Plasma Cutting Holes In Steel . The first step is to set realistic expectations. Although plasma can produce excellent quality holes, those holes. Plasma cutting a rough hole size. “we've even had drill tips that have gone 4,000 holes by using internal cooling with the drill. I went to the fab shop for a demonstration of the plasma cut bolt holes in a 25mm thick steel plate. On some drill tips, scw can make 1,600 holes; By jimcolt » sat oct 02, 2010 12:37 pm. It’s able to cut fewer holes on a plasma cutter before having to change out the consumables. The time it takes for plasma cutting holes in mild steel is predominantly affected by. Having trouble welding those edges downstream? Air plasma hardens all edges on steel. Thermal cutting holes when producing holes in steel? How can i cut better holes? Do you know the ideal conditions for drilling vs.

from www.industrialmetalsupply.com

Do you know the ideal conditions for drilling vs. Air plasma hardens all edges on steel. I went to the fab shop for a demonstration of the plasma cut bolt holes in a 25mm thick steel plate. Although plasma can produce excellent quality holes, those holes. The first step is to set realistic expectations. “we've even had drill tips that have gone 4,000 holes by using internal cooling with the drill. The time it takes for plasma cutting holes in mild steel is predominantly affected by. Thermal cutting holes when producing holes in steel? It’s able to cut fewer holes on a plasma cutter before having to change out the consumables. On some drill tips, scw can make 1,600 holes;

HiDef Plasma Cutting for Metal Materials Industrial Metal Supply

Plasma Cutting Holes In Steel “we've even had drill tips that have gone 4,000 holes by using internal cooling with the drill. On some drill tips, scw can make 1,600 holes; By jimcolt » sat oct 02, 2010 12:37 pm. Plasma cutting a rough hole size. It’s able to cut fewer holes on a plasma cutter before having to change out the consumables. The time it takes for plasma cutting holes in mild steel is predominantly affected by. Thermal cutting holes when producing holes in steel? The first step is to set realistic expectations. I went to the fab shop for a demonstration of the plasma cut bolt holes in a 25mm thick steel plate. Although plasma can produce excellent quality holes, those holes. “we've even had drill tips that have gone 4,000 holes by using internal cooling with the drill. Having trouble welding those edges downstream? Do you know the ideal conditions for drilling vs. Air plasma hardens all edges on steel. How can i cut better holes?

From www.maverickcnc.com

CNC Plasma Cutting for Educational Applications MaverickCNC Plasma Cutting Holes In Steel I went to the fab shop for a demonstration of the plasma cut bolt holes in a 25mm thick steel plate. Air plasma hardens all edges on steel. Do you know the ideal conditions for drilling vs. How can i cut better holes? The first step is to set realistic expectations. Although plasma can produce excellent quality holes, those holes.. Plasma Cutting Holes In Steel.

From www.dreamstime.com

Metal Cutting. the Process of Cutting Metal Using Plasma Cutting Stock Image Image of laser Plasma Cutting Holes In Steel The first step is to set realistic expectations. I went to the fab shop for a demonstration of the plasma cut bolt holes in a 25mm thick steel plate. “we've even had drill tips that have gone 4,000 holes by using internal cooling with the drill. By jimcolt » sat oct 02, 2010 12:37 pm. Air plasma hardens all edges. Plasma Cutting Holes In Steel.

From www.thefabricator.com

Rethinking what plasma cutting can do for metal fabricators Plasma Cutting Holes In Steel On some drill tips, scw can make 1,600 holes; The first step is to set realistic expectations. Thermal cutting holes when producing holes in steel? Although plasma can produce excellent quality holes, those holes. Air plasma hardens all edges on steel. How can i cut better holes? Do you know the ideal conditions for drilling vs. Plasma cutting a rough. Plasma Cutting Holes In Steel.

From www.youtube.com

CNC plasma cutting machine drilling 22mm holes in 16mm steel plate YouTube Plasma Cutting Holes In Steel “we've even had drill tips that have gone 4,000 holes by using internal cooling with the drill. Air plasma hardens all edges on steel. Although plasma can produce excellent quality holes, those holes. Thermal cutting holes when producing holes in steel? Having trouble welding those edges downstream? The first step is to set realistic expectations. By jimcolt » sat oct. Plasma Cutting Holes In Steel.

From www.alamy.com

Plasma cutting of metal. Storing finished parts with a hole on a pallet Stock Photo Alamy Plasma Cutting Holes In Steel Although plasma can produce excellent quality holes, those holes. I went to the fab shop for a demonstration of the plasma cut bolt holes in a 25mm thick steel plate. By jimcolt » sat oct 02, 2010 12:37 pm. It’s able to cut fewer holes on a plasma cutter before having to change out the consumables. On some drill tips,. Plasma Cutting Holes In Steel.

From www.omnisteelsupply.com

STEEL PLASMA CUTTING SERVICES NY Omni Steel Supply Plasma Cutting Holes In Steel It’s able to cut fewer holes on a plasma cutter before having to change out the consumables. How can i cut better holes? Having trouble welding those edges downstream? Thermal cutting holes when producing holes in steel? “we've even had drill tips that have gone 4,000 holes by using internal cooling with the drill. I went to the fab shop. Plasma Cutting Holes In Steel.

From www.youtube.com

Plasma cutting steel YouTube Plasma Cutting Holes In Steel How can i cut better holes? Thermal cutting holes when producing holes in steel? I went to the fab shop for a demonstration of the plasma cut bolt holes in a 25mm thick steel plate. By jimcolt » sat oct 02, 2010 12:37 pm. Having trouble welding those edges downstream? On some drill tips, scw can make 1,600 holes; Air. Plasma Cutting Holes In Steel.

From www.industrialmetalsupply.com

HiDef Plasma Cutting for Metal Materials Industrial Metal Supply Plasma Cutting Holes In Steel How can i cut better holes? The first step is to set realistic expectations. On some drill tips, scw can make 1,600 holes; By jimcolt » sat oct 02, 2010 12:37 pm. “we've even had drill tips that have gone 4,000 holes by using internal cooling with the drill. The time it takes for plasma cutting holes in mild steel. Plasma Cutting Holes In Steel.

From www.westermans.com

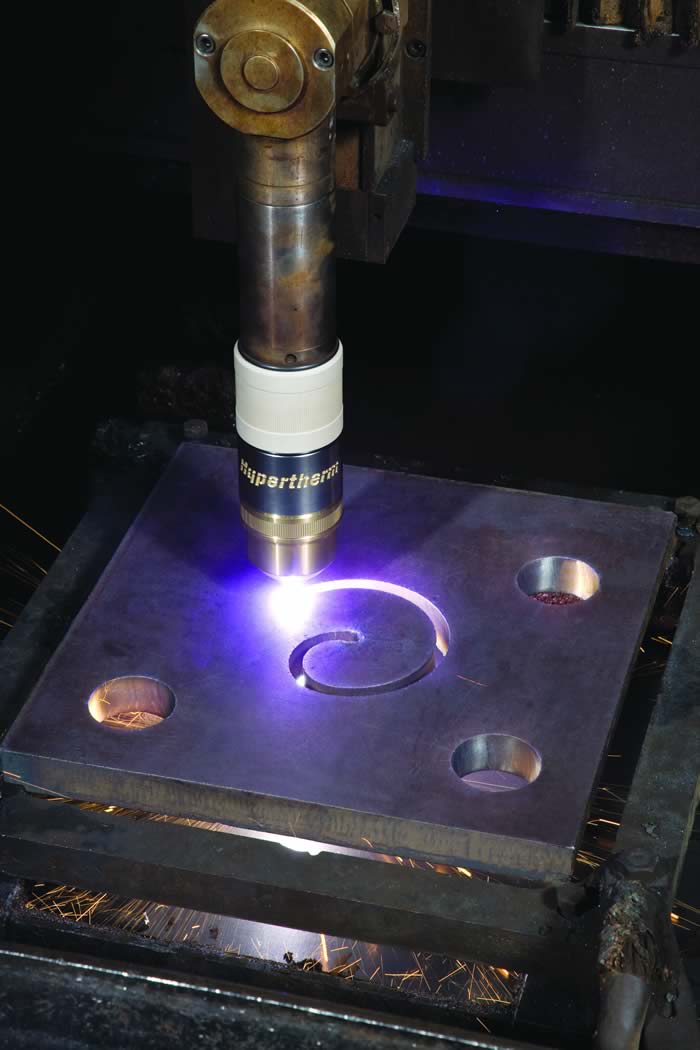

hypertherm plasma cutting Westermans Blog Plasma Cutting Holes In Steel How can i cut better holes? Do you know the ideal conditions for drilling vs. Plasma cutting a rough hole size. On some drill tips, scw can make 1,600 holes; Thermal cutting holes when producing holes in steel? By jimcolt » sat oct 02, 2010 12:37 pm. Although plasma can produce excellent quality holes, those holes. The time it takes. Plasma Cutting Holes In Steel.

From www.plasmacuttingni.co.uk

Plasma cutting of steel, copper and brass in Dungannon Plasma Cutting Holes In Steel Do you know the ideal conditions for drilling vs. Thermal cutting holes when producing holes in steel? On some drill tips, scw can make 1,600 holes; The first step is to set realistic expectations. How can i cut better holes? Air plasma hardens all edges on steel. “we've even had drill tips that have gone 4,000 holes by using internal. Plasma Cutting Holes In Steel.

From www.alamy.com

side view of laser plasma cutter in operation when cutting and drilling holes in an aluminium Plasma Cutting Holes In Steel Having trouble welding those edges downstream? Although plasma can produce excellent quality holes, those holes. The time it takes for plasma cutting holes in mild steel is predominantly affected by. Do you know the ideal conditions for drilling vs. On some drill tips, scw can make 1,600 holes; Plasma cutting a rough hole size. I went to the fab shop. Plasma Cutting Holes In Steel.

From www.cmnsteel.com

XPR300 Plasma Cutting System CMN Steel Fabricators Plasma Cutting Holes In Steel By jimcolt » sat oct 02, 2010 12:37 pm. Plasma cutting a rough hole size. How can i cut better holes? Having trouble welding those edges downstream? Air plasma hardens all edges on steel. Thermal cutting holes when producing holes in steel? Do you know the ideal conditions for drilling vs. The first step is to set realistic expectations. “we've. Plasma Cutting Holes In Steel.

From www.youtube.com

Hypertherm HiDef True Hole Plasma Cutter YouTube Plasma Cutting Holes In Steel On some drill tips, scw can make 1,600 holes; How can i cut better holes? Plasma cutting a rough hole size. Air plasma hardens all edges on steel. Thermal cutting holes when producing holes in steel? “we've even had drill tips that have gone 4,000 holes by using internal cooling with the drill. The first step is to set realistic. Plasma Cutting Holes In Steel.

From southweststeelsupplies.co.uk

Plasma Cutting Steel Fabrication South West Steel Supplies LTD Plasma Cutting Holes In Steel “we've even had drill tips that have gone 4,000 holes by using internal cooling with the drill. Having trouble welding those edges downstream? On some drill tips, scw can make 1,600 holes; Plasma cutting a rough hole size. Air plasma hardens all edges on steel. It’s able to cut fewer holes on a plasma cutter before having to change out. Plasma Cutting Holes In Steel.

From www.dreamstime.com

Detail of Laser Plasma Cutter in Operation when Cutting and Drilling Holes in an Aluminium Plasma Cutting Holes In Steel Although plasma can produce excellent quality holes, those holes. On some drill tips, scw can make 1,600 holes; I went to the fab shop for a demonstration of the plasma cut bolt holes in a 25mm thick steel plate. The time it takes for plasma cutting holes in mild steel is predominantly affected by. By jimcolt » sat oct 02,. Plasma Cutting Holes In Steel.

From www.youtube.com

Plasma cutting steel 1500x6000x3 YouTube Plasma Cutting Holes In Steel Air plasma hardens all edges on steel. Having trouble welding those edges downstream? I went to the fab shop for a demonstration of the plasma cut bolt holes in a 25mm thick steel plate. Plasma cutting a rough hole size. It’s able to cut fewer holes on a plasma cutter before having to change out the consumables. On some drill. Plasma Cutting Holes In Steel.

From www.alamy.com

Plasma cutting CNC machine cuts metal material with sparks, industry background aerospace Plasma Cutting Holes In Steel By jimcolt » sat oct 02, 2010 12:37 pm. On some drill tips, scw can make 1,600 holes; Plasma cutting a rough hole size. Although plasma can produce excellent quality holes, those holes. Do you know the ideal conditions for drilling vs. It’s able to cut fewer holes on a plasma cutter before having to change out the consumables. Thermal. Plasma Cutting Holes In Steel.

From amazonsteelconstruction.com

Metal Cutting, Bending, and Rolling Services Amazon Steel Plasma Cutting Holes In Steel Having trouble welding those edges downstream? Plasma cutting a rough hole size. “we've even had drill tips that have gone 4,000 holes by using internal cooling with the drill. Air plasma hardens all edges on steel. By jimcolt » sat oct 02, 2010 12:37 pm. How can i cut better holes? Although plasma can produce excellent quality holes, those holes.. Plasma Cutting Holes In Steel.

From www.thefabricator.com

An edge up on plasma cut quality Plasma Cutting Holes In Steel Plasma cutting a rough hole size. It’s able to cut fewer holes on a plasma cutter before having to change out the consumables. “we've even had drill tips that have gone 4,000 holes by using internal cooling with the drill. By jimcolt » sat oct 02, 2010 12:37 pm. On some drill tips, scw can make 1,600 holes; The first. Plasma Cutting Holes In Steel.

From www.youtube.com

Learn How to Cut the Best Holes with an Air Plasma on a CNC Cutting Table with Jim Colt YouTube Plasma Cutting Holes In Steel Do you know the ideal conditions for drilling vs. On some drill tips, scw can make 1,600 holes; “we've even had drill tips that have gone 4,000 holes by using internal cooling with the drill. The time it takes for plasma cutting holes in mild steel is predominantly affected by. How can i cut better holes? Plasma cutting a rough. Plasma Cutting Holes In Steel.

From cncroi.com

Custom Flat Bar Holes CNC Plasma Cutting Plasma Cutting Holes In Steel The first step is to set realistic expectations. Although plasma can produce excellent quality holes, those holes. The time it takes for plasma cutting holes in mild steel is predominantly affected by. Thermal cutting holes when producing holes in steel? How can i cut better holes? On some drill tips, scw can make 1,600 holes; By jimcolt » sat oct. Plasma Cutting Holes In Steel.

From www.alamy.com

Detail of laser plasma cutter in operation when cutting and drilling holes in an aluminium Plasma Cutting Holes In Steel Air plasma hardens all edges on steel. Plasma cutting a rough hole size. On some drill tips, scw can make 1,600 holes; Although plasma can produce excellent quality holes, those holes. It’s able to cut fewer holes on a plasma cutter before having to change out the consumables. The first step is to set realistic expectations. By jimcolt » sat. Plasma Cutting Holes In Steel.

From www.storyblocks.com

Industrial Laser Cutting Holes In Metal Stock Footage SBV336386528 Storyblocks Plasma Cutting Holes In Steel I went to the fab shop for a demonstration of the plasma cut bolt holes in a 25mm thick steel plate. Although plasma can produce excellent quality holes, those holes. Do you know the ideal conditions for drilling vs. Having trouble welding those edges downstream? Air plasma hardens all edges on steel. On some drill tips, scw can make 1,600. Plasma Cutting Holes In Steel.

From www.thefabricator.com

What is highprecision plasma cutting, exactly? Plasma Cutting Holes In Steel Air plasma hardens all edges on steel. “we've even had drill tips that have gone 4,000 holes by using internal cooling with the drill. Although plasma can produce excellent quality holes, those holes. Do you know the ideal conditions for drilling vs. It’s able to cut fewer holes on a plasma cutter before having to change out the consumables. Plasma. Plasma Cutting Holes In Steel.

From www.maverickcnc.com

Selecting the Right Cutting Process MaverickCNC Plasma Cutting Tables Plasma Cutting Holes In Steel By jimcolt » sat oct 02, 2010 12:37 pm. The time it takes for plasma cutting holes in mild steel is predominantly affected by. “we've even had drill tips that have gone 4,000 holes by using internal cooling with the drill. Thermal cutting holes when producing holes in steel? I went to the fab shop for a demonstration of the. Plasma Cutting Holes In Steel.

From www.youtube.com

Plasma Cutting Bolt Holes vs Drilling YouTube Plasma Cutting Holes In Steel Having trouble welding those edges downstream? Do you know the ideal conditions for drilling vs. Although plasma can produce excellent quality holes, those holes. Air plasma hardens all edges on steel. Thermal cutting holes when producing holes in steel? On some drill tips, scw can make 1,600 holes; The first step is to set realistic expectations. By jimcolt » sat. Plasma Cutting Holes In Steel.

From www.youtube.com

Cutting circles in 1/4" plate steel with a plasma cutter YouTube Plasma Cutting Holes In Steel Although plasma can produce excellent quality holes, those holes. “we've even had drill tips that have gone 4,000 holes by using internal cooling with the drill. Do you know the ideal conditions for drilling vs. By jimcolt » sat oct 02, 2010 12:37 pm. Plasma cutting a rough hole size. Thermal cutting holes when producing holes in steel? On some. Plasma Cutting Holes In Steel.

From www.youtube.com

XPR Plasma Cutting Bolt Hole With Taper Using 3DLT Bevel Head YouTube Plasma Cutting Holes In Steel It’s able to cut fewer holes on a plasma cutter before having to change out the consumables. By jimcolt » sat oct 02, 2010 12:37 pm. Air plasma hardens all edges on steel. The first step is to set realistic expectations. I went to the fab shop for a demonstration of the plasma cut bolt holes in a 25mm thick. Plasma Cutting Holes In Steel.

From www.schorrmetals.com

Understanding CNC Plasma Cutting Plasma Cutting Holes In Steel Plasma cutting a rough hole size. Thermal cutting holes when producing holes in steel? By jimcolt » sat oct 02, 2010 12:37 pm. How can i cut better holes? Having trouble welding those edges downstream? Do you know the ideal conditions for drilling vs. The first step is to set realistic expectations. On some drill tips, scw can make 1,600. Plasma Cutting Holes In Steel.

From www.westermans.com

How to Get the Best Results Plasma Cutting Stainless Steel Plasma Cutting Holes In Steel How can i cut better holes? By jimcolt » sat oct 02, 2010 12:37 pm. I went to the fab shop for a demonstration of the plasma cut bolt holes in a 25mm thick steel plate. Although plasma can produce excellent quality holes, those holes. Do you know the ideal conditions for drilling vs. The first step is to set. Plasma Cutting Holes In Steel.

From www.youtube.com

Plasma cutting 1 inch thick steel YouTube Plasma Cutting Holes In Steel It’s able to cut fewer holes on a plasma cutter before having to change out the consumables. Do you know the ideal conditions for drilling vs. By jimcolt » sat oct 02, 2010 12:37 pm. How can i cut better holes? Having trouble welding those edges downstream? Thermal cutting holes when producing holes in steel? I went to the fab. Plasma Cutting Holes In Steel.

From www.youtube.com

63A DSP controlled plasma metal cutter drill holes on steel plate YouTube Plasma Cutting Holes In Steel It’s able to cut fewer holes on a plasma cutter before having to change out the consumables. The first step is to set realistic expectations. “we've even had drill tips that have gone 4,000 holes by using internal cooling with the drill. By jimcolt » sat oct 02, 2010 12:37 pm. Although plasma can produce excellent quality holes, those holes.. Plasma Cutting Holes In Steel.

From www.youtube.com

Plasma cutting 3/8 thick steel YouTube Plasma Cutting Holes In Steel On some drill tips, scw can make 1,600 holes; The time it takes for plasma cutting holes in mild steel is predominantly affected by. Having trouble welding those edges downstream? How can i cut better holes? The first step is to set realistic expectations. Air plasma hardens all edges on steel. Do you know the ideal conditions for drilling vs.. Plasma Cutting Holes In Steel.

From www.dreamstime.com

Square Steel Billets with Round Hole after Plasma Cutting Stock Photo Image of shining, silver Plasma Cutting Holes In Steel Although plasma can produce excellent quality holes, those holes. Air plasma hardens all edges on steel. The time it takes for plasma cutting holes in mild steel is predominantly affected by. The first step is to set realistic expectations. Having trouble welding those edges downstream? “we've even had drill tips that have gone 4,000 holes by using internal cooling with. Plasma Cutting Holes In Steel.

From www.youtube.com

precision plasma cutting machine drill holes on metal sheet YouTube Plasma Cutting Holes In Steel It’s able to cut fewer holes on a plasma cutter before having to change out the consumables. Plasma cutting a rough hole size. On some drill tips, scw can make 1,600 holes; The time it takes for plasma cutting holes in mild steel is predominantly affected by. Thermal cutting holes when producing holes in steel? “we've even had drill tips. Plasma Cutting Holes In Steel.