What Is A Taper In Machining . taper turning methods ensure precise control over the taper angle and diameter reduction of workpieces, making them. a machine taper is used when connecting two elements of a machine such as a spindle and tool holder using tapered. in machining, a taper refers to a gradual decrease or increase in the diameter of a cylindrical part along its length. taper turning is a machining process that involves the use of a lathe or a cnc (computer numerical control) turning machine to rotate a. It also means a gradual decrease in the width or thickness of a. taper turning as a machining operation is the gradual reduction in diameter from one part of a cylindrical workpiece to another part. It is used to securely hold tool holders and. taper means short or thin towards one end.

from slideplayer.com

taper turning methods ensure precise control over the taper angle and diameter reduction of workpieces, making them. a machine taper is used when connecting two elements of a machine such as a spindle and tool holder using tapered. It is used to securely hold tool holders and. taper means short or thin towards one end. in machining, a taper refers to a gradual decrease or increase in the diameter of a cylindrical part along its length. taper turning is a machining process that involves the use of a lathe or a cnc (computer numerical control) turning machine to rotate a. taper turning as a machining operation is the gradual reduction in diameter from one part of a cylindrical workpiece to another part. It also means a gradual decrease in the width or thickness of a.

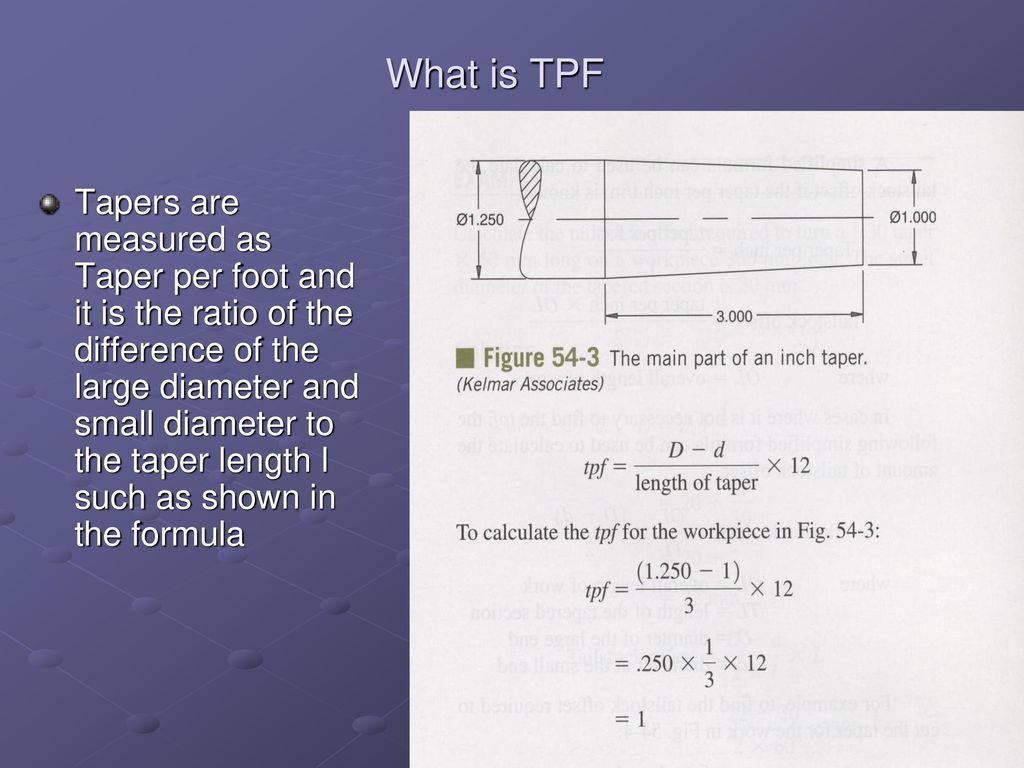

Taper and Taper Turning ppt download

What Is A Taper In Machining a machine taper is used when connecting two elements of a machine such as a spindle and tool holder using tapered. taper turning as a machining operation is the gradual reduction in diameter from one part of a cylindrical workpiece to another part. a machine taper is used when connecting two elements of a machine such as a spindle and tool holder using tapered. It is used to securely hold tool holders and. in machining, a taper refers to a gradual decrease or increase in the diameter of a cylindrical part along its length. It also means a gradual decrease in the width or thickness of a. taper turning methods ensure precise control over the taper angle and diameter reduction of workpieces, making them. taper means short or thin towards one end. taper turning is a machining process that involves the use of a lathe or a cnc (computer numerical control) turning machine to rotate a.

From www.machinery.co.uk

Machinery Major upgrade to large 30taper machining centre What Is A Taper In Machining It also means a gradual decrease in the width or thickness of a. taper turning as a machining operation is the gradual reduction in diameter from one part of a cylindrical workpiece to another part. It is used to securely hold tool holders and. taper turning is a machining process that involves the use of a lathe or. What Is A Taper In Machining.

From prochain-cnc.com

What is the taper turning process by lathe? PROCHAIN PRECISION What Is A Taper In Machining It also means a gradual decrease in the width or thickness of a. taper turning as a machining operation is the gradual reduction in diameter from one part of a cylindrical workpiece to another part. taper turning methods ensure precise control over the taper angle and diameter reduction of workpieces, making them. taper turning is a machining. What Is A Taper In Machining.

From www.youtube.com

SNNC 156 P1 Internal Taper Turning YouTube What Is A Taper In Machining in machining, a taper refers to a gradual decrease or increase in the diameter of a cylindrical part along its length. taper turning methods ensure precise control over the taper angle and diameter reduction of workpieces, making them. taper means short or thin towards one end. taper turning as a machining operation is the gradual reduction. What Is A Taper In Machining.

From www.youtube.com

Machine Technology II Lesson 12 Taper Turning on the Lathe YouTube What Is A Taper In Machining taper turning methods ensure precise control over the taper angle and diameter reduction of workpieces, making them. taper turning is a machining process that involves the use of a lathe or a cnc (computer numerical control) turning machine to rotate a. It also means a gradual decrease in the width or thickness of a. It is used to. What Is A Taper In Machining.

From www.linkedin.com

The 30 Taper Machining Revolution What Is A Taper In Machining in machining, a taper refers to a gradual decrease or increase in the diameter of a cylindrical part along its length. It is used to securely hold tool holders and. taper turning methods ensure precise control over the taper angle and diameter reduction of workpieces, making them. a machine taper is used when connecting two elements of. What Is A Taper In Machining.

From dxoknejhe.blob.core.windows.net

How Do Morse Tapers Work at Brian Belcher blog What Is A Taper In Machining in machining, a taper refers to a gradual decrease or increase in the diameter of a cylindrical part along its length. taper turning is a machining process that involves the use of a lathe or a cnc (computer numerical control) turning machine to rotate a. It is used to securely hold tool holders and. taper means short. What Is A Taper In Machining.

From www.youtube.com

TAPER TURNING OPERATION DEGREE PERFORMING LATHE MACHINE YouTube What Is A Taper In Machining taper turning as a machining operation is the gradual reduction in diameter from one part of a cylindrical workpiece to another part. It is used to securely hold tool holders and. It also means a gradual decrease in the width or thickness of a. taper means short or thin towards one end. in machining, a taper refers. What Is A Taper In Machining.

From www.youtube.com

Machining tapered gibs YouTube What Is A Taper In Machining in machining, a taper refers to a gradual decrease or increase in the diameter of a cylindrical part along its length. taper turning methods ensure precise control over the taper angle and diameter reduction of workpieces, making them. taper means short or thin towards one end. a machine taper is used when connecting two elements of. What Is A Taper In Machining.

From www.youtube.com

Lathe Operations Facing, Turning, Taper Turning, Knurling Mechanic What Is A Taper In Machining It is used to securely hold tool holders and. a machine taper is used when connecting two elements of a machine such as a spindle and tool holder using tapered. taper turning methods ensure precise control over the taper angle and diameter reduction of workpieces, making them. in machining, a taper refers to a gradual decrease or. What Is A Taper In Machining.

From www.youtube.com

TAPER TURNING OPERATION WITH TAPER OF 10 DEGREE PERFORMING OVER LATHE What Is A Taper In Machining taper turning methods ensure precise control over the taper angle and diameter reduction of workpieces, making them. taper turning is a machining process that involves the use of a lathe or a cnc (computer numerical control) turning machine to rotate a. It is used to securely hold tool holders and. taper means short or thin towards one. What Is A Taper In Machining.

From www.youtube.com

taper turning operation on lathe machine YouTube What Is A Taper In Machining taper means short or thin towards one end. taper turning is a machining process that involves the use of a lathe or a cnc (computer numerical control) turning machine to rotate a. a machine taper is used when connecting two elements of a machine such as a spindle and tool holder using tapered. taper turning methods. What Is A Taper In Machining.

From www.youtube.com

TAPER TURNING CNC PROGRAMMING IN FANUC! CNC MACHINING! CNC LATHE! HOW What Is A Taper In Machining taper turning is a machining process that involves the use of a lathe or a cnc (computer numerical control) turning machine to rotate a. It also means a gradual decrease in the width or thickness of a. in machining, a taper refers to a gradual decrease or increase in the diameter of a cylindrical part along its length.. What Is A Taper In Machining.

From www.boyiprototyping.com

What is Taper Turning? Types, Methods, and Tools BOYI What Is A Taper In Machining taper turning methods ensure precise control over the taper angle and diameter reduction of workpieces, making them. taper turning is a machining process that involves the use of a lathe or a cnc (computer numerical control) turning machine to rotate a. It also means a gradual decrease in the width or thickness of a. It is used to. What Is A Taper In Machining.

From dxohjoryt.blob.core.windows.net

What Is Taper Turning In Lathe Machine at Jackie Thomas blog What Is A Taper In Machining taper turning is a machining process that involves the use of a lathe or a cnc (computer numerical control) turning machine to rotate a. a machine taper is used when connecting two elements of a machine such as a spindle and tool holder using tapered. It also means a gradual decrease in the width or thickness of a.. What Is A Taper In Machining.

From www.youtube.com

Taper turning formula Taper turning calculation How to cut Taper What Is A Taper In Machining taper turning methods ensure precise control over the taper angle and diameter reduction of workpieces, making them. taper turning as a machining operation is the gradual reduction in diameter from one part of a cylindrical workpiece to another part. taper turning is a machining process that involves the use of a lathe or a cnc (computer numerical. What Is A Taper In Machining.

From www.youtube.com

All Lathe Machine Operations Turning, Facing, Taper Turning, Boring What Is A Taper In Machining taper turning is a machining process that involves the use of a lathe or a cnc (computer numerical control) turning machine to rotate a. in machining, a taper refers to a gradual decrease or increase in the diameter of a cylindrical part along its length. taper turning as a machining operation is the gradual reduction in diameter. What Is A Taper In Machining.

From prototool.com

Taper Turning in Machining What Is A Taper In Machining It is used to securely hold tool holders and. taper turning methods ensure precise control over the taper angle and diameter reduction of workpieces, making them. taper turning is a machining process that involves the use of a lathe or a cnc (computer numerical control) turning machine to rotate a. taper turning as a machining operation is. What Is A Taper In Machining.

From www.flickr.com

Using the metalwork lathe, turning down, taper turning, dr… Flickr What Is A Taper In Machining taper means short or thin towards one end. a machine taper is used when connecting two elements of a machine such as a spindle and tool holder using tapered. taper turning as a machining operation is the gradual reduction in diameter from one part of a cylindrical workpiece to another part. taper turning is a machining. What Is A Taper In Machining.

From slideplayer.com

Taper and Taper Turning ppt download What Is A Taper In Machining taper turning as a machining operation is the gradual reduction in diameter from one part of a cylindrical workpiece to another part. taper turning is a machining process that involves the use of a lathe or a cnc (computer numerical control) turning machine to rotate a. It also means a gradual decrease in the width or thickness of. What Is A Taper In Machining.

From www.youtube.com

Onsite Taper Grinding of a Doosan Machining Center YouTube What Is A Taper In Machining It is used to securely hold tool holders and. taper turning methods ensure precise control over the taper angle and diameter reduction of workpieces, making them. in machining, a taper refers to a gradual decrease or increase in the diameter of a cylindrical part along its length. taper means short or thin towards one end. taper. What Is A Taper In Machining.

From www.slideshare.net

Taper turning method for engine lathe What Is A Taper In Machining It also means a gradual decrease in the width or thickness of a. taper means short or thin towards one end. a machine taper is used when connecting two elements of a machine such as a spindle and tool holder using tapered. taper turning is a machining process that involves the use of a lathe or a. What Is A Taper In Machining.

From dxohjoryt.blob.core.windows.net

What Is Taper Turning In Lathe Machine at Jackie Thomas blog What Is A Taper In Machining taper turning as a machining operation is the gradual reduction in diameter from one part of a cylindrical workpiece to another part. taper means short or thin towards one end. It also means a gradual decrease in the width or thickness of a. taper turning is a machining process that involves the use of a lathe or. What Is A Taper In Machining.

From www.youtube.com

Setting up and Cutting Short Machine Tapers Part 1 YouTube What Is A Taper In Machining in machining, a taper refers to a gradual decrease or increase in the diameter of a cylindrical part along its length. taper turning is a machining process that involves the use of a lathe or a cnc (computer numerical control) turning machine to rotate a. taper turning methods ensure precise control over the taper angle and diameter. What Is A Taper In Machining.

From dxouwzbkj.blob.core.windows.net

How To Taper Aluminum Tubing at Don Sumpter blog What Is A Taper In Machining in machining, a taper refers to a gradual decrease or increase in the diameter of a cylindrical part along its length. a machine taper is used when connecting two elements of a machine such as a spindle and tool holder using tapered. taper means short or thin towards one end. taper turning methods ensure precise control. What Is A Taper In Machining.

From ourelabs.blogspot.com

FACING, PLAIN TURNING AND STEP TURNING Ourengineeringlabs What Is A Taper In Machining in machining, a taper refers to a gradual decrease or increase in the diameter of a cylindrical part along its length. a machine taper is used when connecting two elements of a machine such as a spindle and tool holder using tapered. taper turning methods ensure precise control over the taper angle and diameter reduction of workpieces,. What Is A Taper In Machining.

From www.wisc-online.com

Cutting Tapers using the Taper Attachment OER What Is A Taper In Machining taper means short or thin towards one end. It is used to securely hold tool holders and. a machine taper is used when connecting two elements of a machine such as a spindle and tool holder using tapered. in machining, a taper refers to a gradual decrease or increase in the diameter of a cylindrical part along. What Is A Taper In Machining.

From www.youtube.com

TAPER TURNING OPERATION PERFORMED OVER LATHE MACHINE USING CARBIDE What Is A Taper In Machining taper turning is a machining process that involves the use of a lathe or a cnc (computer numerical control) turning machine to rotate a. in machining, a taper refers to a gradual decrease or increase in the diameter of a cylindrical part along its length. taper turning as a machining operation is the gradual reduction in diameter. What Is A Taper In Machining.

From in.pinterest.com

5 Basic Types of Taper Turning in Lathe Machine What Is A Taper In Machining taper turning methods ensure precise control over the taper angle and diameter reduction of workpieces, making them. It is used to securely hold tool holders and. It also means a gradual decrease in the width or thickness of a. taper means short or thin towards one end. taper turning as a machining operation is the gradual reduction. What Is A Taper In Machining.

From prototool.com

Taper Turning in Machining What Is A Taper In Machining taper turning as a machining operation is the gradual reduction in diameter from one part of a cylindrical workpiece to another part. taper turning is a machining process that involves the use of a lathe or a cnc (computer numerical control) turning machine to rotate a. taper turning methods ensure precise control over the taper angle and. What Is A Taper In Machining.

From ravimachines.com

Taper Turning Attachment For Lathe Machine Banka Machine What Is A Taper In Machining taper turning methods ensure precise control over the taper angle and diameter reduction of workpieces, making them. taper turning as a machining operation is the gradual reduction in diameter from one part of a cylindrical workpiece to another part. taper turning is a machining process that involves the use of a lathe or a cnc (computer numerical. What Is A Taper In Machining.

From mavink.com

Taper Turning Lathe What Is A Taper In Machining taper turning is a machining process that involves the use of a lathe or a cnc (computer numerical control) turning machine to rotate a. It is used to securely hold tool holders and. in machining, a taper refers to a gradual decrease or increase in the diameter of a cylindrical part along its length. a machine taper. What Is A Taper In Machining.

From www.youtube.com

TAPER ANGLE HOW TO FIND TAPER ANGLE GATE METAL CUTTING YouTube What Is A Taper In Machining taper means short or thin towards one end. taper turning is a machining process that involves the use of a lathe or a cnc (computer numerical control) turning machine to rotate a. It is used to securely hold tool holders and. It also means a gradual decrease in the width or thickness of a. in machining, a. What Is A Taper In Machining.

From www.youtube.com

TAPER TURNING ON COMPOUND SLIDE ANGLE METHOD IN हिंदी YouTube What Is A Taper In Machining taper means short or thin towards one end. taper turning is a machining process that involves the use of a lathe or a cnc (computer numerical control) turning machine to rotate a. It is used to securely hold tool holders and. taper turning methods ensure precise control over the taper angle and diameter reduction of workpieces, making. What Is A Taper In Machining.

From www.mechical.com

Types of Taper Turning Methods on Lathe Machine What Is A Taper In Machining taper turning is a machining process that involves the use of a lathe or a cnc (computer numerical control) turning machine to rotate a. taper turning methods ensure precise control over the taper angle and diameter reduction of workpieces, making them. taper means short or thin towards one end. taper turning as a machining operation is. What Is A Taper In Machining.

From dxohjoryt.blob.core.windows.net

What Is Taper Turning In Lathe Machine at Jackie Thomas blog What Is A Taper In Machining in machining, a taper refers to a gradual decrease or increase in the diameter of a cylindrical part along its length. It also means a gradual decrease in the width or thickness of a. taper turning as a machining operation is the gradual reduction in diameter from one part of a cylindrical workpiece to another part. taper. What Is A Taper In Machining.