How To Countersink Plexiglass . Laser cutting, making add comments. For drilling a hole in acrylic you need a very pointy drill bit. How to tap a thread in acrylic perspex, lucite, plexiglass using your cordless drill driver. I’ve sawn, routed and drilled perspex before. Make sure that you are using the correct sized pilot hole for the countersink and it should make a very clean and smooth cut without. The 118 and 135 degree bits will probably crack it. Do not apply too much force as this can cause the material to crack. Whether you're a diy enthusiast or a professional, our step. Learn how to cut and drill holes in plexiglass with our comprehensive guide. The final of creative precision. Measure the diameter of the screw’s shaft with calipers. Countersinking should be done at a low speed, and perpindicular to I recently bought a laser cutter (running on a pi) and started working with acrylic (perspex). Drill slowly and steadily with gentle pressure, and keep the plexiglass cool with water or lubricant. It machines beautifully as long as you’re not too.

from fr.boyiprototyping.com

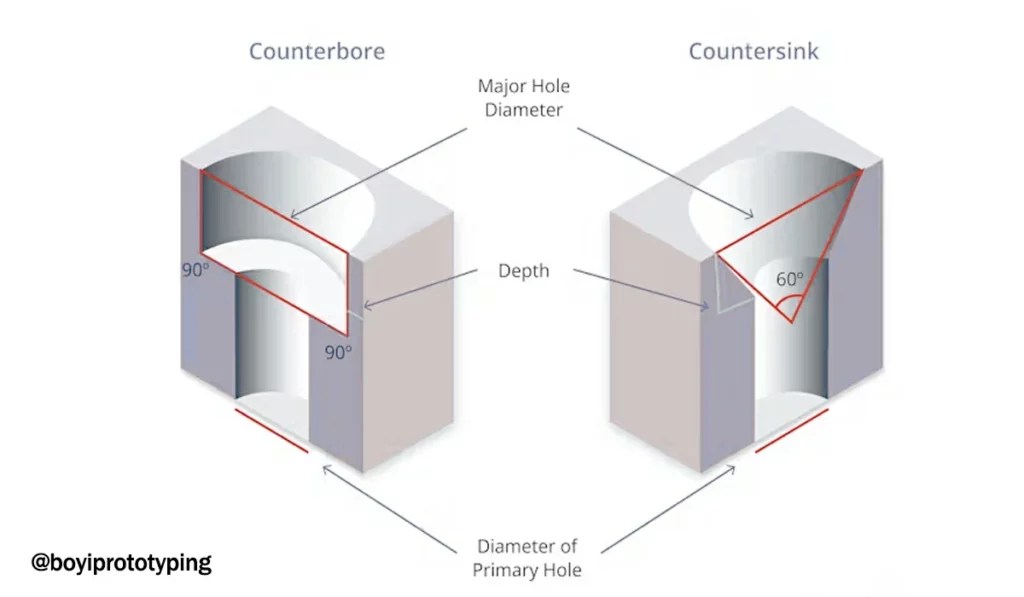

It machines beautifully as long as you’re not too. The 118 and 135 degree bits will probably crack it. I recently bought a laser cutter (running on a pi) and started working with acrylic (perspex). Learn how to cut and drill holes in plexiglass with our comprehensive guide. Measure the diameter of the screw’s shaft with calipers. For drilling a hole in acrylic you need a very pointy drill bit. I’ve sawn, routed and drilled perspex before. Countersinking should be done at a low speed, and perpindicular to Do not apply too much force as this can cause the material to crack. I think something around 60 degrees is about right.

How to Drill Countersink Holes Benefits and Best Practices BOYI

How To Countersink Plexiglass Do not apply too much force as this can cause the material to crack. For drilling a hole in acrylic you need a very pointy drill bit. Measure the diameter of the screw’s shaft with calipers. Make sure that you are using the correct sized pilot hole for the countersink and it should make a very clean and smooth cut without. Do not apply too much force as this can cause the material to crack. I think something around 60 degrees is about right. Laser cutting, making add comments. It machines beautifully as long as you’re not too. I recently bought a laser cutter (running on a pi) and started working with acrylic (perspex). Secure the plexiglass in place, mark the spot the begin drilling. Drill slowly and steadily with gentle pressure, and keep the plexiglass cool with water or lubricant. Whether you're a diy enthusiast or a professional, our step. The 118 and 135 degree bits will probably crack it. I’ve sawn, routed and drilled perspex before. Countersinking should be done at a low speed, and perpindicular to Open the jaws of the calipers wide enough so you can put the screw between them.

From www.wikihow.com

How to Countersink 13 Steps (with Pictures) wikiHow How To Countersink Plexiglass Open the jaws of the calipers wide enough so you can put the screw between them. How to tap a thread in acrylic perspex, lucite, plexiglass using your cordless drill driver. Learn how to cut and drill holes in plexiglass with our comprehensive guide. Do not apply too much force as this can cause the material to crack. The 118. How To Countersink Plexiglass.

From sendcutsend.com

The Benefits of Countersinking SendCutSend How To Countersink Plexiglass Measure the diameter of the screw’s shaft with calipers. Laser cutting, making add comments. Open the jaws of the calipers wide enough so you can put the screw between them. For drilling a hole in acrylic you need a very pointy drill bit. Countersinking should be done at a low speed, and perpindicular to Learn how to cut and drill. How To Countersink Plexiglass.

From dxoieatkz.blob.core.windows.net

Countersink Solidworks Drawing at Jeremy Stewart blog How To Countersink Plexiglass I think something around 60 degrees is about right. Learn how to cut and drill holes in plexiglass with our comprehensive guide. How to tap a thread in acrylic perspex, lucite, plexiglass using your cordless drill driver. Countersinking should be done at a low speed, and perpindicular to Make sure that you are using the correct sized pilot hole for. How To Countersink Plexiglass.

From sendcutsend.com

The Benefits of Countersinking SendCutSend How To Countersink Plexiglass Drill slowly and steadily with gentle pressure, and keep the plexiglass cool with water or lubricant. Measure the diameter of the screw’s shaft with calipers. The final of creative precision. Countersinking should be done at a low speed, and perpindicular to I’ve sawn, routed and drilled perspex before. Laser cutting, making add comments. Secure the plexiglass in place, mark the. How To Countersink Plexiglass.

From klattifvq.blob.core.windows.net

Countersink Process Definition at Marcia Camacho blog How To Countersink Plexiglass Drill slowly and steadily with gentle pressure, and keep the plexiglass cool with water or lubricant. How to tap a thread in acrylic perspex, lucite, plexiglass using your cordless drill driver. Countersinking should be done at a low speed, and perpindicular to I think something around 60 degrees is about right. For drilling a hole in acrylic you need a. How To Countersink Plexiglass.

From weekproyeuh.blogspot.com

How To Make Your Own Plexiglass Woodworking Project of the Week How To Countersink Plexiglass Laser cutting, making add comments. Whether you're a diy enthusiast or a professional, our step. I recently bought a laser cutter (running on a pi) and started working with acrylic (perspex). Secure the plexiglass in place, mark the spot the begin drilling. Make sure that you are using the correct sized pilot hole for the countersink and it should make. How To Countersink Plexiglass.

From www.hgtv.com

How to Cut Acrylic Plexiglass Sheets 2 Ways HGTV How To Countersink Plexiglass Laser cutting, making add comments. How to tap a thread in acrylic perspex, lucite, plexiglass using your cordless drill driver. Learn how to cut and drill holes in plexiglass with our comprehensive guide. I recently bought a laser cutter (running on a pi) and started working with acrylic (perspex). It machines beautifully as long as you’re not too. The 118. How To Countersink Plexiglass.

From www.popularwoodworking.com

How to Make A Perfect Countersink Popular Woodworking How To Countersink Plexiglass Do not apply too much force as this can cause the material to crack. I recently bought a laser cutter (running on a pi) and started working with acrylic (perspex). Open the jaws of the calipers wide enough so you can put the screw between them. Whether you're a diy enthusiast or a professional, our step. It machines beautifully as. How To Countersink Plexiglass.

From www.wikihow.com

How to Countersink 9 Steps (with Pictures) wikiHow How To Countersink Plexiglass Open the jaws of the calipers wide enough so you can put the screw between them. Countersinking should be done at a low speed, and perpindicular to Laser cutting, making add comments. I recently bought a laser cutter (running on a pi) and started working with acrylic (perspex). Whether you're a diy enthusiast or a professional, our step. Secure the. How To Countersink Plexiglass.

From fr.boyiprototyping.com

How to Drill Countersink Holes Benefits and Best Practices BOYI How To Countersink Plexiglass Laser cutting, making add comments. Measure the diameter of the screw’s shaft with calipers. The final of creative precision. I recently bought a laser cutter (running on a pi) and started working with acrylic (perspex). It machines beautifully as long as you’re not too. Open the jaws of the calipers wide enough so you can put the screw between them.. How To Countersink Plexiglass.

From tips.acehardware.com

Plexiglass Tools & Materials ACE Tips & Advice How To Countersink Plexiglass It machines beautifully as long as you’re not too. I think something around 60 degrees is about right. Learn how to cut and drill holes in plexiglass with our comprehensive guide. The final of creative precision. Open the jaws of the calipers wide enough so you can put the screw between them. Whether you're a diy enthusiast or a professional,. How To Countersink Plexiglass.

From www.wikihow.com

How to Countersink 9 Steps (with Pictures) wikiHow How To Countersink Plexiglass Measure the diameter of the screw’s shaft with calipers. I recently bought a laser cutter (running on a pi) and started working with acrylic (perspex). I’ve sawn, routed and drilled perspex before. It machines beautifully as long as you’re not too. Countersinking should be done at a low speed, and perpindicular to The final of creative precision. Whether you're a. How To Countersink Plexiglass.

From www.artofit.org

How to make a perfect countersink Artofit How To Countersink Plexiglass Drill slowly and steadily with gentle pressure, and keep the plexiglass cool with water or lubricant. How to tap a thread in acrylic perspex, lucite, plexiglass using your cordless drill driver. The 118 and 135 degree bits will probably crack it. For drilling a hole in acrylic you need a very pointy drill bit. Learn how to cut and drill. How To Countersink Plexiglass.

From gluethings.com

How to Glue Plexiglass to Glass? Glue Things How To Countersink Plexiglass Make sure that you are using the correct sized pilot hole for the countersink and it should make a very clean and smooth cut without. Drill slowly and steadily with gentle pressure, and keep the plexiglass cool with water or lubricant. How to tap a thread in acrylic perspex, lucite, plexiglass using your cordless drill driver. Open the jaws of. How To Countersink Plexiglass.

From www.finepowertools.com

Countersink Angles Common Angles and Their Applications How To Countersink Plexiglass Open the jaws of the calipers wide enough so you can put the screw between them. How to tap a thread in acrylic perspex, lucite, plexiglass using your cordless drill driver. Secure the plexiglass in place, mark the spot the begin drilling. Countersinking should be done at a low speed, and perpindicular to Measure the diameter of the screw’s shaft. How To Countersink Plexiglass.

From www.youtube.com

How To Cut Plexiglass With A Jigsaw YouTube How To Countersink Plexiglass Do not apply too much force as this can cause the material to crack. Make sure that you are using the correct sized pilot hole for the countersink and it should make a very clean and smooth cut without. I think something around 60 degrees is about right. I recently bought a laser cutter (running on a pi) and started. How To Countersink Plexiglass.

From www.wikihow.com

How to Countersink 13 Steps (with Pictures) wikiHow How To Countersink Plexiglass Drill slowly and steadily with gentle pressure, and keep the plexiglass cool with water or lubricant. How to tap a thread in acrylic perspex, lucite, plexiglass using your cordless drill driver. I recently bought a laser cutter (running on a pi) and started working with acrylic (perspex). Open the jaws of the calipers wide enough so you can put the. How To Countersink Plexiglass.

From mamaneedsaproject.com

How to Cut Plexiglass with a Jigsaw (Step by Step Guide) How To Countersink Plexiglass I recently bought a laser cutter (running on a pi) and started working with acrylic (perspex). The final of creative precision. I’ve sawn, routed and drilled perspex before. Measure the diameter of the screw’s shaft with calipers. Secure the plexiglass in place, mark the spot the begin drilling. I think something around 60 degrees is about right. Countersinking should be. How To Countersink Plexiglass.

From sendcutsend.com

The Benefits of Countersinking SendCutSend How To Countersink Plexiglass Open the jaws of the calipers wide enough so you can put the screw between them. The final of creative precision. Countersinking should be done at a low speed, and perpindicular to How to tap a thread in acrylic perspex, lucite, plexiglass using your cordless drill driver. The 118 and 135 degree bits will probably crack it. Make sure that. How To Countersink Plexiglass.

From ohsospotless.com

How to Clean Plexiglass Without Scratching It How To Countersink Plexiglass How to tap a thread in acrylic perspex, lucite, plexiglass using your cordless drill driver. Learn how to cut and drill holes in plexiglass with our comprehensive guide. The 118 and 135 degree bits will probably crack it. Drill slowly and steadily with gentle pressure, and keep the plexiglass cool with water or lubricant. I’ve sawn, routed and drilled perspex. How To Countersink Plexiglass.

From www.youtube.com

10 tips & tricks PLEXIGLASS working HOMEMADE YouTube How To Countersink Plexiglass The 118 and 135 degree bits will probably crack it. Learn how to cut and drill holes in plexiglass with our comprehensive guide. Whether you're a diy enthusiast or a professional, our step. I’ve sawn, routed and drilled perspex before. Countersinking should be done at a low speed, and perpindicular to For drilling a hole in acrylic you need a. How To Countersink Plexiglass.

From ceeojgcl.blob.core.windows.net

How To Size A Countersink at Fred Mota blog How To Countersink Plexiglass Open the jaws of the calipers wide enough so you can put the screw between them. How to tap a thread in acrylic perspex, lucite, plexiglass using your cordless drill driver. Countersinking should be done at a low speed, and perpindicular to I think something around 60 degrees is about right. For drilling a hole in acrylic you need a. How To Countersink Plexiglass.

From www.theengineeringknowledge.com

What is Countersink vs. Counterbore Holes in Machining The How To Countersink Plexiglass Whether you're a diy enthusiast or a professional, our step. Open the jaws of the calipers wide enough so you can put the screw between them. How to tap a thread in acrylic perspex, lucite, plexiglass using your cordless drill driver. Do not apply too much force as this can cause the material to crack. Measure the diameter of the. How To Countersink Plexiglass.

From www.wikihow.com

How to Countersink 13 Steps (with Pictures) wikiHow How To Countersink Plexiglass It machines beautifully as long as you’re not too. I recently bought a laser cutter (running on a pi) and started working with acrylic (perspex). Do not apply too much force as this can cause the material to crack. Make sure that you are using the correct sized pilot hole for the countersink and it should make a very clean. How To Countersink Plexiglass.

From www.archute.com

How to Bend Plexiglass Sheets for DIY Projects At Home Archute How To Countersink Plexiglass For drilling a hole in acrylic you need a very pointy drill bit. Drill slowly and steadily with gentle pressure, and keep the plexiglass cool with water or lubricant. Secure the plexiglass in place, mark the spot the begin drilling. How to tap a thread in acrylic perspex, lucite, plexiglass using your cordless drill driver. I think something around 60. How To Countersink Plexiglass.

From www.thespruce.com

How to Clean Plexiglass in 5 Easy Steps How To Countersink Plexiglass How to tap a thread in acrylic perspex, lucite, plexiglass using your cordless drill driver. The final of creative precision. Laser cutting, making add comments. I recently bought a laser cutter (running on a pi) and started working with acrylic (perspex). Do not apply too much force as this can cause the material to crack. Drill slowly and steadily with. How To Countersink Plexiglass.

From sendcutsend.com

The Benefits of Countersinking SendCutSend How To Countersink Plexiglass Secure the plexiglass in place, mark the spot the begin drilling. Learn how to cut and drill holes in plexiglass with our comprehensive guide. The 118 and 135 degree bits will probably crack it. It machines beautifully as long as you’re not too. I’ve sawn, routed and drilled perspex before. Open the jaws of the calipers wide enough so you. How To Countersink Plexiglass.

From www.gdandtbasics.com

Countersink GD&T Basics How To Countersink Plexiglass I’ve sawn, routed and drilled perspex before. Open the jaws of the calipers wide enough so you can put the screw between them. It machines beautifully as long as you’re not too. Measure the diameter of the screw’s shaft with calipers. Do not apply too much force as this can cause the material to crack. I think something around 60. How To Countersink Plexiglass.

From www.wikihow.com

How to Countersink 13 Steps (with Pictures) wikiHow How To Countersink Plexiglass Make sure that you are using the correct sized pilot hole for the countersink and it should make a very clean and smooth cut without. Open the jaws of the calipers wide enough so you can put the screw between them. Laser cutting, making add comments. I’ve sawn, routed and drilled perspex before. Drill slowly and steadily with gentle pressure,. How To Countersink Plexiglass.

From www.pinterest.com

Countersinks that Works My countersinks produced rough and wavey holes How To Countersink Plexiglass The 118 and 135 degree bits will probably crack it. I recently bought a laser cutter (running on a pi) and started working with acrylic (perspex). Learn how to cut and drill holes in plexiglass with our comprehensive guide. It machines beautifully as long as you’re not too. Whether you're a diy enthusiast or a professional, our step. The final. How To Countersink Plexiglass.

From www.cnccookbook.com

Countersink Depth Calculator [ Free Machinist Tool ] How To Countersink Plexiglass I recently bought a laser cutter (running on a pi) and started working with acrylic (perspex). The 118 and 135 degree bits will probably crack it. Laser cutting, making add comments. I think something around 60 degrees is about right. Open the jaws of the calipers wide enough so you can put the screw between them. It machines beautifully as. How To Countersink Plexiglass.

From www.hgtv.com

How to Cut Acrylic Plexiglass Sheets 2 Ways HGTV How To Countersink Plexiglass The 118 and 135 degree bits will probably crack it. Make sure that you are using the correct sized pilot hole for the countersink and it should make a very clean and smooth cut without. Secure the plexiglass in place, mark the spot the begin drilling. For drilling a hole in acrylic you need a very pointy drill bit. I. How To Countersink Plexiglass.

From www.novacam.com

3D countersink measurement noncontact and automated Novacam How To Countersink Plexiglass Learn how to cut and drill holes in plexiglass with our comprehensive guide. Drill slowly and steadily with gentle pressure, and keep the plexiglass cool with water or lubricant. The final of creative precision. It machines beautifully as long as you’re not too. Countersinking should be done at a low speed, and perpindicular to Measure the diameter of the screw’s. How To Countersink Plexiglass.

From www.youtube.com

How To Cut Plexiglass With A Utility Knife YouTube How To Countersink Plexiglass I’ve sawn, routed and drilled perspex before. The 118 and 135 degree bits will probably crack it. Countersinking should be done at a low speed, and perpindicular to Open the jaws of the calipers wide enough so you can put the screw between them. Make sure that you are using the correct sized pilot hole for the countersink and it. How To Countersink Plexiglass.

From sendcutsend.com

Countersink Design Best Practices SendCutSend How To Countersink Plexiglass I think something around 60 degrees is about right. I recently bought a laser cutter (running on a pi) and started working with acrylic (perspex). For drilling a hole in acrylic you need a very pointy drill bit. Measure the diameter of the screw’s shaft with calipers. Learn how to cut and drill holes in plexiglass with our comprehensive guide.. How To Countersink Plexiglass.