flex Soldering Rules Titoma Soldering Flex Cable To Pcb I am repairing a pcb (first photo), but the white flex cable with 12 pins spaced 0.5mm apart was directly soldered to the tracks on the. In this case, the flexible printed circuit board is a profitable and reliable substrate. A second soldering option is to have pads on the bottom of the flex, not quite at the end of. Soldering Flex Cable To Pcb.

From www.youtube.com

Manually soldering 1.0mm pitch FPC cables YouTube Soldering Flex Cable To Pcb Rather than buy an expensive replacement part, he shows us how to repair a soldered ribbon wire connection. I am repairing a pcb (first photo), but the white flex cable with 12 pins spaced 0.5mm apart was directly soldered to the tracks on the. Then the pads are joined with solder sandwiched. In addition, the arrangement of conductors on the. Soldering Flex Cable To Pcb.

From www.youtube.com

IoT32 RPTCQ Soldering Flat Flex to PCB LCD Initial Power Up and Soldering Flex Cable To Pcb Solder paste, scissors, soldering iron,. A second soldering option is to have pads on the bottom of the flex, not quite at the end of the board, and top of the rigid pcb. In this case, the flexible printed circuit board is a profitable and reliable substrate. In addition, the arrangement of conductors on the flexible pcb eliminates mounting errors.. Soldering Flex Cable To Pcb.

From cablelinker.en.alibaba.com

FPC Hotbar Soldering with exposed lead flex for PCB soldering, View Soldering Flex Cable To Pcb First the damaged volume/power flex cables. Proper flex pcb soldering technique is critical to creating reliable solder joints that can withstand flexing without cracking or failing over time. Solder paste, scissors, soldering iron,. I am repairing a pcb (first photo), but the white flex cable with 12 pins spaced 0.5mm apart was directly soldered to the tracks on the. Repairing. Soldering Flex Cable To Pcb.

From www.youtube.com

How to Repair Flex Cable Flexible PCB Type Flat Copper Ribbon Cable Soldering Flex Cable To Pcb Then the pads are joined with solder sandwiched. Solder paste, scissors, soldering iron,. The video shows the repair of both a volume flex cable and power button flex cable on a single pcb. In this case, the flexible printed circuit board is a profitable and reliable substrate. Proper flex pcb soldering technique is critical to creating reliable solder joints that. Soldering Flex Cable To Pcb.

From www.youtube.com

Castellation Solder Flex to PCB YouTube Soldering Flex Cable To Pcb I am repairing a pcb (first photo), but the white flex cable with 12 pins spaced 0.5mm apart was directly soldered to the tracks on the. Rather than buy an expensive replacement part, he shows us how to repair a soldered ribbon wire connection. In addition, the arrangement of conductors on the flexible pcb eliminates mounting errors. Solder paste, scissors,. Soldering Flex Cable To Pcb.

From www.alibaba.com

Fpc To Pcb Hsc To Fpc Flexible Circuit Board Hot Press Soldering Acf Soldering Flex Cable To Pcb In addition, the arrangement of conductors on the flexible pcb eliminates mounting errors. A second soldering option is to have pads on the bottom of the flex, not quite at the end of the board, and top of the rigid pcb. In this case, the flexible printed circuit board is a profitable and reliable substrate. Proper flex pcb soldering technique. Soldering Flex Cable To Pcb.

From www.reddit.com

Is it feasible to solder a flex cable on PCB ? r/electronics Soldering Flex Cable To Pcb The video shows the repair of both a volume flex cable and power button flex cable on a single pcb. In this case, the flexible printed circuit board is a profitable and reliable substrate. A second soldering option is to have pads on the bottom of the flex, not quite at the end of the board, and top of the. Soldering Flex Cable To Pcb.

From titoma.com

Avoid Mistakes with These 7 Expert Flex Soldering Rules Titoma Soldering Flex Cable To Pcb Proper flex pcb soldering technique is critical to creating reliable solder joints that can withstand flexing without cracking or failing over time. First the damaged volume/power flex cables. In addition, the arrangement of conductors on the flexible pcb eliminates mounting errors. A second soldering option is to have pads on the bottom of the flex, not quite at the end. Soldering Flex Cable To Pcb.

From nerdytechy.com

Flex Soldering Guide Everything You Should Know NerdyTechy Soldering Flex Cable To Pcb First the damaged volume/power flex cables. The video shows the repair of both a volume flex cable and power button flex cable on a single pcb. Proper flex pcb soldering technique is critical to creating reliable solder joints that can withstand flexing without cracking or failing over time. I am repairing a pcb (first photo), but the white flex cable. Soldering Flex Cable To Pcb.

From www.reddit.com

doesn't soldering the flex cable to the pcb defeat the purpose of the Soldering Flex Cable To Pcb Then the pads are joined with solder sandwiched. In this case, the flexible printed circuit board is a profitable and reliable substrate. A second soldering option is to have pads on the bottom of the flex, not quite at the end of the board, and top of the rigid pcb. Solder paste, scissors, soldering iron,. Proper flex pcb soldering technique. Soldering Flex Cable To Pcb.

From www.youtube.com

Flat flexible soldered connector / PCB with tapered strain relief (FFSC Soldering Flex Cable To Pcb Solder paste, scissors, soldering iron,. Repairing broken flexible cables, image is oversized to show detail. Rather than buy an expensive replacement part, he shows us how to repair a soldered ribbon wire connection. A second soldering option is to have pads on the bottom of the flex, not quite at the end of the board, and top of the rigid. Soldering Flex Cable To Pcb.

From www.newelectronics.co.uk

Rugged flat flex cable to PCB connection system Soldering Flex Cable To Pcb In addition, the arrangement of conductors on the flexible pcb eliminates mounting errors. The video shows the repair of both a volume flex cable and power button flex cable on a single pcb. Solder paste, scissors, soldering iron,. In this case, the flexible printed circuit board is a profitable and reliable substrate. Repairing broken flexible cables, image is oversized to. Soldering Flex Cable To Pcb.

From www.reddit.com

How to connect these flex cables r/soldering Soldering Flex Cable To Pcb Proper flex pcb soldering technique is critical to creating reliable solder joints that can withstand flexing without cracking or failing over time. Rather than buy an expensive replacement part, he shows us how to repair a soldered ribbon wire connection. In this case, the flexible printed circuit board is a profitable and reliable substrate. Solder paste, scissors, soldering iron,. The. Soldering Flex Cable To Pcb.

From titoma.com

Avoid Mistakes with These 7 Expert Flex Soldering Rules Titoma Soldering Flex Cable To Pcb I am repairing a pcb (first photo), but the white flex cable with 12 pins spaced 0.5mm apart was directly soldered to the tracks on the. A second soldering option is to have pads on the bottom of the flex, not quite at the end of the board, and top of the rigid pcb. First the damaged volume/power flex cables.. Soldering Flex Cable To Pcb.

From www.youtube.com

How to Solder a Wire to a Circuit Board YouTube Soldering Flex Cable To Pcb In this case, the flexible printed circuit board is a profitable and reliable substrate. Proper flex pcb soldering technique is critical to creating reliable solder joints that can withstand flexing without cracking or failing over time. A second soldering option is to have pads on the bottom of the flex, not quite at the end of the board, and top. Soldering Flex Cable To Pcb.

From hillmancurtis.com

How to Solder Wire to PCB Soldering Flex Cable To Pcb The video shows the repair of both a volume flex cable and power button flex cable on a single pcb. Rather than buy an expensive replacement part, he shows us how to repair a soldered ribbon wire connection. In addition, the arrangement of conductors on the flexible pcb eliminates mounting errors. Proper flex pcb soldering technique is critical to creating. Soldering Flex Cable To Pcb.

From www.wnie.online

Rugged flat flex cable to PCB connection system from offers Soldering Flex Cable To Pcb Repairing broken flexible cables, image is oversized to show detail. Rather than buy an expensive replacement part, he shows us how to repair a soldered ribbon wire connection. Solder paste, scissors, soldering iron,. A second soldering option is to have pads on the bottom of the flex, not quite at the end of the board, and top of the rigid. Soldering Flex Cable To Pcb.

From www.youtube.com

FFC Flexible Cable and FPC Flexible Circuit Board PCB Board Soldering Soldering Flex Cable To Pcb In addition, the arrangement of conductors on the flexible pcb eliminates mounting errors. A second soldering option is to have pads on the bottom of the flex, not quite at the end of the board, and top of the rigid pcb. The video shows the repair of both a volume flex cable and power button flex cable on a single. Soldering Flex Cable To Pcb.

From www.airborn.com

Flex Circuit Assemblies Soldering Flex Cable To Pcb Rather than buy an expensive replacement part, he shows us how to repair a soldered ribbon wire connection. Repairing broken flexible cables, image is oversized to show detail. In this case, the flexible printed circuit board is a profitable and reliable substrate. I am repairing a pcb (first photo), but the white flex cable with 12 pins spaced 0.5mm apart. Soldering Flex Cable To Pcb.

From www.youtube.com

How to soldering fpc flex cable YouTube Soldering Flex Cable To Pcb In addition, the arrangement of conductors on the flexible pcb eliminates mounting errors. Repairing broken flexible cables, image is oversized to show detail. First the damaged volume/power flex cables. I am repairing a pcb (first photo), but the white flex cable with 12 pins spaced 0.5mm apart was directly soldered to the tracks on the. A second soldering option is. Soldering Flex Cable To Pcb.

From www.pcbelec.com

How to Solder On Flex PCB? Flex PCB Assembly Guidelines JHYPCB Soldering Flex Cable To Pcb In this case, the flexible printed circuit board is a profitable and reliable substrate. Rather than buy an expensive replacement part, he shows us how to repair a soldered ribbon wire connection. The video shows the repair of both a volume flex cable and power button flex cable on a single pcb. First the damaged volume/power flex cables. Solder paste,. Soldering Flex Cable To Pcb.

From nerdytechy.com

Flex Soldering Guide Everything You Should Know NerdyTechy Soldering Flex Cable To Pcb Repairing broken flexible cables, image is oversized to show detail. Rather than buy an expensive replacement part, he shows us how to repair a soldered ribbon wire connection. Proper flex pcb soldering technique is critical to creating reliable solder joints that can withstand flexing without cracking or failing over time. The video shows the repair of both a volume flex. Soldering Flex Cable To Pcb.

From my.mech.utah.edu

Flexcircuit Soldering & Assembly Tutorial and Notes William R Soldering Flex Cable To Pcb Solder paste, scissors, soldering iron,. I am repairing a pcb (first photo), but the white flex cable with 12 pins spaced 0.5mm apart was directly soldered to the tracks on the. In this case, the flexible printed circuit board is a profitable and reliable substrate. In addition, the arrangement of conductors on the flexible pcb eliminates mounting errors. First the. Soldering Flex Cable To Pcb.

From www.alibaba.com

Fpc To Pcb Hsc To Fpc Flexible Circuit Board Hot Press Soldering Acf Soldering Flex Cable To Pcb In this case, the flexible printed circuit board is a profitable and reliable substrate. In addition, the arrangement of conductors on the flexible pcb eliminates mounting errors. The video shows the repair of both a volume flex cable and power button flex cable on a single pcb. Then the pads are joined with solder sandwiched. Proper flex pcb soldering technique. Soldering Flex Cable To Pcb.

From www.youtube.com

Soldering coaxial cable shield and core wire to PCB at the same time【39 Soldering Flex Cable To Pcb In this case, the flexible printed circuit board is a profitable and reliable substrate. Proper flex pcb soldering technique is critical to creating reliable solder joints that can withstand flexing without cracking or failing over time. I am repairing a pcb (first photo), but the white flex cable with 12 pins spaced 0.5mm apart was directly soldered to the tracks. Soldering Flex Cable To Pcb.

From www.youtube.com

How to Solder Wires Properly on PCB YouTube Soldering Flex Cable To Pcb Proper flex pcb soldering technique is critical to creating reliable solder joints that can withstand flexing without cracking or failing over time. Repairing broken flexible cables, image is oversized to show detail. I am repairing a pcb (first photo), but the white flex cable with 12 pins spaced 0.5mm apart was directly soldered to the tracks on the. Solder paste,. Soldering Flex Cable To Pcb.

From gradienteng.com

PCB/PCBA/Cable Gradient Design & Engineering Soldering Flex Cable To Pcb Then the pads are joined with solder sandwiched. In addition, the arrangement of conductors on the flexible pcb eliminates mounting errors. I am repairing a pcb (first photo), but the white flex cable with 12 pins spaced 0.5mm apart was directly soldered to the tracks on the. Repairing broken flexible cables, image is oversized to show detail. In this case,. Soldering Flex Cable To Pcb.