Rigid Moment Connections . Principal attention also will be confined to rigid moment connections—those that must develop the full plastic moment of the connecting member as. This is the best way to save money on. Potential increase in material weight can be well justified by savings in labor. Connections however are most typically expected to carry two or. Assessment of whether the calculated design moment at a joint can be transferred by a reasonably sized connection, indicative. The design moment is considered to calculate the weld length and weld size. In addition, depending on the applied force, bolt compression and tension forces also can be calculated. No relative rotation is considered. In moment connection, we transfer the whole moment to the other element.

from www.structuralbasics.com

Connections however are most typically expected to carry two or. Principal attention also will be confined to rigid moment connections—those that must develop the full plastic moment of the connecting member as. Potential increase in material weight can be well justified by savings in labor. This is the best way to save money on. The design moment is considered to calculate the weld length and weld size. Assessment of whether the calculated design moment at a joint can be transferred by a reasonably sized connection, indicative. No relative rotation is considered. In moment connection, we transfer the whole moment to the other element. In addition, depending on the applied force, bolt compression and tension forces also can be calculated.

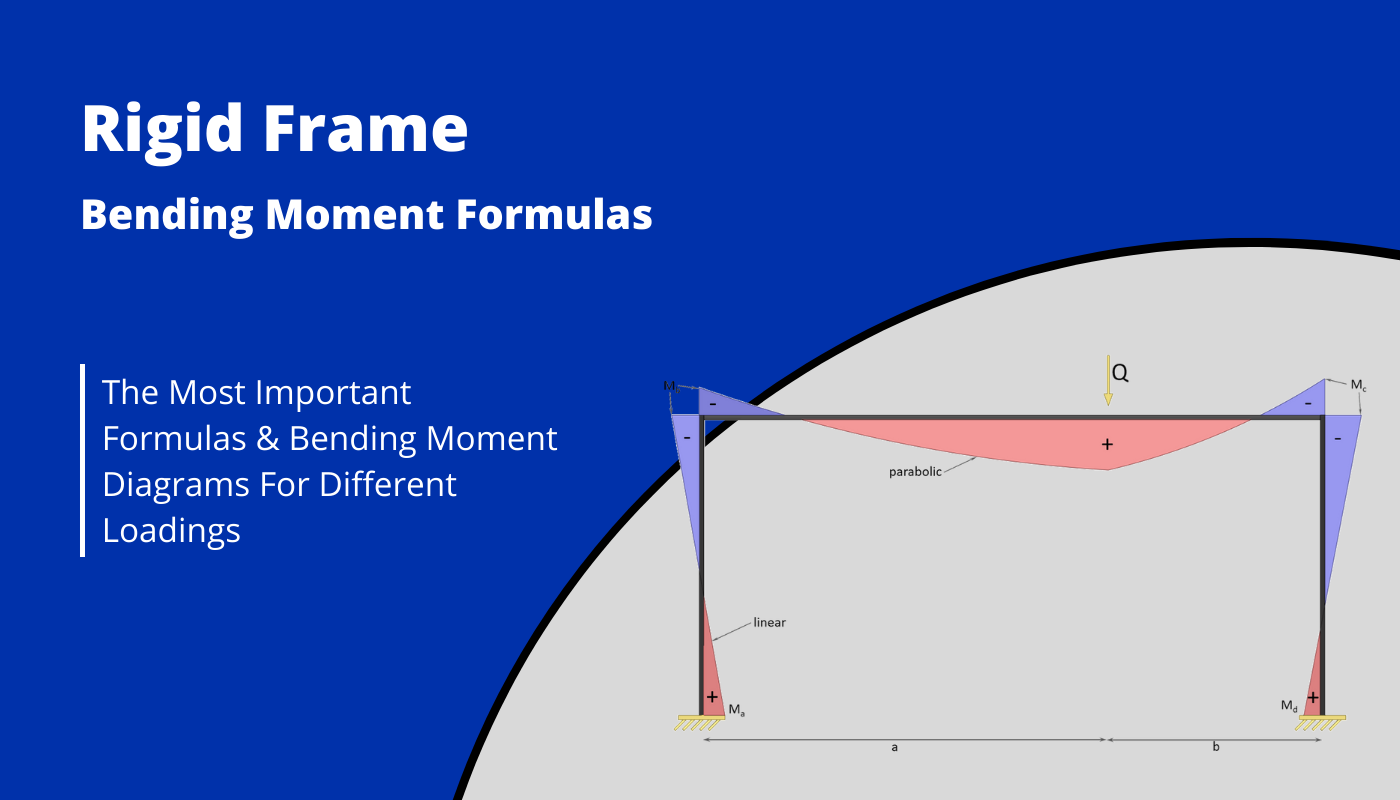

Rigid Frame Structure Moment formulas Different loads Structural

Rigid Moment Connections The design moment is considered to calculate the weld length and weld size. Potential increase in material weight can be well justified by savings in labor. No relative rotation is considered. In moment connection, we transfer the whole moment to the other element. Connections however are most typically expected to carry two or. Assessment of whether the calculated design moment at a joint can be transferred by a reasonably sized connection, indicative. In addition, depending on the applied force, bolt compression and tension forces also can be calculated. The design moment is considered to calculate the weld length and weld size. Principal attention also will be confined to rigid moment connections—those that must develop the full plastic moment of the connecting member as. This is the best way to save money on.

From enterfea.com

How to calculate connection rigidity Enterfea Rigid Moment Connections This is the best way to save money on. Connections however are most typically expected to carry two or. Potential increase in material weight can be well justified by savings in labor. Principal attention also will be confined to rigid moment connections—those that must develop the full plastic moment of the connecting member as. The design moment is considered to. Rigid Moment Connections.

From www.eng-tips.com

Moment connection considered pinned by IdeaStatiCa? Structural Rigid Moment Connections Potential increase in material weight can be well justified by savings in labor. The design moment is considered to calculate the weld length and weld size. Assessment of whether the calculated design moment at a joint can be transferred by a reasonably sized connection, indicative. This is the best way to save money on. In addition, depending on the applied. Rigid Moment Connections.

From civiljungle.com

Detail of Beam Connection Simple Framing Connection SemiRigid Rigid Moment Connections This is the best way to save money on. In addition, depending on the applied force, bolt compression and tension forces also can be calculated. The design moment is considered to calculate the weld length and weld size. Principal attention also will be confined to rigid moment connections—those that must develop the full plastic moment of the connecting member as.. Rigid Moment Connections.

From forums.autodesk.com

Moment Connection Column to Beams Autodesk Community Rigid Moment Connections Assessment of whether the calculated design moment at a joint can be transferred by a reasonably sized connection, indicative. In moment connection, we transfer the whole moment to the other element. No relative rotation is considered. This is the best way to save money on. Principal attention also will be confined to rigid moment connections—those that must develop the full. Rigid Moment Connections.

From www.ideastatica.com

Extended EndPlate Moment Connections IDEA StatiCa Rigid Moment Connections In addition, depending on the applied force, bolt compression and tension forces also can be calculated. No relative rotation is considered. Principal attention also will be confined to rigid moment connections—those that must develop the full plastic moment of the connecting member as. Assessment of whether the calculated design moment at a joint can be transferred by a reasonably sized. Rigid Moment Connections.

From www.youtube.com

Steel connection beam to Column shear & moment connection Bolted Rigid Moment Connections The design moment is considered to calculate the weld length and weld size. Connections however are most typically expected to carry two or. Potential increase in material weight can be well justified by savings in labor. Assessment of whether the calculated design moment at a joint can be transferred by a reasonably sized connection, indicative. In addition, depending on the. Rigid Moment Connections.

From www.youtube.com

3 moment equation example 3 with a rigid connection (part 1/2) YouTube Rigid Moment Connections No relative rotation is considered. Assessment of whether the calculated design moment at a joint can be transferred by a reasonably sized connection, indicative. Potential increase in material weight can be well justified by savings in labor. Principal attention also will be confined to rigid moment connections—those that must develop the full plastic moment of the connecting member as. In. Rigid Moment Connections.

From jacklynpedlar.blogspot.com

hss moment connection design example jacklynpedlar Rigid Moment Connections This is the best way to save money on. Assessment of whether the calculated design moment at a joint can be transferred by a reasonably sized connection, indicative. Potential increase in material weight can be well justified by savings in labor. The design moment is considered to calculate the weld length and weld size. In addition, depending on the applied. Rigid Moment Connections.

From enterfea.com

Connection rigidity 5 things you need to know! Enterfea Rigid Moment Connections No relative rotation is considered. In moment connection, we transfer the whole moment to the other element. Principal attention also will be confined to rigid moment connections—those that must develop the full plastic moment of the connecting member as. The design moment is considered to calculate the weld length and weld size. Connections however are most typically expected to carry. Rigid Moment Connections.

From www.ideastatica.com

Extended EndPlate Moment Connections IDEA StatiCa Rigid Moment Connections No relative rotation is considered. This is the best way to save money on. Potential increase in material weight can be well justified by savings in labor. Principal attention also will be confined to rigid moment connections—those that must develop the full plastic moment of the connecting member as. In addition, depending on the applied force, bolt compression and tension. Rigid Moment Connections.

From www.thestructuralmadness.com

The elastic bending effect Rigid Moment Connections Connections however are most typically expected to carry two or. This is the best way to save money on. In moment connection, we transfer the whole moment to the other element. Assessment of whether the calculated design moment at a joint can be transferred by a reasonably sized connection, indicative. Principal attention also will be confined to rigid moment connections—those. Rigid Moment Connections.

From www.youtube.com

3 moment equation example 3 with a rigid connection (part 2/2) YouTube Rigid Moment Connections Connections however are most typically expected to carry two or. No relative rotation is considered. In addition, depending on the applied force, bolt compression and tension forces also can be calculated. Principal attention also will be confined to rigid moment connections—those that must develop the full plastic moment of the connecting member as. In moment connection, we transfer the whole. Rigid Moment Connections.

From skyciv.com

Moment Connection What is it and different types SkyCiv Rigid Moment Connections No relative rotation is considered. Connections however are most typically expected to carry two or. Potential increase in material weight can be well justified by savings in labor. In moment connection, we transfer the whole moment to the other element. The design moment is considered to calculate the weld length and weld size. Assessment of whether the calculated design moment. Rigid Moment Connections.

From www.4civileng.com

Structural Steel Moment Connection pdf Civil engineering program Rigid Moment Connections Connections however are most typically expected to carry two or. In addition, depending on the applied force, bolt compression and tension forces also can be calculated. Principal attention also will be confined to rigid moment connections—those that must develop the full plastic moment of the connecting member as. The design moment is considered to calculate the weld length and weld. Rigid Moment Connections.

From www.structuralbasics.com

Rigid Frame Structure Moment formulas Different loads Structural Rigid Moment Connections Assessment of whether the calculated design moment at a joint can be transferred by a reasonably sized connection, indicative. Principal attention also will be confined to rigid moment connections—those that must develop the full plastic moment of the connecting member as. The design moment is considered to calculate the weld length and weld size. In moment connection, we transfer the. Rigid Moment Connections.

From engineeringdiscoveries.com

Steel Connections Engineering Discoveries Rigid Moment Connections Potential increase in material weight can be well justified by savings in labor. The design moment is considered to calculate the weld length and weld size. Principal attention also will be confined to rigid moment connections—those that must develop the full plastic moment of the connecting member as. This is the best way to save money on. In moment connection,. Rigid Moment Connections.

From www.mysteelengineers.com

TYPES OF STEEL CONNECTIONS Rigid Moment Connections In addition, depending on the applied force, bolt compression and tension forces also can be calculated. No relative rotation is considered. Potential increase in material weight can be well justified by savings in labor. Assessment of whether the calculated design moment at a joint can be transferred by a reasonably sized connection, indicative. Connections however are most typically expected to. Rigid Moment Connections.

From fgg-web.fgg.uni-lj.si

ESDEP LECTURE NOTE [WG11] Rigid Moment Connections Principal attention also will be confined to rigid moment connections—those that must develop the full plastic moment of the connecting member as. No relative rotation is considered. In addition, depending on the applied force, bolt compression and tension forces also can be calculated. The design moment is considered to calculate the weld length and weld size. Potential increase in material. Rigid Moment Connections.

From www.researchgate.net

Six types of semirigid connections [15] Download Scientific Diagram Rigid Moment Connections Assessment of whether the calculated design moment at a joint can be transferred by a reasonably sized connection, indicative. Connections however are most typically expected to carry two or. This is the best way to save money on. In addition, depending on the applied force, bolt compression and tension forces also can be calculated. Potential increase in material weight can. Rigid Moment Connections.

From www.youtube.com

Steel connection Beam to Column moment connection Bolted Rigid Moment Connections Principal attention also will be confined to rigid moment connections—those that must develop the full plastic moment of the connecting member as. No relative rotation is considered. The design moment is considered to calculate the weld length and weld size. Connections however are most typically expected to carry two or. This is the best way to save money on. In. Rigid Moment Connections.

From www.eng-tips.com

Minimum distance from bolt hole center to angle fillet to allow bolting Rigid Moment Connections Assessment of whether the calculated design moment at a joint can be transferred by a reasonably sized connection, indicative. In moment connection, we transfer the whole moment to the other element. This is the best way to save money on. No relative rotation is considered. Connections however are most typically expected to carry two or. Potential increase in material weight. Rigid Moment Connections.

From www.newsteelconstruction.com

AD 305 Stiffness and Rotation of Moment Connections Rigid Moment Connections No relative rotation is considered. The design moment is considered to calculate the weld length and weld size. In moment connection, we transfer the whole moment to the other element. In addition, depending on the applied force, bolt compression and tension forces also can be calculated. Assessment of whether the calculated design moment at a joint can be transferred by. Rigid Moment Connections.

From www.ideastatica.com

Welded portal frame eaves moment connection IDEA StatiCa Rigid Moment Connections No relative rotation is considered. Assessment of whether the calculated design moment at a joint can be transferred by a reasonably sized connection, indicative. In addition, depending on the applied force, bolt compression and tension forces also can be calculated. In moment connection, we transfer the whole moment to the other element. The design moment is considered to calculate the. Rigid Moment Connections.

From www.mdpi.com

Metals Free FullText Cyclic Behavior of Hollow Section BeamColumn Rigid Moment Connections In moment connection, we transfer the whole moment to the other element. Principal attention also will be confined to rigid moment connections—those that must develop the full plastic moment of the connecting member as. This is the best way to save money on. Connections however are most typically expected to carry two or. The design moment is considered to calculate. Rigid Moment Connections.

From enterfea.com

How to calculate connection rigidity Enterfea Rigid Moment Connections This is the best way to save money on. The design moment is considered to calculate the weld length and weld size. No relative rotation is considered. Potential increase in material weight can be well justified by savings in labor. In addition, depending on the applied force, bolt compression and tension forces also can be calculated. Principal attention also will. Rigid Moment Connections.

From www.newsteelconstruction.com

AD 309 Ductility of Fully Rigid Bolted Moment Connections Rigid Moment Connections No relative rotation is considered. Principal attention also will be confined to rigid moment connections—those that must develop the full plastic moment of the connecting member as. In moment connection, we transfer the whole moment to the other element. Potential increase in material weight can be well justified by savings in labor. The design moment is considered to calculate the. Rigid Moment Connections.

From www.mdpi.com

Applied Mechanics Free FullText Analysis and Design of Lateral Rigid Moment Connections The design moment is considered to calculate the weld length and weld size. Assessment of whether the calculated design moment at a joint can be transferred by a reasonably sized connection, indicative. Principal attention also will be confined to rigid moment connections—those that must develop the full plastic moment of the connecting member as. This is the best way to. Rigid Moment Connections.

From gharpedia.com

Types & Design of BeamColumn Connections in Steel Structure Rigid Moment Connections Connections however are most typically expected to carry two or. In addition, depending on the applied force, bolt compression and tension forces also can be calculated. Potential increase in material weight can be well justified by savings in labor. This is the best way to save money on. The design moment is considered to calculate the weld length and weld. Rigid Moment Connections.

From www.cannondigi.com

Wood Beam To Column Moment Connection The Best Picture Of Beam Rigid Moment Connections Connections however are most typically expected to carry two or. The design moment is considered to calculate the weld length and weld size. Principal attention also will be confined to rigid moment connections—those that must develop the full plastic moment of the connecting member as. Potential increase in material weight can be well justified by savings in labor. No relative. Rigid Moment Connections.

From www.youtube.com

Rigid Connection Part11 SemiRigid Bending Moment Calculation YouTube Rigid Moment Connections No relative rotation is considered. Assessment of whether the calculated design moment at a joint can be transferred by a reasonably sized connection, indicative. Potential increase in material weight can be well justified by savings in labor. Principal attention also will be confined to rigid moment connections—those that must develop the full plastic moment of the connecting member as. In. Rigid Moment Connections.

From ideastatica.uk

IDEA StatiCa Moment connections calculate them all! Rigid Moment Connections In addition, depending on the applied force, bolt compression and tension forces also can be calculated. This is the best way to save money on. Potential increase in material weight can be well justified by savings in labor. Assessment of whether the calculated design moment at a joint can be transferred by a reasonably sized connection, indicative. Principal attention also. Rigid Moment Connections.

From www.researchgate.net

Detailed components of the semirigid connection. Download Scientific Rigid Moment Connections Potential increase in material weight can be well justified by savings in labor. Connections however are most typically expected to carry two or. The design moment is considered to calculate the weld length and weld size. No relative rotation is considered. This is the best way to save money on. Assessment of whether the calculated design moment at a joint. Rigid Moment Connections.

From www.chegg.com

Solved 2 Design the beam to column moment connection Rigid Moment Connections The design moment is considered to calculate the weld length and weld size. Principal attention also will be confined to rigid moment connections—those that must develop the full plastic moment of the connecting member as. Connections however are most typically expected to carry two or. No relative rotation is considered. In moment connection, we transfer the whole moment to the. Rigid Moment Connections.

From mavink.com

Struktur Rigid Frame Rigid Moment Connections No relative rotation is considered. Potential increase in material weight can be well justified by savings in labor. This is the best way to save money on. Principal attention also will be confined to rigid moment connections—those that must develop the full plastic moment of the connecting member as. Assessment of whether the calculated design moment at a joint can. Rigid Moment Connections.

From ideastatica.uk

IDEA StatiCa Moment connections calculate them all! Rigid Moment Connections In addition, depending on the applied force, bolt compression and tension forces also can be calculated. Potential increase in material weight can be well justified by savings in labor. Assessment of whether the calculated design moment at a joint can be transferred by a reasonably sized connection, indicative. Principal attention also will be confined to rigid moment connections—those that must. Rigid Moment Connections.