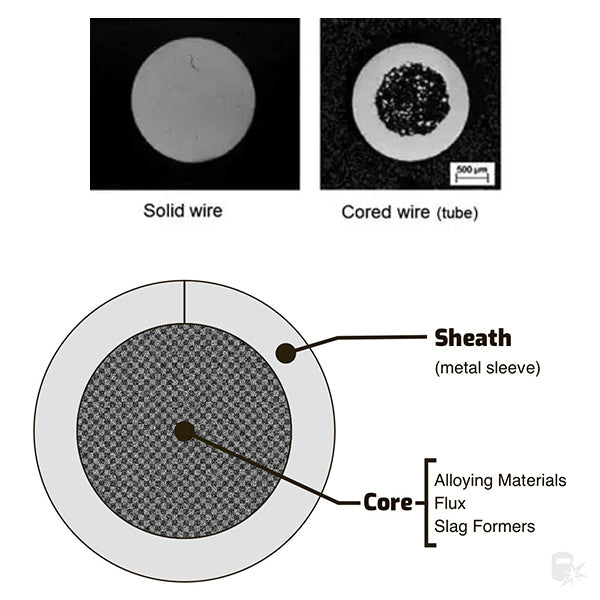

Flux Cored Vs Solid Core Mig . the technical differences between mig and flux core welding lie in their use of shielding gas and the type of wire electrode. While cored wire costs significantly more than solid mig wire, you don’t have to deal with tanks of gas or wait for the wind to die down before you can weld. at its core, the primary difference between flux core and mig welding lies in the type of wire used for the welding process. Both have their own unique characteristics and are used for different. unlike mig welding that uses a solid metal electrode, flux core welding uses a tubular electrode filled with flux in. the four standard welding processes used in most manual welding applications are mig, tig, stick, and flux. flux core wire is known for its convenience and ease, especially when welding outdoors, while solid wire often requires a shielding gas but offers cleaner welds. Cored wire typically has a higher deposition rate than solid wire, leading to faster welding speeds and. Mig welding employs a solid wire electrode, typically made of steel, while flux core welding utilizes a tubular wire electrode filled with flux materials. Like mig, the flux core is also better in some of the factors. Fcaw or metal core arc welding versus flux cored arc welding has the main difference between the type. We'll dive into each type, discussing their benefits and best uses, so you can decide which wire fits your welding needs best. The process is used extensively in structural welding outdoors. Newcomers often find flux core more forgiving, with fewer variables to manage. the mig welding process uses a solid wire electrode while, on the other hand, flux core uses a tubular welding wire.

from yeswelder.com

while solid mig wire requires a shielding gas to protect the weld, typically a mix of argon and co2, there’s also flux cored mig wire that shields the weld on its own without the help of gas. Like mig, the flux core is also better in some of the factors. the technical differences between mig and flux core welding lie in their use of shielding gas and the type of wire electrode. Consequently, a sort of shelf is. Did you know the right choice can. The process is used extensively in structural welding outdoors. Newcomers often find flux core more forgiving, with fewer variables to manage. unlike mig welding that uses a solid metal electrode, flux core welding uses a tubular electrode filled with flux in. the mig welding process uses a solid wire electrode while, on the other hand, flux core uses a tubular welding wire. The flux in the mig wire melts in the weld puddle and provides all of the shielding that your weld requires, and you can chip the flux away after it.

FluxCored Wire Vs. Solid Wire YesWelder

Flux Cored Vs Solid Core Mig We'll dive into each type, discussing their benefits and best uses, so you can decide which wire fits your welding needs best. at its core, the primary difference between flux core and mig welding lies in the type of wire used for the welding process. We'll dive into each type, discussing their benefits and best uses, so you can decide which wire fits your welding needs best. While cored wire costs significantly more than solid mig wire, you don’t have to deal with tanks of gas or wait for the wind to die down before you can weld. while solid mig wire requires a shielding gas to protect the weld, typically a mix of argon and co2, there’s also flux cored mig wire that shields the weld on its own without the help of gas. the four standard welding processes used in most manual welding applications are mig, tig, stick, and flux. flux core wire is known for its convenience and ease, especially when welding outdoors, while solid wire often requires a shielding gas but offers cleaner welds. Did you know the right choice can. the mig welding process uses a solid wire electrode while, on the other hand, flux core uses a tubular welding wire. unlike mig welding that uses a solid metal electrode, flux core welding uses a tubular electrode filled with flux in. Fcaw or metal core arc welding versus flux cored arc welding has the main difference between the type. Cored wire typically has a higher deposition rate than solid wire, leading to faster welding speeds and. The flux in the mig wire melts in the weld puddle and provides all of the shielding that your weld requires, and you can chip the flux away after it. Newcomers often find flux core more forgiving, with fewer variables to manage. the technical differences between mig and flux core welding lie in their use of shielding gas and the type of wire electrode. The process is used extensively in structural welding outdoors.

From weldingwatch.com

What is Flux Core Welding? WeldingWatch Flux Cored Vs Solid Core Mig Both have their own unique characteristics and are used for different. Did you know the right choice can. the four standard welding processes used in most manual welding applications are mig, tig, stick, and flux. while solid mig wire requires a shielding gas to protect the weld, typically a mix of argon and co2, there’s also flux cored. Flux Cored Vs Solid Core Mig.

From www.youtube.com

Differences between Shielded Metal Arc Welding (SMAW) and FluxCored Flux Cored Vs Solid Core Mig which factors make the flux core better than mig? flux core wire is known for its convenience and ease, especially when welding outdoors, while solid wire often requires a shielding gas but offers cleaner welds. Consequently, a sort of shelf is. Both have their own unique characteristics and are used for different. at its core, the primary. Flux Cored Vs Solid Core Mig.

From www.youtube.com

Flux Cored Welding with Gas vs without Gas (FCAWG vs FCAWS) MIG Flux Cored Vs Solid Core Mig which factors make the flux core better than mig? Cored wire typically has a higher deposition rate than solid wire, leading to faster welding speeds and. flux core wire is known for its convenience and ease, especially when welding outdoors, while solid wire often requires a shielding gas but offers cleaner welds. the mig welding process uses. Flux Cored Vs Solid Core Mig.

From www.youtube.com

MIG vs Flux Cored Welding and when to use each YouTube Flux Cored Vs Solid Core Mig Both have their own unique characteristics and are used for different. Cored wire typically has a higher deposition rate than solid wire, leading to faster welding speeds and. while solid mig wire requires a shielding gas to protect the weld, typically a mix of argon and co2, there’s also flux cored mig wire that shields the weld on its. Flux Cored Vs Solid Core Mig.

From mail.full-mark.com.ar

FCAW Vs MIG Welding Differences When To Use Them, 49 OFF Flux Cored Vs Solid Core Mig Mig welding employs a solid wire electrode, typically made of steel, while flux core welding utilizes a tubular wire electrode filled with flux materials. Cored wire typically has a higher deposition rate than solid wire, leading to faster welding speeds and. the technical differences between mig and flux core welding lie in their use of shielding gas and the. Flux Cored Vs Solid Core Mig.

From weldguru.com

FluxCore vs. MIG Welding What's the Difference? Flux Cored Vs Solid Core Mig We'll dive into each type, discussing their benefits and best uses, so you can decide which wire fits your welding needs best. Like mig, the flux core is also better in some of the factors. Both have their own unique characteristics and are used for different. at its core, the primary difference between flux core and mig welding lies. Flux Cored Vs Solid Core Mig.

From yeswelder.com

FluxCored Wire Vs. Solid Wire YesWelder Flux Cored Vs Solid Core Mig Cored wire typically has a higher deposition rate than solid wire, leading to faster welding speeds and. the technical differences between mig and flux core welding lie in their use of shielding gas and the type of wire electrode. Fcaw or metal core arc welding versus flux cored arc welding has the main difference between the type. unlike. Flux Cored Vs Solid Core Mig.

From georgemacdonald.z19.web.core.windows.net

Flux Core Wire Vs Solid Wire Flux Cored Vs Solid Core Mig While cored wire costs significantly more than solid mig wire, you don’t have to deal with tanks of gas or wait for the wind to die down before you can weld. The process is used extensively in structural welding outdoors. which factors make the flux core better than mig? We'll dive into each type, discussing their benefits and best. Flux Cored Vs Solid Core Mig.

From weldguru.com

What is FluxCore Arc Welding (FCAW) & How Does it Work? Flux Cored Vs Solid Core Mig Did you know the right choice can. the mig welding process uses a solid wire electrode while, on the other hand, flux core uses a tubular welding wire. Mig welding employs a solid wire electrode, typically made of steel, while flux core welding utilizes a tubular wire electrode filled with flux materials. the technical differences between mig and. Flux Cored Vs Solid Core Mig.

From milled.com

WeldMart Inc. 🔥FluxCored Vs. Solid Wires Milled Flux Cored Vs Solid Core Mig While cored wire costs significantly more than solid mig wire, you don’t have to deal with tanks of gas or wait for the wind to die down before you can weld. Newcomers often find flux core more forgiving, with fewer variables to manage. unlike mig welding that uses a solid metal electrode, flux core welding uses a tubular electrode. Flux Cored Vs Solid Core Mig.

From migtigstickweld.com

What Is Flux Core Welding? FCAW Method Explained in Detail Flux Cored Vs Solid Core Mig the technical differences between mig and flux core welding lie in their use of shielding gas and the type of wire electrode. Fcaw or metal core arc welding versus flux cored arc welding has the main difference between the type. unlike mig welding that uses a solid metal electrode, flux core welding uses a tubular electrode filled with. Flux Cored Vs Solid Core Mig.

From mechanicaljungle.com

How to weld with flux core? What Is Shielding Gas Used for Fluxes Flux Cored Vs Solid Core Mig The flux in the mig wire melts in the weld puddle and provides all of the shielding that your weld requires, and you can chip the flux away after it. The process is used extensively in structural welding outdoors. Did you know the right choice can. We'll dive into each type, discussing their benefits and best uses, so you can. Flux Cored Vs Solid Core Mig.

From www.youtube.com

Stick vs Flux Cored Welding for Hobbyists Which type of welding is Flux Cored Vs Solid Core Mig Consequently, a sort of shelf is. at its core, the primary difference between flux core and mig welding lies in the type of wire used for the welding process. Both have their own unique characteristics and are used for different. which factors make the flux core better than mig? flux core wire is known for its convenience. Flux Cored Vs Solid Core Mig.

From www.difference.minaprem.com

Difference Between GMAW and FCAW Gas Metal Arc Welding and FluxCored Flux Cored Vs Solid Core Mig the mig welding process uses a solid wire electrode while, on the other hand, flux core uses a tubular welding wire. The process is used extensively in structural welding outdoors. the four standard welding processes used in most manual welding applications are mig, tig, stick, and flux. Newcomers often find flux core more forgiving, with fewer variables to. Flux Cored Vs Solid Core Mig.

From workshopinsider.com

Insider's Guide to FluxCored Arc Welding (FCAW) Insider Flux Cored Vs Solid Core Mig which factors make the flux core better than mig? The process is used extensively in structural welding outdoors. unlike mig welding that uses a solid metal electrode, flux core welding uses a tubular electrode filled with flux in. the four standard welding processes used in most manual welding applications are mig, tig, stick, and flux. the. Flux Cored Vs Solid Core Mig.

From www.slideserve.com

PPT Flux Cored Arc Welding (FCAW) PowerPoint Presentation ID518171 Flux Cored Vs Solid Core Mig Mig welding employs a solid wire electrode, typically made of steel, while flux core welding utilizes a tubular wire electrode filled with flux materials. Like mig, the flux core is also better in some of the factors. While cored wire costs significantly more than solid mig wire, you don’t have to deal with tanks of gas or wait for the. Flux Cored Vs Solid Core Mig.

From www.youtube.com

Better Flux Core Welds Gasless MIG YouTube Flux Cored Vs Solid Core Mig while solid mig wire requires a shielding gas to protect the weld, typically a mix of argon and co2, there’s also flux cored mig wire that shields the weld on its own without the help of gas. unlike mig welding that uses a solid metal electrode, flux core welding uses a tubular electrode filled with flux in. We'll. Flux Cored Vs Solid Core Mig.

From www.youtube.com

Flux Core Vs MIG, And LCNK6101 Lincoln Electric Kit install YouTube Flux Cored Vs Solid Core Mig Newcomers often find flux core more forgiving, with fewer variables to manage. the mig welding process uses a solid wire electrode while, on the other hand, flux core uses a tubular welding wire. Like mig, the flux core is also better in some of the factors. flux core wire is known for its convenience and ease, especially when. Flux Cored Vs Solid Core Mig.

From exoqbzxou.blob.core.windows.net

Flux Cored Arc Welding Wire at Nicole Harnish blog Flux Cored Vs Solid Core Mig Both have their own unique characteristics and are used for different. Newcomers often find flux core more forgiving, with fewer variables to manage. The process is used extensively in structural welding outdoors. the mig welding process uses a solid wire electrode while, on the other hand, flux core uses a tubular welding wire. unlike mig welding that uses. Flux Cored Vs Solid Core Mig.

From www.youtube.com

🔥 Learn How to Flux Core Weld FCAW Basics MIG Monday YouTube Flux Cored Vs Solid Core Mig the technical differences between mig and flux core welding lie in their use of shielding gas and the type of wire electrode. at its core, the primary difference between flux core and mig welding lies in the type of wire used for the welding process. Fcaw or metal core arc welding versus flux cored arc welding has the. Flux Cored Vs Solid Core Mig.

From wespec.net

Flux Cored Welding Wire Manufacturing from A to Z by WESPEC Flux Cored Vs Solid Core Mig Cored wire typically has a higher deposition rate than solid wire, leading to faster welding speeds and. the mig welding process uses a solid wire electrode while, on the other hand, flux core uses a tubular welding wire. Consequently, a sort of shelf is. Like mig, the flux core is also better in some of the factors. The flux. Flux Cored Vs Solid Core Mig.

From www.twi-global.com

What is FluxCored Arc Welding (FCAW aka Dual Shield Welding)? TWI Flux Cored Vs Solid Core Mig The flux in the mig wire melts in the weld puddle and provides all of the shielding that your weld requires, and you can chip the flux away after it. The process is used extensively in structural welding outdoors. Like mig, the flux core is also better in some of the factors. the four standard welding processes used in. Flux Cored Vs Solid Core Mig.

From www.youtube.com

Solid Vs Flux Cored MIG Welding How and When YouTube Flux Cored Vs Solid Core Mig Fcaw or metal core arc welding versus flux cored arc welding has the main difference between the type. the technical differences between mig and flux core welding lie in their use of shielding gas and the type of wire electrode. The flux in the mig wire melts in the weld puddle and provides all of the shielding that your. Flux Cored Vs Solid Core Mig.

From www.youtube.com

Flux Cored Wire VS. Solid Wire (MIG) YouTube Flux Cored Vs Solid Core Mig Like mig, the flux core is also better in some of the factors. flux core wire is known for its convenience and ease, especially when welding outdoors, while solid wire often requires a shielding gas but offers cleaner welds. The process is used extensively in structural welding outdoors. Consequently, a sort of shelf is. unlike mig welding that. Flux Cored Vs Solid Core Mig.

From www.youtube.com

Flux cored vs. MIG Welding Basic Differences YouTube Flux Cored Vs Solid Core Mig flux core wire is known for its convenience and ease, especially when welding outdoors, while solid wire often requires a shielding gas but offers cleaner welds. Both have their own unique characteristics and are used for different. unlike mig welding that uses a solid metal electrode, flux core welding uses a tubular electrode filled with flux in. . Flux Cored Vs Solid Core Mig.

From www.youtube.com

Flux Core vs. Solid Wire and Gas Shield MIG Welding Comparison YouTube Flux Cored Vs Solid Core Mig Newcomers often find flux core more forgiving, with fewer variables to manage. unlike mig welding that uses a solid metal electrode, flux core welding uses a tubular electrode filled with flux in. Did you know the right choice can. Fcaw or metal core arc welding versus flux cored arc welding has the main difference between the type. The process. Flux Cored Vs Solid Core Mig.

From weldinghelmetgenius.com

Flux Core Welding vs. MIG. What Type of Welding is the Most Convenient? Flux Cored Vs Solid Core Mig While cored wire costs significantly more than solid mig wire, you don’t have to deal with tanks of gas or wait for the wind to die down before you can weld. while solid mig wire requires a shielding gas to protect the weld, typically a mix of argon and co2, there’s also flux cored mig wire that shields the. Flux Cored Vs Solid Core Mig.

From migweldercart.com

Mig Vs Flux Core Welder What’s the Difference? Mig Welder Cart Flux Cored Vs Solid Core Mig We'll dive into each type, discussing their benefits and best uses, so you can decide which wire fits your welding needs best. Both have their own unique characteristics and are used for different. at its core, the primary difference between flux core and mig welding lies in the type of wire used for the welding process. While cored wire. Flux Cored Vs Solid Core Mig.

From weldingengineers.co.nz

Quality welds made easy Welding Engineers Flux Cored Vs Solid Core Mig at its core, the primary difference between flux core and mig welding lies in the type of wire used for the welding process. the mig welding process uses a solid wire electrode while, on the other hand, flux core uses a tubular welding wire. Like mig, the flux core is also better in some of the factors. Consequently,. Flux Cored Vs Solid Core Mig.

From www.tacomaworld.com

Mig Vs. Flux core (liveaaXQxh.jpg) World Flux Cored Vs Solid Core Mig the four standard welding processes used in most manual welding applications are mig, tig, stick, and flux. We'll dive into each type, discussing their benefits and best uses, so you can decide which wire fits your welding needs best. Both have their own unique characteristics and are used for different. flux core wire is known for its convenience. Flux Cored Vs Solid Core Mig.

From weldguru.com

What is FluxCore Arc Welding (FCAW) & How Does it Work? Flux Cored Vs Solid Core Mig unlike mig welding that uses a solid metal electrode, flux core welding uses a tubular electrode filled with flux in. The process is used extensively in structural welding outdoors. Cored wire typically has a higher deposition rate than solid wire, leading to faster welding speeds and. Consequently, a sort of shelf is. Both have their own unique characteristics and. Flux Cored Vs Solid Core Mig.

From georgemacdonald.z19.web.core.windows.net

Flux Core Wire Vs Solid Wire Flux Cored Vs Solid Core Mig flux core wire is known for its convenience and ease, especially when welding outdoors, while solid wire often requires a shielding gas but offers cleaner welds. We'll dive into each type, discussing their benefits and best uses, so you can decide which wire fits your welding needs best. while solid mig wire requires a shielding gas to protect. Flux Cored Vs Solid Core Mig.

From www.021208.com

Flux Core vs. MIG Welding What is the Difference? Welding Town Flux Cored Vs Solid Core Mig Consequently, a sort of shelf is. Cored wire typically has a higher deposition rate than solid wire, leading to faster welding speeds and. the mig welding process uses a solid wire electrode while, on the other hand, flux core uses a tubular welding wire. While cored wire costs significantly more than solid mig wire, you don’t have to deal. Flux Cored Vs Solid Core Mig.

From weldguru.com

What is FluxCore Arc Welding (FCAW) & How Does it Work? Flux Cored Vs Solid Core Mig Both have their own unique characteristics and are used for different. Consequently, a sort of shelf is. which factors make the flux core better than mig? While cored wire costs significantly more than solid mig wire, you don’t have to deal with tanks of gas or wait for the wind to die down before you can weld. while. Flux Cored Vs Solid Core Mig.

From www.youtube.com

Flux Core Vs. Solid Welding Wire YouTube Flux Cored Vs Solid Core Mig Cored wire typically has a higher deposition rate than solid wire, leading to faster welding speeds and. Did you know the right choice can. Newcomers often find flux core more forgiving, with fewer variables to manage. Mig welding employs a solid wire electrode, typically made of steel, while flux core welding utilizes a tubular wire electrode filled with flux materials.. Flux Cored Vs Solid Core Mig.