Polishing Wheel Risk Assessment . There are five main steps involved in conducting an effective abrasive wheel risk assessment: Following are some key points for the preparation of abrasive wheel risk assessment, and for the complete editable word format by just clicking the link at the end of. Use, care and protection of abrasive wheels 1 scope and definitions 1.1 scope this safety standard sets forth requirements for the safe. Decide who might be harmed and how. This guide will focus on four principal hazards associated with the use of abrasives in the workplace and. The correct wheel for the type of machine, speed and material to be cut will be ordered and supplied. An abrasive wheel risk assessment should identify any potential and existing hazards associated with grinding in your workplace and the control measures that should be put in place to eliminate or reduce the risk they pose to workers. In addition to looking at essential training needs, the guide also focuses on details such as: Check abrasive wheels and discs.

from www.abtac.co.uk

Following are some key points for the preparation of abrasive wheel risk assessment, and for the complete editable word format by just clicking the link at the end of. There are five main steps involved in conducting an effective abrasive wheel risk assessment: This guide will focus on four principal hazards associated with the use of abrasives in the workplace and. Decide who might be harmed and how. Use, care and protection of abrasive wheels 1 scope and definitions 1.1 scope this safety standard sets forth requirements for the safe. An abrasive wheel risk assessment should identify any potential and existing hazards associated with grinding in your workplace and the control measures that should be put in place to eliminate or reduce the risk they pose to workers. Check abrasive wheels and discs. In addition to looking at essential training needs, the guide also focuses on details such as: The correct wheel for the type of machine, speed and material to be cut will be ordered and supplied.

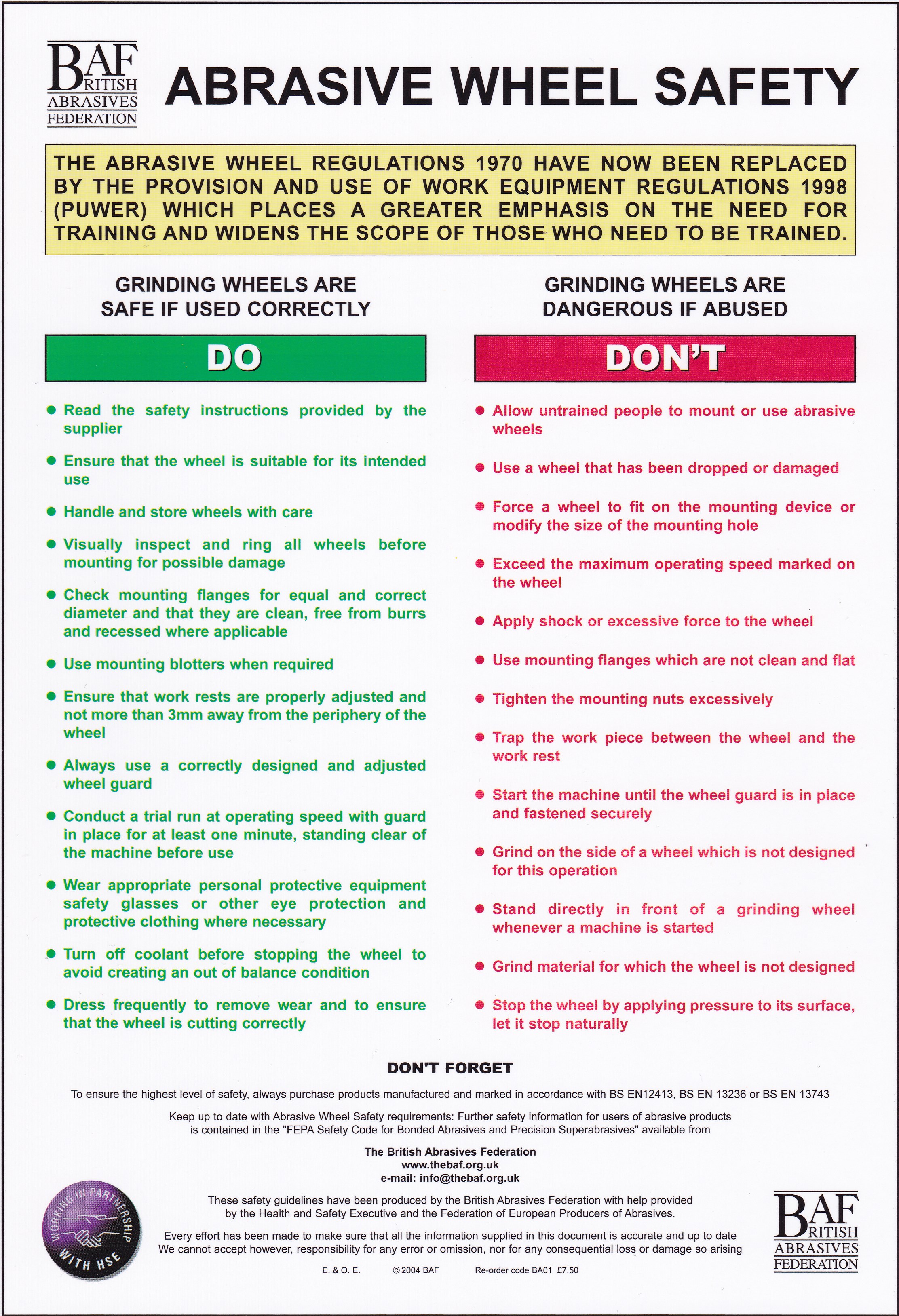

Abrasive safety poster do's and don'ts

Polishing Wheel Risk Assessment Decide who might be harmed and how. There are five main steps involved in conducting an effective abrasive wheel risk assessment: This guide will focus on four principal hazards associated with the use of abrasives in the workplace and. The correct wheel for the type of machine, speed and material to be cut will be ordered and supplied. Decide who might be harmed and how. Following are some key points for the preparation of abrasive wheel risk assessment, and for the complete editable word format by just clicking the link at the end of. In addition to looking at essential training needs, the guide also focuses on details such as: Check abrasive wheels and discs. An abrasive wheel risk assessment should identify any potential and existing hazards associated with grinding in your workplace and the control measures that should be put in place to eliminate or reduce the risk they pose to workers. Use, care and protection of abrasive wheels 1 scope and definitions 1.1 scope this safety standard sets forth requirements for the safe.

From safetishop.myshopify.com

Abrasive Wheels Risk Assessment Safeti Shop Polishing Wheel Risk Assessment Following are some key points for the preparation of abrasive wheel risk assessment, and for the complete editable word format by just clicking the link at the end of. The correct wheel for the type of machine, speed and material to be cut will be ordered and supplied. Check abrasive wheels and discs. In addition to looking at essential training. Polishing Wheel Risk Assessment.

From es.scribd.com

Tyre Risk Assessment Tire Hazards Polishing Wheel Risk Assessment In addition to looking at essential training needs, the guide also focuses on details such as: This guide will focus on four principal hazards associated with the use of abrasives in the workplace and. Decide who might be harmed and how. Use, care and protection of abrasive wheels 1 scope and definitions 1.1 scope this safety standard sets forth requirements. Polishing Wheel Risk Assessment.

From www.hsedocuments.com

RISK ASSESSMENTPAINTING AND DECORATING HSE Documents Polishing Wheel Risk Assessment This guide will focus on four principal hazards associated with the use of abrasives in the workplace and. Use, care and protection of abrasive wheels 1 scope and definitions 1.1 scope this safety standard sets forth requirements for the safe. The correct wheel for the type of machine, speed and material to be cut will be ordered and supplied. Following. Polishing Wheel Risk Assessment.

From trisk.io

Don’t reinvent the wheel Risk Assessment and Incident Response Plan Blog Trisk CPA Polishing Wheel Risk Assessment Decide who might be harmed and how. Use, care and protection of abrasive wheels 1 scope and definitions 1.1 scope this safety standard sets forth requirements for the safe. This guide will focus on four principal hazards associated with the use of abrasives in the workplace and. Following are some key points for the preparation of abrasive wheel risk assessment,. Polishing Wheel Risk Assessment.

From safeti.com

Abrasive Wheels Risk Assessment PLUS Free CPD Training Polishing Wheel Risk Assessment Check abrasive wheels and discs. Use, care and protection of abrasive wheels 1 scope and definitions 1.1 scope this safety standard sets forth requirements for the safe. This guide will focus on four principal hazards associated with the use of abrasives in the workplace and. Following are some key points for the preparation of abrasive wheel risk assessment, and for. Polishing Wheel Risk Assessment.

From www.hsedocuments.com

Abrasive Wheels Risk Assessment HSE Documents Polishing Wheel Risk Assessment The correct wheel for the type of machine, speed and material to be cut will be ordered and supplied. This guide will focus on four principal hazards associated with the use of abrasives in the workplace and. Use, care and protection of abrasive wheels 1 scope and definitions 1.1 scope this safety standard sets forth requirements for the safe. Decide. Polishing Wheel Risk Assessment.

From www.easy-quizzz.com

Abrasive Wheels Risk Assessment A Comprehensive Guide Polishing Wheel Risk Assessment In addition to looking at essential training needs, the guide also focuses on details such as: Following are some key points for the preparation of abrasive wheel risk assessment, and for the complete editable word format by just clicking the link at the end of. Check abrasive wheels and discs. There are five main steps involved in conducting an effective. Polishing Wheel Risk Assessment.

From www.scribd.com

RH Wheel Risk Assessment PDF Risk Assessment Risk Polishing Wheel Risk Assessment This guide will focus on four principal hazards associated with the use of abrasives in the workplace and. Check abrasive wheels and discs. Following are some key points for the preparation of abrasive wheel risk assessment, and for the complete editable word format by just clicking the link at the end of. There are five main steps involved in conducting. Polishing Wheel Risk Assessment.

From www.abtac.co.uk

Abrasive safety poster use of equipment Polishing Wheel Risk Assessment Check abrasive wheels and discs. Following are some key points for the preparation of abrasive wheel risk assessment, and for the complete editable word format by just clicking the link at the end of. An abrasive wheel risk assessment should identify any potential and existing hazards associated with grinding in your workplace and the control measures that should be put. Polishing Wheel Risk Assessment.

From www.upwork.com

Abrasive Wheel Risk Assessment Upwork Polishing Wheel Risk Assessment In addition to looking at essential training needs, the guide also focuses on details such as: This guide will focus on four principal hazards associated with the use of abrasives in the workplace and. An abrasive wheel risk assessment should identify any potential and existing hazards associated with grinding in your workplace and the control measures that should be put. Polishing Wheel Risk Assessment.

From www.abtac.co.uk

Abrasive safety poster do's and don'ts Polishing Wheel Risk Assessment Decide who might be harmed and how. In addition to looking at essential training needs, the guide also focuses on details such as: There are five main steps involved in conducting an effective abrasive wheel risk assessment: Use, care and protection of abrasive wheels 1 scope and definitions 1.1 scope this safety standard sets forth requirements for the safe. Following. Polishing Wheel Risk Assessment.

From 12designandtechnology-cole.weebly.com

Risk Assessments Elsie Cole Polishing Wheel Risk Assessment An abrasive wheel risk assessment should identify any potential and existing hazards associated with grinding in your workplace and the control measures that should be put in place to eliminate or reduce the risk they pose to workers. There are five main steps involved in conducting an effective abrasive wheel risk assessment: Following are some key points for the preparation. Polishing Wheel Risk Assessment.

From www.qhsedocuments.com

RISK ASSESSMENT ABRASIVE WHEELS Polishing Wheel Risk Assessment There are five main steps involved in conducting an effective abrasive wheel risk assessment: Check abrasive wheels and discs. The correct wheel for the type of machine, speed and material to be cut will be ordered and supplied. An abrasive wheel risk assessment should identify any potential and existing hazards associated with grinding in your workplace and the control measures. Polishing Wheel Risk Assessment.

From expertcivil.com

Conducting an Abrasive Wheel Risk Assessment Polishing Wheel Risk Assessment Decide who might be harmed and how. This guide will focus on four principal hazards associated with the use of abrasives in the workplace and. Use, care and protection of abrasive wheels 1 scope and definitions 1.1 scope this safety standard sets forth requirements for the safe. An abrasive wheel risk assessment should identify any potential and existing hazards associated. Polishing Wheel Risk Assessment.

From www.civil-engineers-2020.com

Risk Assessment Template for Plaster Work Polishing Wheel Risk Assessment Check abrasive wheels and discs. Following are some key points for the preparation of abrasive wheel risk assessment, and for the complete editable word format by just clicking the link at the end of. There are five main steps involved in conducting an effective abrasive wheel risk assessment: An abrasive wheel risk assessment should identify any potential and existing hazards. Polishing Wheel Risk Assessment.

From www.haspod.com

Abrasive Wheels Risk Assessment Template HASpod Polishing Wheel Risk Assessment There are five main steps involved in conducting an effective abrasive wheel risk assessment: Following are some key points for the preparation of abrasive wheel risk assessment, and for the complete editable word format by just clicking the link at the end of. This guide will focus on four principal hazards associated with the use of abrasives in the workplace. Polishing Wheel Risk Assessment.

From www.carneyconsultancy.co.uk

Risk Assessment B01 ABRASIVE WHEELS Polishing Wheel Risk Assessment This guide will focus on four principal hazards associated with the use of abrasives in the workplace and. Check abrasive wheels and discs. An abrasive wheel risk assessment should identify any potential and existing hazards associated with grinding in your workplace and the control measures that should be put in place to eliminate or reduce the risk they pose to. Polishing Wheel Risk Assessment.

From safeti.com

Abrasive Wheels Risk Assessment PLUS Free CPD Training Polishing Wheel Risk Assessment Check abrasive wheels and discs. There are five main steps involved in conducting an effective abrasive wheel risk assessment: The correct wheel for the type of machine, speed and material to be cut will be ordered and supplied. Following are some key points for the preparation of abrasive wheel risk assessment, and for the complete editable word format by just. Polishing Wheel Risk Assessment.

From www.researchgate.net

Structure of the polishing wheel. Download Scientific Diagram Polishing Wheel Risk Assessment This guide will focus on four principal hazards associated with the use of abrasives in the workplace and. The correct wheel for the type of machine, speed and material to be cut will be ordered and supplied. Following are some key points for the preparation of abrasive wheel risk assessment, and for the complete editable word format by just clicking. Polishing Wheel Risk Assessment.

From www.hseprof.com

HSE Docs Download HSE Risk Assesment for Welding activities Polishing Wheel Risk Assessment The correct wheel for the type of machine, speed and material to be cut will be ordered and supplied. There are five main steps involved in conducting an effective abrasive wheel risk assessment: In addition to looking at essential training needs, the guide also focuses on details such as: Check abrasive wheels and discs. An abrasive wheel risk assessment should. Polishing Wheel Risk Assessment.

From www.hsedocuments.com

HSE DOCUMENTSABRASIVE WHEEL RISK ASSESSMENT HSE Documents Polishing Wheel Risk Assessment Following are some key points for the preparation of abrasive wheel risk assessment, and for the complete editable word format by just clicking the link at the end of. Check abrasive wheels and discs. Decide who might be harmed and how. The correct wheel for the type of machine, speed and material to be cut will be ordered and supplied.. Polishing Wheel Risk Assessment.

From www.slideshare.net

NGIRisk Assessment Polishing Wheel Risk Assessment Use, care and protection of abrasive wheels 1 scope and definitions 1.1 scope this safety standard sets forth requirements for the safe. Check abrasive wheels and discs. An abrasive wheel risk assessment should identify any potential and existing hazards associated with grinding in your workplace and the control measures that should be put in place to eliminate or reduce the. Polishing Wheel Risk Assessment.

From www.researchgate.net

Structure of the polishing wheel. Download Scientific Diagram Polishing Wheel Risk Assessment In addition to looking at essential training needs, the guide also focuses on details such as: There are five main steps involved in conducting an effective abrasive wheel risk assessment: Following are some key points for the preparation of abrasive wheel risk assessment, and for the complete editable word format by just clicking the link at the end of. An. Polishing Wheel Risk Assessment.

From www.easy-quizzz.com

Abrasive Wheels Risk Assessment A Comprehensive Guide Polishing Wheel Risk Assessment There are five main steps involved in conducting an effective abrasive wheel risk assessment: The correct wheel for the type of machine, speed and material to be cut will be ordered and supplied. This guide will focus on four principal hazards associated with the use of abrasives in the workplace and. Check abrasive wheels and discs. Decide who might be. Polishing Wheel Risk Assessment.

From safeti.com

Risk Assessment Archives Safeti Polishing Wheel Risk Assessment An abrasive wheel risk assessment should identify any potential and existing hazards associated with grinding in your workplace and the control measures that should be put in place to eliminate or reduce the risk they pose to workers. In addition to looking at essential training needs, the guide also focuses on details such as: The correct wheel for the type. Polishing Wheel Risk Assessment.

From www.scribd.com

Hazards Identification Risk Assessment Control PDF Crane (Machine) Grinding (Abrasive Cutting) Polishing Wheel Risk Assessment Decide who might be harmed and how. Use, care and protection of abrasive wheels 1 scope and definitions 1.1 scope this safety standard sets forth requirements for the safe. The correct wheel for the type of machine, speed and material to be cut will be ordered and supplied. Following are some key points for the preparation of abrasive wheel risk. Polishing Wheel Risk Assessment.

From safeti.com

Abrasive Wheels Risk Assessment PLUS Free CPD Training Polishing Wheel Risk Assessment There are five main steps involved in conducting an effective abrasive wheel risk assessment: The correct wheel for the type of machine, speed and material to be cut will be ordered and supplied. Use, care and protection of abrasive wheels 1 scope and definitions 1.1 scope this safety standard sets forth requirements for the safe. Decide who might be harmed. Polishing Wheel Risk Assessment.

From www.studypool.com

SOLUTION Safety risk assessment marble flooring Studypool Polishing Wheel Risk Assessment Decide who might be harmed and how. Following are some key points for the preparation of abrasive wheel risk assessment, and for the complete editable word format by just clicking the link at the end of. In addition to looking at essential training needs, the guide also focuses on details such as: The correct wheel for the type of machine,. Polishing Wheel Risk Assessment.

From www.scribd.com

Abrasive Wheels PDF Personal Protective Equipment Risk Polishing Wheel Risk Assessment Check abrasive wheels and discs. Following are some key points for the preparation of abrasive wheel risk assessment, and for the complete editable word format by just clicking the link at the end of. There are five main steps involved in conducting an effective abrasive wheel risk assessment: The correct wheel for the type of machine, speed and material to. Polishing Wheel Risk Assessment.

From studylib.net

Plant and Equipment Risk Management Form Polishing Wheel Risk Assessment In addition to looking at essential training needs, the guide also focuses on details such as: Decide who might be harmed and how. This guide will focus on four principal hazards associated with the use of abrasives in the workplace and. An abrasive wheel risk assessment should identify any potential and existing hazards associated with grinding in your workplace and. Polishing Wheel Risk Assessment.

From www.haspod.com

Abrasive Wheels Risk Assessment Template HASpod Polishing Wheel Risk Assessment The correct wheel for the type of machine, speed and material to be cut will be ordered and supplied. Use, care and protection of abrasive wheels 1 scope and definitions 1.1 scope this safety standard sets forth requirements for the safe. This guide will focus on four principal hazards associated with the use of abrasives in the workplace and. Decide. Polishing Wheel Risk Assessment.

From www.scribd.com

Forklift Risk Assessment Forklift Emergency Management Polishing Wheel Risk Assessment Check abrasive wheels and discs. This guide will focus on four principal hazards associated with the use of abrasives in the workplace and. Following are some key points for the preparation of abrasive wheel risk assessment, and for the complete editable word format by just clicking the link at the end of. There are five main steps involved in conducting. Polishing Wheel Risk Assessment.

From safeti.com

Angle Grinder Risk Assessment Download PLUS Training Polishing Wheel Risk Assessment Following are some key points for the preparation of abrasive wheel risk assessment, and for the complete editable word format by just clicking the link at the end of. There are five main steps involved in conducting an effective abrasive wheel risk assessment: Decide who might be harmed and how. This guide will focus on four principal hazards associated with. Polishing Wheel Risk Assessment.

From www.scribd.com

Abrasive Wheels Risk Assessment Download Free PDF Risk Assessment Risk Polishing Wheel Risk Assessment Decide who might be harmed and how. This guide will focus on four principal hazards associated with the use of abrasives in the workplace and. There are five main steps involved in conducting an effective abrasive wheel risk assessment: Use, care and protection of abrasive wheels 1 scope and definitions 1.1 scope this safety standard sets forth requirements for the. Polishing Wheel Risk Assessment.

From technologystudent.com

The Polishing Machine Health and Safety Polishing Wheel Risk Assessment In addition to looking at essential training needs, the guide also focuses on details such as: There are five main steps involved in conducting an effective abrasive wheel risk assessment: Use, care and protection of abrasive wheels 1 scope and definitions 1.1 scope this safety standard sets forth requirements for the safe. Check abrasive wheels and discs. An abrasive wheel. Polishing Wheel Risk Assessment.