Brazing Aluminum Radiator . When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. First thing to do is see if that radiator is furnace brazed like a lot of auto radiators are. Controlled atmosphere brazing of aluminum (cab), using a noncorrosive flux, is the preferred process for manufacturing. My understanding is the tubes are brazed in with some lower. I’ve got an aluminum radiator that i need to section and weld new side tank end caps on like this. Controlled atmosphere brazing (cab) using a noncorrosive flux, is the preferred process for manufacturing aluminum heat exchangers such. If so then when you apply heat something else will likely come apart or leak.

from tarazon.com

If so then when you apply heat something else will likely come apart or leak. First thing to do is see if that radiator is furnace brazed like a lot of auto radiators are. I’ve got an aluminum radiator that i need to section and weld new side tank end caps on like this. Controlled atmosphere brazing of aluminum (cab), using a noncorrosive flux, is the preferred process for manufacturing. Controlled atmosphere brazing (cab) using a noncorrosive flux, is the preferred process for manufacturing aluminum heat exchangers such. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. My understanding is the tubes are brazed in with some lower.

Brazing Aluminum Curved Motorcycle Radiator Buy curved motorcycle radiator, Motorcycle

Brazing Aluminum Radiator Controlled atmosphere brazing of aluminum (cab), using a noncorrosive flux, is the preferred process for manufacturing. First thing to do is see if that radiator is furnace brazed like a lot of auto radiators are. If so then when you apply heat something else will likely come apart or leak. Controlled atmosphere brazing of aluminum (cab), using a noncorrosive flux, is the preferred process for manufacturing. Controlled atmosphere brazing (cab) using a noncorrosive flux, is the preferred process for manufacturing aluminum heat exchangers such. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. My understanding is the tubes are brazed in with some lower. I’ve got an aluminum radiator that i need to section and weld new side tank end caps on like this.

From inductionheattreatment.com

High Frequency Induction Brazing of Aluminum Radiator The Leading Induction Heating Machine Brazing Aluminum Radiator My understanding is the tubes are brazed in with some lower. If so then when you apply heat something else will likely come apart or leak. Controlled atmosphere brazing (cab) using a noncorrosive flux, is the preferred process for manufacturing aluminum heat exchangers such. I’ve got an aluminum radiator that i need to section and weld new side tank end. Brazing Aluminum Radiator.

From www.acp-aluminiumcompositepanel.com

High Frequency Aluminum Radiator Brazing , Car Radiator Cooling System Brazing Aluminum Radiator I’ve got an aluminum radiator that i need to section and weld new side tank end caps on like this. First thing to do is see if that radiator is furnace brazed like a lot of auto radiators are. Controlled atmosphere brazing (cab) using a noncorrosive flux, is the preferred process for manufacturing aluminum heat exchangers such. If so then. Brazing Aluminum Radiator.

From www.radiatormachines.com

Controlled Atmosphere Aluminium Radiator Brazing Furnace 1000 200 8000MM Brazing Aluminum Radiator My understanding is the tubes are brazed in with some lower. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. I’ve got an aluminum radiator that i need to section and weld new side tank end caps on like this. If so then when you apply heat something else will. Brazing Aluminum Radiator.

From www.tf-works.com

ARC Aluminum Radiator for R32 GTR Brazing Aluminum Radiator If so then when you apply heat something else will likely come apart or leak. Controlled atmosphere brazing (cab) using a noncorrosive flux, is the preferred process for manufacturing aluminum heat exchangers such. My understanding is the tubes are brazed in with some lower. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high. Brazing Aluminum Radiator.

From www.aluminiumcarradiators.com

Hard brazing aluminum radiator for Hyumdai VELOSTER 1.6' 11 , high performance radiator Brazing Aluminum Radiator Controlled atmosphere brazing of aluminum (cab), using a noncorrosive flux, is the preferred process for manufacturing. My understanding is the tubes are brazed in with some lower. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. If so then when you apply heat something else will likely come apart or. Brazing Aluminum Radiator.

From kingaautoparts.en.made-in-china.com

2007 Corolla Brazing Aluminum Radiator 164000t040 China Radiator and Cooling System Brazing Aluminum Radiator I’ve got an aluminum radiator that i need to section and weld new side tank end caps on like this. Controlled atmosphere brazing of aluminum (cab), using a noncorrosive flux, is the preferred process for manufacturing. First thing to do is see if that radiator is furnace brazed like a lot of auto radiators are. Controlled atmosphere brazing (cab) using. Brazing Aluminum Radiator.

From tarazon.com

[B2B] Motorcycle Manual Brazing Aluminum Radiator for YAMAHA Buy Motorcycle Radiator, Brazed Brazing Aluminum Radiator Controlled atmosphere brazing of aluminum (cab), using a noncorrosive flux, is the preferred process for manufacturing. My understanding is the tubes are brazed in with some lower. First thing to do is see if that radiator is furnace brazed like a lot of auto radiators are. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not. Brazing Aluminum Radiator.

From www.researchgate.net

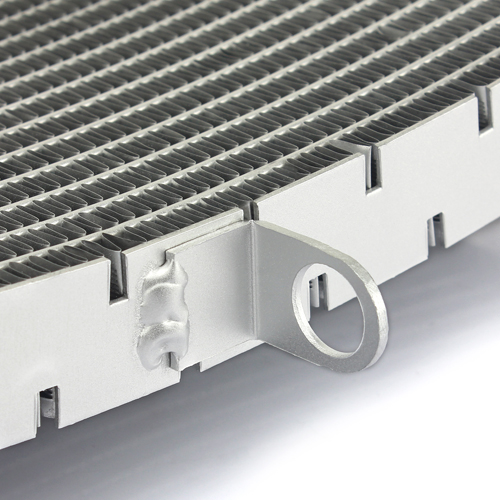

Detail of the heat transfer surface of the aluminum radiator (formed... Download Scientific Brazing Aluminum Radiator When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. My understanding is the tubes are brazed in with some lower. Controlled atmosphere brazing of aluminum (cab), using a noncorrosive flux, is the preferred process for manufacturing. Controlled atmosphere brazing (cab) using a noncorrosive flux, is the preferred process for manufacturing. Brazing Aluminum Radiator.

From tarazon.com

[B2B] Motorcycle Manual Brazing Aluminum Radiator for YAMAHA Buy Motorcycle Radiator, Brazed Brazing Aluminum Radiator First thing to do is see if that radiator is furnace brazed like a lot of auto radiators are. My understanding is the tubes are brazed in with some lower. I’ve got an aluminum radiator that i need to section and weld new side tank end caps on like this. Controlled atmosphere brazing (cab) using a noncorrosive flux, is the. Brazing Aluminum Radiator.

From tarazon.com

Brazing Aluminum Curved Motorcycle Radiator Buy curved motorcycle radiator, Motorcycle Brazing Aluminum Radiator When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. My understanding is the tubes are brazed in with some lower. Controlled atmosphere brazing (cab) using a noncorrosive flux, is the preferred process for manufacturing aluminum heat exchangers such. First thing to do is see if that radiator is furnace brazed. Brazing Aluminum Radiator.

From yisaiya.en.hisupplier.com

aluminum brazing radiator from China manufacturer Ruian Yisaiya Unit Co.,Ltd. Brazing Aluminum Radiator Controlled atmosphere brazing (cab) using a noncorrosive flux, is the preferred process for manufacturing aluminum heat exchangers such. First thing to do is see if that radiator is furnace brazed like a lot of auto radiators are. My understanding is the tubes are brazed in with some lower. Controlled atmosphere brazing of aluminum (cab), using a noncorrosive flux, is the. Brazing Aluminum Radiator.

From www.aluminiumfoilroll.com

Highly Efficient Brazing Aluminum Radiator Tube Precision Cutting ASTM Brazing Aluminum Radiator When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. Controlled atmosphere brazing (cab) using a noncorrosive flux, is the preferred process for manufacturing aluminum heat exchangers such. Controlled atmosphere brazing of aluminum (cab), using a noncorrosive flux, is the preferred process for manufacturing. I’ve got an aluminum radiator that i. Brazing Aluminum Radiator.

From www.aluminiumcarradiators.com

Hard brazing aluminum radiator for Hyumdai VELOSTER 1.6' 11 , high performance radiator Brazing Aluminum Radiator First thing to do is see if that radiator is furnace brazed like a lot of auto radiators are. If so then when you apply heat something else will likely come apart or leak. My understanding is the tubes are brazed in with some lower. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require. Brazing Aluminum Radiator.

From www.jonyautoparts.com

China Hard Brazing Aluminum Radiator Manufacturers, Suppliers Factory Direct Wholesale JONY Brazing Aluminum Radiator Controlled atmosphere brazing of aluminum (cab), using a noncorrosive flux, is the preferred process for manufacturing. If so then when you apply heat something else will likely come apart or leak. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. First thing to do is see if that radiator is. Brazing Aluminum Radiator.

From tarazon.com

Brazing Aluminum Curved Motorcycle Radiator Buy curved motorcycle radiator, Motorcycle Brazing Aluminum Radiator My understanding is the tubes are brazed in with some lower. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. If so then when you apply heat something else will likely come apart or leak. Controlled atmosphere brazing (cab) using a noncorrosive flux, is the preferred process for manufacturing aluminum. Brazing Aluminum Radiator.

From tarazon.com

[B2B] Motorcycle Manual Brazing Aluminum Radiator for YAMAHA Buy Motorcycle Radiator, Brazed Brazing Aluminum Radiator First thing to do is see if that radiator is furnace brazed like a lot of auto radiators are. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. Controlled atmosphere brazing (cab) using a noncorrosive flux, is the preferred process for manufacturing aluminum heat exchangers such. If so then when. Brazing Aluminum Radiator.

From tarazon.com

[B2B]Custom Motorcycle Brazing Aluminum Radiator for KAWASAKI Buy Motorcycle Radiator Brazing Aluminum Radiator Controlled atmosphere brazing (cab) using a noncorrosive flux, is the preferred process for manufacturing aluminum heat exchangers such. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. First thing to do is see if that radiator is furnace brazed like a lot of auto radiators are. I’ve got an aluminum. Brazing Aluminum Radiator.

From www.jonyautoparts.com

China Hard Brazing Aluminum Radiator Manufacturers, Suppliers Factory Direct Wholesale JONY Brazing Aluminum Radiator Controlled atmosphere brazing of aluminum (cab), using a noncorrosive flux, is the preferred process for manufacturing. My understanding is the tubes are brazed in with some lower. Controlled atmosphere brazing (cab) using a noncorrosive flux, is the preferred process for manufacturing aluminum heat exchangers such. First thing to do is see if that radiator is furnace brazed like a lot. Brazing Aluminum Radiator.

From www.youtube.com

BEST Welding/Repair Alum Radiator with BRAZING DURAFIX rods YouTube Brazing Aluminum Radiator I’ve got an aluminum radiator that i need to section and weld new side tank end caps on like this. Controlled atmosphere brazing of aluminum (cab), using a noncorrosive flux, is the preferred process for manufacturing. If so then when you apply heat something else will likely come apart or leak. Controlled atmosphere brazing (cab) using a noncorrosive flux, is. Brazing Aluminum Radiator.

From www.aluminium-brazing.com

Aluminium Brazing System Design for Temperature Profilers Aluminium Brazing Brazing Aluminum Radiator If so then when you apply heat something else will likely come apart or leak. My understanding is the tubes are brazed in with some lower. I’ve got an aluminum radiator that i need to section and weld new side tank end caps on like this. First thing to do is see if that radiator is furnace brazed like a. Brazing Aluminum Radiator.

From www.aluminiumcarradiators.com

Brazing Aluminum 2000 Nissan Radiator For Almera Mt Car Spare Parts 214100m000/0m100 Brazing Aluminum Radiator I’ve got an aluminum radiator that i need to section and weld new side tank end caps on like this. First thing to do is see if that radiator is furnace brazed like a lot of auto radiators are. Controlled atmosphere brazing (cab) using a noncorrosive flux, is the preferred process for manufacturing aluminum heat exchangers such. My understanding is. Brazing Aluminum Radiator.

From www.auto-partsradiator.com

2KD MT Brazing Aluminum Radiator For HILUX VIGO /INNOVA 20062009 164000L250 Brazing Aluminum Radiator If so then when you apply heat something else will likely come apart or leak. Controlled atmosphere brazing of aluminum (cab), using a noncorrosive flux, is the preferred process for manufacturing. My understanding is the tubes are brazed in with some lower. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of. Brazing Aluminum Radiator.

From www.aluminiumcarradiators.com

Aluminum Brazing Truck High Performance Radiators For Hyundai Manual OEM 25310 5H200 Brazing Aluminum Radiator If so then when you apply heat something else will likely come apart or leak. My understanding is the tubes are brazed in with some lower. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. Controlled atmosphere brazing (cab) using a noncorrosive flux, is the preferred process for manufacturing aluminum. Brazing Aluminum Radiator.

From www.youtube.com

Radiator Repair Aluminum Brazing Motorcycle 2007 Kawasaki ZX6R HOW TO YouTube Brazing Aluminum Radiator I’ve got an aluminum radiator that i need to section and weld new side tank end caps on like this. My understanding is the tubes are brazed in with some lower. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. If so then when you apply heat something else will. Brazing Aluminum Radiator.

From www.tf-works.com

ARC Aluminum Radiator for R32 GTR Brazing Aluminum Radiator If so then when you apply heat something else will likely come apart or leak. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. My understanding is the tubes are brazed in with some lower. First thing to do is see if that radiator is furnace brazed like a lot. Brazing Aluminum Radiator.

From www.vacfurnace.com

Aluminum radiators vacuum brazing oven SIMUWU Vacuum Furnace Brazing Aluminum Radiator My understanding is the tubes are brazed in with some lower. Controlled atmosphere brazing of aluminum (cab), using a noncorrosive flux, is the preferred process for manufacturing. I’ve got an aluminum radiator that i need to section and weld new side tank end caps on like this. First thing to do is see if that radiator is furnace brazed like. Brazing Aluminum Radiator.

From ultraflexpower.com

Induction Brazing of Aluminum Radiators UltraFlex Power Brazing Aluminum Radiator Controlled atmosphere brazing (cab) using a noncorrosive flux, is the preferred process for manufacturing aluminum heat exchangers such. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. If so then when you apply heat something else will likely come apart or leak. I’ve got an aluminum radiator that i need. Brazing Aluminum Radiator.

From ultraflexpower.com

Induction Brazing of Aluminum Radiators UltraFlex Power Brazing Aluminum Radiator When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. I’ve got an aluminum radiator that i need to section and weld new side tank end caps on like this. If so then when you apply heat something else will likely come apart or leak. Controlled atmosphere brazing (cab) using a. Brazing Aluminum Radiator.

From radiatormachine.com

6 Meter Auto Aluminium Radiator Brazing Furnace Brazing Aluminum Radiator Controlled atmosphere brazing (cab) using a noncorrosive flux, is the preferred process for manufacturing aluminum heat exchangers such. Controlled atmosphere brazing of aluminum (cab), using a noncorrosive flux, is the preferred process for manufacturing. If so then when you apply heat something else will likely come apart or leak. I’ve got an aluminum radiator that i need to section and. Brazing Aluminum Radiator.

From www.radiatormakingmachine.com

Continuous Aluminum Radiator Brazing Furnace For Brazing Radiator Intercooler Condenser Brazing Aluminum Radiator Controlled atmosphere brazing of aluminum (cab), using a noncorrosive flux, is the preferred process for manufacturing. First thing to do is see if that radiator is furnace brazed like a lot of auto radiators are. Controlled atmosphere brazing (cab) using a noncorrosive flux, is the preferred process for manufacturing aluminum heat exchangers such. If so then when you apply heat. Brazing Aluminum Radiator.

From radiatormachine.com

Aluminium Radiator Brazing Furnace Radiator Making Machinery Brazing Aluminum Radiator Controlled atmosphere brazing (cab) using a noncorrosive flux, is the preferred process for manufacturing aluminum heat exchangers such. I’ve got an aluminum radiator that i need to section and weld new side tank end caps on like this. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. If so then. Brazing Aluminum Radiator.

From ultraflexpower.com

Induction Brazing of Aluminum Radiators UltraFlex Power Brazing Aluminum Radiator If so then when you apply heat something else will likely come apart or leak. Controlled atmosphere brazing (cab) using a noncorrosive flux, is the preferred process for manufacturing aluminum heat exchangers such. I’ve got an aluminum radiator that i need to section and weld new side tank end caps on like this. When compared to welding equipment, aluminum brazing. Brazing Aluminum Radiator.

From tarazon.com

Brazing Aluminum Curved Motorcycle Radiator Buy curved motorcycle radiator, Motorcycle Brazing Aluminum Radiator I’ve got an aluminum radiator that i need to section and weld new side tank end caps on like this. Controlled atmosphere brazing of aluminum (cab), using a noncorrosive flux, is the preferred process for manufacturing. My understanding is the tubes are brazed in with some lower. First thing to do is see if that radiator is furnace brazed like. Brazing Aluminum Radiator.

From tarazon.com

Brazing Aluminum Curved Motorcycle Radiator Buy curved motorcycle radiator, Motorcycle Brazing Aluminum Radiator When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage. My understanding is the tubes are brazed in with some lower. Controlled atmosphere brazing of aluminum (cab), using a noncorrosive flux, is the preferred process for manufacturing. If so then when you apply heat something else will likely come apart or. Brazing Aluminum Radiator.

From tarazon.com

Brazing Aluminum Curved Motorcycle Radiator Buy curved motorcycle radiator, Motorcycle Brazing Aluminum Radiator Controlled atmosphere brazing (cab) using a noncorrosive flux, is the preferred process for manufacturing aluminum heat exchangers such. I’ve got an aluminum radiator that i need to section and weld new side tank end caps on like this. If so then when you apply heat something else will likely come apart or leak. First thing to do is see if. Brazing Aluminum Radiator.