Pump Cost Calculator . The pump sizing calculator was developed by oilgas engineers, a professional engineer and pump expert. To calculate the cost of running your pump, we need two figures: The calculator will take into account the energy. It is the best tool for pump station. The energy cost per hour for pumping water can be calculated in imperial units as. Calculate the energy cost of pumping water. Understanding a pump system’s energy cost requires more than simply evaluating the pump, motor, and drive. The number of kilowatt hours per m³ of liquid, and. Kilowatt hours per m³ of liquid. New equipment savings per hour (usd) $ new equipment savings cost (usd) $ Simply input data including initial pump costs, installation costs and annual recurring costs such as maintenance. A detailed tutorial on calculating water pumping costs based on volume flow rate, pump head, cost rate, pump efficiency, and motor efficiency.

from lavoniatrotter.blogspot.com

The pump sizing calculator was developed by oilgas engineers, a professional engineer and pump expert. Calculate the energy cost of pumping water. To calculate the cost of running your pump, we need two figures: Understanding a pump system’s energy cost requires more than simply evaluating the pump, motor, and drive. New equipment savings per hour (usd) $ new equipment savings cost (usd) $ Kilowatt hours per m³ of liquid. The number of kilowatt hours per m³ of liquid, and. A detailed tutorial on calculating water pumping costs based on volume flow rate, pump head, cost rate, pump efficiency, and motor efficiency. The energy cost per hour for pumping water can be calculated in imperial units as. Simply input data including initial pump costs, installation costs and annual recurring costs such as maintenance.

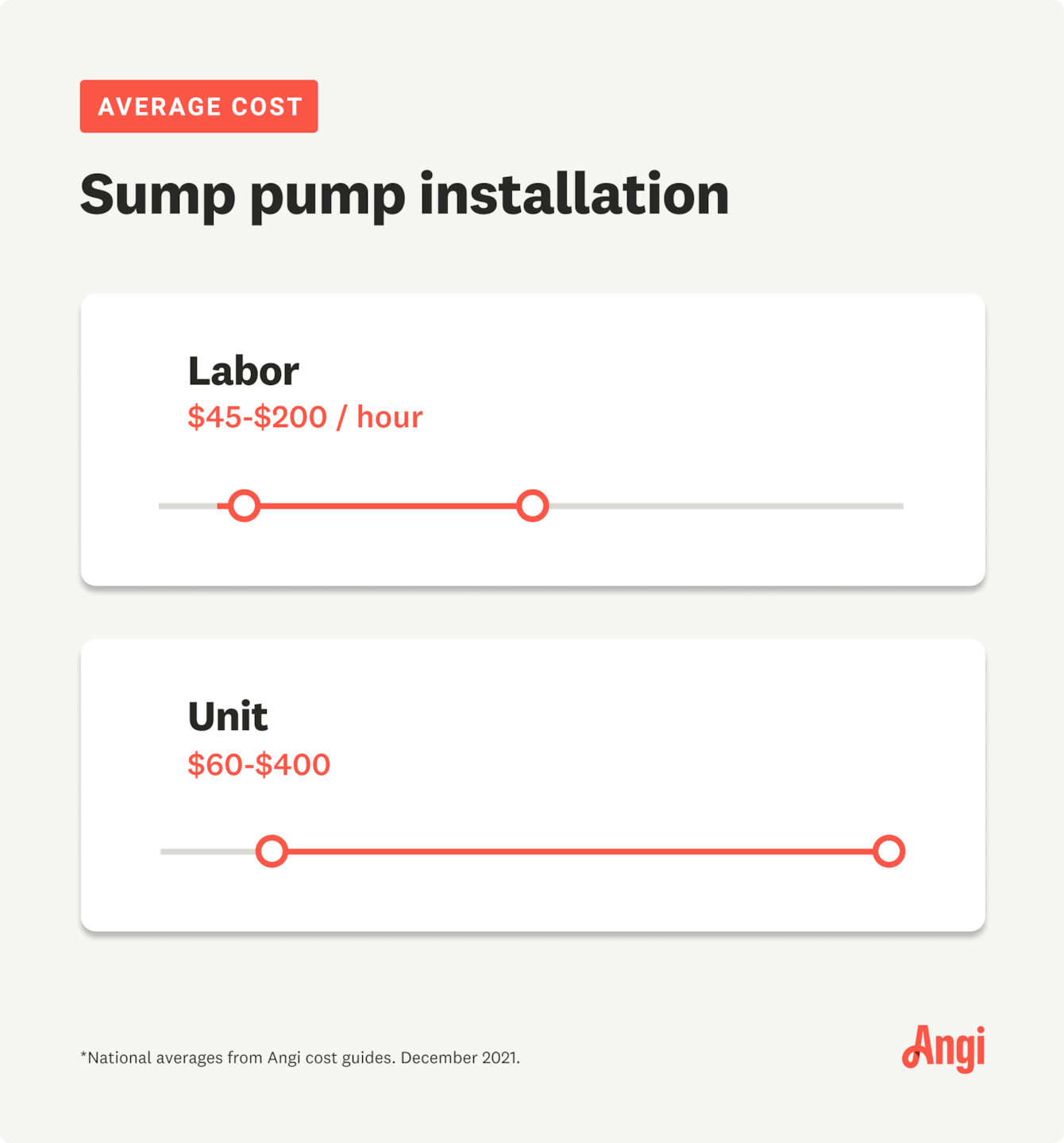

what is the average cost of a sump pump installation Elissa Agee

Pump Cost Calculator The pump sizing calculator was developed by oilgas engineers, a professional engineer and pump expert. Understanding a pump system’s energy cost requires more than simply evaluating the pump, motor, and drive. To calculate the cost of running your pump, we need two figures: It is the best tool for pump station. Simply input data including initial pump costs, installation costs and annual recurring costs such as maintenance. Kilowatt hours per m³ of liquid. The pump sizing calculator was developed by oilgas engineers, a professional engineer and pump expert. Calculate the energy cost of pumping water. The energy cost per hour for pumping water can be calculated in imperial units as. The calculator will take into account the energy. The number of kilowatt hours per m³ of liquid, and. A detailed tutorial on calculating water pumping costs based on volume flow rate, pump head, cost rate, pump efficiency, and motor efficiency. New equipment savings per hour (usd) $ new equipment savings cost (usd) $

From www.scribd.com

Pump_Calculator PDF Pump Cost Calculator To calculate the cost of running your pump, we need two figures: Calculate the energy cost of pumping water. A detailed tutorial on calculating water pumping costs based on volume flow rate, pump head, cost rate, pump efficiency, and motor efficiency. Simply input data including initial pump costs, installation costs and annual recurring costs such as maintenance. Kilowatt hours per. Pump Cost Calculator.

From www.scribd.com

Pump Sizing Calculator Guide PDF Pump Reynolds Number Pump Cost Calculator A detailed tutorial on calculating water pumping costs based on volume flow rate, pump head, cost rate, pump efficiency, and motor efficiency. Calculate the energy cost of pumping water. The pump sizing calculator was developed by oilgas engineers, a professional engineer and pump expert. Simply input data including initial pump costs, installation costs and annual recurring costs such as maintenance.. Pump Cost Calculator.

From calculatorshub.net

Slurry Pump Calculator Online Pump Cost Calculator The number of kilowatt hours per m³ of liquid, and. Calculate the energy cost of pumping water. It is the best tool for pump station. The calculator will take into account the energy. The energy cost per hour for pumping water can be calculated in imperial units as. The pump sizing calculator was developed by oilgas engineers, a professional engineer. Pump Cost Calculator.

From www.youtube.com

Pump Chart Basics Explained Pump curve HVACR YouTube Pump Cost Calculator Simply input data including initial pump costs, installation costs and annual recurring costs such as maintenance. The calculator will take into account the energy. Calculate the energy cost of pumping water. To calculate the cost of running your pump, we need two figures: The energy cost per hour for pumping water can be calculated in imperial units as. Kilowatt hours. Pump Cost Calculator.

From theengineeringmindset.com

Pump calculations The Engineering Mindset Pump Cost Calculator Understanding a pump system’s energy cost requires more than simply evaluating the pump, motor, and drive. New equipment savings per hour (usd) $ new equipment savings cost (usd) $ Simply input data including initial pump costs, installation costs and annual recurring costs such as maintenance. To calculate the cost of running your pump, we need two figures: The pump sizing. Pump Cost Calculator.

From engineeringxls.blogspot.com

Engineeringxls Sump Pump Excel Sheet Calculation Pump Cost Calculator Kilowatt hours per m³ of liquid. Calculate the energy cost of pumping water. The pump sizing calculator was developed by oilgas engineers, a professional engineer and pump expert. The number of kilowatt hours per m³ of liquid, and. To calculate the cost of running your pump, we need two figures: Simply input data including initial pump costs, installation costs and. Pump Cost Calculator.

From www.scribd.com

VSD Calculator for Pumps Energy and Cost Savings Analysis Tool PDF Horsepower Kilowatt Hour Pump Cost Calculator The energy cost per hour for pumping water can be calculated in imperial units as. To calculate the cost of running your pump, we need two figures: It is the best tool for pump station. Calculate the energy cost of pumping water. Simply input data including initial pump costs, installation costs and annual recurring costs such as maintenance. Understanding a. Pump Cost Calculator.

From www.waterworld.com

Pump cost calculator WaterWorld Pump Cost Calculator The energy cost per hour for pumping water can be calculated in imperial units as. The number of kilowatt hours per m³ of liquid, and. Kilowatt hours per m³ of liquid. New equipment savings per hour (usd) $ new equipment savings cost (usd) $ To calculate the cost of running your pump, we need two figures: Understanding a pump system’s. Pump Cost Calculator.

From aynslierogan.blogspot.com

23+ Calculating Hydraulic Horsepower AynslieRogan Pump Cost Calculator It is the best tool for pump station. To calculate the cost of running your pump, we need two figures: Kilowatt hours per m³ of liquid. Calculate the energy cost of pumping water. The energy cost per hour for pumping water can be calculated in imperial units as. Understanding a pump system’s energy cost requires more than simply evaluating the. Pump Cost Calculator.

From sanitaryfittings.us

How to Calculate Pump Flow Rate A StepbyStep Guide Sanitary Fittings Pump Cost Calculator The energy cost per hour for pumping water can be calculated in imperial units as. New equipment savings per hour (usd) $ new equipment savings cost (usd) $ Calculate the energy cost of pumping water. The number of kilowatt hours per m³ of liquid, and. Understanding a pump system’s energy cost requires more than simply evaluating the pump, motor, and. Pump Cost Calculator.

From www.pumpsandsystems.com

A StepbyStep Approach to Pump Selection Pumps & Systems Pump Cost Calculator The energy cost per hour for pumping water can be calculated in imperial units as. Simply input data including initial pump costs, installation costs and annual recurring costs such as maintenance. It is the best tool for pump station. The number of kilowatt hours per m³ of liquid, and. To calculate the cost of running your pump, we need two. Pump Cost Calculator.

From www.pumps.org

Pump Savings Calculator Updated Version Released and How to Calculate Energy Pump Cost Calculator Simply input data including initial pump costs, installation costs and annual recurring costs such as maintenance. The pump sizing calculator was developed by oilgas engineers, a professional engineer and pump expert. The calculator will take into account the energy. The number of kilowatt hours per m³ of liquid, and. A detailed tutorial on calculating water pumping costs based on volume. Pump Cost Calculator.

From chesheets.com

Pump Sizing Calculation Spreadsheet Pump Cost Calculator It is the best tool for pump station. Kilowatt hours per m³ of liquid. The number of kilowatt hours per m³ of liquid, and. Understanding a pump system’s energy cost requires more than simply evaluating the pump, motor, and drive. To calculate the cost of running your pump, we need two figures: The pump sizing calculator was developed by oilgas. Pump Cost Calculator.

From calculator.academy

Heat Pump Operating Cost Calculator Calculator Academy Pump Cost Calculator The number of kilowatt hours per m³ of liquid, and. New equipment savings per hour (usd) $ new equipment savings cost (usd) $ Understanding a pump system’s energy cost requires more than simply evaluating the pump, motor, and drive. Kilowatt hours per m³ of liquid. The energy cost per hour for pumping water can be calculated in imperial units as.. Pump Cost Calculator.

From www.mepengineersclub.com

Pump Calculations, Flow Rate, RPM, Head Pressure, & Impeller Diameter Pump Cost Calculator The pump sizing calculator was developed by oilgas engineers, a professional engineer and pump expert. Kilowatt hours per m³ of liquid. Simply input data including initial pump costs, installation costs and annual recurring costs such as maintenance. Understanding a pump system’s energy cost requires more than simply evaluating the pump, motor, and drive. It is the best tool for pump. Pump Cost Calculator.

From calculatorshub.net

Pump Efficiency Calculator Online Pump Cost Calculator The number of kilowatt hours per m³ of liquid, and. Understanding a pump system’s energy cost requires more than simply evaluating the pump, motor, and drive. The pump sizing calculator was developed by oilgas engineers, a professional engineer and pump expert. To calculate the cost of running your pump, we need two figures: Calculate the energy cost of pumping water.. Pump Cost Calculator.

From www.engproguides.com

Chilled Water Pump Calculator, Quickly Size and Select your Chilled Water Pump Design Tools Pump Cost Calculator To calculate the cost of running your pump, we need two figures: The calculator will take into account the energy. The number of kilowatt hours per m³ of liquid, and. Calculate the energy cost of pumping water. The pump sizing calculator was developed by oilgas engineers, a professional engineer and pump expert. Simply input data including initial pump costs, installation. Pump Cost Calculator.

From www.mepengineersclub.com

Pump Sizing Calculation Sheet Download Pump Cost Calculator To calculate the cost of running your pump, we need two figures: Calculate the energy cost of pumping water. A detailed tutorial on calculating water pumping costs based on volume flow rate, pump head, cost rate, pump efficiency, and motor efficiency. The calculator will take into account the energy. Understanding a pump system’s energy cost requires more than simply evaluating. Pump Cost Calculator.

From www.waterworld.com

Pump cost calculator WaterWorld Pump Cost Calculator Calculate the energy cost of pumping water. It is the best tool for pump station. To calculate the cost of running your pump, we need two figures: The pump sizing calculator was developed by oilgas engineers, a professional engineer and pump expert. The number of kilowatt hours per m³ of liquid, and. Kilowatt hours per m³ of liquid. The energy. Pump Cost Calculator.

From empoweringpumps.com

Pump Pros Know Calculate Pump System Energy Costs Empowering Pumps and Equipment Pump Cost Calculator To calculate the cost of running your pump, we need two figures: Kilowatt hours per m³ of liquid. Simply input data including initial pump costs, installation costs and annual recurring costs such as maintenance. A detailed tutorial on calculating water pumping costs based on volume flow rate, pump head, cost rate, pump efficiency, and motor efficiency. The energy cost per. Pump Cost Calculator.

From theengineeringmindset.com

Pump calculations The Engineering Mindset Pump Cost Calculator It is the best tool for pump station. The energy cost per hour for pumping water can be calculated in imperial units as. To calculate the cost of running your pump, we need two figures: A detailed tutorial on calculating water pumping costs based on volume flow rate, pump head, cost rate, pump efficiency, and motor efficiency. Simply input data. Pump Cost Calculator.

From calculatorshub.net

Peristaltic Pump Calculator Online Pump Cost Calculator The calculator will take into account the energy. To calculate the cost of running your pump, we need two figures: Calculate the energy cost of pumping water. Understanding a pump system’s energy cost requires more than simply evaluating the pump, motor, and drive. Kilowatt hours per m³ of liquid. New equipment savings per hour (usd) $ new equipment savings cost. Pump Cost Calculator.

From inventory.powerzone.com

Power Zone Calculators Pump Engineering Calculators Pump Cost Calculator Simply input data including initial pump costs, installation costs and annual recurring costs such as maintenance. A detailed tutorial on calculating water pumping costs based on volume flow rate, pump head, cost rate, pump efficiency, and motor efficiency. Calculate the energy cost of pumping water. The pump sizing calculator was developed by oilgas engineers, a professional engineer and pump expert.. Pump Cost Calculator.

From estimatorflorida.com

Heat Pump Installation Cost Calculator and Estimator Estimate Florida Consulting Pump Cost Calculator Calculate the energy cost of pumping water. Understanding a pump system’s energy cost requires more than simply evaluating the pump, motor, and drive. A detailed tutorial on calculating water pumping costs based on volume flow rate, pump head, cost rate, pump efficiency, and motor efficiency. Kilowatt hours per m³ of liquid. The number of kilowatt hours per m³ of liquid,. Pump Cost Calculator.

From www.youtube.com

Free Calculator to easily design water pump size in a couple of seconds (get apps from comment Pump Cost Calculator New equipment savings per hour (usd) $ new equipment savings cost (usd) $ To calculate the cost of running your pump, we need two figures: The calculator will take into account the energy. Kilowatt hours per m³ of liquid. A detailed tutorial on calculating water pumping costs based on volume flow rate, pump head, cost rate, pump efficiency, and motor. Pump Cost Calculator.

From pondanswers.com

Pond Pump Running Cost Calculator Estimate Your Pond Expenses Pump Cost Calculator The pump sizing calculator was developed by oilgas engineers, a professional engineer and pump expert. Calculate the energy cost of pumping water. Understanding a pump system’s energy cost requires more than simply evaluating the pump, motor, and drive. A detailed tutorial on calculating water pumping costs based on volume flow rate, pump head, cost rate, pump efficiency, and motor efficiency.. Pump Cost Calculator.

From www.achrnews.com

The Secret to Energy and Cost Savings Pump System Evaluation 20201008 ACHR News Pump Cost Calculator The pump sizing calculator was developed by oilgas engineers, a professional engineer and pump expert. The calculator will take into account the energy. Kilowatt hours per m³ of liquid. To calculate the cost of running your pump, we need two figures: The energy cost per hour for pumping water can be calculated in imperial units as. Calculate the energy cost. Pump Cost Calculator.

From www.remodelingcalculator.org

2023 Heat Pump Cost Calculator Estimate The Cost To Install A Heat Pump Pump Cost Calculator The pump sizing calculator was developed by oilgas engineers, a professional engineer and pump expert. The number of kilowatt hours per m³ of liquid, and. The calculator will take into account the energy. It is the best tool for pump station. The energy cost per hour for pumping water can be calculated in imperial units as. To calculate the cost. Pump Cost Calculator.

From www.researchgate.net

CALCULATION OF TOTAL COST A 5 HP SOLAR PUMP Download Table Pump Cost Calculator To calculate the cost of running your pump, we need two figures: The pump sizing calculator was developed by oilgas engineers, a professional engineer and pump expert. The energy cost per hour for pumping water can be calculated in imperial units as. Calculate the energy cost of pumping water. Simply input data including initial pump costs, installation costs and annual. Pump Cost Calculator.

From chemicalprocessengineering.com

Centrifugal Pump Calculation Excel Template Pump Cost Calculator Simply input data including initial pump costs, installation costs and annual recurring costs such as maintenance. The calculator will take into account the energy. To calculate the cost of running your pump, we need two figures: Understanding a pump system’s energy cost requires more than simply evaluating the pump, motor, and drive. Calculate the energy cost of pumping water. The. Pump Cost Calculator.

From www.engtank.com

Pump Calculation Spreadsheet Standard EngTank Pump Cost Calculator It is the best tool for pump station. Calculate the energy cost of pumping water. The number of kilowatt hours per m³ of liquid, and. The calculator will take into account the energy. The energy cost per hour for pumping water can be calculated in imperial units as. The pump sizing calculator was developed by oilgas engineers, a professional engineer. Pump Cost Calculator.

From www.pumpsandsystems.com

How to Define & Measure Centrifugal Pump Efficiency Part 1 Pumps & Systems Pump Cost Calculator Kilowatt hours per m³ of liquid. New equipment savings per hour (usd) $ new equipment savings cost (usd) $ The pump sizing calculator was developed by oilgas engineers, a professional engineer and pump expert. The calculator will take into account the energy. A detailed tutorial on calculating water pumping costs based on volume flow rate, pump head, cost rate, pump. Pump Cost Calculator.

From calculator.academy

Pump Efficiency Calculator Calculator Academy Pump Cost Calculator The pump sizing calculator was developed by oilgas engineers, a professional engineer and pump expert. A detailed tutorial on calculating water pumping costs based on volume flow rate, pump head, cost rate, pump efficiency, and motor efficiency. The number of kilowatt hours per m³ of liquid, and. To calculate the cost of running your pump, we need two figures: New. Pump Cost Calculator.

From lavoniatrotter.blogspot.com

what is the average cost of a sump pump installation Elissa Agee Pump Cost Calculator The number of kilowatt hours per m³ of liquid, and. The pump sizing calculator was developed by oilgas engineers, a professional engineer and pump expert. Calculate the energy cost of pumping water. Understanding a pump system’s energy cost requires more than simply evaluating the pump, motor, and drive. New equipment savings per hour (usd) $ new equipment savings cost (usd). Pump Cost Calculator.

From www.furnaceprices.ca

HVAC Calculators FurnacePrices.ca Pump Cost Calculator The number of kilowatt hours per m³ of liquid, and. Simply input data including initial pump costs, installation costs and annual recurring costs such as maintenance. The energy cost per hour for pumping water can be calculated in imperial units as. New equipment savings per hour (usd) $ new equipment savings cost (usd) $ The calculator will take into account. Pump Cost Calculator.