Rockwell Hardness Test Chart . Rockwell hardness testing reference guide. The most common is the static load indentation hardness test, such as brinell hardness (hb), rockwell hardness (hra, hrb, hrc), and vickers hardness (hv). 21 rows a rockwell hardness tester. Astm e18 contains a listing of all regular rockwell scales and typical materials for which these scales are applicable. The rockwell scale is a hardness scale based on indentation hardness of a material. You should obtain a copy of this standard, read and understand the. In the knife blade manufacturing business, hardness ratings follow a predetermined chart which is commonly called the rockwell c scale. The higher the number on the rc scale, the harder the. Rockwell hardness test using rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc,.

from www.tec-science.com

In the knife blade manufacturing business, hardness ratings follow a predetermined chart which is commonly called the rockwell c scale. The rockwell scale is a hardness scale based on indentation hardness of a material. Rockwell hardness test using rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc,. The higher the number on the rc scale, the harder the. The most common is the static load indentation hardness test, such as brinell hardness (hb), rockwell hardness (hra, hrb, hrc), and vickers hardness (hv). You should obtain a copy of this standard, read and understand the. 21 rows a rockwell hardness tester. Rockwell hardness testing reference guide. Astm e18 contains a listing of all regular rockwell scales and typical materials for which these scales are applicable.

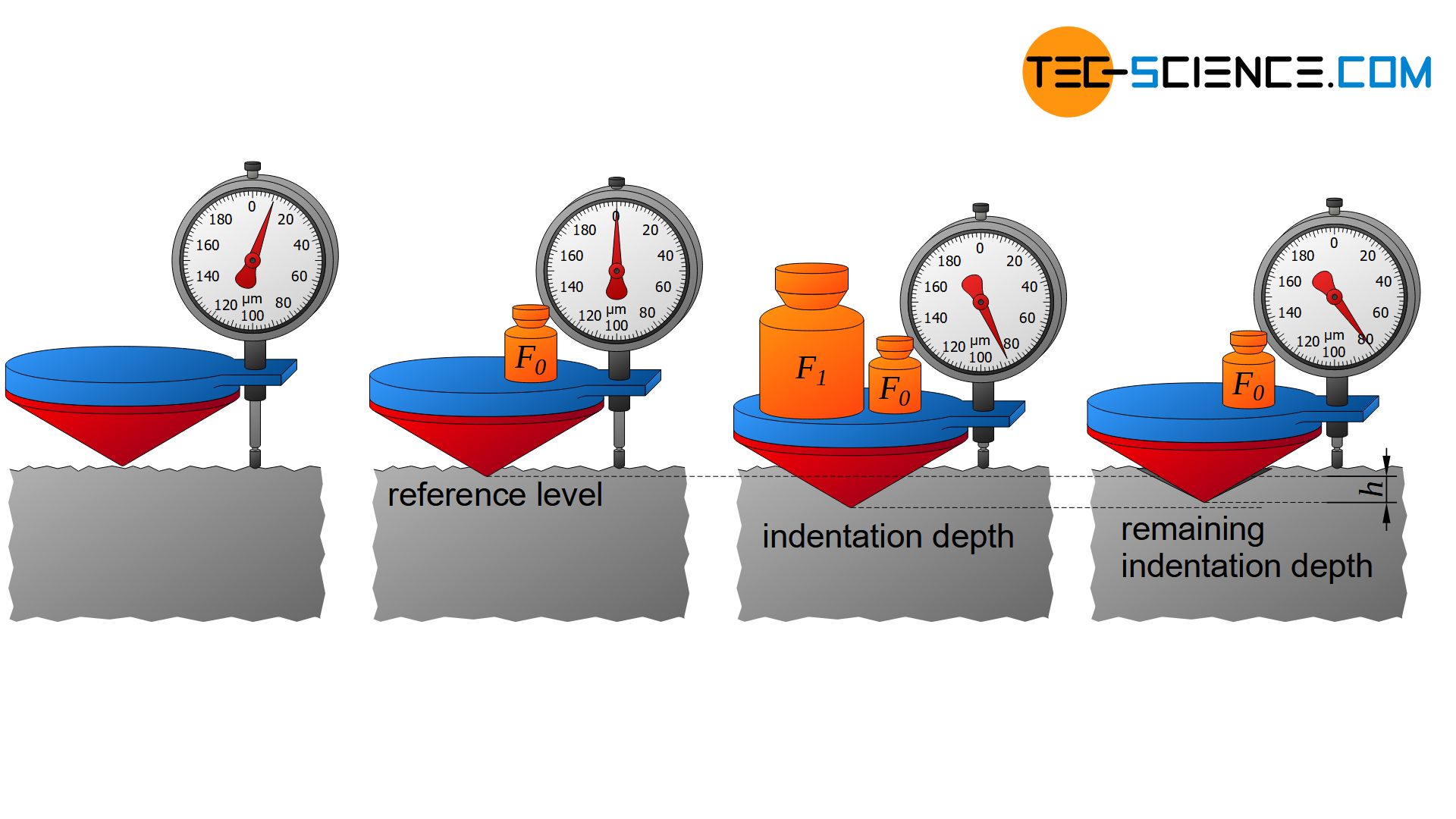

Rockwell hardness test tecscience

Rockwell Hardness Test Chart The rockwell scale is a hardness scale based on indentation hardness of a material. You should obtain a copy of this standard, read and understand the. In the knife blade manufacturing business, hardness ratings follow a predetermined chart which is commonly called the rockwell c scale. The rockwell scale is a hardness scale based on indentation hardness of a material. The most common is the static load indentation hardness test, such as brinell hardness (hb), rockwell hardness (hra, hrb, hrc), and vickers hardness (hv). Astm e18 contains a listing of all regular rockwell scales and typical materials for which these scales are applicable. 21 rows a rockwell hardness tester. Rockwell hardness test using rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc,. The higher the number on the rc scale, the harder the. Rockwell hardness testing reference guide.

From ar.inspiredpencil.com

Rockwell Hardness Test Rockwell Hardness Test Chart The most common is the static load indentation hardness test, such as brinell hardness (hb), rockwell hardness (hra, hrb, hrc), and vickers hardness (hv). 21 rows a rockwell hardness tester. You should obtain a copy of this standard, read and understand the. Rockwell hardness testing reference guide. Rockwell hardness test using rockwell hardness scale is one of the extensively used. Rockwell Hardness Test Chart.

From mungfali.com

Rockwell Hardness Scale Chart Rockwell Hardness Test Chart In the knife blade manufacturing business, hardness ratings follow a predetermined chart which is commonly called the rockwell c scale. The rockwell scale is a hardness scale based on indentation hardness of a material. The most common is the static load indentation hardness test, such as brinell hardness (hb), rockwell hardness (hra, hrb, hrc), and vickers hardness (hv). The higher. Rockwell Hardness Test Chart.

From brokeasshome.com

Rockwell Hardness Table Of Steel Rockwell Hardness Test Chart 21 rows a rockwell hardness tester. Rockwell hardness testing reference guide. The rockwell scale is a hardness scale based on indentation hardness of a material. In the knife blade manufacturing business, hardness ratings follow a predetermined chart which is commonly called the rockwell c scale. The higher the number on the rc scale, the harder the. You should obtain a. Rockwell Hardness Test Chart.

From www.brystartools.com

Hardness Conversion Chart Rockwell "B" Hardness Range Rockwell Hardness Test Chart You should obtain a copy of this standard, read and understand the. In the knife blade manufacturing business, hardness ratings follow a predetermined chart which is commonly called the rockwell c scale. The most common is the static load indentation hardness test, such as brinell hardness (hb), rockwell hardness (hra, hrb, hrc), and vickers hardness (hv). The higher the number. Rockwell Hardness Test Chart.

From mavink.com

Rockwell B Hardness Conversion Chart Rockwell Hardness Test Chart You should obtain a copy of this standard, read and understand the. 21 rows a rockwell hardness tester. Rockwell hardness testing reference guide. The most common is the static load indentation hardness test, such as brinell hardness (hb), rockwell hardness (hra, hrb, hrc), and vickers hardness (hv). The higher the number on the rc scale, the harder the. In the. Rockwell Hardness Test Chart.

From digitalmicrometers.co.uk

7 Types Of Hardness Testers! The Best Method, Scale, And Test For Your Rockwell Hardness Test Chart The rockwell scale is a hardness scale based on indentation hardness of a material. Rockwell hardness test using rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc,. Rockwell hardness testing reference guide. In the knife blade manufacturing business, hardness ratings follow a predetermined chart which is. Rockwell Hardness Test Chart.

From lookfordiagnosis.com

Hardness Rockwell Hardness Test Chart In the knife blade manufacturing business, hardness ratings follow a predetermined chart which is commonly called the rockwell c scale. 21 rows a rockwell hardness tester. Rockwell hardness testing reference guide. You should obtain a copy of this standard, read and understand the. Rockwell hardness test using rockwell hardness scale is one of the extensively used and accurate hardness test. Rockwell Hardness Test Chart.

From ourelabs.blogspot.com

ROCKWELL HARDNESS TEST Ourengineeringlabs Rockwell Hardness Test Chart Astm e18 contains a listing of all regular rockwell scales and typical materials for which these scales are applicable. The rockwell scale is a hardness scale based on indentation hardness of a material. In the knife blade manufacturing business, hardness ratings follow a predetermined chart which is commonly called the rockwell c scale. You should obtain a copy of this. Rockwell Hardness Test Chart.

From pdfslide.net

BrinellRockwell Hardness Chart JP CHART Visit us at http/ Brinell Rockwell Hardness Test Chart Rockwell hardness testing reference guide. The most common is the static load indentation hardness test, such as brinell hardness (hb), rockwell hardness (hra, hrb, hrc), and vickers hardness (hv). 21 rows a rockwell hardness tester. Rockwell hardness test using rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead,. Rockwell Hardness Test Chart.

From mungfali.com

Rockwell Hardness Scale Chart Rockwell Hardness Test Chart Astm e18 contains a listing of all regular rockwell scales and typical materials for which these scales are applicable. 21 rows a rockwell hardness tester. The most common is the static load indentation hardness test, such as brinell hardness (hb), rockwell hardness (hra, hrb, hrc), and vickers hardness (hv). Rockwell hardness test using rockwell hardness scale is one of the. Rockwell Hardness Test Chart.

From www.educationalstuffs.in

STRENGTH OF MATERIALS Rockwell Hardness Test Rockwell Hardness Test Chart The higher the number on the rc scale, the harder the. The most common is the static load indentation hardness test, such as brinell hardness (hb), rockwell hardness (hra, hrb, hrc), and vickers hardness (hv). You should obtain a copy of this standard, read and understand the. Astm e18 contains a listing of all regular rockwell scales and typical materials. Rockwell Hardness Test Chart.

From www.youtube.com

ROCKWELL HARDNESS TEST HOW TO PERFORM ROCKWELL HARDNESS TEST Rockwell Hardness Test Chart The most common is the static load indentation hardness test, such as brinell hardness (hb), rockwell hardness (hra, hrb, hrc), and vickers hardness (hv). Astm e18 contains a listing of all regular rockwell scales and typical materials for which these scales are applicable. In the knife blade manufacturing business, hardness ratings follow a predetermined chart which is commonly called the. Rockwell Hardness Test Chart.

From www.brystartools.com

Hardness Conversion Chart Rockwell "C" Hardness Range Rockwell Hardness Test Chart The higher the number on the rc scale, the harder the. The rockwell scale is a hardness scale based on indentation hardness of a material. You should obtain a copy of this standard, read and understand the. Astm e18 contains a listing of all regular rockwell scales and typical materials for which these scales are applicable. The most common is. Rockwell Hardness Test Chart.

From atrona.com

Rockwell C Hardness Conversion Chart PDF ATRONA Test Labs Loves Rockwell Hardness Test Chart The most common is the static load indentation hardness test, such as brinell hardness (hb), rockwell hardness (hra, hrb, hrc), and vickers hardness (hv). You should obtain a copy of this standard, read and understand the. In the knife blade manufacturing business, hardness ratings follow a predetermined chart which is commonly called the rockwell c scale. Astm e18 contains a. Rockwell Hardness Test Chart.

From www.scribd.com

Rockwell Hardness Test Rockwell Hardness Test Chart You should obtain a copy of this standard, read and understand the. The rockwell scale is a hardness scale based on indentation hardness of a material. In the knife blade manufacturing business, hardness ratings follow a predetermined chart which is commonly called the rockwell c scale. Rockwell hardness test using rockwell hardness scale is one of the extensively used and. Rockwell Hardness Test Chart.

From mungfali.com

Rockwell Hardness Scale Chart Rockwell Hardness Test Chart You should obtain a copy of this standard, read and understand the. The most common is the static load indentation hardness test, such as brinell hardness (hb), rockwell hardness (hra, hrb, hrc), and vickers hardness (hv). The higher the number on the rc scale, the harder the. Astm e18 contains a listing of all regular rockwell scales and typical materials. Rockwell Hardness Test Chart.

From www.buehler.com

Rockwell Hardness Testing Buehler Canada Metallography Equipment Rockwell Hardness Test Chart Rockwell hardness testing reference guide. In the knife blade manufacturing business, hardness ratings follow a predetermined chart which is commonly called the rockwell c scale. Rockwell hardness test using rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc,. Astm e18 contains a listing of all regular. Rockwell Hardness Test Chart.

From hitestlab.com

Rockwell Hardness Test PT Hitestlab Rockwell Hardness Test Chart Rockwell hardness test using rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc,. 21 rows a rockwell hardness tester. The most common is the static load indentation hardness test, such as brinell hardness (hb), rockwell hardness (hra, hrb, hrc), and vickers hardness (hv). Astm e18 contains. Rockwell Hardness Test Chart.

From www.hardnessgauge.com

Rockwell Hardness Testing Hardness Tester Rockwell Hardness Test Chart The rockwell scale is a hardness scale based on indentation hardness of a material. The higher the number on the rc scale, the harder the. 21 rows a rockwell hardness tester. Rockwell hardness testing reference guide. The most common is the static load indentation hardness test, such as brinell hardness (hb), rockwell hardness (hra, hrb, hrc), and vickers hardness (hv).. Rockwell Hardness Test Chart.

From printablemathias.z13.web.core.windows.net

Rockwell Hardness C Scale Chart Rockwell Hardness Test Chart 21 rows a rockwell hardness tester. The most common is the static load indentation hardness test, such as brinell hardness (hb), rockwell hardness (hra, hrb, hrc), and vickers hardness (hv). Astm e18 contains a listing of all regular rockwell scales and typical materials for which these scales are applicable. The rockwell scale is a hardness scale based on indentation hardness. Rockwell Hardness Test Chart.

From tillyclark.z13.web.core.windows.net

Rockwell Hardness Conversion Chart Rockwell Hardness Test Chart Rockwell hardness test using rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc,. In the knife blade manufacturing business, hardness ratings follow a predetermined chart which is commonly called the rockwell c scale. The most common is the static load indentation hardness test, such as brinell. Rockwell Hardness Test Chart.

From ar.inspiredpencil.com

Rockwell Hardness Chart Rockwell Hardness Test Chart Rockwell hardness testing reference guide. Rockwell hardness test using rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc,. 21 rows a rockwell hardness tester. The rockwell scale is a hardness scale based on indentation hardness of a material. The higher the number on the rc scale,. Rockwell Hardness Test Chart.

From amesportablehardnesstesters.com

Hardness Testing in Rockwell Scales Rockwell Hardness Test Chart You should obtain a copy of this standard, read and understand the. Astm e18 contains a listing of all regular rockwell scales and typical materials for which these scales are applicable. In the knife blade manufacturing business, hardness ratings follow a predetermined chart which is commonly called the rockwell c scale. The most common is the static load indentation hardness. Rockwell Hardness Test Chart.

From extrudesign.com

How Rockwell Hardness Test is conducted? ExtruDesign Rockwell Hardness Test Chart The rockwell scale is a hardness scale based on indentation hardness of a material. Astm e18 contains a listing of all regular rockwell scales and typical materials for which these scales are applicable. You should obtain a copy of this standard, read and understand the. The most common is the static load indentation hardness test, such as brinell hardness (hb),. Rockwell Hardness Test Chart.

From ar.inspiredpencil.com

Rockwell Hardness Chart Rockwell Hardness Test Chart The higher the number on the rc scale, the harder the. Rockwell hardness testing reference guide. 21 rows a rockwell hardness tester. Rockwell hardness test using rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc,. You should obtain a copy of this standard, read and understand. Rockwell Hardness Test Chart.

From www.tec-science.com

Rockwell hardness test tecscience Rockwell Hardness Test Chart The higher the number on the rc scale, the harder the. The most common is the static load indentation hardness test, such as brinell hardness (hb), rockwell hardness (hra, hrb, hrc), and vickers hardness (hv). Astm e18 contains a listing of all regular rockwell scales and typical materials for which these scales are applicable. You should obtain a copy of. Rockwell Hardness Test Chart.

From www.struers.com

Rockwell hardness testing insight Rockwell Hardness Test Chart The rockwell scale is a hardness scale based on indentation hardness of a material. Rockwell hardness test using rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc,. You should obtain a copy of this standard, read and understand the. Astm e18 contains a listing of all. Rockwell Hardness Test Chart.

From www.flexbar.com

"C" Scale Rockwell Hardness Test Block — Flexbar Machine Corporation Rockwell Hardness Test Chart Rockwell hardness test using rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc,. Rockwell hardness testing reference guide. 21 rows a rockwell hardness tester. Astm e18 contains a listing of all regular rockwell scales and typical materials for which these scales are applicable. You should obtain. Rockwell Hardness Test Chart.

From www.pinterest.com

Metal Hardness Chart based on Rockwell scale and ductility. Metal fab Rockwell Hardness Test Chart In the knife blade manufacturing business, hardness ratings follow a predetermined chart which is commonly called the rockwell c scale. Rockwell hardness testing reference guide. The higher the number on the rc scale, the harder the. The rockwell scale is a hardness scale based on indentation hardness of a material. The most common is the static load indentation hardness test,. Rockwell Hardness Test Chart.

From theconstructor.org

How To Perform Rockwell Hardness Test? The Constructor Rockwell Hardness Test Chart Rockwell hardness testing reference guide. Astm e18 contains a listing of all regular rockwell scales and typical materials for which these scales are applicable. The rockwell scale is a hardness scale based on indentation hardness of a material. Rockwell hardness test using rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for. Rockwell Hardness Test Chart.

From mungfali.com

Rockwell Hardness Scale Chart Rockwell Hardness Test Chart Astm e18 contains a listing of all regular rockwell scales and typical materials for which these scales are applicable. Rockwell hardness test using rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc,. The higher the number on the rc scale, the harder the. In the knife. Rockwell Hardness Test Chart.

From mungfali.com

Rockwell Hardness Scale Chart Rockwell Hardness Test Chart The higher the number on the rc scale, the harder the. Rockwell hardness testing reference guide. Astm e18 contains a listing of all regular rockwell scales and typical materials for which these scales are applicable. The most common is the static load indentation hardness test, such as brinell hardness (hb), rockwell hardness (hra, hrb, hrc), and vickers hardness (hv). The. Rockwell Hardness Test Chart.

From www.myxxgirl.com

Hardness Conversion Chart Calculator Tests For Rockwell Brinell My Rockwell Hardness Test Chart The higher the number on the rc scale, the harder the. You should obtain a copy of this standard, read and understand the. The most common is the static load indentation hardness test, such as brinell hardness (hb), rockwell hardness (hra, hrb, hrc), and vickers hardness (hv). Astm e18 contains a listing of all regular rockwell scales and typical materials. Rockwell Hardness Test Chart.

From www.gordonengland.co.uk

Hardness Conversion Chart for Soft Metals ( Rockwell B Scale ) Rockwell Hardness Test Chart In the knife blade manufacturing business, hardness ratings follow a predetermined chart which is commonly called the rockwell c scale. 21 rows a rockwell hardness tester. Astm e18 contains a listing of all regular rockwell scales and typical materials for which these scales are applicable. Rockwell hardness test using rockwell hardness scale is one of the extensively used and accurate. Rockwell Hardness Test Chart.

From amesportablehardnesstesters.com

The Rockwell Metal Hardness Scales Explained Rockwell Hardness Test Chart The higher the number on the rc scale, the harder the. 21 rows a rockwell hardness tester. The most common is the static load indentation hardness test, such as brinell hardness (hb), rockwell hardness (hra, hrb, hrc), and vickers hardness (hv). Astm e18 contains a listing of all regular rockwell scales and typical materials for which these scales are applicable.. Rockwell Hardness Test Chart.