Tool Cfm Requirements . calculating cfm requirements for air tools. cfm stands for cubic feet per minute and it is the measurement of air flow rate that an air tool requires. Every air tool has a recommended cfm requirement that’s set by. the formula for calculating required cfm is relatively straightforward: Luckily, we’ve got what you need exactly, and that’s the northstar. When it comes to selecting the right compressor for air tools, calculating. Cfm = (tool airflow requirement x number of tools) x safety factor. From calculating requirements to choosing the right. It is important because it. cfm determines how much power the air compressor provides to air tools. most air tools need 0.5 to 5 cfm at 90 psi. discover how to determine the ideal cfm for your air tools in this comprehensive guide. Choosing the right air compressor cfm is crucial for efficient.

from thesprucetools.com

Choosing the right air compressor cfm is crucial for efficient. cfm determines how much power the air compressor provides to air tools. Luckily, we’ve got what you need exactly, and that’s the northstar. Every air tool has a recommended cfm requirement that’s set by. Cfm = (tool airflow requirement x number of tools) x safety factor. most air tools need 0.5 to 5 cfm at 90 psi. cfm stands for cubic feet per minute and it is the measurement of air flow rate that an air tool requires. When it comes to selecting the right compressor for air tools, calculating. calculating cfm requirements for air tools. discover how to determine the ideal cfm for your air tools in this comprehensive guide.

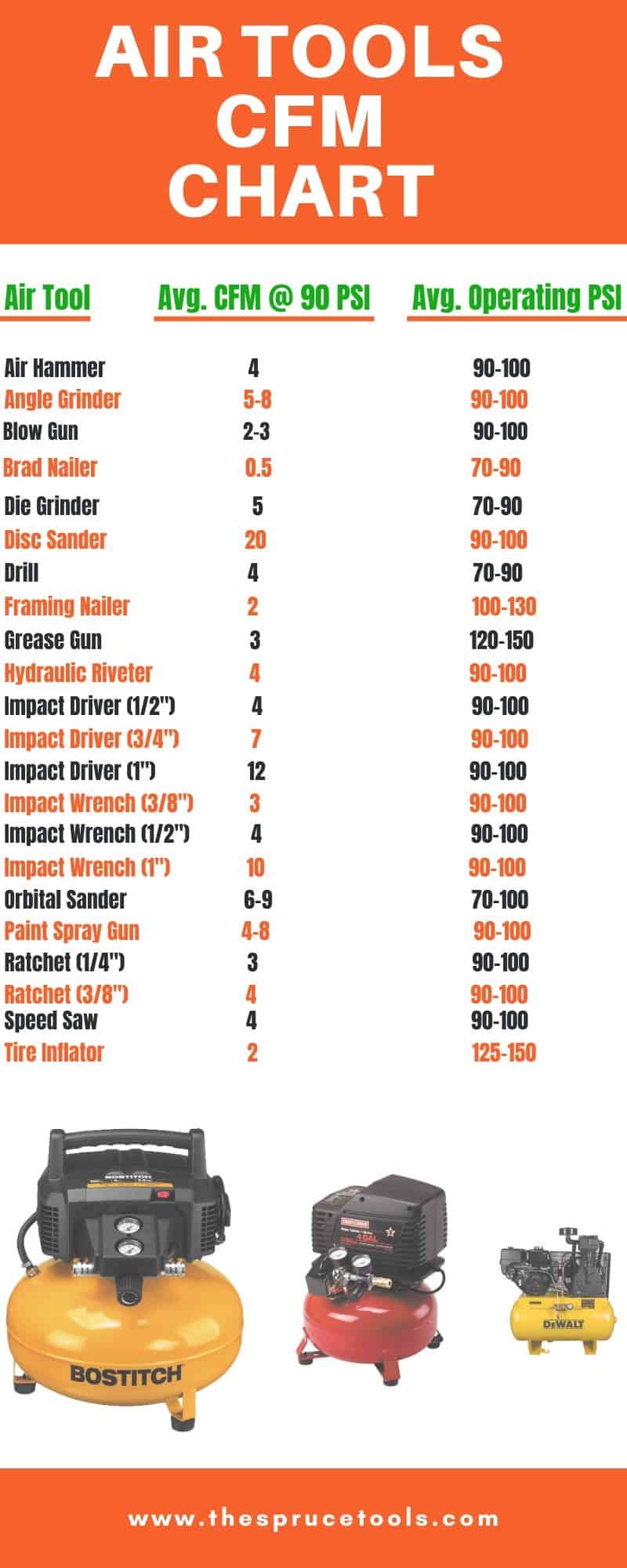

What Size Air Compressor Do I Need for Air Tools? (With CFM Chart)

Tool Cfm Requirements Choosing the right air compressor cfm is crucial for efficient. Luckily, we’ve got what you need exactly, and that’s the northstar. Every air tool has a recommended cfm requirement that’s set by. cfm stands for cubic feet per minute and it is the measurement of air flow rate that an air tool requires. calculating cfm requirements for air tools. When it comes to selecting the right compressor for air tools, calculating. cfm determines how much power the air compressor provides to air tools. Cfm = (tool airflow requirement x number of tools) x safety factor. most air tools need 0.5 to 5 cfm at 90 psi. discover how to determine the ideal cfm for your air tools in this comprehensive guide. Choosing the right air compressor cfm is crucial for efficient. From calculating requirements to choosing the right. the formula for calculating required cfm is relatively straightforward: It is important because it.

From sensibledigs.com

What Size Air Compressor Do I Need (With Size Chart) Sensible Digs Tool Cfm Requirements It is important because it. When it comes to selecting the right compressor for air tools, calculating. cfm stands for cubic feet per minute and it is the measurement of air flow rate that an air tool requires. calculating cfm requirements for air tools. Every air tool has a recommended cfm requirement that’s set by. Cfm = (tool. Tool Cfm Requirements.

From jamesherbert.z13.web.core.windows.net

Grille Size Cfm Chart Tool Cfm Requirements When it comes to selecting the right compressor for air tools, calculating. cfm stands for cubic feet per minute and it is the measurement of air flow rate that an air tool requires. From calculating requirements to choosing the right. Luckily, we’ve got what you need exactly, and that’s the northstar. calculating cfm requirements for air tools. . Tool Cfm Requirements.

From tendsupplies.com

Air Tool Efficiency PSI vs. CFM Explained Tend Industrial Supplies Tool Cfm Requirements cfm stands for cubic feet per minute and it is the measurement of air flow rate that an air tool requires. cfm determines how much power the air compressor provides to air tools. discover how to determine the ideal cfm for your air tools in this comprehensive guide. the formula for calculating required cfm is relatively. Tool Cfm Requirements.

From shoptoolreviews.com

NorthStar Electric 80Gallon Air Compressor Review STR Tool Cfm Requirements When it comes to selecting the right compressor for air tools, calculating. the formula for calculating required cfm is relatively straightforward: cfm stands for cubic feet per minute and it is the measurement of air flow rate that an air tool requires. From calculating requirements to choosing the right. calculating cfm requirements for air tools. Choosing the. Tool Cfm Requirements.

From www.youtube.com

How to Calculate CFM of AHU Live Demonstration of CFM testing of AHU Tool Cfm Requirements It is important because it. Choosing the right air compressor cfm is crucial for efficient. the formula for calculating required cfm is relatively straightforward: calculating cfm requirements for air tools. When it comes to selecting the right compressor for air tools, calculating. discover how to determine the ideal cfm for your air tools in this comprehensive guide.. Tool Cfm Requirements.

From thedigitalprojectmanager.com

10 Best Requirements Management Tools Reviewed For 2024 Tool Cfm Requirements most air tools need 0.5 to 5 cfm at 90 psi. Choosing the right air compressor cfm is crucial for efficient. the formula for calculating required cfm is relatively straightforward: From calculating requirements to choosing the right. cfm determines how much power the air compressor provides to air tools. It is important because it. Luckily, we’ve got. Tool Cfm Requirements.

From www.youtube.com

CFM Calculation how to calculate CFM YouTube Tool Cfm Requirements the formula for calculating required cfm is relatively straightforward: calculating cfm requirements for air tools. discover how to determine the ideal cfm for your air tools in this comprehensive guide. Every air tool has a recommended cfm requirement that’s set by. Choosing the right air compressor cfm is crucial for efficient. From calculating requirements to choosing the. Tool Cfm Requirements.

From bceweb.org

Cfm Usage Chart A Visual Reference of Charts Chart Master Tool Cfm Requirements cfm determines how much power the air compressor provides to air tools. Cfm = (tool airflow requirement x number of tools) x safety factor. Choosing the right air compressor cfm is crucial for efficient. From calculating requirements to choosing the right. Every air tool has a recommended cfm requirement that’s set by. It is important because it. the. Tool Cfm Requirements.

From jodiejoyce.z21.web.core.windows.net

Air Tool Cfm Chart Tool Cfm Requirements Cfm = (tool airflow requirement x number of tools) x safety factor. cfm stands for cubic feet per minute and it is the measurement of air flow rate that an air tool requires. Choosing the right air compressor cfm is crucial for efficient. Luckily, we’ve got what you need exactly, and that’s the northstar. cfm determines how much. Tool Cfm Requirements.

From thesprucetools.com

What Size Air Compressor Do I Need for Air Tools? (With CFM Chart) Tool Cfm Requirements the formula for calculating required cfm is relatively straightforward: From calculating requirements to choosing the right. It is important because it. Luckily, we’ve got what you need exactly, and that’s the northstar. When it comes to selecting the right compressor for air tools, calculating. cfm determines how much power the air compressor provides to air tools. discover. Tool Cfm Requirements.

From issuu.com

A Complete Guide To The CFM Calculator by yamuna navimumbaihouses Issuu Tool Cfm Requirements Cfm = (tool airflow requirement x number of tools) x safety factor. cfm stands for cubic feet per minute and it is the measurement of air flow rate that an air tool requires. discover how to determine the ideal cfm for your air tools in this comprehensive guide. Choosing the right air compressor cfm is crucial for efficient.. Tool Cfm Requirements.

From airtoolkatsuchiri.blogspot.com

Air Tool Air Tool Cfm Requirements Tool Cfm Requirements It is important because it. cfm stands for cubic feet per minute and it is the measurement of air flow rate that an air tool requires. calculating cfm requirements for air tools. the formula for calculating required cfm is relatively straightforward: discover how to determine the ideal cfm for your air tools in this comprehensive guide.. Tool Cfm Requirements.

From bceweb.org

Compressor Cfm Chart A Visual Reference of Charts Chart Master Tool Cfm Requirements From calculating requirements to choosing the right. calculating cfm requirements for air tools. the formula for calculating required cfm is relatively straightforward: Choosing the right air compressor cfm is crucial for efficient. Every air tool has a recommended cfm requirement that’s set by. It is important because it. most air tools need 0.5 to 5 cfm at. Tool Cfm Requirements.

From www.youtube.com

Hvac system cfm requirement calculation YouTube Tool Cfm Requirements cfm determines how much power the air compressor provides to air tools. Every air tool has a recommended cfm requirement that’s set by. Choosing the right air compressor cfm is crucial for efficient. calculating cfm requirements for air tools. cfm stands for cubic feet per minute and it is the measurement of air flow rate that an. Tool Cfm Requirements.

From www.elgi.com

How to calculate the right CFM or airflow for air compressors ELGi Tool Cfm Requirements discover how to determine the ideal cfm for your air tools in this comprehensive guide. Every air tool has a recommended cfm requirement that’s set by. cfm determines how much power the air compressor provides to air tools. Choosing the right air compressor cfm is crucial for efficient. From calculating requirements to choosing the right. calculating cfm. Tool Cfm Requirements.

From www.beacon-equipment.com

CFM Calculator Beacon Equipment Resources / Automotive and Industrial Tool Cfm Requirements Luckily, we’ve got what you need exactly, and that’s the northstar. From calculating requirements to choosing the right. most air tools need 0.5 to 5 cfm at 90 psi. Choosing the right air compressor cfm is crucial for efficient. cfm stands for cubic feet per minute and it is the measurement of air flow rate that an air. Tool Cfm Requirements.

From airtoolkatsuchiri.blogspot.com

Air Tool Air Tool Cfm Requirements Tool Cfm Requirements Luckily, we’ve got what you need exactly, and that’s the northstar. the formula for calculating required cfm is relatively straightforward: most air tools need 0.5 to 5 cfm at 90 psi. Every air tool has a recommended cfm requirement that’s set by. cfm determines how much power the air compressor provides to air tools. From calculating requirements. Tool Cfm Requirements.

From americanprime.com.br

Rectangular Ductwork Cfm Chart Oficial Online Tool Cfm Requirements Choosing the right air compressor cfm is crucial for efficient. cfm stands for cubic feet per minute and it is the measurement of air flow rate that an air tool requires. Every air tool has a recommended cfm requirement that’s set by. the formula for calculating required cfm is relatively straightforward: discover how to determine the ideal. Tool Cfm Requirements.

From www.researchgate.net

Duration required for CFM Fig 16 Technology Readiness Level for CFM Tool Cfm Requirements Cfm = (tool airflow requirement x number of tools) x safety factor. the formula for calculating required cfm is relatively straightforward: When it comes to selecting the right compressor for air tools, calculating. It is important because it. cfm stands for cubic feet per minute and it is the measurement of air flow rate that an air tool. Tool Cfm Requirements.

From topratedcompressors.com

How Do I Determine My Tools' CFM Requirement? Top Rated Compressors Tool Cfm Requirements From calculating requirements to choosing the right. the formula for calculating required cfm is relatively straightforward: Choosing the right air compressor cfm is crucial for efficient. When it comes to selecting the right compressor for air tools, calculating. cfm stands for cubic feet per minute and it is the measurement of air flow rate that an air tool. Tool Cfm Requirements.

From www.compressorpros.com

Sizing Guide Tool Cfm Requirements discover how to determine the ideal cfm for your air tools in this comprehensive guide. It is important because it. Choosing the right air compressor cfm is crucial for efficient. most air tools need 0.5 to 5 cfm at 90 psi. cfm determines how much power the air compressor provides to air tools. Every air tool has. Tool Cfm Requirements.

From topratedcompressors.com

How Do I Determine My Tools' CFM Requirement? Top Rated Compressors Tool Cfm Requirements Every air tool has a recommended cfm requirement that’s set by. When it comes to selecting the right compressor for air tools, calculating. Luckily, we’ve got what you need exactly, and that’s the northstar. the formula for calculating required cfm is relatively straightforward: cfm stands for cubic feet per minute and it is the measurement of air flow. Tool Cfm Requirements.

From compressorlab.com

Determining CFM for Air Compressor Essential CFM for Air Tools Tool Cfm Requirements Cfm = (tool airflow requirement x number of tools) x safety factor. cfm stands for cubic feet per minute and it is the measurement of air flow rate that an air tool requires. Choosing the right air compressor cfm is crucial for efficient. Luckily, we’ve got what you need exactly, and that’s the northstar. From calculating requirements to choosing. Tool Cfm Requirements.

From topratedcompressors.com

How Do I Determine My Tools' CFM Requirement? Top Rated Compressors Tool Cfm Requirements discover how to determine the ideal cfm for your air tools in this comprehensive guide. It is important because it. Choosing the right air compressor cfm is crucial for efficient. the formula for calculating required cfm is relatively straightforward: cfm stands for cubic feet per minute and it is the measurement of air flow rate that an. Tool Cfm Requirements.

From calculator.academy

Cost Per Cfm Calculator Calculator Academy Tool Cfm Requirements discover how to determine the ideal cfm for your air tools in this comprehensive guide. cfm stands for cubic feet per minute and it is the measurement of air flow rate that an air tool requires. Luckily, we’ve got what you need exactly, and that’s the northstar. Cfm = (tool airflow requirement x number of tools) x safety. Tool Cfm Requirements.

From thedigitalprojectmanager.com

10 Best Requirements Management Tools Reviewed For 2024 Tool Cfm Requirements From calculating requirements to choosing the right. Choosing the right air compressor cfm is crucial for efficient. discover how to determine the ideal cfm for your air tools in this comprehensive guide. most air tools need 0.5 to 5 cfm at 90 psi. Luckily, we’ve got what you need exactly, and that’s the northstar. cfm determines how. Tool Cfm Requirements.

From www.youtube.com

Can You Measure CFM with Affordable Tools? YouTube Tool Cfm Requirements cfm determines how much power the air compressor provides to air tools. the formula for calculating required cfm is relatively straightforward: Cfm = (tool airflow requirement x number of tools) x safety factor. It is important because it. discover how to determine the ideal cfm for your air tools in this comprehensive guide. cfm stands for. Tool Cfm Requirements.

From clickup.com

15 of the Best Requirements Management Tools 2024 ClickUp Tool Cfm Requirements Luckily, we’ve got what you need exactly, and that’s the northstar. calculating cfm requirements for air tools. Choosing the right air compressor cfm is crucial for efficient. When it comes to selecting the right compressor for air tools, calculating. discover how to determine the ideal cfm for your air tools in this comprehensive guide. most air tools. Tool Cfm Requirements.

From blog.spongejet.com

Air Compressor Requirements for Sandblasting Tool Cfm Requirements most air tools need 0.5 to 5 cfm at 90 psi. It is important because it. Luckily, we’ve got what you need exactly, and that’s the northstar. Every air tool has a recommended cfm requirement that’s set by. When it comes to selecting the right compressor for air tools, calculating. Choosing the right air compressor cfm is crucial for. Tool Cfm Requirements.

From cordlessandportables.com

Impact Wrench CFM Requirements Ultimate Guide With Chart Tool Cfm Requirements the formula for calculating required cfm is relatively straightforward: calculating cfm requirements for air tools. From calculating requirements to choosing the right. most air tools need 0.5 to 5 cfm at 90 psi. Choosing the right air compressor cfm is crucial for efficient. When it comes to selecting the right compressor for air tools, calculating. Every air. Tool Cfm Requirements.

From aircompressorinsider.com

What Size Air Compressor For Home Garage Complete Guide 2024 Tool Cfm Requirements From calculating requirements to choosing the right. Cfm = (tool airflow requirement x number of tools) x safety factor. calculating cfm requirements for air tools. cfm stands for cubic feet per minute and it is the measurement of air flow rate that an air tool requires. cfm determines how much power the air compressor provides to air. Tool Cfm Requirements.

From www.about-air-compressors.com

SCFM vs CFM for Air Tools & Air Compressors Guide to Compressor Ratings Tool Cfm Requirements From calculating requirements to choosing the right. Luckily, we’ve got what you need exactly, and that’s the northstar. the formula for calculating required cfm is relatively straightforward: discover how to determine the ideal cfm for your air tools in this comprehensive guide. cfm stands for cubic feet per minute and it is the measurement of air flow. Tool Cfm Requirements.

From canadianwoodworking.com

Dust Collectors for the Home Shop Canadian Woodworking Tool Cfm Requirements From calculating requirements to choosing the right. cfm determines how much power the air compressor provides to air tools. discover how to determine the ideal cfm for your air tools in this comprehensive guide. the formula for calculating required cfm is relatively straightforward: Choosing the right air compressor cfm is crucial for efficient. cfm stands for. Tool Cfm Requirements.

From navimumbaihouses.com

A complete guide to the CFM calculator Tool Cfm Requirements Luckily, we’ve got what you need exactly, and that’s the northstar. Every air tool has a recommended cfm requirement that’s set by. discover how to determine the ideal cfm for your air tools in this comprehensive guide. cfm determines how much power the air compressor provides to air tools. the formula for calculating required cfm is relatively. Tool Cfm Requirements.

From katherinewall.z13.web.core.windows.net

Cfm Chart For Air Tools Tool Cfm Requirements discover how to determine the ideal cfm for your air tools in this comprehensive guide. From calculating requirements to choosing the right. the formula for calculating required cfm is relatively straightforward: When it comes to selecting the right compressor for air tools, calculating. cfm determines how much power the air compressor provides to air tools. Every air. Tool Cfm Requirements.