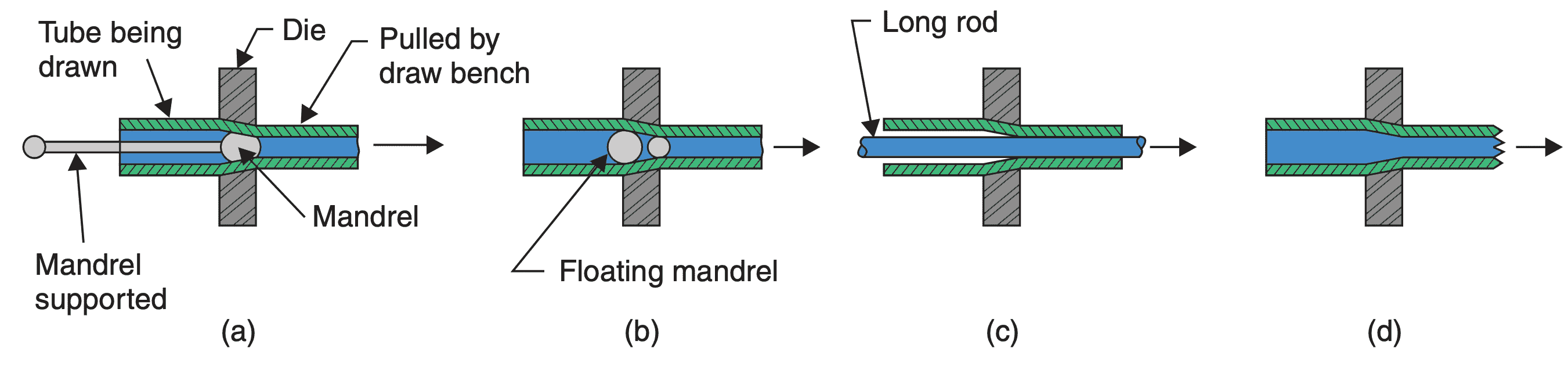

Tube Drawing Types . Procuring the raw material, pointing, drawing, straightening, and finishing are the five steps fabricators need to keep in mind. Several manufacturing processes have been developed for drawing tubes. Besides these processes, the tube drawing may also be carried out through roller dies in which case the die friction is substantially reduced. Various tube drawing methods are utilized, depending on the quality required, tubing length, and material used. These are illustrated in fig. Understanding that drawing a tube requires more than just pointing and drawing is a good start to a successful draw. Tube drawing is a metalworking process used to create a tube with a smaller diameter by pulling, or drawing, a larger diameter tube through a die. In order to realize the above aims, four types of tube drawing processes, are employed. What the processes all have in common is that the tube to be drawn.

from extrudesign.com

In order to realize the above aims, four types of tube drawing processes, are employed. Several manufacturing processes have been developed for drawing tubes. Besides these processes, the tube drawing may also be carried out through roller dies in which case the die friction is substantially reduced. What the processes all have in common is that the tube to be drawn. Various tube drawing methods are utilized, depending on the quality required, tubing length, and material used. These are illustrated in fig. Procuring the raw material, pointing, drawing, straightening, and finishing are the five steps fabricators need to keep in mind. Tube drawing is a metalworking process used to create a tube with a smaller diameter by pulling, or drawing, a larger diameter tube through a die. Understanding that drawing a tube requires more than just pointing and drawing is a good start to a successful draw.

What is Wire Drawing, Tube Drawing and Making? ExtruDesign

Tube Drawing Types Procuring the raw material, pointing, drawing, straightening, and finishing are the five steps fabricators need to keep in mind. Procuring the raw material, pointing, drawing, straightening, and finishing are the five steps fabricators need to keep in mind. Several manufacturing processes have been developed for drawing tubes. Various tube drawing methods are utilized, depending on the quality required, tubing length, and material used. In order to realize the above aims, four types of tube drawing processes, are employed. These are illustrated in fig. What the processes all have in common is that the tube to be drawn. Understanding that drawing a tube requires more than just pointing and drawing is a good start to a successful draw. Besides these processes, the tube drawing may also be carried out through roller dies in which case the die friction is substantially reduced. Tube drawing is a metalworking process used to create a tube with a smaller diameter by pulling, or drawing, a larger diameter tube through a die.

From www.youtube.com

Tube Drawing YouTube Tube Drawing Types Various tube drawing methods are utilized, depending on the quality required, tubing length, and material used. Understanding that drawing a tube requires more than just pointing and drawing is a good start to a successful draw. Several manufacturing processes have been developed for drawing tubes. These are illustrated in fig. Procuring the raw material, pointing, drawing, straightening, and finishing are. Tube Drawing Types.

From www.youtube.com

Types of drawingwire drawing,rod drawing and tube drawing YouTube Tube Drawing Types Procuring the raw material, pointing, drawing, straightening, and finishing are the five steps fabricators need to keep in mind. Tube drawing is a metalworking process used to create a tube with a smaller diameter by pulling, or drawing, a larger diameter tube through a die. In order to realize the above aims, four types of tube drawing processes, are employed.. Tube Drawing Types.

From www.manufacturingguide.com

Tube drawing Find suppliers, processes & material Tube Drawing Types Besides these processes, the tube drawing may also be carried out through roller dies in which case the die friction is substantially reduced. What the processes all have in common is that the tube to be drawn. Several manufacturing processes have been developed for drawing tubes. Tube drawing is a metalworking process used to create a tube with a smaller. Tube Drawing Types.

From www.engineerknow.com

Tube Drawing Tube Drawing Types What the processes all have in common is that the tube to be drawn. These are illustrated in fig. Tube drawing is a metalworking process used to create a tube with a smaller diameter by pulling, or drawing, a larger diameter tube through a die. Various tube drawing methods are utilized, depending on the quality required, tubing length, and material. Tube Drawing Types.

From drawingtube.org

Drawing Tube Drawing Tube Tube Drawing Types Understanding that drawing a tube requires more than just pointing and drawing is a good start to a successful draw. What the processes all have in common is that the tube to be drawn. Procuring the raw material, pointing, drawing, straightening, and finishing are the five steps fabricators need to keep in mind. Several manufacturing processes have been developed for. Tube Drawing Types.

From www.youtube.com

How to read piping isometric drawing, Pipe fitter training, Watch the Tube Drawing Types Tube drawing is a metalworking process used to create a tube with a smaller diameter by pulling, or drawing, a larger diameter tube through a die. Understanding that drawing a tube requires more than just pointing and drawing is a good start to a successful draw. In order to realize the above aims, four types of tube drawing processes, are. Tube Drawing Types.

From www.reddit.com

What is Wire Drawing, Tube Drawing and Making? ExtruDesign r Tube Drawing Types In order to realize the above aims, four types of tube drawing processes, are employed. Tube drawing is a metalworking process used to create a tube with a smaller diameter by pulling, or drawing, a larger diameter tube through a die. What the processes all have in common is that the tube to be drawn. Understanding that drawing a tube. Tube Drawing Types.

From www.youtube.com

Test tube 🧪 drawing for kids Test tube drawing YouTube Tube Drawing Types What the processes all have in common is that the tube to be drawn. These are illustrated in fig. Besides these processes, the tube drawing may also be carried out through roller dies in which case the die friction is substantially reduced. Procuring the raw material, pointing, drawing, straightening, and finishing are the five steps fabricators need to keep in. Tube Drawing Types.

From ahssinsights.org

High Frequency Tube/Pipe Welding AHSS Guidelines Tube Drawing Types Procuring the raw material, pointing, drawing, straightening, and finishing are the five steps fabricators need to keep in mind. In order to realize the above aims, four types of tube drawing processes, are employed. Besides these processes, the tube drawing may also be carried out through roller dies in which case the die friction is substantially reduced. Understanding that drawing. Tube Drawing Types.

From slideplayer.com

PLASTIC FORMING PROCRSSES ppt download Tube Drawing Types Procuring the raw material, pointing, drawing, straightening, and finishing are the five steps fabricators need to keep in mind. In order to realize the above aims, four types of tube drawing processes, are employed. What the processes all have in common is that the tube to be drawn. These are illustrated in fig. Understanding that drawing a tube requires more. Tube Drawing Types.

From drawinghowtos.com

How to Draw Paint Tubes Step by Step Easy Drawing Guides Drawing Howtos Tube Drawing Types Several manufacturing processes have been developed for drawing tubes. What the processes all have in common is that the tube to be drawn. Procuring the raw material, pointing, drawing, straightening, and finishing are the five steps fabricators need to keep in mind. These are illustrated in fig. Besides these processes, the tube drawing may also be carried out through roller. Tube Drawing Types.

From www.doublestonesteel.com

How the simple industrial process of tube drawing allows for the Tube Drawing Types In order to realize the above aims, four types of tube drawing processes, are employed. Procuring the raw material, pointing, drawing, straightening, and finishing are the five steps fabricators need to keep in mind. Several manufacturing processes have been developed for drawing tubes. Understanding that drawing a tube requires more than just pointing and drawing is a good start to. Tube Drawing Types.

From extrudesign.com

What is Wire Drawing, Tube Drawing and Making? ExtruDesign Tube Drawing Types Understanding that drawing a tube requires more than just pointing and drawing is a good start to a successful draw. These are illustrated in fig. Various tube drawing methods are utilized, depending on the quality required, tubing length, and material used. Besides these processes, the tube drawing may also be carried out through roller dies in which case the die. Tube Drawing Types.

From www.researchgate.net

(PDF) Analysis of Tube Drawing with a Floating Plug Tube Drawing Types Besides these processes, the tube drawing may also be carried out through roller dies in which case the die friction is substantially reduced. Understanding that drawing a tube requires more than just pointing and drawing is a good start to a successful draw. Various tube drawing methods are utilized, depending on the quality required, tubing length, and material used. Procuring. Tube Drawing Types.

From www.mech4study.com

Types of Drawing Process Wire Drawing, Rod Drawing and Tube Drawing Tube Drawing Types Various tube drawing methods are utilized, depending on the quality required, tubing length, and material used. These are illustrated in fig. Tube drawing is a metalworking process used to create a tube with a smaller diameter by pulling, or drawing, a larger diameter tube through a die. What the processes all have in common is that the tube to be. Tube Drawing Types.

From www.youtube.com

how to draw a test tube step by step test tube drawing YouTube Tube Drawing Types What the processes all have in common is that the tube to be drawn. Besides these processes, the tube drawing may also be carried out through roller dies in which case the die friction is substantially reduced. Tube drawing is a metalworking process used to create a tube with a smaller diameter by pulling, or drawing, a larger diameter tube. Tube Drawing Types.

From drawingideas.netlify.app

Order Of Blood Draw Tubes And Additives Tube Drawing Types In order to realize the above aims, four types of tube drawing processes, are employed. Procuring the raw material, pointing, drawing, straightening, and finishing are the five steps fabricators need to keep in mind. What the processes all have in common is that the tube to be drawn. Tube drawing is a metalworking process used to create a tube with. Tube Drawing Types.

From www.researchgate.net

Schematic of tube drawing process with a fixed mandrel Download Tube Drawing Types What the processes all have in common is that the tube to be drawn. Various tube drawing methods are utilized, depending on the quality required, tubing length, and material used. Understanding that drawing a tube requires more than just pointing and drawing is a good start to a successful draw. Procuring the raw material, pointing, drawing, straightening, and finishing are. Tube Drawing Types.

From www.mech4study.com

Types of Drawing Process Wire Drawing, Rod Drawing and Tube Drawing Tube Drawing Types Several manufacturing processes have been developed for drawing tubes. Various tube drawing methods are utilized, depending on the quality required, tubing length, and material used. Understanding that drawing a tube requires more than just pointing and drawing is a good start to a successful draw. Besides these processes, the tube drawing may also be carried out through roller dies in. Tube Drawing Types.

From www.mech4study.com

Types of Drawing Process Wire Drawing, Rod Drawing and Tube Drawing Tube Drawing Types What the processes all have in common is that the tube to be drawn. Several manufacturing processes have been developed for drawing tubes. Besides these processes, the tube drawing may also be carried out through roller dies in which case the die friction is substantially reduced. Procuring the raw material, pointing, drawing, straightening, and finishing are the five steps fabricators. Tube Drawing Types.

From www.youtube.com

Drawing 101 How to draw tubes YouTube Tube Drawing Types Procuring the raw material, pointing, drawing, straightening, and finishing are the five steps fabricators need to keep in mind. What the processes all have in common is that the tube to be drawn. Various tube drawing methods are utilized, depending on the quality required, tubing length, and material used. In order to realize the above aims, four types of tube. Tube Drawing Types.

From www.researchgate.net

Schematic of tube drawing process with a fixed mandrel Download Tube Drawing Types Besides these processes, the tube drawing may also be carried out through roller dies in which case the die friction is substantially reduced. Several manufacturing processes have been developed for drawing tubes. Procuring the raw material, pointing, drawing, straightening, and finishing are the five steps fabricators need to keep in mind. In order to realize the above aims, four types. Tube Drawing Types.

From www.researchgate.net

Drawbench used for tube drawing process Download Scientific Diagram Tube Drawing Types In order to realize the above aims, four types of tube drawing processes, are employed. Understanding that drawing a tube requires more than just pointing and drawing is a good start to a successful draw. What the processes all have in common is that the tube to be drawn. Procuring the raw material, pointing, drawing, straightening, and finishing are the. Tube Drawing Types.

From www.pinterest.com

Pin on Wirework Tube Drawing Types These are illustrated in fig. What the processes all have in common is that the tube to be drawn. Besides these processes, the tube drawing may also be carried out through roller dies in which case the die friction is substantially reduced. Understanding that drawing a tube requires more than just pointing and drawing is a good start to a. Tube Drawing Types.

From www.researchgate.net

Glass tube drawing during tubing process Download Scientific Diagram Tube Drawing Types What the processes all have in common is that the tube to be drawn. Procuring the raw material, pointing, drawing, straightening, and finishing are the five steps fabricators need to keep in mind. These are illustrated in fig. Various tube drawing methods are utilized, depending on the quality required, tubing length, and material used. Besides these processes, the tube drawing. Tube Drawing Types.

From harleyclarke.z19.web.core.windows.net

Blood Draw Order Tube Color Chart Tube Drawing Types Tube drawing is a metalworking process used to create a tube with a smaller diameter by pulling, or drawing, a larger diameter tube through a die. In order to realize the above aims, four types of tube drawing processes, are employed. Understanding that drawing a tube requires more than just pointing and drawing is a good start to a successful. Tube Drawing Types.

From www.scribd.com

Types of Drawing ProcessWire Drawing, Rod Drawing and Tube Drawing Tube Drawing Types Besides these processes, the tube drawing may also be carried out through roller dies in which case the die friction is substantially reduced. Procuring the raw material, pointing, drawing, straightening, and finishing are the five steps fabricators need to keep in mind. Understanding that drawing a tube requires more than just pointing and drawing is a good start to a. Tube Drawing Types.

From www.youtube.com

Tube Drawing & Types of Tube Drawing YouTube Tube Drawing Types These are illustrated in fig. Several manufacturing processes have been developed for drawing tubes. What the processes all have in common is that the tube to be drawn. Procuring the raw material, pointing, drawing, straightening, and finishing are the five steps fabricators need to keep in mind. In order to realize the above aims, four types of tube drawing processes,. Tube Drawing Types.

From www.youtube.com

How to draw tube well step by step so easy YouTube Tube Drawing Types Procuring the raw material, pointing, drawing, straightening, and finishing are the five steps fabricators need to keep in mind. Various tube drawing methods are utilized, depending on the quality required, tubing length, and material used. Understanding that drawing a tube requires more than just pointing and drawing is a good start to a successful draw. In order to realize the. Tube Drawing Types.

From www.manufacturingguide.com

Tube drawing Find suppliers, processes & material Tube Drawing Types These are illustrated in fig. In order to realize the above aims, four types of tube drawing processes, are employed. Understanding that drawing a tube requires more than just pointing and drawing is a good start to a successful draw. Several manufacturing processes have been developed for drawing tubes. Procuring the raw material, pointing, drawing, straightening, and finishing are the. Tube Drawing Types.

From www.scribd.com

Tube Drawing Process PDF Annealing (Metallurgy) Rolling Tube Drawing Types Procuring the raw material, pointing, drawing, straightening, and finishing are the five steps fabricators need to keep in mind. In order to realize the above aims, four types of tube drawing processes, are employed. Besides these processes, the tube drawing may also be carried out through roller dies in which case the die friction is substantially reduced. Understanding that drawing. Tube Drawing Types.

From www.studypool.com

SOLUTION Wire Tube Drawing Presentation Studypool Tube Drawing Types Tube drawing is a metalworking process used to create a tube with a smaller diameter by pulling, or drawing, a larger diameter tube through a die. Procuring the raw material, pointing, drawing, straightening, and finishing are the five steps fabricators need to keep in mind. What the processes all have in common is that the tube to be drawn. Various. Tube Drawing Types.

From www.youtube.com

Tube Drawing Process YouTube Tube Drawing Types In order to realize the above aims, four types of tube drawing processes, are employed. Procuring the raw material, pointing, drawing, straightening, and finishing are the five steps fabricators need to keep in mind. Besides these processes, the tube drawing may also be carried out through roller dies in which case the die friction is substantially reduced. These are illustrated. Tube Drawing Types.

From extrudesign.com

What is Wire Drawing, Tube Drawing and Making? ExtruDesign Tube Drawing Types Understanding that drawing a tube requires more than just pointing and drawing is a good start to a successful draw. Besides these processes, the tube drawing may also be carried out through roller dies in which case the die friction is substantially reduced. In order to realize the above aims, four types of tube drawing processes, are employed. What the. Tube Drawing Types.

From www.tubemethods.com

Tube Drawing and Manufacturing Tube Methods, Inc. Tube Drawing Types Several manufacturing processes have been developed for drawing tubes. What the processes all have in common is that the tube to be drawn. Tube drawing is a metalworking process used to create a tube with a smaller diameter by pulling, or drawing, a larger diameter tube through a die. Procuring the raw material, pointing, drawing, straightening, and finishing are the. Tube Drawing Types.