Soldered Joint Method . In electronics, solder joints are typically used to connect electrical components such as resistors, capacitors, and integrated circuits to printed circuit boards (pcbs). This versatile technique can be applied to a variety of materials and is commonly used in electronics for its ability to create reliable connections. Understanding the microstructure and composition of solder joint is crucial in designing reliable joints, optimizing soldering. In this chapter, we evaluate the reliability of the produced solder. In essence, soldering joints is the process of melting and cooling a wire or strip of metal to create a strong bond between two surfaces, often without the use of screws or other fasteners. The formation of a solder joint is made possible by (i) introducing fluxing agents to remove the oxide layer present on metal surfaces and (ii). Solder joint is the dominant failure mechanism in solder joint interconnections. The process involves heating the solder to its melting point using a soldering iron or a soldering gun. The characteristics of these three elements—component, substrate, and solder joint—together with the use conditions, the.

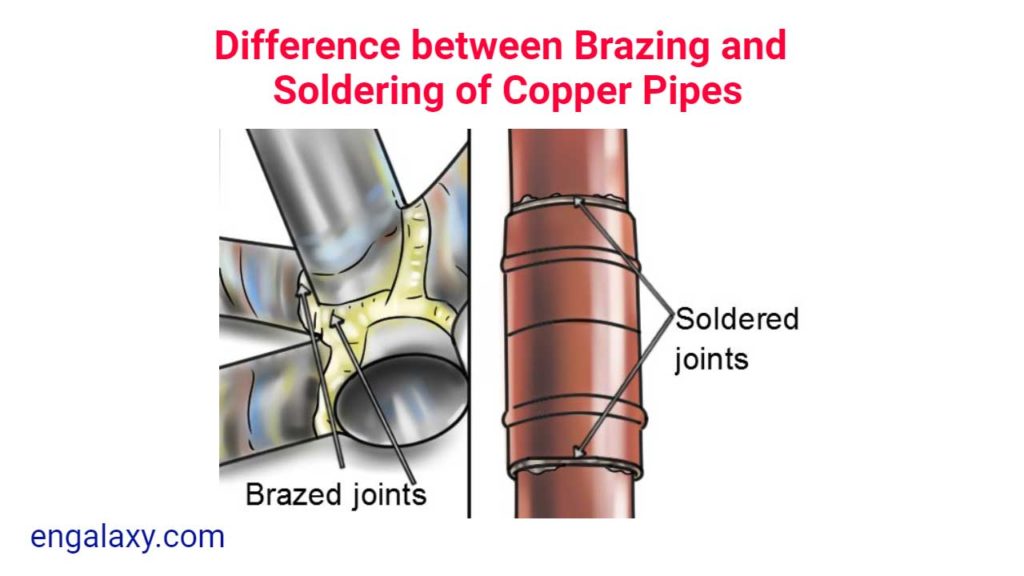

from engalaxy.com

This versatile technique can be applied to a variety of materials and is commonly used in electronics for its ability to create reliable connections. The characteristics of these three elements—component, substrate, and solder joint—together with the use conditions, the. In essence, soldering joints is the process of melting and cooling a wire or strip of metal to create a strong bond between two surfaces, often without the use of screws or other fasteners. Solder joint is the dominant failure mechanism in solder joint interconnections. In electronics, solder joints are typically used to connect electrical components such as resistors, capacitors, and integrated circuits to printed circuit boards (pcbs). In this chapter, we evaluate the reliability of the produced solder. The formation of a solder joint is made possible by (i) introducing fluxing agents to remove the oxide layer present on metal surfaces and (ii). The process involves heating the solder to its melting point using a soldering iron or a soldering gun. Understanding the microstructure and composition of solder joint is crucial in designing reliable joints, optimizing soldering.

Lokring Solder Free Tube Connections Your Best Guide in 2024 The

Soldered Joint Method In this chapter, we evaluate the reliability of the produced solder. This versatile technique can be applied to a variety of materials and is commonly used in electronics for its ability to create reliable connections. In electronics, solder joints are typically used to connect electrical components such as resistors, capacitors, and integrated circuits to printed circuit boards (pcbs). In this chapter, we evaluate the reliability of the produced solder. Understanding the microstructure and composition of solder joint is crucial in designing reliable joints, optimizing soldering. The characteristics of these three elements—component, substrate, and solder joint—together with the use conditions, the. In essence, soldering joints is the process of melting and cooling a wire or strip of metal to create a strong bond between two surfaces, often without the use of screws or other fasteners. The process involves heating the solder to its melting point using a soldering iron or a soldering gun. The formation of a solder joint is made possible by (i) introducing fluxing agents to remove the oxide layer present on metal surfaces and (ii). Solder joint is the dominant failure mechanism in solder joint interconnections.

From slidecourse.blogspot.com

How To Solder Copper Pipes Slide Course Soldered Joint Method In essence, soldering joints is the process of melting and cooling a wire or strip of metal to create a strong bond between two surfaces, often without the use of screws or other fasteners. The formation of a solder joint is made possible by (i) introducing fluxing agents to remove the oxide layer present on metal surfaces and (ii). Solder. Soldered Joint Method.

From www.electronicsandyou.com

How to Solder Wires Together Correctly Like a Pro (Easy Tips and Tricks) Soldered Joint Method Understanding the microstructure and composition of solder joint is crucial in designing reliable joints, optimizing soldering. In electronics, solder joints are typically used to connect electrical components such as resistors, capacitors, and integrated circuits to printed circuit boards (pcbs). The process involves heating the solder to its melting point using a soldering iron or a soldering gun. This versatile technique. Soldered Joint Method.

From www.researchgate.net

(PDF) A new hybrid bonding technique Adhesivesoft soldered joints Soldered Joint Method In this chapter, we evaluate the reliability of the produced solder. The process involves heating the solder to its melting point using a soldering iron or a soldering gun. The formation of a solder joint is made possible by (i) introducing fluxing agents to remove the oxide layer present on metal surfaces and (ii). In essence, soldering joints is the. Soldered Joint Method.

From www.electronicsandyou.com

How to Solder Electronic Components Hand Soldering Tips & Tutorial Soldered Joint Method The formation of a solder joint is made possible by (i) introducing fluxing agents to remove the oxide layer present on metal surfaces and (ii). In this chapter, we evaluate the reliability of the produced solder. The characteristics of these three elements—component, substrate, and solder joint—together with the use conditions, the. In electronics, solder joints are typically used to connect. Soldered Joint Method.

From circuitdbditheism.z13.web.core.windows.net

How To Solder Wiring Soldered Joint Method The process involves heating the solder to its melting point using a soldering iron or a soldering gun. This versatile technique can be applied to a variety of materials and is commonly used in electronics for its ability to create reliable connections. Understanding the microstructure and composition of solder joint is crucial in designing reliable joints, optimizing soldering. The characteristics. Soldered Joint Method.

From www.mingledorffs.com

Soldering, Brazing, and Welding Mingledorff's Soldered Joint Method In essence, soldering joints is the process of melting and cooling a wire or strip of metal to create a strong bond between two surfaces, often without the use of screws or other fasteners. Solder joint is the dominant failure mechanism in solder joint interconnections. The formation of a solder joint is made possible by (i) introducing fluxing agents to. Soldered Joint Method.

From www.youtube.com

How To Solder Intro/Joining Stranded Wires Part 1 YouTube Soldered Joint Method Solder joint is the dominant failure mechanism in solder joint interconnections. In this chapter, we evaluate the reliability of the produced solder. In electronics, solder joints are typically used to connect electrical components such as resistors, capacitors, and integrated circuits to printed circuit boards (pcbs). The characteristics of these three elements—component, substrate, and solder joint—together with the use conditions, the.. Soldered Joint Method.

From www.youtube.com

How to Solder Properly 5 Soldering Joint Splices YouTube Soldered Joint Method The process involves heating the solder to its melting point using a soldering iron or a soldering gun. The characteristics of these three elements—component, substrate, and solder joint—together with the use conditions, the. This versatile technique can be applied to a variety of materials and is commonly used in electronics for its ability to create reliable connections. In electronics, solder. Soldered Joint Method.

From wiredataboettiy2.z21.web.core.windows.net

How To Connect Wires With Solder Soldered Joint Method The characteristics of these three elements—component, substrate, and solder joint—together with the use conditions, the. Solder joint is the dominant failure mechanism in solder joint interconnections. The formation of a solder joint is made possible by (i) introducing fluxing agents to remove the oxide layer present on metal surfaces and (ii). The process involves heating the solder to its melting. Soldered Joint Method.

From www.youtube.com

How to CORRECTLY Solder A Vertical Copper Pipe Guide Soldered Joint Method This versatile technique can be applied to a variety of materials and is commonly used in electronics for its ability to create reliable connections. Understanding the microstructure and composition of solder joint is crucial in designing reliable joints, optimizing soldering. The process involves heating the solder to its melting point using a soldering iron or a soldering gun. In this. Soldered Joint Method.

From mechathon.com

Soldering vs Brazing; Its Process, Advantages, Disadvantages Soldered Joint Method Solder joint is the dominant failure mechanism in solder joint interconnections. The formation of a solder joint is made possible by (i) introducing fluxing agents to remove the oxide layer present on metal surfaces and (ii). In essence, soldering joints is the process of melting and cooling a wire or strip of metal to create a strong bond between two. Soldered Joint Method.

From www.circuitstoday.com

Basic Soldering Tips Soldered Joint Method The formation of a solder joint is made possible by (i) introducing fluxing agents to remove the oxide layer present on metal surfaces and (ii). In electronics, solder joints are typically used to connect electrical components such as resistors, capacitors, and integrated circuits to printed circuit boards (pcbs). Understanding the microstructure and composition of solder joint is crucial in designing. Soldered Joint Method.

From exyparswu.blob.core.windows.net

How To Solder Board at Tommy Partridge blog Soldered Joint Method The formation of a solder joint is made possible by (i) introducing fluxing agents to remove the oxide layer present on metal surfaces and (ii). Understanding the microstructure and composition of solder joint is crucial in designing reliable joints, optimizing soldering. The characteristics of these three elements—component, substrate, and solder joint—together with the use conditions, the. In essence, soldering joints. Soldered Joint Method.

From www.youtube.com

How to heatshrink a soldered joint YouTube Soldered Joint Method The process involves heating the solder to its melting point using a soldering iron or a soldering gun. In electronics, solder joints are typically used to connect electrical components such as resistors, capacitors, and integrated circuits to printed circuit boards (pcbs). The formation of a solder joint is made possible by (i) introducing fluxing agents to remove the oxide layer. Soldered Joint Method.

From cejznhpi.blob.core.windows.net

Solder The Joints at Williams Engel blog Soldered Joint Method Understanding the microstructure and composition of solder joint is crucial in designing reliable joints, optimizing soldering. This versatile technique can be applied to a variety of materials and is commonly used in electronics for its ability to create reliable connections. Solder joint is the dominant failure mechanism in solder joint interconnections. The formation of a solder joint is made possible. Soldered Joint Method.

From www.borisfavre.com

Closeup of the soldered joint Soldered Joint Method The process involves heating the solder to its melting point using a soldering iron or a soldering gun. In essence, soldering joints is the process of melting and cooling a wire or strip of metal to create a strong bond between two surfaces, often without the use of screws or other fasteners. This versatile technique can be applied to a. Soldered Joint Method.

From www.arcweldingpro.com

How to Solder Copper Pipe to Stainless Steel? Your Welding Solutions Soldered Joint Method In this chapter, we evaluate the reliability of the produced solder. The characteristics of these three elements—component, substrate, and solder joint—together with the use conditions, the. In electronics, solder joints are typically used to connect electrical components such as resistors, capacitors, and integrated circuits to printed circuit boards (pcbs). Understanding the microstructure and composition of solder joint is crucial in. Soldered Joint Method.

From www.youtube.com

Metal Joining Processes Welding, Riveting, Bolting, Brazing, Soldering Soldered Joint Method In this chapter, we evaluate the reliability of the produced solder. Understanding the microstructure and composition of solder joint is crucial in designing reliable joints, optimizing soldering. Solder joint is the dominant failure mechanism in solder joint interconnections. This versatile technique can be applied to a variety of materials and is commonly used in electronics for its ability to create. Soldered Joint Method.

From www.youtube.com

How to solder two wires together Crutchfield YouTube Soldered Joint Method The formation of a solder joint is made possible by (i) introducing fluxing agents to remove the oxide layer present on metal surfaces and (ii). The process involves heating the solder to its melting point using a soldering iron or a soldering gun. In electronics, solder joints are typically used to connect electrical components such as resistors, capacitors, and integrated. Soldered Joint Method.

From www.circuitbasics.com

Tips for Good Soldering Technique Circuit Basics Soldered Joint Method In electronics, solder joints are typically used to connect electrical components such as resistors, capacitors, and integrated circuits to printed circuit boards (pcbs). The formation of a solder joint is made possible by (i) introducing fluxing agents to remove the oxide layer present on metal surfaces and (ii). In essence, soldering joints is the process of melting and cooling a. Soldered Joint Method.

From www.alamy.com

worker makes a soldered joint in a shipyard Stock Photo Alamy Soldered Joint Method The characteristics of these three elements—component, substrate, and solder joint—together with the use conditions, the. This versatile technique can be applied to a variety of materials and is commonly used in electronics for its ability to create reliable connections. The formation of a solder joint is made possible by (i) introducing fluxing agents to remove the oxide layer present on. Soldered Joint Method.

From www.youtube.com

How to solder flat seam joint by franklincustomcopperworks llc Soldered Joint Method This versatile technique can be applied to a variety of materials and is commonly used in electronics for its ability to create reliable connections. The process involves heating the solder to its melting point using a soldering iron or a soldering gun. In this chapter, we evaluate the reliability of the produced solder. In electronics, solder joints are typically used. Soldered Joint Method.

From www.youtube.com

How to waterproof a soldered joint with grease YouTube Soldered Joint Method In essence, soldering joints is the process of melting and cooling a wire or strip of metal to create a strong bond between two surfaces, often without the use of screws or other fasteners. The characteristics of these three elements—component, substrate, and solder joint—together with the use conditions, the. In this chapter, we evaluate the reliability of the produced solder.. Soldered Joint Method.

From engalaxy.com

Lokring Solder Free Tube Connections Your Best Guide in 2024 The Soldered Joint Method This versatile technique can be applied to a variety of materials and is commonly used in electronics for its ability to create reliable connections. In this chapter, we evaluate the reliability of the produced solder. The process involves heating the solder to its melting point using a soldering iron or a soldering gun. In electronics, solder joints are typically used. Soldered Joint Method.

From www.researchgate.net

(a) Mechanical lapjoint fabrication setup, (b) Soldered lapjoint Soldered Joint Method The process involves heating the solder to its melting point using a soldering iron or a soldering gun. The formation of a solder joint is made possible by (i) introducing fluxing agents to remove the oxide layer present on metal surfaces and (ii). The characteristics of these three elements—component, substrate, and solder joint—together with the use conditions, the. In essence,. Soldered Joint Method.

From exosypdwj.blob.core.windows.net

Soldering Joint at Samantha Jimmerson blog Soldered Joint Method The process involves heating the solder to its melting point using a soldering iron or a soldering gun. In electronics, solder joints are typically used to connect electrical components such as resistors, capacitors, and integrated circuits to printed circuit boards (pcbs). Understanding the microstructure and composition of solder joint is crucial in designing reliable joints, optimizing soldering. Solder joint is. Soldered Joint Method.

From weldingtroop.com

What Is Soldering? An Indepth Guide [Definition, Types, and Meaning] Soldered Joint Method The characteristics of these three elements—component, substrate, and solder joint—together with the use conditions, the. In electronics, solder joints are typically used to connect electrical components such as resistors, capacitors, and integrated circuits to printed circuit boards (pcbs). Understanding the microstructure and composition of solder joint is crucial in designing reliable joints, optimizing soldering. This versatile technique can be applied. Soldered Joint Method.

From www.youtube.com

Soldering 101 6. Soldering a Wire to a Terminal YouTube Soldered Joint Method In electronics, solder joints are typically used to connect electrical components such as resistors, capacitors, and integrated circuits to printed circuit boards (pcbs). The process involves heating the solder to its melting point using a soldering iron or a soldering gun. This versatile technique can be applied to a variety of materials and is commonly used in electronics for its. Soldered Joint Method.

From www.pcbaaa.com

Understanding solder joint basics and techniques IBE Electronics Soldered Joint Method This versatile technique can be applied to a variety of materials and is commonly used in electronics for its ability to create reliable connections. The formation of a solder joint is made possible by (i) introducing fluxing agents to remove the oxide layer present on metal surfaces and (ii). Understanding the microstructure and composition of solder joint is crucial in. Soldered Joint Method.

From studylib.net

15 Soldering Brazing and riveting Soldered Joint Method In essence, soldering joints is the process of melting and cooling a wire or strip of metal to create a strong bond between two surfaces, often without the use of screws or other fasteners. Solder joint is the dominant failure mechanism in solder joint interconnections. In electronics, solder joints are typically used to connect electrical components such as resistors, capacitors,. Soldered Joint Method.

From www.cruxweld.com

The Difference between Soldering and Brazing with Welding [The Soldered Joint Method Solder joint is the dominant failure mechanism in solder joint interconnections. The characteristics of these three elements—component, substrate, and solder joint—together with the use conditions, the. In electronics, solder joints are typically used to connect electrical components such as resistors, capacitors, and integrated circuits to printed circuit boards (pcbs). In this chapter, we evaluate the reliability of the produced solder.. Soldered Joint Method.

From www.semanticscholar.org

Figure 1 from A new hybrid bonding technique Adhesivesoft soldered Soldered Joint Method The formation of a solder joint is made possible by (i) introducing fluxing agents to remove the oxide layer present on metal surfaces and (ii). In electronics, solder joints are typically used to connect electrical components such as resistors, capacitors, and integrated circuits to printed circuit boards (pcbs). The process involves heating the solder to its melting point using a. Soldered Joint Method.

From www.lifehacker.com.au

The Basics Of Soldering Explained [Infographic] Soldered Joint Method Understanding the microstructure and composition of solder joint is crucial in designing reliable joints, optimizing soldering. Solder joint is the dominant failure mechanism in solder joint interconnections. This versatile technique can be applied to a variety of materials and is commonly used in electronics for its ability to create reliable connections. The characteristics of these three elements—component, substrate, and solder. Soldered Joint Method.

From rushpcb.com

What is a Solder Joint? RushPcb Soldered Joint Method The process involves heating the solder to its melting point using a soldering iron or a soldering gun. In electronics, solder joints are typically used to connect electrical components such as resistors, capacitors, and integrated circuits to printed circuit boards (pcbs). Solder joint is the dominant failure mechanism in solder joint interconnections. Understanding the microstructure and composition of solder joint. Soldered Joint Method.

From klakjsukh.blob.core.windows.net

Soldering Joint Flux at Allison Tarvin blog Soldered Joint Method In electronics, solder joints are typically used to connect electrical components such as resistors, capacitors, and integrated circuits to printed circuit boards (pcbs). In this chapter, we evaluate the reliability of the produced solder. Understanding the microstructure and composition of solder joint is crucial in designing reliable joints, optimizing soldering. The characteristics of these three elements—component, substrate, and solder joint—together. Soldered Joint Method.