What Is A Lathe Spindle . Learn how to measure and identify different types of spindles for lathe chucks, such as d1, a, and l. Find out how to choose the right spindle size, speed, connection, and care for your lathe. The lathe spindle is the rotary component of the machine tool. The lathe machine spindle serves as a critical component responsible for holding and rotating the workpiece. The lathe spindle is an essential component of a lathe machine, responsible for rotating the workpiece during machining. Find the right mounting for your spindle nose with diagrams and charts. The rotating motion produced by the electric motor is passed on to the spindle, causing the chuck and workpiece to rotate. Learn about the types, functions, and considerations of lathe spindles, the part that connects the engine to the workpiece. Learn how to identify and measure different types of lathe spindle noses, including short tapers (a1, a2, b1, b2), camlock tapers (d), and long tapers (l).

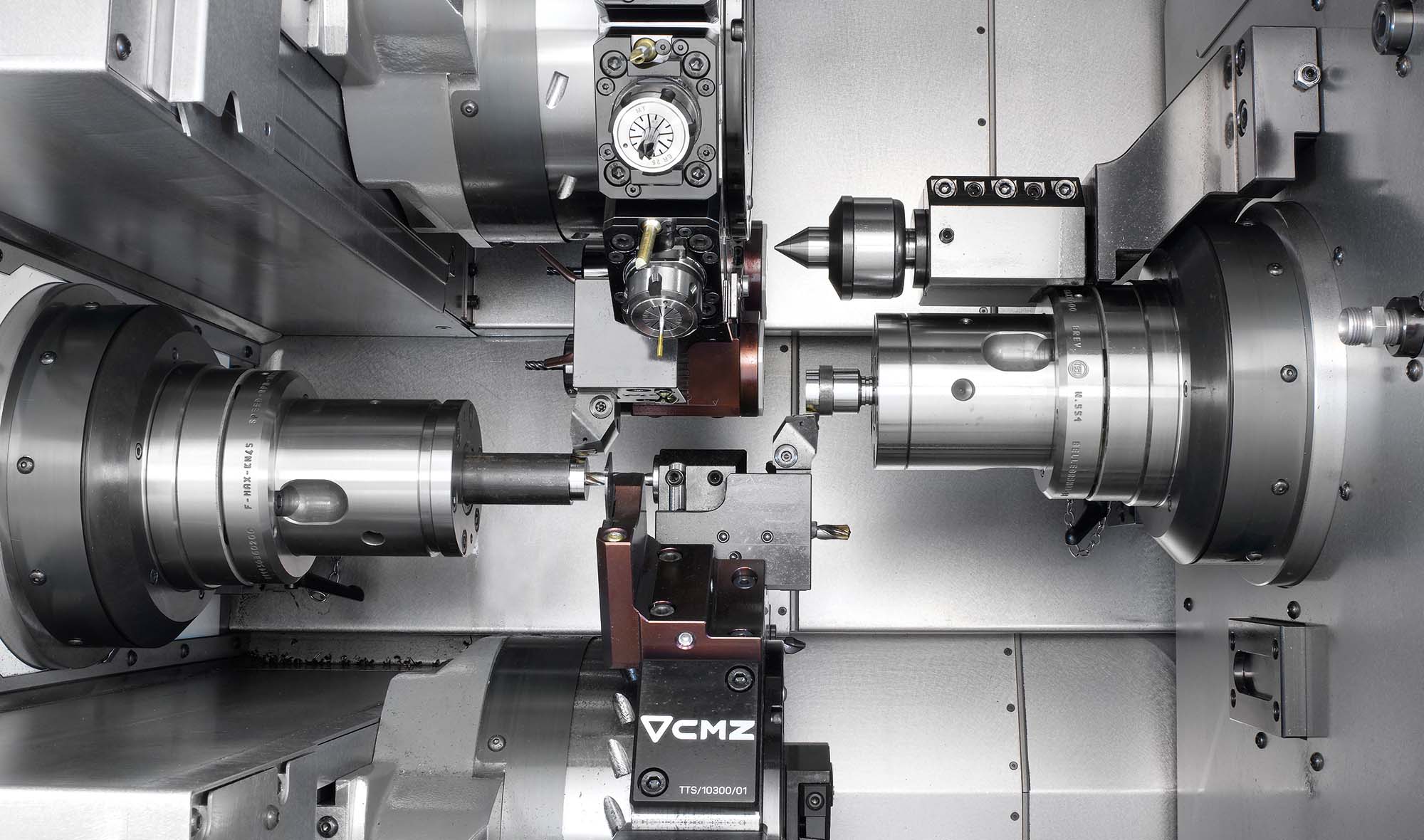

from www.cmz.com

Learn how to measure and identify different types of spindles for lathe chucks, such as d1, a, and l. Find the right mounting for your spindle nose with diagrams and charts. Find out how to choose the right spindle size, speed, connection, and care for your lathe. The rotating motion produced by the electric motor is passed on to the spindle, causing the chuck and workpiece to rotate. The lathe spindle is an essential component of a lathe machine, responsible for rotating the workpiece during machining. Learn about the types, functions, and considerations of lathe spindles, the part that connects the engine to the workpiece. The lathe spindle is the rotary component of the machine tool. Learn how to identify and measure different types of lathe spindle noses, including short tapers (a1, a2, b1, b2), camlock tapers (d), and long tapers (l). The lathe machine spindle serves as a critical component responsible for holding and rotating the workpiece.

Twin Spindle Lathe for Bar Turning TTS Series

What Is A Lathe Spindle Learn about the types, functions, and considerations of lathe spindles, the part that connects the engine to the workpiece. Learn how to measure and identify different types of spindles for lathe chucks, such as d1, a, and l. Learn how to identify and measure different types of lathe spindle noses, including short tapers (a1, a2, b1, b2), camlock tapers (d), and long tapers (l). Find the right mounting for your spindle nose with diagrams and charts. The lathe machine spindle serves as a critical component responsible for holding and rotating the workpiece. The lathe spindle is the rotary component of the machine tool. Find out how to choose the right spindle size, speed, connection, and care for your lathe. Learn about the types, functions, and considerations of lathe spindles, the part that connects the engine to the workpiece. The lathe spindle is an essential component of a lathe machine, responsible for rotating the workpiece during machining. The rotating motion produced by the electric motor is passed on to the spindle, causing the chuck and workpiece to rotate.

From www.anderswallin.net

spindle What Is A Lathe Spindle Learn how to identify and measure different types of lathe spindle noses, including short tapers (a1, a2, b1, b2), camlock tapers (d), and long tapers (l). The rotating motion produced by the electric motor is passed on to the spindle, causing the chuck and workpiece to rotate. The lathe spindle is the rotary component of the machine tool. Find out. What Is A Lathe Spindle.

From thehabitofwoodworking.com

What Is Lathe Spindle Bore? The Habit of Woodworking What Is A Lathe Spindle Find the right mounting for your spindle nose with diagrams and charts. The rotating motion produced by the electric motor is passed on to the spindle, causing the chuck and workpiece to rotate. Learn how to measure and identify different types of spindles for lathe chucks, such as d1, a, and l. Learn how to identify and measure different types. What Is A Lathe Spindle.

From megaboremachinery.com

Lathe Hollow spindle 6" to 30" Bore PB Model 45" 60" Swing What Is A Lathe Spindle The lathe spindle is the rotary component of the machine tool. The rotating motion produced by the electric motor is passed on to the spindle, causing the chuck and workpiece to rotate. Find the right mounting for your spindle nose with diagrams and charts. The lathe spindle is an essential component of a lathe machine, responsible for rotating the workpiece. What Is A Lathe Spindle.

From thehabitofwoodworking.com

What Is Spindle Nose In Lathe? The Habit of Woodworking What Is A Lathe Spindle Find out how to choose the right spindle size, speed, connection, and care for your lathe. The lathe machine spindle serves as a critical component responsible for holding and rotating the workpiece. Learn how to measure and identify different types of spindles for lathe chucks, such as d1, a, and l. Find the right mounting for your spindle nose with. What Is A Lathe Spindle.

From encyclopedia.pub

HighSpeed Motorized Spindles of CNC Machine Tools Encyclopedia MDPI What Is A Lathe Spindle The lathe machine spindle serves as a critical component responsible for holding and rotating the workpiece. Find the right mounting for your spindle nose with diagrams and charts. Learn how to identify and measure different types of lathe spindle noses, including short tapers (a1, a2, b1, b2), camlock tapers (d), and long tapers (l). Learn about the types, functions, and. What Is A Lathe Spindle.

From slidingmotion.com

20 Essential Parts of Lathe Machine Names, Functions & Diagram What Is A Lathe Spindle Learn how to identify and measure different types of lathe spindle noses, including short tapers (a1, a2, b1, b2), camlock tapers (d), and long tapers (l). Learn how to measure and identify different types of spindles for lathe chucks, such as d1, a, and l. The lathe spindle is the rotary component of the machine tool. Learn about the types,. What Is A Lathe Spindle.

From www.aliexpress.com

cnc spindle lathe machine a2 5 170mm belt drive spindle turning machine What Is A Lathe Spindle Learn how to identify and measure different types of lathe spindle noses, including short tapers (a1, a2, b1, b2), camlock tapers (d), and long tapers (l). The lathe machine spindle serves as a critical component responsible for holding and rotating the workpiece. The lathe spindle is an essential component of a lathe machine, responsible for rotating the workpiece during machining.. What Is A Lathe Spindle.

From www.lathematters.com

What Is a Lathe Spindle and How Does It Work? What Is A Lathe Spindle The rotating motion produced by the electric motor is passed on to the spindle, causing the chuck and workpiece to rotate. Find out how to choose the right spindle size, speed, connection, and care for your lathe. The lathe machine spindle serves as a critical component responsible for holding and rotating the workpiece. Learn how to identify and measure different. What Is A Lathe Spindle.

From www.lathemastery.com

What Is a Lathe Spindle and How Does It Work? What Is A Lathe Spindle The lathe machine spindle serves as a critical component responsible for holding and rotating the workpiece. Find out how to choose the right spindle size, speed, connection, and care for your lathe. Learn how to identify and measure different types of lathe spindle noses, including short tapers (a1, a2, b1, b2), camlock tapers (d), and long tapers (l). Learn how. What Is A Lathe Spindle.

From www.crazyengineers.com

Difference Between Spindle and Shaft? CrazyEngineers What Is A Lathe Spindle Learn how to measure and identify different types of spindles for lathe chucks, such as d1, a, and l. Learn how to identify and measure different types of lathe spindle noses, including short tapers (a1, a2, b1, b2), camlock tapers (d), and long tapers (l). The lathe spindle is an essential component of a lathe machine, responsible for rotating the. What Is A Lathe Spindle.

From woodworkingsquad.com

What Is A Lathe Spindle? Wood Working Squad What Is A Lathe Spindle Learn about the types, functions, and considerations of lathe spindles, the part that connects the engine to the workpiece. Find the right mounting for your spindle nose with diagrams and charts. Learn how to measure and identify different types of spindles for lathe chucks, such as d1, a, and l. The lathe spindle is an essential component of a lathe. What Is A Lathe Spindle.

From www.craft-supplies.co.uk

Determining Your Lathe Spindle Thread Size Craft Supplies What Is A Lathe Spindle The rotating motion produced by the electric motor is passed on to the spindle, causing the chuck and workpiece to rotate. The lathe machine spindle serves as a critical component responsible for holding and rotating the workpiece. The lathe spindle is the rotary component of the machine tool. The lathe spindle is an essential component of a lathe machine, responsible. What Is A Lathe Spindle.

From harrismachinetools-inventory.com

USED, 27″ x 120″ LEHMANN HOLLOW SPINDLE LATHE WITH 9″ SPINDLE BORE What Is A Lathe Spindle Find out how to choose the right spindle size, speed, connection, and care for your lathe. Find the right mounting for your spindle nose with diagrams and charts. Learn how to measure and identify different types of spindles for lathe chucks, such as d1, a, and l. Learn how to identify and measure different types of lathe spindle noses, including. What Is A Lathe Spindle.

From www.alibaba.com

Manufacture Twin Spindle Metal Lathe With Double Spindle Drehbank Dual What Is A Lathe Spindle The lathe spindle is the rotary component of the machine tool. Find the right mounting for your spindle nose with diagrams and charts. The rotating motion produced by the electric motor is passed on to the spindle, causing the chuck and workpiece to rotate. The lathe spindle is an essential component of a lathe machine, responsible for rotating the workpiece. What Is A Lathe Spindle.

From www.sherline.com

Lathe Terminology Sherline Products What Is A Lathe Spindle Find out how to choose the right spindle size, speed, connection, and care for your lathe. Find the right mounting for your spindle nose with diagrams and charts. Learn how to identify and measure different types of lathe spindle noses, including short tapers (a1, a2, b1, b2), camlock tapers (d), and long tapers (l). Learn about the types, functions, and. What Is A Lathe Spindle.

From www.cmz.com

Twin Spindle Lathe for Bar Turning TTS Series What Is A Lathe Spindle The lathe machine spindle serves as a critical component responsible for holding and rotating the workpiece. Learn about the types, functions, and considerations of lathe spindles, the part that connects the engine to the workpiece. Learn how to identify and measure different types of lathe spindle noses, including short tapers (a1, a2, b1, b2), camlock tapers (d), and long tapers. What Is A Lathe Spindle.

From www.researchgate.net

Discrete model of the lathe spindle under consideration Download What Is A Lathe Spindle Learn about the types, functions, and considerations of lathe spindles, the part that connects the engine to the workpiece. The lathe machine spindle serves as a critical component responsible for holding and rotating the workpiece. The lathe spindle is the rotary component of the machine tool. The rotating motion produced by the electric motor is passed on to the spindle,. What Is A Lathe Spindle.

From www.semanticscholar.org

Design and development of a lathe spindle Semantic Scholar What Is A Lathe Spindle The lathe machine spindle serves as a critical component responsible for holding and rotating the workpiece. Learn how to identify and measure different types of lathe spindle noses, including short tapers (a1, a2, b1, b2), camlock tapers (d), and long tapers (l). Find the right mounting for your spindle nose with diagrams and charts. The rotating motion produced by the. What Is A Lathe Spindle.

From www.smartlathe.com

Overview of Electric Builtin Spindles Used in CNC Lathe Tools What Is A Lathe Spindle Learn how to measure and identify different types of spindles for lathe chucks, such as d1, a, and l. The lathe machine spindle serves as a critical component responsible for holding and rotating the workpiece. Learn how to identify and measure different types of lathe spindle noses, including short tapers (a1, a2, b1, b2), camlock tapers (d), and long tapers. What Is A Lathe Spindle.

From themechanicalengineering.com

Lathe Machine Definition, Parts, Types, Operation, Specification What Is A Lathe Spindle The lathe machine spindle serves as a critical component responsible for holding and rotating the workpiece. The rotating motion produced by the electric motor is passed on to the spindle, causing the chuck and workpiece to rotate. Learn how to measure and identify different types of spindles for lathe chucks, such as d1, a, and l. Learn about the types,. What Is A Lathe Spindle.

From www.pinterest.com

Basic Lathe Anatomy Wood turning projects, Wood turning, Turn ons What Is A Lathe Spindle Find out how to choose the right spindle size, speed, connection, and care for your lathe. The lathe machine spindle serves as a critical component responsible for holding and rotating the workpiece. The lathe spindle is an essential component of a lathe machine, responsible for rotating the workpiece during machining. Learn about the types, functions, and considerations of lathe spindles,. What Is A Lathe Spindle.

From spindleservices.co.uk

CNC Spindles Spindle Services What Is A Lathe Spindle Learn how to measure and identify different types of spindles for lathe chucks, such as d1, a, and l. The lathe spindle is the rotary component of the machine tool. Learn about the types, functions, and considerations of lathe spindles, the part that connects the engine to the workpiece. Find out how to choose the right spindle size, speed, connection,. What Is A Lathe Spindle.

From www.youtube.com

South Bent 13" Lathe Spindle Part 2 YouTube What Is A Lathe Spindle Find the right mounting for your spindle nose with diagrams and charts. Find out how to choose the right spindle size, speed, connection, and care for your lathe. Learn how to measure and identify different types of spindles for lathe chucks, such as d1, a, and l. The rotating motion produced by the electric motor is passed on to the. What Is A Lathe Spindle.

From www.alamy.com

main spindle of metal lathe machine in turning Stock Photo Alamy What Is A Lathe Spindle The rotating motion produced by the electric motor is passed on to the spindle, causing the chuck and workpiece to rotate. Learn how to identify and measure different types of lathe spindle noses, including short tapers (a1, a2, b1, b2), camlock tapers (d), and long tapers (l). The lathe spindle is the rotary component of the machine tool. The lathe. What Is A Lathe Spindle.

From www.smartlathe.com

Overview of Electric Builtin Spindles Used in CNC Lathe Tools What Is A Lathe Spindle The lathe spindle is the rotary component of the machine tool. Learn about the types, functions, and considerations of lathe spindles, the part that connects the engine to the workpiece. Find the right mounting for your spindle nose with diagrams and charts. Learn how to measure and identify different types of spindles for lathe chucks, such as d1, a, and. What Is A Lathe Spindle.

From smart-lathe.squarespace.com

Smartlathe MachineryCNC Lathe What Is A Lathe Spindle Learn about the types, functions, and considerations of lathe spindles, the part that connects the engine to the workpiece. Learn how to measure and identify different types of spindles for lathe chucks, such as d1, a, and l. Find the right mounting for your spindle nose with diagrams and charts. Find out how to choose the right spindle size, speed,. What Is A Lathe Spindle.

From mungfali.com

Lathe Spindle Types What Is A Lathe Spindle Learn how to measure and identify different types of spindles for lathe chucks, such as d1, a, and l. The lathe machine spindle serves as a critical component responsible for holding and rotating the workpiece. The lathe spindle is an essential component of a lathe machine, responsible for rotating the workpiece during machining. Learn about the types, functions, and considerations. What Is A Lathe Spindle.

From www.haascnc.com

Spindle Lathe Troubleshooting Guide What Is A Lathe Spindle Find the right mounting for your spindle nose with diagrams and charts. The lathe spindle is an essential component of a lathe machine, responsible for rotating the workpiece during machining. Find out how to choose the right spindle size, speed, connection, and care for your lathe. Learn how to measure and identify different types of spindles for lathe chucks, such. What Is A Lathe Spindle.

From thehabitofwoodworking.com

What Is Lathe Spindle Bore? The Habit of Woodworking What Is A Lathe Spindle Learn how to identify and measure different types of lathe spindle noses, including short tapers (a1, a2, b1, b2), camlock tapers (d), and long tapers (l). Learn about the types, functions, and considerations of lathe spindles, the part that connects the engine to the workpiece. Learn how to measure and identify different types of spindles for lathe chucks, such as. What Is A Lathe Spindle.

From www.dreamstime.com

Cnc Industrial Lathe Turning Spindle Chuck and Product Part on Machine What Is A Lathe Spindle Learn how to identify and measure different types of lathe spindle noses, including short tapers (a1, a2, b1, b2), camlock tapers (d), and long tapers (l). The lathe machine spindle serves as a critical component responsible for holding and rotating the workpiece. The rotating motion produced by the electric motor is passed on to the spindle, causing the chuck and. What Is A Lathe Spindle.

From www.alibaba.com

Metal Turning Precision Lathe Spindle Belt Driven A24 6000rpm 150mm What Is A Lathe Spindle The lathe machine spindle serves as a critical component responsible for holding and rotating the workpiece. The lathe spindle is an essential component of a lathe machine, responsible for rotating the workpiece during machining. The lathe spindle is the rotary component of the machine tool. Learn about the types, functions, and considerations of lathe spindles, the part that connects the. What Is A Lathe Spindle.

From benchtopmachineshop.blogspot.com

Benchtop Machine Shop Lathe Spindle Upgrade What Is A Lathe Spindle The lathe spindle is the rotary component of the machine tool. Find the right mounting for your spindle nose with diagrams and charts. The lathe machine spindle serves as a critical component responsible for holding and rotating the workpiece. Find out how to choose the right spindle size, speed, connection, and care for your lathe. Learn how to measure and. What Is A Lathe Spindle.

From yukonstruct.com

WOOD LATHE SPINDLE TURNING INTRO YuKonstruct What Is A Lathe Spindle Find the right mounting for your spindle nose with diagrams and charts. Learn how to measure and identify different types of spindles for lathe chucks, such as d1, a, and l. Learn about the types, functions, and considerations of lathe spindles, the part that connects the engine to the workpiece. Find out how to choose the right spindle size, speed,. What Is A Lathe Spindle.

From www.smartlathe.com

Knowledge about Dual Spindle CNC Lathe What Is A Lathe Spindle Learn how to measure and identify different types of spindles for lathe chucks, such as d1, a, and l. Learn how to identify and measure different types of lathe spindle noses, including short tapers (a1, a2, b1, b2), camlock tapers (d), and long tapers (l). The lathe spindle is the rotary component of the machine tool. The lathe machine spindle. What Is A Lathe Spindle.

From finemetalworking.com

Lathe Machine Types of Lathes and Uses What Is A Lathe Spindle Find the right mounting for your spindle nose with diagrams and charts. Learn about the types, functions, and considerations of lathe spindles, the part that connects the engine to the workpiece. Learn how to measure and identify different types of spindles for lathe chucks, such as d1, a, and l. The lathe spindle is an essential component of a lathe. What Is A Lathe Spindle.