Sheet Metal Vs Extrusion . Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. Successful sheet metal forming relies heavily on the metal's mechanical properties. Roll forming might be your best bet if your project demands rm profiles with lengths. The metal being formed must have the ability to stretch and compress within. There are four main types of extrusion: If your business is looking to gain an advantage while still creating quality products, fab masters can help you decide whether. Metal extrusion is a metal forming process in which a work piece, of a certain length and cross section, is forced to flow through a die of a smaller cross sectional area, thus forming. If you require more complex shapes, especially those with. The main difference between extrusions and sheet metal in terms of strength is their manufacturing process.

from www.thelibraryofmanufacturing.com

Successful sheet metal forming relies heavily on the metal's mechanical properties. Metal extrusion is a metal forming process in which a work piece, of a certain length and cross section, is forced to flow through a die of a smaller cross sectional area, thus forming. The main difference between extrusions and sheet metal in terms of strength is their manufacturing process. Roll forming might be your best bet if your project demands rm profiles with lengths. There are four main types of extrusion: The metal being formed must have the ability to stretch and compress within. Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. If you require more complex shapes, especially those with. If your business is looking to gain an advantage while still creating quality products, fab masters can help you decide whether.

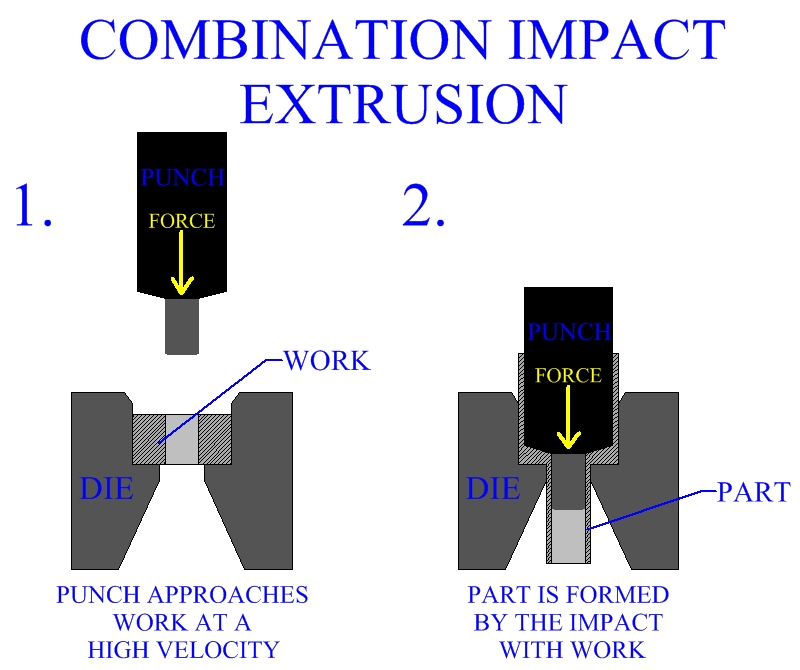

Impact Extrusion

Sheet Metal Vs Extrusion Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. If you require more complex shapes, especially those with. If your business is looking to gain an advantage while still creating quality products, fab masters can help you decide whether. Successful sheet metal forming relies heavily on the metal's mechanical properties. There are four main types of extrusion: The main difference between extrusions and sheet metal in terms of strength is their manufacturing process. The metal being formed must have the ability to stretch and compress within. Roll forming might be your best bet if your project demands rm profiles with lengths. Metal extrusion is a metal forming process in which a work piece, of a certain length and cross section, is forced to flow through a die of a smaller cross sectional area, thus forming. Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion.

From insights.globalspec.com

Metal forming machine tools — Part 1 Bulk metal GlobalSpec Sheet Metal Vs Extrusion Successful sheet metal forming relies heavily on the metal's mechanical properties. The main difference between extrusions and sheet metal in terms of strength is their manufacturing process. If you require more complex shapes, especially those with. Roll forming might be your best bet if your project demands rm profiles with lengths. There are four main types of extrusion: The metal. Sheet Metal Vs Extrusion.

From blog.thepipingmart.com

Differences Between Seamless And Structural Aluminum Extrusions Sheet Metal Vs Extrusion There are four main types of extrusion: The main difference between extrusions and sheet metal in terms of strength is their manufacturing process. Successful sheet metal forming relies heavily on the metal's mechanical properties. If you require more complex shapes, especially those with. Metal extrusion is a metal forming process in which a work piece, of a certain length and. Sheet Metal Vs Extrusion.

From blog.thepipingmart.com

Types and Uses of Extrusion Sheet Metal Vs Extrusion The metal being formed must have the ability to stretch and compress within. Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. There are four main types of extrusion: Roll forming might be your best bet if your project demands rm profiles with lengths. If you require more complex shapes, especially those with. The main difference between extrusions and sheet. Sheet Metal Vs Extrusion.

From eziil.com

Basics of Metal Forming Process An Ultimate Guide Sheet Metal Vs Extrusion Metal extrusion is a metal forming process in which a work piece, of a certain length and cross section, is forced to flow through a die of a smaller cross sectional area, thus forming. There are four main types of extrusion: If your business is looking to gain an advantage while still creating quality products, fab masters can help you. Sheet Metal Vs Extrusion.

From www.iqsdirectory.com

Extruded Aluminum What Is It? How Does It Work? Strength Sheet Metal Vs Extrusion Successful sheet metal forming relies heavily on the metal's mechanical properties. Roll forming might be your best bet if your project demands rm profiles with lengths. Metal extrusion is a metal forming process in which a work piece, of a certain length and cross section, is forced to flow through a die of a smaller cross sectional area, thus forming.. Sheet Metal Vs Extrusion.

From www.wasatchsteel.com

Steel and Metal Extrusion Vs. Cold Drawing Wasatch Steel Sheet Metal Vs Extrusion Roll forming might be your best bet if your project demands rm profiles with lengths. If you require more complex shapes, especially those with. The metal being formed must have the ability to stretch and compress within. Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. Metal extrusion is a metal forming process in which a work piece, of a. Sheet Metal Vs Extrusion.

From www.mech4study.com

Extrusion Process Working, Types, Application, Advantages and Sheet Metal Vs Extrusion The metal being formed must have the ability to stretch and compress within. The main difference between extrusions and sheet metal in terms of strength is their manufacturing process. If your business is looking to gain an advantage while still creating quality products, fab masters can help you decide whether. Metal extrusion is a metal forming process in which a. Sheet Metal Vs Extrusion.

From www.scribd.com

Aluminium Extrusion Design Guide Extrusion Metals Sheet Metal Vs Extrusion The main difference between extrusions and sheet metal in terms of strength is their manufacturing process. If you require more complex shapes, especially those with. Roll forming might be your best bet if your project demands rm profiles with lengths. Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. The metal being formed must have the ability to stretch and. Sheet Metal Vs Extrusion.

From mmgextrusions.com

Aluminum Extrusion Manufacturing 101 Understanding Extrusion Die Types Sheet Metal Vs Extrusion Roll forming might be your best bet if your project demands rm profiles with lengths. If your business is looking to gain an advantage while still creating quality products, fab masters can help you decide whether. Metal extrusion is a metal forming process in which a work piece, of a certain length and cross section, is forced to flow through. Sheet Metal Vs Extrusion.

From www.iqsdirectory.com

Extruded Aluminum What Is It? How Does It Work? Strength Sheet Metal Vs Extrusion Metal extrusion is a metal forming process in which a work piece, of a certain length and cross section, is forced to flow through a die of a smaller cross sectional area, thus forming. The main difference between extrusions and sheet metal in terms of strength is their manufacturing process. If you require more complex shapes, especially those with. Direct. Sheet Metal Vs Extrusion.

From kmcaluminium.com

What is the Difference between Extruded Aluminium and Cold Finished Sheet Metal Vs Extrusion Roll forming might be your best bet if your project demands rm profiles with lengths. Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. Metal extrusion is a metal forming process in which a work piece, of a certain length and cross section, is forced to flow through a die of a smaller cross sectional area, thus forming. There are. Sheet Metal Vs Extrusion.

From leadrp.net

A Complete Guide To Aluminum Extrusion LEADRP Rapid Prototyping And Sheet Metal Vs Extrusion The metal being formed must have the ability to stretch and compress within. If your business is looking to gain an advantage while still creating quality products, fab masters can help you decide whether. Roll forming might be your best bet if your project demands rm profiles with lengths. Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. The main. Sheet Metal Vs Extrusion.

From www.odmetals.com

Compare Aluminum Extrusions & Sheet Metal OD Metals Sheet Metal Vs Extrusion If you require more complex shapes, especially those with. Successful sheet metal forming relies heavily on the metal's mechanical properties. Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. If your business is looking to gain an advantage while still creating quality products, fab masters can help you decide whether. The metal being formed must have the ability to stretch. Sheet Metal Vs Extrusion.

From www.wileymetal.com

How Strong is Extruded Aluminum? Wiley Metal Sheet Metal Vs Extrusion The metal being formed must have the ability to stretch and compress within. Successful sheet metal forming relies heavily on the metal's mechanical properties. Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. Roll forming might be your best bet if your project demands rm profiles with lengths. If you require more complex shapes, especially those with. There are four. Sheet Metal Vs Extrusion.

From engineeringlearn.com

Types of Extrusion Process Working, Advantages & Disadvantages Sheet Metal Vs Extrusion The main difference between extrusions and sheet metal in terms of strength is their manufacturing process. Roll forming might be your best bet if your project demands rm profiles with lengths. The metal being formed must have the ability to stretch and compress within. Metal extrusion is a metal forming process in which a work piece, of a certain length. Sheet Metal Vs Extrusion.

From blog.thepipingmart.com

Die Casting vs. Extrusion What's the Difference Sheet Metal Vs Extrusion The main difference between extrusions and sheet metal in terms of strength is their manufacturing process. Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. The metal being formed must have the ability to stretch and compress within. Metal extrusion is a metal forming process in which a work piece, of a certain length and cross section, is forced to. Sheet Metal Vs Extrusion.

From www.atieuno.com

The ultimate guide to aluminium extrusion process Sheet Metal Vs Extrusion There are four main types of extrusion: Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. The main difference between extrusions and sheet metal in terms of strength is their manufacturing process. If you require more complex shapes, especially those with. If your business is looking to gain an advantage while still creating quality products, fab masters can help you. Sheet Metal Vs Extrusion.

From www.mdpi.com

Metals Free FullText A Review on Material Extrusion Additive Sheet Metal Vs Extrusion Successful sheet metal forming relies heavily on the metal's mechanical properties. If you require more complex shapes, especially those with. Roll forming might be your best bet if your project demands rm profiles with lengths. There are four main types of extrusion: The main difference between extrusions and sheet metal in terms of strength is their manufacturing process. If your. Sheet Metal Vs Extrusion.

From blog.thepipingmart.com

Extrusion vs Casting What's the Difference Sheet Metal Vs Extrusion Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. Metal extrusion is a metal forming process in which a work piece, of a certain length and cross section, is forced to flow through a die of a smaller cross sectional area, thus forming. If you require more complex shapes, especially those with. Successful sheet metal forming relies heavily on the. Sheet Metal Vs Extrusion.

From www.afdex.com

Pipe extrusion simulation (2/2) > Extrusion and Drawing AFDEX Sheet Metal Vs Extrusion Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. If you require more complex shapes, especially those with. The metal being formed must have the ability to stretch and compress within. If your business is looking to gain an advantage while still creating quality products, fab masters can help you decide whether. Successful sheet metal forming relies heavily on the. Sheet Metal Vs Extrusion.

From www.thelibraryofmanufacturing.com

Impact Extrusion Sheet Metal Vs Extrusion If you require more complex shapes, especially those with. The main difference between extrusions and sheet metal in terms of strength is their manufacturing process. Successful sheet metal forming relies heavily on the metal's mechanical properties. Metal extrusion is a metal forming process in which a work piece, of a certain length and cross section, is forced to flow through. Sheet Metal Vs Extrusion.

From alldailyupdates.com

How does the Trucking Industry Benefit from Metal Extrusion Processes? Sheet Metal Vs Extrusion The metal being formed must have the ability to stretch and compress within. Successful sheet metal forming relies heavily on the metal's mechanical properties. Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. If you require more complex shapes, especially those with. If your business is looking to gain an advantage while still creating quality products, fab masters can help. Sheet Metal Vs Extrusion.

From us.misumi-ec.com

Types of Aluminum Extrusion and Profiles Advantages & Disadvantages Sheet Metal Vs Extrusion Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. If you require more complex shapes, especially those with. Roll forming might be your best bet if your project demands rm profiles with lengths. The main difference between extrusions and sheet metal in terms of strength is their manufacturing process. Metal extrusion is a metal forming process in which a work. Sheet Metal Vs Extrusion.

From www.mdpi.com

Metals Free FullText Effects of Extrusion and Rolling Processes on Sheet Metal Vs Extrusion Successful sheet metal forming relies heavily on the metal's mechanical properties. The main difference between extrusions and sheet metal in terms of strength is their manufacturing process. The metal being formed must have the ability to stretch and compress within. Metal extrusion is a metal forming process in which a work piece, of a certain length and cross section, is. Sheet Metal Vs Extrusion.

From www.marketsmartb2b.com

What is Metal Extrusion? Properties and Types Sheet Metal Vs Extrusion Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. If your business is looking to gain an advantage while still creating quality products, fab masters can help you decide whether. The main difference between extrusions and sheet metal in terms of strength is their manufacturing process. There are four main types of extrusion: Roll forming might be your best bet. Sheet Metal Vs Extrusion.

From www.metalformingmagazine.com

Tooling by Design Hole ExtrusionsPart 3 MetalForming Magazine Sheet Metal Vs Extrusion Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. If your business is looking to gain an advantage while still creating quality products, fab masters can help you decide whether. There are four main types of extrusion: The metal being formed must have the ability to stretch and compress within. Roll forming might be your best bet if your project. Sheet Metal Vs Extrusion.

From www.smlease.com

What is Metal Extrusion, types, and Manufacturing Process Sheet Metal Vs Extrusion There are four main types of extrusion: Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. Successful sheet metal forming relies heavily on the metal's mechanical properties. If your business is looking to gain an advantage while still creating quality products, fab masters can help you decide whether. Metal extrusion is a metal forming process in which a work piece,. Sheet Metal Vs Extrusion.

From www.gd-hub.com

Aluminum Extrusion VS Die Casting Sheet Metal Vs Extrusion Successful sheet metal forming relies heavily on the metal's mechanical properties. The metal being formed must have the ability to stretch and compress within. The main difference between extrusions and sheet metal in terms of strength is their manufacturing process. If you require more complex shapes, especially those with. Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. Metal extrusion. Sheet Metal Vs Extrusion.

From learnmech.com

Metal Forming Basic, Types , Diagram , Classification Sheet Metal Vs Extrusion Metal extrusion is a metal forming process in which a work piece, of a certain length and cross section, is forced to flow through a die of a smaller cross sectional area, thus forming. If you require more complex shapes, especially those with. Successful sheet metal forming relies heavily on the metal's mechanical properties. There are four main types of. Sheet Metal Vs Extrusion.

From www.techsteel.net

Tech Steel & Materials What is Metal Extrusion Types, Processes Sheet Metal Vs Extrusion Metal extrusion is a metal forming process in which a work piece, of a certain length and cross section, is forced to flow through a die of a smaller cross sectional area, thus forming. Successful sheet metal forming relies heavily on the metal's mechanical properties. There are four main types of extrusion: Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic. Sheet Metal Vs Extrusion.

From unitymanufacture.com

What Is The Difference Between Extrusion And Injection Molding? Unity Sheet Metal Vs Extrusion The metal being formed must have the ability to stretch and compress within. Metal extrusion is a metal forming process in which a work piece, of a certain length and cross section, is forced to flow through a die of a smaller cross sectional area, thus forming. If your business is looking to gain an advantage while still creating quality. Sheet Metal Vs Extrusion.

From www.thefabricator.com

R&D Update Edge fracture in hole extrusion and flanging, Part I Sheet Metal Vs Extrusion Direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. The main difference between extrusions and sheet metal in terms of strength is their manufacturing process. If you require more complex shapes, especially those with. Metal extrusion is a metal forming process in which a work piece, of a certain length and cross section, is forced to flow through a die. Sheet Metal Vs Extrusion.

From www.iqsdirectory.com

Sheet Metal Fabrication What Is It? How Does It Work? Sheet Metal Vs Extrusion Successful sheet metal forming relies heavily on the metal's mechanical properties. The main difference between extrusions and sheet metal in terms of strength is their manufacturing process. Roll forming might be your best bet if your project demands rm profiles with lengths. Metal extrusion is a metal forming process in which a work piece, of a certain length and cross. Sheet Metal Vs Extrusion.

From www.iqsdirectory.com

Extruded Aluminum What Is It? How Does It Work? Strength Sheet Metal Vs Extrusion If you require more complex shapes, especially those with. If your business is looking to gain an advantage while still creating quality products, fab masters can help you decide whether. Successful sheet metal forming relies heavily on the metal's mechanical properties. The metal being formed must have the ability to stretch and compress within. The main difference between extrusions and. Sheet Metal Vs Extrusion.

From www.youtube.com

Difference between Drawing and Extrusion with the help of animation Sheet Metal Vs Extrusion If your business is looking to gain an advantage while still creating quality products, fab masters can help you decide whether. Roll forming might be your best bet if your project demands rm profiles with lengths. There are four main types of extrusion: The metal being formed must have the ability to stretch and compress within. The main difference between. Sheet Metal Vs Extrusion.