Gas Pressures For Welding . How to set gas pressure on a mig welder; Different gasses used in mig welding; When the base materials heat up and start melting, they are further pressed against each other. Tip size numbers vary among manufacturers,. Depending on your welding material and the environmental conditions, the gas flow rate usually ranges from 18 to 22 cfh (cubic ft/hr) for a. Impurities in the joining surfaces are. Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. The ideal gas pressure range for mig welding should be three to eight psi; This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding. The ideal gas pressure for welding stainless steel typically falls within the range of 25 to 30 cubic feet per hour (cfh) or 12 to 15 liters per minute (lpm), depending on. The right gas pressure for mig welding.

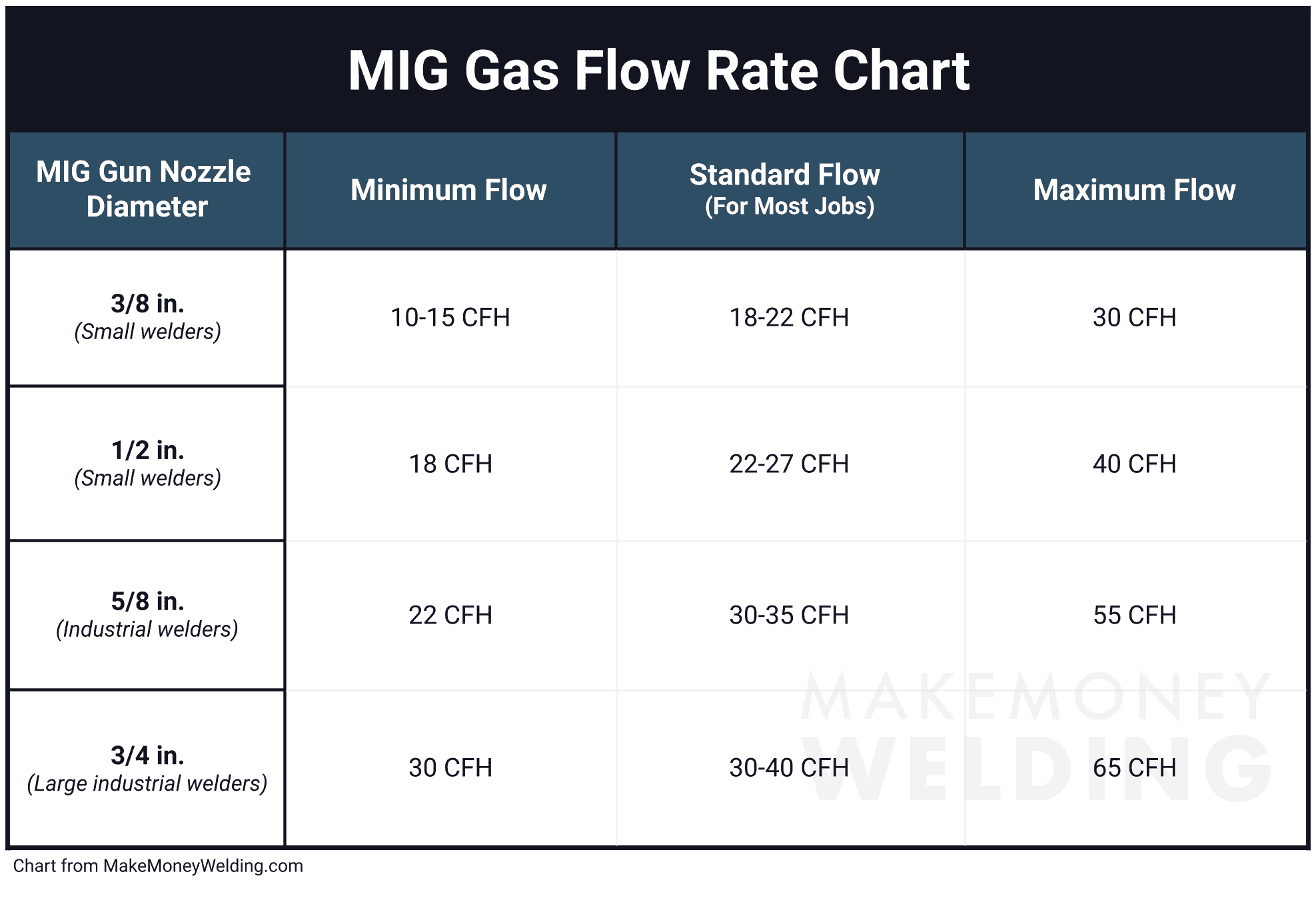

from makemoneywelding.com

When the base materials heat up and start melting, they are further pressed against each other. Impurities in the joining surfaces are. The right gas pressure for mig welding. The ideal gas pressure range for mig welding should be three to eight psi; Depending on your welding material and the environmental conditions, the gas flow rate usually ranges from 18 to 22 cfh (cubic ft/hr) for a. The ideal gas pressure for welding stainless steel typically falls within the range of 25 to 30 cubic feet per hour (cfh) or 12 to 15 liters per minute (lpm), depending on. Tip size numbers vary among manufacturers,. How to set gas pressure on a mig welder; Different gasses used in mig welding; This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding.

MIG Welding Gas Pressure Settings

Gas Pressures For Welding When the base materials heat up and start melting, they are further pressed against each other. Impurities in the joining surfaces are. How to set gas pressure on a mig welder; The ideal gas pressure for welding stainless steel typically falls within the range of 25 to 30 cubic feet per hour (cfh) or 12 to 15 liters per minute (lpm), depending on. When the base materials heat up and start melting, they are further pressed against each other. Depending on your welding material and the environmental conditions, the gas flow rate usually ranges from 18 to 22 cfh (cubic ft/hr) for a. The ideal gas pressure range for mig welding should be three to eight psi; This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding. Different gasses used in mig welding; Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. Tip size numbers vary among manufacturers,. The right gas pressure for mig welding.

From www.homedepot.com

XtremepowerUS 2 in. Rear Mount Acetylene Gas Welding Regulator Pressure Gas Pressures For Welding The right gas pressure for mig welding. Tip size numbers vary among manufacturers,. Depending on your welding material and the environmental conditions, the gas flow rate usually ranges from 18 to 22 cfh (cubic ft/hr) for a. Different gasses used in mig welding; When the base materials heat up and start melting, they are further pressed against each other. How. Gas Pressures For Welding.

From weldingmastermind.com

MIG Gas Settings How to Set Gas on MIG Welder Welding Mastermind Gas Pressures For Welding Different gasses used in mig welding; Tip size numbers vary among manufacturers,. Depending on your welding material and the environmental conditions, the gas flow rate usually ranges from 18 to 22 cfh (cubic ft/hr) for a. The ideal gas pressure range for mig welding should be three to eight psi; Impurities in the joining surfaces are. When the base materials. Gas Pressures For Welding.

From www.machines4u.com.au

The Beginner's Guide To Gas Welding Gas Pressures For Welding Depending on your welding material and the environmental conditions, the gas flow rate usually ranges from 18 to 22 cfh (cubic ft/hr) for a. How to set gas pressure on a mig welder; Impurities in the joining surfaces are. This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal. Gas Pressures For Welding.

From www.youtube.com

Rebar Gas Pressure Welding Machine YouTube Gas Pressures For Welding Different gasses used in mig welding; Impurities in the joining surfaces are. The right gas pressure for mig welding. Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. Depending on your welding material and the environmental conditions, the gas flow rate usually ranges from 18 to 22 cfh (cubic ft/hr) for a. The ideal gas. Gas Pressures For Welding.

From rst-web.com

Selecting the Right Shielding Gas For Your Welding Process RonSon's Gas Pressures For Welding Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. Tip size numbers vary among manufacturers,. The ideal gas pressure range for mig welding should be three to eight psi; The right gas pressure for mig welding. How to set gas pressure on a mig welder; This article will show you how to set the flow. Gas Pressures For Welding.

From blog.thepipingmart.com

Gas Pressure Welding Machine Advantages and Disadvantages Gas Pressures For Welding How to set gas pressure on a mig welder; Different gasses used in mig welding; Depending on your welding material and the environmental conditions, the gas flow rate usually ranges from 18 to 22 cfh (cubic ft/hr) for a. Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. When the base materials heat up and. Gas Pressures For Welding.

From mavink.com

Welding Gas Pressure Chart Gas Pressures For Welding The right gas pressure for mig welding. Tip size numbers vary among manufacturers,. How to set gas pressure on a mig welder; Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding. The. Gas Pressures For Welding.

From www.youtube.com

How to Calculate Gas Pressure Welding Cost for Lapping of Different Dia Gas Pressures For Welding Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. The right gas pressure for mig welding. Impurities in the joining surfaces are. The ideal gas pressure range for mig welding should be three to eight psi; How to set gas pressure on a mig welder; The ideal gas pressure for welding stainless steel typically falls. Gas Pressures For Welding.

From makemoneywelding.com

Explained Best MIG Welding Shielding Gas To Use Gas Pressures For Welding The ideal gas pressure for welding stainless steel typically falls within the range of 25 to 30 cubic feet per hour (cfh) or 12 to 15 liters per minute (lpm), depending on. The right gas pressure for mig welding. Tip size numbers vary among manufacturers,. Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. Depending. Gas Pressures For Welding.

From www.slideserve.com

PPT Let’s Look at the Processes COLD WELDING PRESSURE GAS WELDING Gas Pressures For Welding This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding. When the base materials heat up and start melting, they are further pressed against each other. Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. The ideal gas pressure for welding stainless. Gas Pressures For Welding.

From weldingzilla.com

MIG Welding Gas Pressure Settings (with Charts) Gas Pressures For Welding The right gas pressure for mig welding. Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. How to set gas pressure on a mig welder; Impurities in the joining surfaces are. This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding. Depending. Gas Pressures For Welding.

From weldguru.com

What Gas Should You Use for TIG Welding? (with Chart) Gas Pressures For Welding How to set gas pressure on a mig welder; The ideal gas pressure for welding stainless steel typically falls within the range of 25 to 30 cubic feet per hour (cfh) or 12 to 15 liters per minute (lpm), depending on. This article will show you how to set the flow rate of gas, the minimum and maximum values and. Gas Pressures For Welding.

From beststudwelders.com

MIG Welding Gas Pressure Settings Complete Guide best stud welders Gas Pressures For Welding How to set gas pressure on a mig welder; The ideal gas pressure range for mig welding should be three to eight psi; Depending on your welding material and the environmental conditions, the gas flow rate usually ranges from 18 to 22 cfh (cubic ft/hr) for a. Tip size numbers vary among manufacturers,. When the base materials heat up and. Gas Pressures For Welding.

From www.alamy.com

Male welder works. Welding joint of large diameter pipe. High pressure Gas Pressures For Welding Impurities in the joining surfaces are. Depending on your welding material and the environmental conditions, the gas flow rate usually ranges from 18 to 22 cfh (cubic ft/hr) for a. The ideal gas pressure range for mig welding should be three to eight psi; This article will show you how to set the flow rate of gas, the minimum and. Gas Pressures For Welding.

From mubashirghori.blogspot.com

Muhammad Mubashir Ghori Understand the Pressure Gas Welding Gas Pressures For Welding Impurities in the joining surfaces are. This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding. The ideal gas pressure range for mig welding should be three to eight psi; Depending on your welding material and the environmental conditions, the gas flow rate usually ranges from 18. Gas Pressures For Welding.

From weldguru.com

MIG Welding Gas Pressure Settings (with Charts) Gas Pressures For Welding When the base materials heat up and start melting, they are further pressed against each other. Depending on your welding material and the environmental conditions, the gas flow rate usually ranges from 18 to 22 cfh (cubic ft/hr) for a. How to set gas pressure on a mig welder; Orifice (drill size) pressure (psi) tables show approximate gas pressures for. Gas Pressures For Welding.

From www.mech4study.com

Gas Welding Principle, Working, Equipment, Application, Advantages Gas Pressures For Welding The right gas pressure for mig welding. Tip size numbers vary among manufacturers,. When the base materials heat up and start melting, they are further pressed against each other. This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding. Orifice (drill size) pressure (psi) tables show approximate. Gas Pressures For Welding.

From weldguru.com

MIG Welding Gas Pressure Settings (with Charts) Gas Pressures For Welding This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding. Different gasses used in mig welding; The ideal gas pressure for welding stainless steel typically falls within the range of 25 to 30 cubic feet per hour (cfh) or 12 to 15 liters per minute (lpm), depending. Gas Pressures For Welding.

From www.semanticscholar.org

Figure 12 from Gas pressure welding method for steel reinforcing bars Gas Pressures For Welding Tip size numbers vary among manufacturers,. The ideal gas pressure range for mig welding should be three to eight psi; How to set gas pressure on a mig welder; Depending on your welding material and the environmental conditions, the gas flow rate usually ranges from 18 to 22 cfh (cubic ft/hr) for a. The ideal gas pressure for welding stainless. Gas Pressures For Welding.

From www.daia-net.co.jp

Products Gas Pressure Welding Total system Daia Corporation Gas Pressures For Welding The ideal gas pressure for welding stainless steel typically falls within the range of 25 to 30 cubic feet per hour (cfh) or 12 to 15 liters per minute (lpm), depending on. When the base materials heat up and start melting, they are further pressed against each other. This article will show you how to set the flow rate of. Gas Pressures For Welding.

From blog.thepipingmart.com

What is Gas Pressure Welding Machine? Uses and Working Gas Pressures For Welding Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. The right gas pressure for mig welding. Tip size numbers vary among manufacturers,. The ideal gas pressure range for mig welding should be three to eight psi; This article will show you how to set the flow rate of gas, the minimum and maximum values and. Gas Pressures For Welding.

From weldingintro.com

How Can You Mig Weld Railroad Track? Gas Pressures For Welding This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding. How to set gas pressure on a mig welder; When the base materials heat up and start melting, they are further pressed against each other. Tip size numbers vary among manufacturers,. The ideal gas pressure for welding. Gas Pressures For Welding.

From www.alamy.com

Gas welding equipment on a tank. Pressure gauges used in welding Gas Pressures For Welding Depending on your welding material and the environmental conditions, the gas flow rate usually ranges from 18 to 22 cfh (cubic ft/hr) for a. The ideal gas pressure for welding stainless steel typically falls within the range of 25 to 30 cubic feet per hour (cfh) or 12 to 15 liters per minute (lpm), depending on. The ideal gas pressure. Gas Pressures For Welding.

From itstillruns.com

How to Set the Gas on an MIG Welder It Still Runs Gas Pressures For Welding How to set gas pressure on a mig welder; Different gasses used in mig welding; When the base materials heat up and start melting, they are further pressed against each other. Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. Depending on your welding material and the environmental conditions, the gas flow rate usually ranges. Gas Pressures For Welding.

From www.sinocrs.com

Gas Pressure Welding Equipment Horizon Building Materials Gas Pressures For Welding Impurities in the joining surfaces are. When the base materials heat up and start melting, they are further pressed against each other. The ideal gas pressure range for mig welding should be three to eight psi; The ideal gas pressure for welding stainless steel typically falls within the range of 25 to 30 cubic feet per hour (cfh) or 12. Gas Pressures For Welding.

From engineeringdiscoveries.com

Gas Welding Principle, Working, Equipment, Application, Advantages And Gas Pressures For Welding The ideal gas pressure range for mig welding should be three to eight psi; Different gasses used in mig welding; When the base materials heat up and start melting, they are further pressed against each other. Depending on your welding material and the environmental conditions, the gas flow rate usually ranges from 18 to 22 cfh (cubic ft/hr) for a.. Gas Pressures For Welding.

From weldempire.com

What Should Be the Gas Pressure for MIG Welding? Weld Empire Gas Pressures For Welding The right gas pressure for mig welding. The ideal gas pressure range for mig welding should be three to eight psi; The ideal gas pressure for welding stainless steel typically falls within the range of 25 to 30 cubic feet per hour (cfh) or 12 to 15 liters per minute (lpm), depending on. When the base materials heat up and. Gas Pressures For Welding.

From weldingwatch.com

MIG Welding Gas Pressure What You Need To Know WeldingWatch Gas Pressures For Welding Tip size numbers vary among manufacturers,. Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. The ideal gas pressure for welding stainless steel typically falls within the range of 25 to 30 cubic feet per hour (cfh) or 12 to 15 liters per minute (lpm), depending on. This article will show you how to set. Gas Pressures For Welding.

From www.perfectwelders.com

How To Optimize MIG Welding Shielding Gas Pressure PERFECT POWER Gas Pressures For Welding Impurities in the joining surfaces are. Different gasses used in mig welding; Depending on your welding material and the environmental conditions, the gas flow rate usually ranges from 18 to 22 cfh (cubic ft/hr) for a. This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding. When. Gas Pressures For Welding.

From www.youtube.com

Reinforcement Lap Joint Welding Gas Pressure Welding System YouTube Gas Pressures For Welding The right gas pressure for mig welding. When the base materials heat up and start melting, they are further pressed against each other. Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. How to set gas pressure on a mig welder; The ideal gas pressure for welding stainless steel typically falls within the range of. Gas Pressures For Welding.

From eziil.com

Gas Welding Types 101 (Oxyfuel, Acetylene) Gas Pressures For Welding The right gas pressure for mig welding. When the base materials heat up and start melting, they are further pressed against each other. The ideal gas pressure for welding stainless steel typically falls within the range of 25 to 30 cubic feet per hour (cfh) or 12 to 15 liters per minute (lpm), depending on. Depending on your welding material. Gas Pressures For Welding.

From weldguru.com

MIG Welding Gas Pressure Settings (with Charts) Gas Pressures For Welding Tip size numbers vary among manufacturers,. Different gasses used in mig welding; Depending on your welding material and the environmental conditions, the gas flow rate usually ranges from 18 to 22 cfh (cubic ft/hr) for a. Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. This article will show you how to set the flow. Gas Pressures For Welding.

From www.mepskills.com

Top 20 Safety Tips For Gas Welding Process Gas Pressures For Welding Impurities in the joining surfaces are. This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding. Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. The ideal gas pressure for welding stainless steel typically falls within the range of 25 to 30. Gas Pressures For Welding.

From blog.thepipingmart.com

Everything You Need To Know About Gas Welding ThePipingMart Blog Gas Pressures For Welding Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. When the base materials heat up and start melting, they are further pressed against each other. Tip size numbers vary among manufacturers,. The right gas pressure for mig welding. How to set gas pressure on a mig welder; This article will show you how to set. Gas Pressures For Welding.

From makemoneywelding.com

MIG Welding Gas Pressure Settings Gas Pressures For Welding Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding. When the base materials heat up and start melting, they are further pressed against each other. The right gas pressure for mig welding.. Gas Pressures For Welding.