Thermal Cycling Durability Test . A power destructive temperature cycle test is recommended when the test object is a semiconductor device. Learn how temperature changes can damage materials and products, and how to design and interpret thermal cycling life tests. Plus, they perform functions in different ways. Cycle thermal dwell test be performed for the appropriate durations (24 hours cold and 144 to 288 hours hot). Thermal cycling test is a reliability and accelerated life test that exposes a device to extreme temperature fluctuations to identify. The thermal cycling test characterizes the behavior of the sensor at a variety of temperatures and places thermal stresses on. Understand the types of damage, the. Even though these tests look similar, they have different reasons. As a minimum, run eight thermal cycles over the approximate temperature range for. Thermal cycling lewis research center practice: These tests are easy to understand how car parts, ceramics, and electronics work. In the world of testing and evaluating the durability of materials, there are 2 tests:

from www.pvtest.cz

Even though these tests look similar, they have different reasons. These tests are easy to understand how car parts, ceramics, and electronics work. Thermal cycling test is a reliability and accelerated life test that exposes a device to extreme temperature fluctuations to identify. As a minimum, run eight thermal cycles over the approximate temperature range for. A power destructive temperature cycle test is recommended when the test object is a semiconductor device. Learn how temperature changes can damage materials and products, and how to design and interpret thermal cycling life tests. Understand the types of damage, the. In the world of testing and evaluating the durability of materials, there are 2 tests: Plus, they perform functions in different ways. Thermal cycling lewis research center practice:

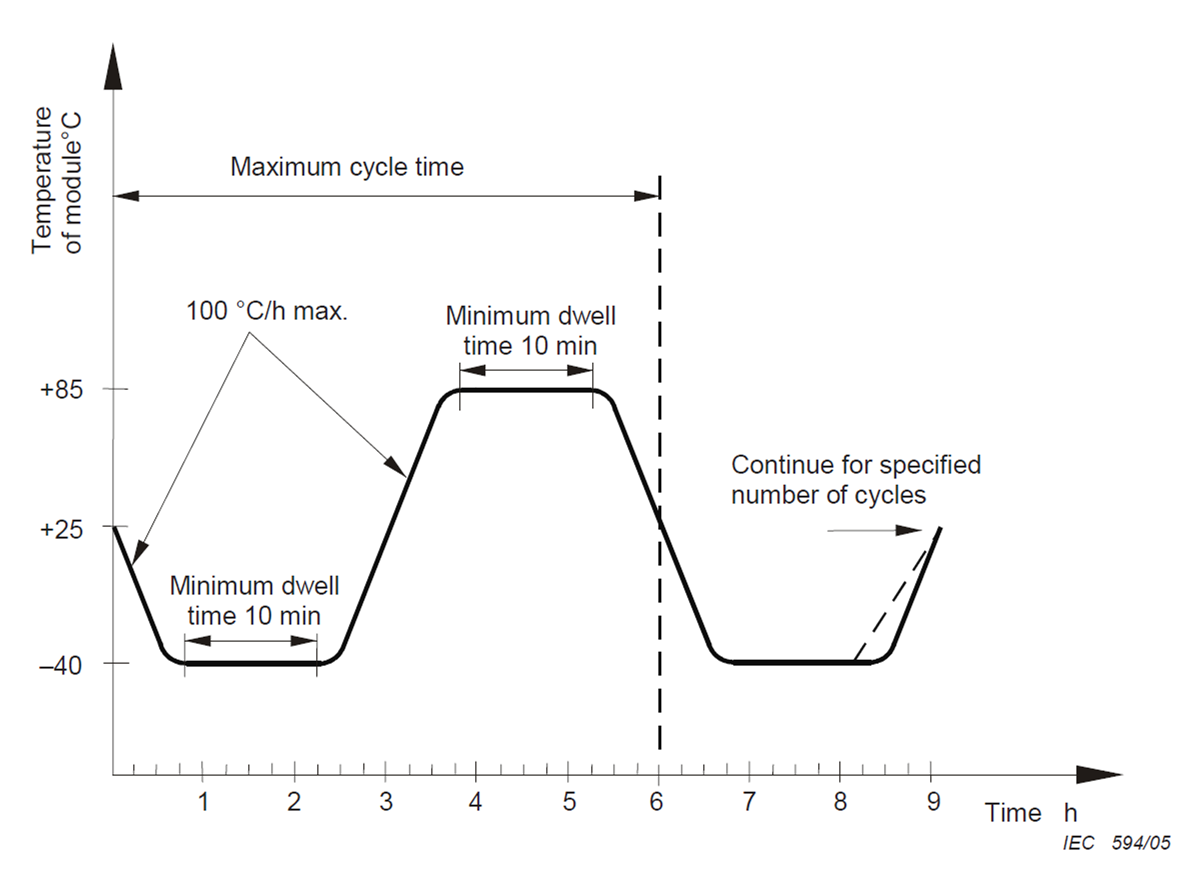

Thermal cycling test

Thermal Cycling Durability Test Even though these tests look similar, they have different reasons. Thermal cycling lewis research center practice: Thermal cycling test is a reliability and accelerated life test that exposes a device to extreme temperature fluctuations to identify. Plus, they perform functions in different ways. Even though these tests look similar, they have different reasons. Cycle thermal dwell test be performed for the appropriate durations (24 hours cold and 144 to 288 hours hot). The thermal cycling test characterizes the behavior of the sensor at a variety of temperatures and places thermal stresses on. As a minimum, run eight thermal cycles over the approximate temperature range for. Learn how temperature changes can damage materials and products, and how to design and interpret thermal cycling life tests. A power destructive temperature cycle test is recommended when the test object is a semiconductor device. These tests are easy to understand how car parts, ceramics, and electronics work. Understand the types of damage, the. In the world of testing and evaluating the durability of materials, there are 2 tests:

From www.chamber-testing.com

Thermal Cycling Test & Thermal shock test,How To Tell? Thermal Cycling Durability Test In the world of testing and evaluating the durability of materials, there are 2 tests: Learn how temperature changes can damage materials and products, and how to design and interpret thermal cycling life tests. Cycle thermal dwell test be performed for the appropriate durations (24 hours cold and 144 to 288 hours hot). Plus, they perform functions in different ways.. Thermal Cycling Durability Test.

From www.slideserve.com

PPT Solder Joint Reliability Assessed by Acoustic Imaging during Thermal Cycling Durability Test The thermal cycling test characterizes the behavior of the sensor at a variety of temperatures and places thermal stresses on. A power destructive temperature cycle test is recommended when the test object is a semiconductor device. Understand the types of damage, the. Thermal cycling lewis research center practice: Learn how temperature changes can damage materials and products, and how to. Thermal Cycling Durability Test.

From www.pvtest.cz

Thermal cycling test Thermal Cycling Durability Test These tests are easy to understand how car parts, ceramics, and electronics work. Cycle thermal dwell test be performed for the appropriate durations (24 hours cold and 144 to 288 hours hot). Understand the types of damage, the. Thermal cycling test is a reliability and accelerated life test that exposes a device to extreme temperature fluctuations to identify. Even though. Thermal Cycling Durability Test.

From www.thermal-engineering.org

How thermal shock testing assesses durability Thermal Cycling Durability Test Cycle thermal dwell test be performed for the appropriate durations (24 hours cold and 144 to 288 hours hot). Plus, they perform functions in different ways. Thermal cycling lewis research center practice: In the world of testing and evaluating the durability of materials, there are 2 tests: A power destructive temperature cycle test is recommended when the test object is. Thermal Cycling Durability Test.

From mpi-thermal.com

Advanced Thermal Cycling Test Equipment for PCB Reliability Test Thermal Cycling Durability Test Learn how temperature changes can damage materials and products, and how to design and interpret thermal cycling life tests. A power destructive temperature cycle test is recommended when the test object is a semiconductor device. The thermal cycling test characterizes the behavior of the sensor at a variety of temperatures and places thermal stresses on. Thermal cycling test is a. Thermal Cycling Durability Test.

From www.researchgate.net

Idealized temperaturetime curves of a thermal cycling stability Thermal Cycling Durability Test A power destructive temperature cycle test is recommended when the test object is a semiconductor device. In the world of testing and evaluating the durability of materials, there are 2 tests: Plus, they perform functions in different ways. Thermal cycling lewis research center practice: Understand the types of damage, the. Thermal cycling test is a reliability and accelerated life test. Thermal Cycling Durability Test.

From www.trelic.fi

Critical parameters of thermal cycling testing Trelic Solutions for Thermal Cycling Durability Test Cycle thermal dwell test be performed for the appropriate durations (24 hours cold and 144 to 288 hours hot). A power destructive temperature cycle test is recommended when the test object is a semiconductor device. The thermal cycling test characterizes the behavior of the sensor at a variety of temperatures and places thermal stresses on. Plus, they perform functions in. Thermal Cycling Durability Test.

From wpo-altertechnology.com

Thermal Cycling Testing services Alter Technology Group Thermal Cycling Durability Test As a minimum, run eight thermal cycles over the approximate temperature range for. The thermal cycling test characterizes the behavior of the sensor at a variety of temperatures and places thermal stresses on. Even though these tests look similar, they have different reasons. Thermal cycling lewis research center practice: Learn how temperature changes can damage materials and products, and how. Thermal Cycling Durability Test.

From mpi-thermal.com

MPI Temperature Forcing Systems Thermal Cycling Test Solutions Thermal Cycling Durability Test Learn how temperature changes can damage materials and products, and how to design and interpret thermal cycling life tests. Plus, they perform functions in different ways. These tests are easy to understand how car parts, ceramics, and electronics work. Cycle thermal dwell test be performed for the appropriate durations (24 hours cold and 144 to 288 hours hot). As a. Thermal Cycling Durability Test.

From www.industrialtestchamber.com

Military 1000L Thermal Cycling Test Equipment , 15℃/M Thermal Cycling Thermal Cycling Durability Test Thermal cycling lewis research center practice: These tests are easy to understand how car parts, ceramics, and electronics work. In the world of testing and evaluating the durability of materials, there are 2 tests: A power destructive temperature cycle test is recommended when the test object is a semiconductor device. Cycle thermal dwell test be performed for the appropriate durations. Thermal Cycling Durability Test.

From belltestchamber.com

Thermal Cycling Testing Temperature Cycling Testing Chambers Thermal Cycling Durability Test These tests are easy to understand how car parts, ceramics, and electronics work. Thermal cycling lewis research center practice: Even though these tests look similar, they have different reasons. Understand the types of damage, the. Learn how temperature changes can damage materials and products, and how to design and interpret thermal cycling life tests. As a minimum, run eight thermal. Thermal Cycling Durability Test.

From www.tec-science.com

Fatigue test tecscience Thermal Cycling Durability Test Even though these tests look similar, they have different reasons. Cycle thermal dwell test be performed for the appropriate durations (24 hours cold and 144 to 288 hours hot). In the world of testing and evaluating the durability of materials, there are 2 tests: Understand the types of damage, the. Thermal cycling test is a reliability and accelerated life test. Thermal Cycling Durability Test.

From www.laboratuar.net

Thermal Cycle Test Thermal Cycling Durability Test Learn how temperature changes can damage materials and products, and how to design and interpret thermal cycling life tests. The thermal cycling test characterizes the behavior of the sensor at a variety of temperatures and places thermal stresses on. These tests are easy to understand how car parts, ceramics, and electronics work. Even though these tests look similar, they have. Thermal Cycling Durability Test.

From www.semanticscholar.org

Figure 1 from Highly Accelerated Thermal Cycling Test for New Type of Thermal Cycling Durability Test Even though these tests look similar, they have different reasons. Plus, they perform functions in different ways. A power destructive temperature cycle test is recommended when the test object is a semiconductor device. These tests are easy to understand how car parts, ceramics, and electronics work. In the world of testing and evaluating the durability of materials, there are 2. Thermal Cycling Durability Test.

From www.enas.fraunhofer.de

Active And passive thermal cycles for automotive applications Thermal Cycling Durability Test Understand the types of damage, the. Thermal cycling test is a reliability and accelerated life test that exposes a device to extreme temperature fluctuations to identify. Learn how temperature changes can damage materials and products, and how to design and interpret thermal cycling life tests. Thermal cycling lewis research center practice: As a minimum, run eight thermal cycles over the. Thermal Cycling Durability Test.

From www.komegtek.com

Thermal Shock vs Thermal Cycling Test Chamber KOMEG China Thermal Cycling Durability Test As a minimum, run eight thermal cycles over the approximate temperature range for. Cycle thermal dwell test be performed for the appropriate durations (24 hours cold and 144 to 288 hours hot). Thermal cycling test is a reliability and accelerated life test that exposes a device to extreme temperature fluctuations to identify. Plus, they perform functions in different ways. A. Thermal Cycling Durability Test.

From www.researchgate.net

Typical thermal cycle (040 to 125 C) profile. Download Scientific Diagram Thermal Cycling Durability Test The thermal cycling test characterizes the behavior of the sensor at a variety of temperatures and places thermal stresses on. Thermal cycling lewis research center practice: Thermal cycling test is a reliability and accelerated life test that exposes a device to extreme temperature fluctuations to identify. As a minimum, run eight thermal cycles over the approximate temperature range for. A. Thermal Cycling Durability Test.

From ht87925057.en.made-in-china.com

High Low Temperature Environment Testing Chamber/ Thermal Cycle Thermal Cycling Durability Test Thermal cycling lewis research center practice: As a minimum, run eight thermal cycles over the approximate temperature range for. Plus, they perform functions in different ways. The thermal cycling test characterizes the behavior of the sensor at a variety of temperatures and places thermal stresses on. Even though these tests look similar, they have different reasons. A power destructive temperature. Thermal Cycling Durability Test.

From www.slideserve.com

PPT Thermal Cycling Tests of Dummy Modules PowerPoint Presentation Thermal Cycling Durability Test As a minimum, run eight thermal cycles over the approximate temperature range for. The thermal cycling test characterizes the behavior of the sensor at a variety of temperatures and places thermal stresses on. Thermal cycling lewis research center practice: These tests are easy to understand how car parts, ceramics, and electronics work. Cycle thermal dwell test be performed for the. Thermal Cycling Durability Test.

From www.researchgate.net

7 Typical Thermal Vacuum Cycling test profile for a payload to be Thermal Cycling Durability Test Plus, they perform functions in different ways. Thermal cycling test is a reliability and accelerated life test that exposes a device to extreme temperature fluctuations to identify. Cycle thermal dwell test be performed for the appropriate durations (24 hours cold and 144 to 288 hours hot). These tests are easy to understand how car parts, ceramics, and electronics work. As. Thermal Cycling Durability Test.

From www.slideserve.com

PPT Solder Joint Reliability Assessed by Acoustic Imaging during Thermal Cycling Durability Test Cycle thermal dwell test be performed for the appropriate durations (24 hours cold and 144 to 288 hours hot). Plus, they perform functions in different ways. As a minimum, run eight thermal cycles over the approximate temperature range for. Learn how temperature changes can damage materials and products, and how to design and interpret thermal cycling life tests. In the. Thermal Cycling Durability Test.

From qcorp.com

Q Corp Thermal Cycle Test Stand Thermal Cycling Durability Test Understand the types of damage, the. Learn how temperature changes can damage materials and products, and how to design and interpret thermal cycling life tests. In the world of testing and evaluating the durability of materials, there are 2 tests: Cycle thermal dwell test be performed for the appropriate durations (24 hours cold and 144 to 288 hours hot). A. Thermal Cycling Durability Test.

From www.en-standard.eu

BS EN 629252017 Concentrator photovoltaic (CPV) modules. Thermal Thermal Cycling Durability Test Understand the types of damage, the. As a minimum, run eight thermal cycles over the approximate temperature range for. Thermal cycling lewis research center practice: Plus, they perform functions in different ways. Learn how temperature changes can damage materials and products, and how to design and interpret thermal cycling life tests. A power destructive temperature cycle test is recommended when. Thermal Cycling Durability Test.

From www.researchgate.net

The thermal cycling testing of coatings. Thermal cycling test setup Thermal Cycling Durability Test The thermal cycling test characterizes the behavior of the sensor at a variety of temperatures and places thermal stresses on. These tests are easy to understand how car parts, ceramics, and electronics work. Thermal cycling lewis research center practice: As a minimum, run eight thermal cycles over the approximate temperature range for. Even though these tests look similar, they have. Thermal Cycling Durability Test.

From www.grandetop.com

Temperature Cycling Test Chambers, RapidRate Thermal Cycle Chamber Thermal Cycling Durability Test In the world of testing and evaluating the durability of materials, there are 2 tests: Learn how temperature changes can damage materials and products, and how to design and interpret thermal cycling life tests. Understand the types of damage, the. A power destructive temperature cycle test is recommended when the test object is a semiconductor device. Cycle thermal dwell test. Thermal Cycling Durability Test.

From www.acsexpress.hk

Humidity Chamber What Is It? How Does It Work? Testing Thermal Cycling Durability Test Cycle thermal dwell test be performed for the appropriate durations (24 hours cold and 144 to 288 hours hot). Thermal cycling test is a reliability and accelerated life test that exposes a device to extreme temperature fluctuations to identify. A power destructive temperature cycle test is recommended when the test object is a semiconductor device. Understand the types of damage,. Thermal Cycling Durability Test.

From winaico.com

19 IEC 61215 Tests to Identify Quality Solar Modules WINAICO Thermal Cycling Durability Test As a minimum, run eight thermal cycles over the approximate temperature range for. Plus, they perform functions in different ways. These tests are easy to understand how car parts, ceramics, and electronics work. Learn how temperature changes can damage materials and products, and how to design and interpret thermal cycling life tests. In the world of testing and evaluating the. Thermal Cycling Durability Test.

From www.ansys.com

How Thermal Cycling Causes Electronics Failure Thermal Cycling Durability Test The thermal cycling test characterizes the behavior of the sensor at a variety of temperatures and places thermal stresses on. A power destructive temperature cycle test is recommended when the test object is a semiconductor device. Cycle thermal dwell test be performed for the appropriate durations (24 hours cold and 144 to 288 hours hot). Learn how temperature changes can. Thermal Cycling Durability Test.

From www.grandetop.com

Temperature Cycling Test Chambers, RapidRate Thermal Cycle Chamber Thermal Cycling Durability Test Thermal cycling test is a reliability and accelerated life test that exposes a device to extreme temperature fluctuations to identify. As a minimum, run eight thermal cycles over the approximate temperature range for. Thermal cycling lewis research center practice: In the world of testing and evaluating the durability of materials, there are 2 tests: Plus, they perform functions in different. Thermal Cycling Durability Test.

From www.climatictestchambers.com

225L Environmental Stress Screening Thermal Cycling Chamber with rapid Thermal Cycling Durability Test Thermal cycling test is a reliability and accelerated life test that exposes a device to extreme temperature fluctuations to identify. Even though these tests look similar, they have different reasons. As a minimum, run eight thermal cycles over the approximate temperature range for. The thermal cycling test characterizes the behavior of the sensor at a variety of temperatures and places. Thermal Cycling Durability Test.

From www.mdpi.com

J. Compos. Sci. Free FullText Durability of Shape Memory Polymer Thermal Cycling Durability Test A power destructive temperature cycle test is recommended when the test object is a semiconductor device. Learn how temperature changes can damage materials and products, and how to design and interpret thermal cycling life tests. Cycle thermal dwell test be performed for the appropriate durations (24 hours cold and 144 to 288 hours hot). The thermal cycling test characterizes the. Thermal Cycling Durability Test.

From www.chamber-testing.com

Thermal Cycling Test & Thermal shock test,How To Tell? Thermal Cycling Durability Test As a minimum, run eight thermal cycles over the approximate temperature range for. A power destructive temperature cycle test is recommended when the test object is a semiconductor device. Thermal cycling lewis research center practice: The thermal cycling test characterizes the behavior of the sensor at a variety of temperatures and places thermal stresses on. Understand the types of damage,. Thermal Cycling Durability Test.

From www.temperature-humiditychamber.com

162L Thermal Cycling Machine Environmental Test Chamber Elevator Type Thermal Cycling Durability Test The thermal cycling test characterizes the behavior of the sensor at a variety of temperatures and places thermal stresses on. Learn how temperature changes can damage materials and products, and how to design and interpret thermal cycling life tests. These tests are easy to understand how car parts, ceramics, and electronics work. Thermal cycling lewis research center practice: As a. Thermal Cycling Durability Test.

From www.chamber-testing.com

Thermal Cycling Test & Thermal shock test,How To Tell? Thermal Cycling Durability Test Thermal cycling lewis research center practice: Understand the types of damage, the. A power destructive temperature cycle test is recommended when the test object is a semiconductor device. In the world of testing and evaluating the durability of materials, there are 2 tests: Cycle thermal dwell test be performed for the appropriate durations (24 hours cold and 144 to 288. Thermal Cycling Durability Test.

From advancedta.com

KEY Thermal Testing Test Profiles — ATA Modular Flow Management Thermal Cycling Durability Test As a minimum, run eight thermal cycles over the approximate temperature range for. Learn how temperature changes can damage materials and products, and how to design and interpret thermal cycling life tests. These tests are easy to understand how car parts, ceramics, and electronics work. Thermal cycling test is a reliability and accelerated life test that exposes a device to. Thermal Cycling Durability Test.