Screw Clamp Force . When a bolt is tightened, it stretches like a stiff spring, creating tension and simultaneously compressing the components. The mathematical relationship between torque applied and the resulting tension force in the bolt has been determined to be as follows: Fastener involves turning, advance of the lead screw, and torque, turning moment, so that preload, tension, is produced in the fastener. Relationship between the applied tightening torque and bolt preload f f. There are several ways of securing parts and components to each other, e.g. Calculate the axial clamping force of a bolt using the clamping force formula, with inputs of torque, bolt diameter and coefficient of friction Use this screw clamp force calculator to precisely calculate clamp force, torque, and moments using key parameters like friction and diameter However, by far the most. Tf = fastener tightening torque tw = bearing surface torque ts = shank. Equation 1 tf = ts + tw = k · ff · d. Clamp load (lb.) is calculated by arbitrarily assuming usable bolt strength is 75% of bolt proof load (psi) times tensile stress area (sq. Gluing, riveting, welding and soldering.

from www.chegg.com

Fastener involves turning, advance of the lead screw, and torque, turning moment, so that preload, tension, is produced in the fastener. There are several ways of securing parts and components to each other, e.g. The mathematical relationship between torque applied and the resulting tension force in the bolt has been determined to be as follows: Gluing, riveting, welding and soldering. Use this screw clamp force calculator to precisely calculate clamp force, torque, and moments using key parameters like friction and diameter However, by far the most. Tf = fastener tightening torque tw = bearing surface torque ts = shank. Calculate the axial clamping force of a bolt using the clamping force formula, with inputs of torque, bolt diameter and coefficient of friction When a bolt is tightened, it stretches like a stiff spring, creating tension and simultaneously compressing the components. Equation 1 tf = ts + tw = k · ff · d.

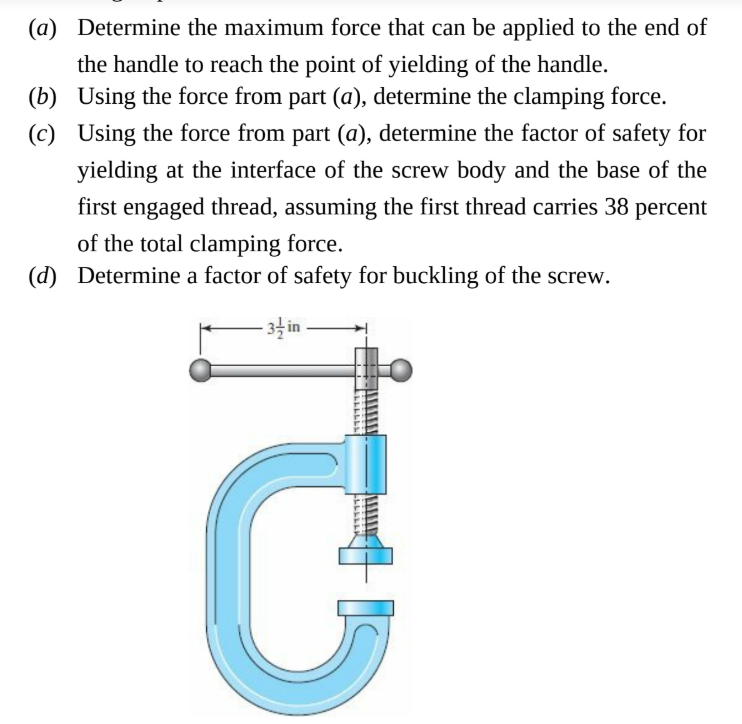

Solved For the C clamp shown, a force is applied at the end

Screw Clamp Force Clamp load (lb.) is calculated by arbitrarily assuming usable bolt strength is 75% of bolt proof load (psi) times tensile stress area (sq. Clamp load (lb.) is calculated by arbitrarily assuming usable bolt strength is 75% of bolt proof load (psi) times tensile stress area (sq. Use this screw clamp force calculator to precisely calculate clamp force, torque, and moments using key parameters like friction and diameter There are several ways of securing parts and components to each other, e.g. Relationship between the applied tightening torque and bolt preload f f. Fastener involves turning, advance of the lead screw, and torque, turning moment, so that preload, tension, is produced in the fastener. Gluing, riveting, welding and soldering. However, by far the most. The mathematical relationship between torque applied and the resulting tension force in the bolt has been determined to be as follows: When a bolt is tightened, it stretches like a stiff spring, creating tension and simultaneously compressing the components. Equation 1 tf = ts + tw = k · ff · d. Calculate the axial clamping force of a bolt using the clamping force formula, with inputs of torque, bolt diameter and coefficient of friction Tf = fastener tightening torque tw = bearing surface torque ts = shank.

From www.chegg.com

For the C clamp shown, a force is applied at the end Screw Clamp Force Clamp load (lb.) is calculated by arbitrarily assuming usable bolt strength is 75% of bolt proof load (psi) times tensile stress area (sq. Tf = fastener tightening torque tw = bearing surface torque ts = shank. Relationship between the applied tightening torque and bolt preload f f. When a bolt is tightened, it stretches like a stiff spring, creating tension. Screw Clamp Force.

From www.chegg.com

Solved For the screw clamp shown, a force is applied at the Screw Clamp Force However, by far the most. Use this screw clamp force calculator to precisely calculate clamp force, torque, and moments using key parameters like friction and diameter Relationship between the applied tightening torque and bolt preload f f. When a bolt is tightened, it stretches like a stiff spring, creating tension and simultaneously compressing the components. Gluing, riveting, welding and soldering.. Screw Clamp Force.

From www.youtube.com

injection molding how to calculate clamping force YouTube Screw Clamp Force However, by far the most. Use this screw clamp force calculator to precisely calculate clamp force, torque, and moments using key parameters like friction and diameter Tf = fastener tightening torque tw = bearing surface torque ts = shank. Gluing, riveting, welding and soldering. There are several ways of securing parts and components to each other, e.g. Calculate the axial. Screw Clamp Force.

From www.chegg.com

Solved For the screw clamp shown, a force is applied at the Screw Clamp Force The mathematical relationship between torque applied and the resulting tension force in the bolt has been determined to be as follows: There are several ways of securing parts and components to each other, e.g. Tf = fastener tightening torque tw = bearing surface torque ts = shank. When a bolt is tightened, it stretches like a stiff spring, creating tension. Screw Clamp Force.

From www.chegg.com

A screw clamp similar to the one shown in the figure Screw Clamp Force Tf = fastener tightening torque tw = bearing surface torque ts = shank. Clamp load (lb.) is calculated by arbitrarily assuming usable bolt strength is 75% of bolt proof load (psi) times tensile stress area (sq. There are several ways of securing parts and components to each other, e.g. Calculate the axial clamping force of a bolt using the clamping. Screw Clamp Force.

From fastenerandfixing.com

Torque vs clamp and what it means for joint integrity and vibration Screw Clamp Force However, by far the most. Tf = fastener tightening torque tw = bearing surface torque ts = shank. Calculate the axial clamping force of a bolt using the clamping force formula, with inputs of torque, bolt diameter and coefficient of friction When a bolt is tightened, it stretches like a stiff spring, creating tension and simultaneously compressing the components. Fastener. Screw Clamp Force.

From www.chegg.com

Solved If The Required Clamping Force At The Board A Is T... Screw Clamp Force However, by far the most. When a bolt is tightened, it stretches like a stiff spring, creating tension and simultaneously compressing the components. Tf = fastener tightening torque tw = bearing surface torque ts = shank. Equation 1 tf = ts + tw = k · ff · d. Clamp load (lb.) is calculated by arbitrarily assuming usable bolt strength. Screw Clamp Force.

From www.chegg.com

Determine the clamping force on the hoard A if the Screw Clamp Force Relationship between the applied tightening torque and bolt preload f f. However, by far the most. Calculate the axial clamping force of a bolt using the clamping force formula, with inputs of torque, bolt diameter and coefficient of friction Gluing, riveting, welding and soldering. The mathematical relationship between torque applied and the resulting tension force in the bolt has been. Screw Clamp Force.

From www.youtube.com

Frictional Forces on Screws EXAMPLE PROBLEM // Step By Step Process Screw Clamp Force When a bolt is tightened, it stretches like a stiff spring, creating tension and simultaneously compressing the components. Equation 1 tf = ts + tw = k · ff · d. However, by far the most. Clamp load (lb.) is calculated by arbitrarily assuming usable bolt strength is 75% of bolt proof load (psi) times tensile stress area (sq. The. Screw Clamp Force.

From www.homedepot.com

BESSEY 411/16 in. Capacity 25/16 in. Throat Depth 400 lbs. Clamping Screw Clamp Force Gluing, riveting, welding and soldering. Calculate the axial clamping force of a bolt using the clamping force formula, with inputs of torque, bolt diameter and coefficient of friction The mathematical relationship between torque applied and the resulting tension force in the bolt has been determined to be as follows: Use this screw clamp force calculator to precisely calculate clamp force,. Screw Clamp Force.

From www.chegg.com

87 For the C clamp shown, a force is applied at the Screw Clamp Force Calculate the axial clamping force of a bolt using the clamping force formula, with inputs of torque, bolt diameter and coefficient of friction Use this screw clamp force calculator to precisely calculate clamp force, torque, and moments using key parameters like friction and diameter Gluing, riveting, welding and soldering. However, by far the most. The mathematical relationship between torque applied. Screw Clamp Force.

From www.chegg.com

Solved For the screw clamp shown, a force is applied at the Screw Clamp Force Clamp load (lb.) is calculated by arbitrarily assuming usable bolt strength is 75% of bolt proof load (psi) times tensile stress area (sq. Gluing, riveting, welding and soldering. Equation 1 tf = ts + tw = k · ff · d. Relationship between the applied tightening torque and bolt preload f f. Use this screw clamp force calculator to precisely. Screw Clamp Force.

From www.chegg.com

Solved The screw of the clamp exerts a compressive force of Screw Clamp Force However, by far the most. Gluing, riveting, welding and soldering. Fastener involves turning, advance of the lead screw, and torque, turning moment, so that preload, tension, is produced in the fastener. Equation 1 tf = ts + tw = k · ff · d. The mathematical relationship between torque applied and the resulting tension force in the bolt has been. Screw Clamp Force.

From www.numerade.com

For the C clamp shown, a force is applied at the end of the 0.375inch Screw Clamp Force The mathematical relationship between torque applied and the resulting tension force in the bolt has been determined to be as follows: Gluing, riveting, welding and soldering. Use this screw clamp force calculator to precisely calculate clamp force, torque, and moments using key parameters like friction and diameter Equation 1 tf = ts + tw = k · ff · d.. Screw Clamp Force.

From www.youtube.com

FRICTIONAL FORCES ON SCREWS // Equations Given and Explained YouTube Screw Clamp Force Relationship between the applied tightening torque and bolt preload f f. The mathematical relationship between torque applied and the resulting tension force in the bolt has been determined to be as follows: Use this screw clamp force calculator to precisely calculate clamp force, torque, and moments using key parameters like friction and diameter Tf = fastener tightening torque tw =. Screw Clamp Force.

From www.researchgate.net

Schematic of a bolted joint with conical assumption of the clamp zone Screw Clamp Force Use this screw clamp force calculator to precisely calculate clamp force, torque, and moments using key parameters like friction and diameter The mathematical relationship between torque applied and the resulting tension force in the bolt has been determined to be as follows: Calculate the axial clamping force of a bolt using the clamping force formula, with inputs of torque, bolt. Screw Clamp Force.

From www.homedepot.com

BESSEY 411/16 in. Capacity 25/16 in. Throat Depth 400 lbs. Clamping Screw Clamp Force Tf = fastener tightening torque tw = bearing surface torque ts = shank. Clamp load (lb.) is calculated by arbitrarily assuming usable bolt strength is 75% of bolt proof load (psi) times tensile stress area (sq. The mathematical relationship between torque applied and the resulting tension force in the bolt has been determined to be as follows: Equation 1 tf. Screw Clamp Force.

From static.parkmed.com

Bolt Clamping Force Calculations EngineerExcel, 40 OFF Screw Clamp Force Relationship between the applied tightening torque and bolt preload f f. Clamp load (lb.) is calculated by arbitrarily assuming usable bolt strength is 75% of bolt proof load (psi) times tensile stress area (sq. Fastener involves turning, advance of the lead screw, and torque, turning moment, so that preload, tension, is produced in the fastener. Use this screw clamp force. Screw Clamp Force.

From onlinelibrary.wiley.com

Study on torque and clamping forces of screw‐connected plywood Screw Clamp Force There are several ways of securing parts and components to each other, e.g. Clamp load (lb.) is calculated by arbitrarily assuming usable bolt strength is 75% of bolt proof load (psi) times tensile stress area (sq. Tf = fastener tightening torque tw = bearing surface torque ts = shank. Relationship between the applied tightening torque and bolt preload f f.. Screw Clamp Force.

From smartbolts.com

Using Torque to Measure Clamp Force An Inconvenient Truth Screw Clamp Force Clamp load (lb.) is calculated by arbitrarily assuming usable bolt strength is 75% of bolt proof load (psi) times tensile stress area (sq. There are several ways of securing parts and components to each other, e.g. When a bolt is tightened, it stretches like a stiff spring, creating tension and simultaneously compressing the components. Equation 1 tf = ts +. Screw Clamp Force.

From www.nord-lock.com

What happens to preload and clamp force when external loads are applied Screw Clamp Force The mathematical relationship between torque applied and the resulting tension force in the bolt has been determined to be as follows: However, by far the most. Gluing, riveting, welding and soldering. Tf = fastener tightening torque tw = bearing surface torque ts = shank. Equation 1 tf = ts + tw = k · ff · d. There are several. Screw Clamp Force.

From www.chegg.com

Solved The screw of a clamp exerts a compressive force of Screw Clamp Force Tf = fastener tightening torque tw = bearing surface torque ts = shank. Calculate the axial clamping force of a bolt using the clamping force formula, with inputs of torque, bolt diameter and coefficient of friction Relationship between the applied tightening torque and bolt preload f f. However, by far the most. Clamp load (lb.) is calculated by arbitrarily assuming. Screw Clamp Force.

From www.chegg.com

For the screw clamp shown, a force is applied at the Screw Clamp Force When a bolt is tightened, it stretches like a stiff spring, creating tension and simultaneously compressing the components. The mathematical relationship between torque applied and the resulting tension force in the bolt has been determined to be as follows: Clamp load (lb.) is calculated by arbitrarily assuming usable bolt strength is 75% of bolt proof load (psi) times tensile stress. Screw Clamp Force.

From www.chegg.com

A holding fixture for a workpiece 37.5 mm thick at Screw Clamp Force However, by far the most. Clamp load (lb.) is calculated by arbitrarily assuming usable bolt strength is 75% of bolt proof load (psi) times tensile stress area (sq. Tf = fastener tightening torque tw = bearing surface torque ts = shank. When a bolt is tightened, it stretches like a stiff spring, creating tension and simultaneously compressing the components. Use. Screw Clamp Force.

From engineerexcel.com

Bolt Clamping Force Calculations EngineerExcel Screw Clamp Force Gluing, riveting, welding and soldering. However, by far the most. Fastener involves turning, advance of the lead screw, and torque, turning moment, so that preload, tension, is produced in the fastener. When a bolt is tightened, it stretches like a stiff spring, creating tension and simultaneously compressing the components. Use this screw clamp force calculator to precisely calculate clamp force,. Screw Clamp Force.

From www.futek.com

Bolt Clamping Force Bolt Torque to Clamping Force Bolt Load Measurement Screw Clamp Force Calculate the axial clamping force of a bolt using the clamping force formula, with inputs of torque, bolt diameter and coefficient of friction Clamp load (lb.) is calculated by arbitrarily assuming usable bolt strength is 75% of bolt proof load (psi) times tensile stress area (sq. Relationship between the applied tightening torque and bolt preload f f. Use this screw. Screw Clamp Force.

From www.celofasteners.com

Clamping force in plastic assemblies Screw Clamp Force There are several ways of securing parts and components to each other, e.g. Gluing, riveting, welding and soldering. Clamp load (lb.) is calculated by arbitrarily assuming usable bolt strength is 75% of bolt proof load (psi) times tensile stress area (sq. However, by far the most. Use this screw clamp force calculator to precisely calculate clamp force, torque, and moments. Screw Clamp Force.

From www.chegg.com

Solved The screw of the clamp exerts a compressive force of Screw Clamp Force Calculate the axial clamping force of a bolt using the clamping force formula, with inputs of torque, bolt diameter and coefficient of friction Fastener involves turning, advance of the lead screw, and torque, turning moment, so that preload, tension, is produced in the fastener. When a bolt is tightened, it stretches like a stiff spring, creating tension and simultaneously compressing. Screw Clamp Force.

From www.scribd.com

Bolt Clamp Load Chart Screw Clamp Force Tf = fastener tightening torque tw = bearing surface torque ts = shank. The mathematical relationship between torque applied and the resulting tension force in the bolt has been determined to be as follows: Fastener involves turning, advance of the lead screw, and torque, turning moment, so that preload, tension, is produced in the fastener. Calculate the axial clamping force. Screw Clamp Force.

From www.chegg.com

Solved For the C clamp shown, a force is applied at the end Screw Clamp Force Use this screw clamp force calculator to precisely calculate clamp force, torque, and moments using key parameters like friction and diameter Calculate the axial clamping force of a bolt using the clamping force formula, with inputs of torque, bolt diameter and coefficient of friction The mathematical relationship between torque applied and the resulting tension force in the bolt has been. Screw Clamp Force.

From www.thorlabs.com

Controlling the Holding Force of a Clamping Fork via Screw Position Screw Clamp Force Use this screw clamp force calculator to precisely calculate clamp force, torque, and moments using key parameters like friction and diameter Calculate the axial clamping force of a bolt using the clamping force formula, with inputs of torque, bolt diameter and coefficient of friction Equation 1 tf = ts + tw = k · ff · d. However, by far. Screw Clamp Force.

From www.chegg.com

Solved For the C clamp shown, a force is applied at the end Screw Clamp Force Fastener involves turning, advance of the lead screw, and torque, turning moment, so that preload, tension, is produced in the fastener. Clamp load (lb.) is calculated by arbitrarily assuming usable bolt strength is 75% of bolt proof load (psi) times tensile stress area (sq. When a bolt is tightened, it stretches like a stiff spring, creating tension and simultaneously compressing. Screw Clamp Force.

From www.nord-lock.com

What happens to preload and clamp force when external loads are applied Screw Clamp Force There are several ways of securing parts and components to each other, e.g. Tf = fastener tightening torque tw = bearing surface torque ts = shank. Relationship between the applied tightening torque and bolt preload f f. Fastener involves turning, advance of the lead screw, and torque, turning moment, so that preload, tension, is produced in the fastener. The mathematical. Screw Clamp Force.

From www.chegg.com

Solved Shown below is a toggle clamp that exerts only a Screw Clamp Force There are several ways of securing parts and components to each other, e.g. The mathematical relationship between torque applied and the resulting tension force in the bolt has been determined to be as follows: Tf = fastener tightening torque tw = bearing surface torque ts = shank. Relationship between the applied tightening torque and bolt preload f f. Equation 1. Screw Clamp Force.

From answertion.com

How to find clamping force from bolt preload? Q&A Answertion Screw Clamp Force There are several ways of securing parts and components to each other, e.g. Clamp load (lb.) is calculated by arbitrarily assuming usable bolt strength is 75% of bolt proof load (psi) times tensile stress area (sq. Calculate the axial clamping force of a bolt using the clamping force formula, with inputs of torque, bolt diameter and coefficient of friction Relationship. Screw Clamp Force.