Mig Welding Copper Wire . to achieve the best results, select a welding wire specifically designed for copper applications. This wire is typically composed of a. mig welding uses a consumable wire electrode and a shielding gas, usually argon, to create an arc that melts the copper and filler material. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. copper mig (metal inert gas) wire provides filler metal for welding copper and other compatible metals. mig welding offers several distinct advantages when applied to copper. The process allows for high deposition rates, enabling efficient and.

from www.alibaba.com

to achieve the best results, select a welding wire specifically designed for copper applications. This wire is typically composed of a. The process allows for high deposition rates, enabling efficient and. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. mig welding offers several distinct advantages when applied to copper. mig welding uses a consumable wire electrode and a shielding gas, usually argon, to create an arc that melts the copper and filler material. copper mig (metal inert gas) wire provides filler metal for welding copper and other compatible metals.

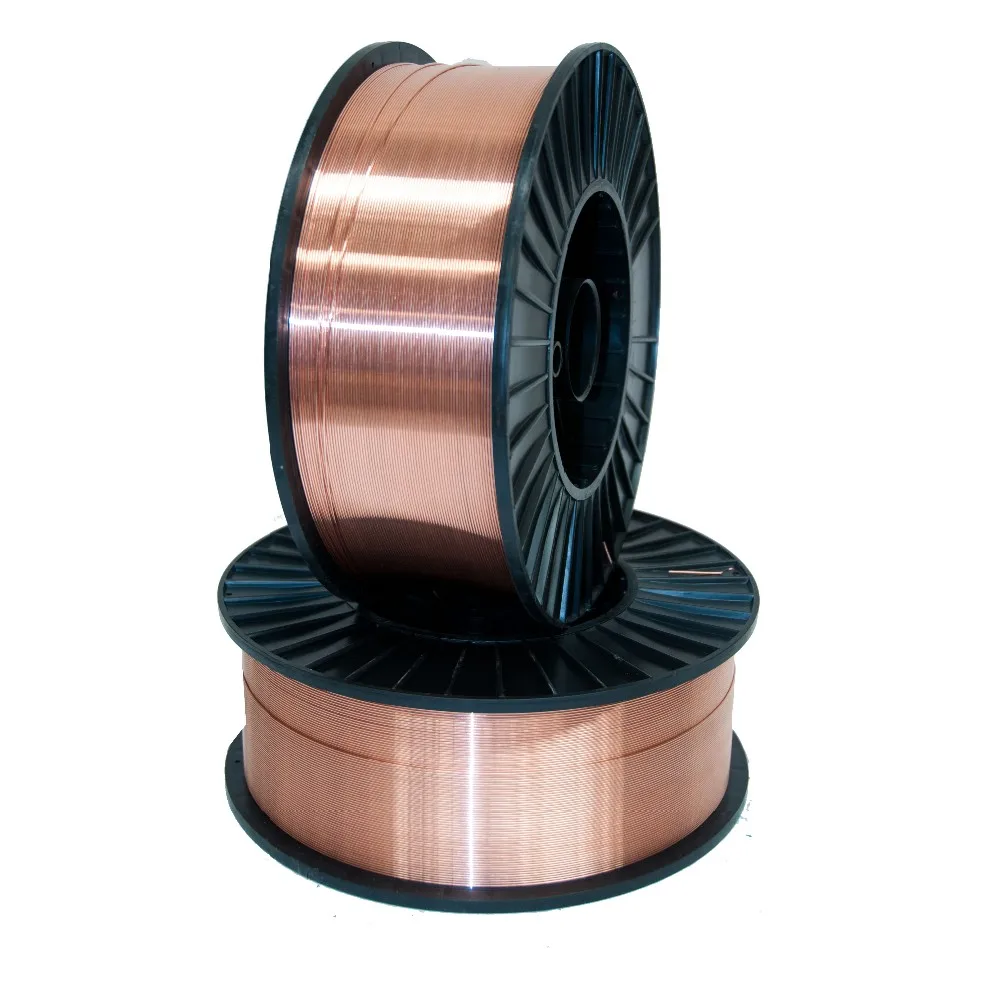

Mig Wire Er70s6 Welding Wire 1.2mm Buy Mig Welding Wire 1.2mm,Copper

Mig Welding Copper Wire the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. mig welding uses a consumable wire electrode and a shielding gas, usually argon, to create an arc that melts the copper and filler material. copper mig (metal inert gas) wire provides filler metal for welding copper and other compatible metals. The process allows for high deposition rates, enabling efficient and. to achieve the best results, select a welding wire specifically designed for copper applications. This wire is typically composed of a. mig welding offers several distinct advantages when applied to copper.

From www.indiamart.com

Copper/Copper Alloy CO2 MIG Welding Wire, Thickness 0.5mm, Packaging Mig Welding Copper Wire mig welding uses a consumable wire electrode and a shielding gas, usually argon, to create an arc that melts the copper and filler material. mig welding offers several distinct advantages when applied to copper. copper mig (metal inert gas) wire provides filler metal for welding copper and other compatible metals. to achieve the best results, select. Mig Welding Copper Wire.

From arcwelders.co.za

MIG Wire ER70S6 Mild Steel 15kg MIG Spools Mig Welding Copper Wire This wire is typically composed of a. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. to achieve the best results, select a welding wire specifically designed for copper applications. The process allows for high deposition rates, enabling efficient and. mig welding uses a consumable wire electrode. Mig Welding Copper Wire.

From eshop.wurth.co.uk

Buy MIG welding wire SG2, fixed reel online Mig Welding Copper Wire This wire is typically composed of a. mig welding uses a consumable wire electrode and a shielding gas, usually argon, to create an arc that melts the copper and filler material. to achieve the best results, select a welding wire specifically designed for copper applications. the most commonly used aluminum mig wires are er5056, a soft wire. Mig Welding Copper Wire.

From cnatlantic.en.made-in-china.com

Atlantic Ercusia MIG Wire for Copper Welding Wire Solid Wires China Mig Welding Copper Wire the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. mig welding uses a consumable wire electrode and a shielding gas, usually argon, to create an arc that melts the copper and filler material. mig welding offers several distinct advantages when applied to copper. The process allows for. Mig Welding Copper Wire.

From www.indiamart.com

1 mm LC Mig Welding Wire at Rs 84/kg LC Welding Wires in Hosur ID Mig Welding Copper Wire mig welding uses a consumable wire electrode and a shielding gas, usually argon, to create an arc that melts the copper and filler material. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. The process allows for high deposition rates, enabling efficient and. copper mig (metal inert. Mig Welding Copper Wire.

From toolsfromus.com

POWERCRAFT MIG WIRE 15KG SOLID COPPER WELDING Tools From Us Mig Welding Copper Wire mig welding uses a consumable wire electrode and a shielding gas, usually argon, to create an arc that melts the copper and filler material. This wire is typically composed of a. to achieve the best results, select a welding wire specifically designed for copper applications. The process allows for high deposition rates, enabling efficient and. copper mig. Mig Welding Copper Wire.

From www.indiamart.com

Copper MIG Welding Wire, 0.8 Mm, Rs 94/unit Uniweld Electrodes ID Mig Welding Copper Wire the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. mig welding offers several distinct advantages when applied to copper. The process allows for high deposition rates, enabling efficient and. to achieve the best results, select a welding wire specifically designed for copper applications. mig welding uses. Mig Welding Copper Wire.

From htwelding888.en.made-in-china.com

Weld MIG Wire Heat Resistance Brazed Copper Wire for Welding China Mig Welding Copper Wire copper mig (metal inert gas) wire provides filler metal for welding copper and other compatible metals. This wire is typically composed of a. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. to achieve the best results, select a welding wire specifically designed for copper applications. . Mig Welding Copper Wire.

From www.alibaba.com

Mig Wire Er70s6 Welding Wire 1.2mm Buy Mig Welding Wire 1.2mm,Copper Mig Welding Copper Wire mig welding uses a consumable wire electrode and a shielding gas, usually argon, to create an arc that melts the copper and filler material. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. The process allows for high deposition rates, enabling efficient and. This wire is typically composed. Mig Welding Copper Wire.

From www.grainger.com

WESTWARD, Copper, ERCuSiA, MIG Welding Wire 41R32241R322 Grainger Mig Welding Copper Wire the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. The process allows for high deposition rates, enabling efficient and. This wire is typically composed of a. mig welding offers several distinct advantages when applied to copper. to achieve the best results, select a welding wire specifically designed. Mig Welding Copper Wire.

From www.katariyasteel.com

ER70S6 MIG Welding Wire Supplier, Stockist in UAE Mig Welding Copper Wire the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. copper mig (metal inert gas) wire provides filler metal for welding copper and other compatible metals. to achieve the best results, select a welding wire specifically designed for copper applications. mig welding offers several distinct advantages when. Mig Welding Copper Wire.

From aipweldingsupplies.co.uk

C11 Copper Mig Wire AIP Welding Mig Welding Copper Wire mig welding offers several distinct advantages when applied to copper. The process allows for high deposition rates, enabling efficient and. copper mig (metal inert gas) wire provides filler metal for welding copper and other compatible metals. to achieve the best results, select a welding wire specifically designed for copper applications. This wire is typically composed of a.. Mig Welding Copper Wire.

From ratemywelder.com

Best MIG Welding Wire Reviews (2023) For Mild Steel & More Mig Welding Copper Wire mig welding uses a consumable wire electrode and a shielding gas, usually argon, to create an arc that melts the copper and filler material. This wire is typically composed of a. copper mig (metal inert gas) wire provides filler metal for welding copper and other compatible metals. to achieve the best results, select a welding wire specifically. Mig Welding Copper Wire.

From www.katariyasteel.com

ER70S6 MIG Welding Wire Supplier, Stockist in Qatar Mig Welding Copper Wire mig welding offers several distinct advantages when applied to copper. to achieve the best results, select a welding wire specifically designed for copper applications. This wire is typically composed of a. copper mig (metal inert gas) wire provides filler metal for welding copper and other compatible metals. the most commonly used aluminum mig wires are er5056,. Mig Welding Copper Wire.

From weldingireland.ie

SUPER 6 HF600 1.2MM Solid Hardfacing Mig Wire 15kg Welding and Mig Welding Copper Wire The process allows for high deposition rates, enabling efficient and. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. mig welding offers several distinct advantages when applied to copper. mig welding uses a consumable wire electrode and a shielding gas, usually argon, to create an arc that. Mig Welding Copper Wire.

From www.northerntool.com

Lincoln Electric SuperArc L56 MIG Welding Wire — Mild Steel, Copper Mig Welding Copper Wire the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. This wire is typically composed of a. to achieve the best results, select a welding wire specifically designed for copper applications. mig welding offers several distinct advantages when applied to copper. The process allows for high deposition rates,. Mig Welding Copper Wire.

From www.manomano.co.uk

Wolf 0.8mm Welding Wire Copper Coated Spool For MIGs Pack of 2 Mig Welding Copper Wire to achieve the best results, select a welding wire specifically designed for copper applications. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. This wire is typically composed of a. mig welding offers several distinct advantages when applied to copper. mig welding uses a consumable wire. Mig Welding Copper Wire.

From www.xcelarc.nz

XcelArc ER100SG High Tensile MIG Wire XcelArc® Welding Supplies Mig Welding Copper Wire the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. copper mig (metal inert gas) wire provides filler metal for welding copper and other compatible metals. to achieve the best results, select a welding wire specifically designed for copper applications. mig welding offers several distinct advantages when. Mig Welding Copper Wire.

From www.sssteelplate.com

Copper Coated 1.2mm Thickness Co2 Mig Welding Wire Mig Welding Copper Wire The process allows for high deposition rates, enabling efficient and. mig welding offers several distinct advantages when applied to copper. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. mig welding uses a consumable wire electrode and a shielding gas, usually argon, to create an arc that. Mig Welding Copper Wire.

From fitwelding.com

MIG Welding Copper Common Mistakes to Avoid When Welding Fit Welding Mig Welding Copper Wire mig welding offers several distinct advantages when applied to copper. to achieve the best results, select a welding wire specifically designed for copper applications. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. copper mig (metal inert gas) wire provides filler metal for welding copper and. Mig Welding Copper Wire.

From weldguru.com

Best MIG Welding Wire 2024 Top Picks & Reviews Mig Welding Copper Wire mig welding offers several distinct advantages when applied to copper. copper mig (metal inert gas) wire provides filler metal for welding copper and other compatible metals. This wire is typically composed of a. to achieve the best results, select a welding wire specifically designed for copper applications. mig welding uses a consumable wire electrode and a. Mig Welding Copper Wire.

From www.electroweld.com.au

Cigweld Mig Welding Wire 0.9Mm 13Kg Autocraft Silicon Copper Alloy Gmaw Mig Welding Copper Wire mig welding offers several distinct advantages when applied to copper. The process allows for high deposition rates, enabling efficient and. copper mig (metal inert gas) wire provides filler metal for welding copper and other compatible metals. This wire is typically composed of a. mig welding uses a consumable wire electrode and a shielding gas, usually argon, to. Mig Welding Copper Wire.

From www.aliexpress.com

2 5 10 Silver Copper Phosphorus Brazing Rods bar mig tig welding Mig Welding Copper Wire mig welding uses a consumable wire electrode and a shielding gas, usually argon, to create an arc that melts the copper and filler material. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. to achieve the best results, select a welding wire specifically designed for copper applications.. Mig Welding Copper Wire.

From www.indiamart.com

Bharani Copper/Copper Alloy 1 mm CO2 MIG Welding Wire at Rs 85/kg in Mig Welding Copper Wire to achieve the best results, select a welding wire specifically designed for copper applications. copper mig (metal inert gas) wire provides filler metal for welding copper and other compatible metals. mig welding offers several distinct advantages when applied to copper. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and. Mig Welding Copper Wire.

From www.indiamart.com

Copper MIG Welding Wire, Thickness 0.020 inch at Rs 90/unit in Chennai Mig Welding Copper Wire copper mig (metal inert gas) wire provides filler metal for welding copper and other compatible metals. This wire is typically composed of a. to achieve the best results, select a welding wire specifically designed for copper applications. mig welding uses a consumable wire electrode and a shielding gas, usually argon, to create an arc that melts the. Mig Welding Copper Wire.

From www.indiamart.com

0.8mm Copper MIG Welding Wire at Rs 90/kg MIG Wire in Rajkot ID Mig Welding Copper Wire the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. copper mig (metal inert gas) wire provides filler metal for welding copper and other compatible metals. The process allows for high deposition rates, enabling efficient and. This wire is typically composed of a. mig welding uses a consumable. Mig Welding Copper Wire.

From www.longtengspecialsteel.com

CO2 Copper Coated Mig Welding Wire 1.6mm 1.2mm 1.0mm GMAW SV08G2S Mig Welding Copper Wire the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. copper mig (metal inert gas) wire provides filler metal for welding copper and other compatible metals. mig welding offers several distinct advantages when applied to copper. This wire is typically composed of a. mig welding uses a. Mig Welding Copper Wire.

From www.grainger.com

WESTWARD MIG Welding Wire Copper, ERCuSiA, 0.035 in, 2 lb 41R322 Mig Welding Copper Wire to achieve the best results, select a welding wire specifically designed for copper applications. This wire is typically composed of a. The process allows for high deposition rates, enabling efficient and. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. mig welding offers several distinct advantages when. Mig Welding Copper Wire.

From systematicltd.com

CO2 Mig Welding Wire Manufacturers In India Systematic Ltd Mig Welding Copper Wire mig welding uses a consumable wire electrode and a shielding gas, usually argon, to create an arc that melts the copper and filler material. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. mig welding offers several distinct advantages when applied to copper. copper mig (metal. Mig Welding Copper Wire.

From dir.indiamart.com

CO2 MIG Welding Wire in Nashik, Maharashtra CO2 MIG Welding Wire Mig Welding Copper Wire mig welding offers several distinct advantages when applied to copper. This wire is typically composed of a. mig welding uses a consumable wire electrode and a shielding gas, usually argon, to create an arc that melts the copper and filler material. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and. Mig Welding Copper Wire.

From www.indiamart.com

Best 1.2 Mm Mig Welding Wire at Rs 1200/box in Jaipur ID 23897016548 Mig Welding Copper Wire mig welding uses a consumable wire electrode and a shielding gas, usually argon, to create an arc that melts the copper and filler material. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. mig welding offers several distinct advantages when applied to copper. copper mig (metal. Mig Welding Copper Wire.

From m10weldnutgosaika.blogspot.com

M10 Weld Nut Copper Mig Welding Mig Welding Copper Wire mig welding offers several distinct advantages when applied to copper. mig welding uses a consumable wire electrode and a shielding gas, usually argon, to create an arc that melts the copper and filler material. This wire is typically composed of a. copper mig (metal inert gas) wire provides filler metal for welding copper and other compatible metals.. Mig Welding Copper Wire.

From www.tradeindia.com

Copper/copper Alloy Mig Welding Wire at Best Price in Mumbai Fortran Mig Welding Copper Wire copper mig (metal inert gas) wire provides filler metal for welding copper and other compatible metals. to achieve the best results, select a welding wire specifically designed for copper applications. mig welding uses a consumable wire electrode and a shielding gas, usually argon, to create an arc that melts the copper and filler material. the most. Mig Welding Copper Wire.

From www.venkateshwire.com

CO2 MIG Welding Wire CO2 MIG Welding Wire For Steel fabrication Mig Welding Copper Wire mig welding uses a consumable wire electrode and a shielding gas, usually argon, to create an arc that melts the copper and filler material. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is. mig welding offers several distinct advantages when applied to copper. copper mig (metal. Mig Welding Copper Wire.

From welding-rods.en.made-in-china.com

Toko 1.2mm 20kg Per Spool Er70s6 Copper Alloy MIG Welding Wires Mig Welding Copper Wire mig welding uses a consumable wire electrode and a shielding gas, usually argon, to create an arc that melts the copper and filler material. This wire is typically composed of a. copper mig (metal inert gas) wire provides filler metal for welding copper and other compatible metals. to achieve the best results, select a welding wire specifically. Mig Welding Copper Wire.