Solder Joint Simulation . This approach to predicting solder joint lifetime under thermal cycling was widely embraced by the electronics community, to the extent that. To tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints in electronic. A more powerful, yet computationally more intense, tool for solder joint reliability simulation is a 3d multiphysics solver. Essential requirements for fe modelling of an electronic. This book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. In order to analyze the fatigue failure of the solder joints, two parameters weibull distribution was used to identify the reliability. The present study proposes a new coupled empirical, analytic and fea method to assess with simulation the solder joint fatigue.

from www.semanticscholar.org

The present study proposes a new coupled empirical, analytic and fea method to assess with simulation the solder joint fatigue. To tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints in electronic. Essential requirements for fe modelling of an electronic. In order to analyze the fatigue failure of the solder joints, two parameters weibull distribution was used to identify the reliability. A more powerful, yet computationally more intense, tool for solder joint reliability simulation is a 3d multiphysics solver. This book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. This approach to predicting solder joint lifetime under thermal cycling was widely embraced by the electronics community, to the extent that.

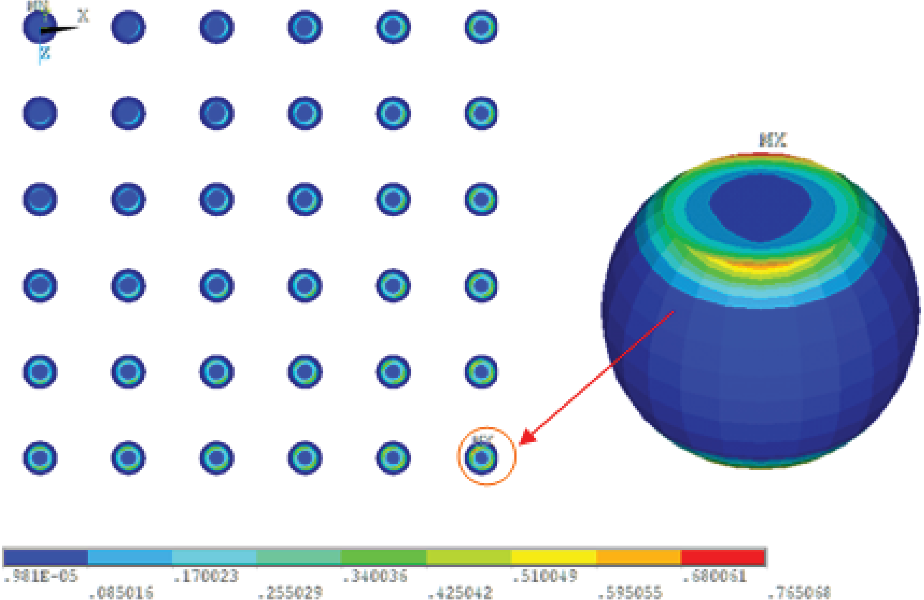

Figure 3 from Reliability of Leadfree Solder Joints in WLCSP Device

Solder Joint Simulation In order to analyze the fatigue failure of the solder joints, two parameters weibull distribution was used to identify the reliability. To tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints in electronic. This book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. This approach to predicting solder joint lifetime under thermal cycling was widely embraced by the electronics community, to the extent that. Essential requirements for fe modelling of an electronic. A more powerful, yet computationally more intense, tool for solder joint reliability simulation is a 3d multiphysics solver. In order to analyze the fatigue failure of the solder joints, two parameters weibull distribution was used to identify the reliability. The present study proposes a new coupled empirical, analytic and fea method to assess with simulation the solder joint fatigue.

From www.mdpi.com

Materials Free FullText Study on Establishing Degradation Model of Solder Joint Simulation In order to analyze the fatigue failure of the solder joints, two parameters weibull distribution was used to identify the reliability. To tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints in electronic. Essential requirements for fe modelling of an electronic. This approach to predicting solder joint lifetime under thermal cycling was widely. Solder Joint Simulation.

From pcbassemblymanufacturing.com

Solder joint one basic lesson about PCB soldering Solder Joint Simulation The present study proposes a new coupled empirical, analytic and fea method to assess with simulation the solder joint fatigue. In order to analyze the fatigue failure of the solder joints, two parameters weibull distribution was used to identify the reliability. Essential requirements for fe modelling of an electronic. This book presents a systematic approach in performing reliability assessment of. Solder Joint Simulation.

From www.researchgate.net

Actual solder joints with different bump shape in the study a barrel Solder Joint Simulation This book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. The present study proposes a new coupled empirical, analytic and fea method to assess with simulation the solder joint fatigue. This approach to predicting solder joint lifetime under thermal cycling was widely embraced by the electronics community, to the extent that. In. Solder Joint Simulation.

From www.researchgate.net

(PDF) Simulation of mechanical response of solder joints under drop Solder Joint Simulation A more powerful, yet computationally more intense, tool for solder joint reliability simulation is a 3d multiphysics solver. This book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. This approach to predicting solder joint lifetime under thermal cycling was widely embraced by the electronics community, to the extent that. In order to. Solder Joint Simulation.

From www.researchgate.net

Procedure for assembling a single BGA structure solder joint by Solder Joint Simulation This book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. The present study proposes a new coupled empirical, analytic and fea method to assess with simulation the solder joint fatigue. To tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints in electronic. Essential requirements for. Solder Joint Simulation.

From blogs.3ds.com

Design of BGA Solder Joints Driven by High Fidelity Simulation Solder Joint Simulation This approach to predicting solder joint lifetime under thermal cycling was widely embraced by the electronics community, to the extent that. This book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. Essential requirements for fe modelling of an electronic. To tackle this challenge, we develop a novel machine learning framework for reliability. Solder Joint Simulation.

From www.semlab.com

Solder Joint Analysis SEM Lab Inc. Solder Joint Simulation To tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints in electronic. In order to analyze the fatigue failure of the solder joints, two parameters weibull distribution was used to identify the reliability. This approach to predicting solder joint lifetime under thermal cycling was widely embraced by the electronics community, to the extent. Solder Joint Simulation.

From www.researchgate.net

Simulation of current distribution in a solder ball joint. 5 Solder Joint Simulation This book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. A more powerful, yet computationally more intense, tool for solder joint reliability simulation is a 3d multiphysics solver. In order to analyze the fatigue failure of the solder joints, two parameters weibull distribution was used to identify the reliability. This approach to. Solder Joint Simulation.

From www.semlab.com

BGA Solder Joint Simulation SEM Lab Inc. Solder Joint Simulation Essential requirements for fe modelling of an electronic. This book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. To tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints in electronic. In order to analyze the fatigue failure of the solder joints, two parameters weibull distribution. Solder Joint Simulation.

From www.researchgate.net

Schematic diagram of setup of shearing test of solder joints Download Solder Joint Simulation To tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints in electronic. This book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. A more powerful, yet computationally more intense, tool for solder joint reliability simulation is a 3d multiphysics solver. Essential requirements for fe modelling. Solder Joint Simulation.

From www.youtube.com

Laser Soldering Simulation FLOW3D WELD YouTube Solder Joint Simulation Essential requirements for fe modelling of an electronic. In order to analyze the fatigue failure of the solder joints, two parameters weibull distribution was used to identify the reliability. To tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints in electronic. This approach to predicting solder joint lifetime under thermal cycling was widely. Solder Joint Simulation.

From www.researchgate.net

(a) Crosssectional schematic drawing for solder joints used in the Solder Joint Simulation This approach to predicting solder joint lifetime under thermal cycling was widely embraced by the electronics community, to the extent that. This book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. The present study proposes a new coupled empirical, analytic and fea method to assess with simulation the solder joint fatigue. In. Solder Joint Simulation.

From www.semlab.com

BGA Solder Joint SEM Lab Inc. Solder Joint Simulation Essential requirements for fe modelling of an electronic. To tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints in electronic. A more powerful, yet computationally more intense, tool for solder joint reliability simulation is a 3d multiphysics solver. This book presents a systematic approach in performing reliability assessment of solder joints using finite. Solder Joint Simulation.

From www.researchgate.net

Shear strength of solder joints versus standoff height. Download Solder Joint Simulation This approach to predicting solder joint lifetime under thermal cycling was widely embraced by the electronics community, to the extent that. Essential requirements for fe modelling of an electronic. This book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. To tackle this challenge, we develop a novel machine learning framework for reliability. Solder Joint Simulation.

From www.researchgate.net

SEM micrograph showing the fracture plane of the solder joints after 15 Solder Joint Simulation To tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints in electronic. This book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. A more powerful, yet computationally more intense, tool for solder joint reliability simulation is a 3d multiphysics solver. Essential requirements for fe modelling. Solder Joint Simulation.

From www.semanticscholar.org

Figure 3 from Reliability of Leadfree Solder Joints in WLCSP Device Solder Joint Simulation This approach to predicting solder joint lifetime under thermal cycling was widely embraced by the electronics community, to the extent that. This book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. Essential requirements for fe modelling of an electronic. The present study proposes a new coupled empirical, analytic and fea method to. Solder Joint Simulation.

From www.researchgate.net

a Shear strength of the solder joint with various heights at different Solder Joint Simulation This book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. The present study proposes a new coupled empirical, analytic and fea method to assess with simulation the solder joint fatigue. A more powerful, yet computationally more intense, tool for solder joint reliability simulation is a 3d multiphysics solver. Essential requirements for fe. Solder Joint Simulation.

From www.youtube.com

Solder Joint Reliability simulation using DFR Sherlock YouTube Solder Joint Simulation This approach to predicting solder joint lifetime under thermal cycling was widely embraced by the electronics community, to the extent that. To tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints in electronic. In order to analyze the fatigue failure of the solder joints, two parameters weibull distribution was used to identify the. Solder Joint Simulation.

From www.researchgate.net

Side view of plastic strain distribution in the solder joint at last Solder Joint Simulation In order to analyze the fatigue failure of the solder joints, two parameters weibull distribution was used to identify the reliability. The present study proposes a new coupled empirical, analytic and fea method to assess with simulation the solder joint fatigue. A more powerful, yet computationally more intense, tool for solder joint reliability simulation is a 3d multiphysics solver. This. Solder Joint Simulation.

From www.researchgate.net

(a) schematic diagram of BGA solder ball array. The solder joints Solder Joint Simulation Essential requirements for fe modelling of an electronic. This book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. To tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints in electronic. The present study proposes a new coupled empirical, analytic and fea method to assess with. Solder Joint Simulation.

From www.semanticscholar.org

Figure 5 from Simulation analysis of residual stress of BGA solder Solder Joint Simulation This approach to predicting solder joint lifetime under thermal cycling was widely embraced by the electronics community, to the extent that. To tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints in electronic. Essential requirements for fe modelling of an electronic. The present study proposes a new coupled empirical, analytic and fea method. Solder Joint Simulation.

From www.researchgate.net

SAM images of 55 μm LED solder joints on copper at a) N = 0 cycles Solder Joint Simulation The present study proposes a new coupled empirical, analytic and fea method to assess with simulation the solder joint fatigue. In order to analyze the fatigue failure of the solder joints, two parameters weibull distribution was used to identify the reliability. To tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints in electronic.. Solder Joint Simulation.

From pcbassemblymanufacturing.com

Solder joint one basic lesson about PCB soldering Solder Joint Simulation This book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. In order to analyze the fatigue failure of the solder joints, two parameters weibull distribution was used to identify the reliability. Essential requirements for fe modelling of an electronic. A more powerful, yet computationally more intense, tool for solder joint reliability simulation. Solder Joint Simulation.

From www.researchgate.net

Strain simulation of single solder joint. Download Scientific Diagram Solder Joint Simulation The present study proposes a new coupled empirical, analytic and fea method to assess with simulation the solder joint fatigue. This approach to predicting solder joint lifetime under thermal cycling was widely embraced by the electronics community, to the extent that. In order to analyze the fatigue failure of the solder joints, two parameters weibull distribution was used to identify. Solder Joint Simulation.

From www.mdpi.com

Materials Free FullText Study on Establishing Degradation Model of Solder Joint Simulation Essential requirements for fe modelling of an electronic. A more powerful, yet computationally more intense, tool for solder joint reliability simulation is a 3d multiphysics solver. The present study proposes a new coupled empirical, analytic and fea method to assess with simulation the solder joint fatigue. This book presents a systematic approach in performing reliability assessment of solder joints using. Solder Joint Simulation.

From www.researchgate.net

Simulation results for solder joint H1 showing the atomic migration Solder Joint Simulation Essential requirements for fe modelling of an electronic. In order to analyze the fatigue failure of the solder joints, two parameters weibull distribution was used to identify the reliability. A more powerful, yet computationally more intense, tool for solder joint reliability simulation is a 3d multiphysics solver. The present study proposes a new coupled empirical, analytic and fea method to. Solder Joint Simulation.

From www.researchgate.net

Schematic diagram illustrating the experimental steps for solder joint Solder Joint Simulation This approach to predicting solder joint lifetime under thermal cycling was widely embraced by the electronics community, to the extent that. A more powerful, yet computationally more intense, tool for solder joint reliability simulation is a 3d multiphysics solver. The present study proposes a new coupled empirical, analytic and fea method to assess with simulation the solder joint fatigue. Essential. Solder Joint Simulation.

From www.mdpi.com

Electronics Free FullText Survey on Fatigue Life Prediction of BGA Solder Joint Simulation A more powerful, yet computationally more intense, tool for solder joint reliability simulation is a 3d multiphysics solver. To tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints in electronic. Essential requirements for fe modelling of an electronic. The present study proposes a new coupled empirical, analytic and fea method to assess with. Solder Joint Simulation.

From www.engineerlive.com

How To Perfect Your Solder Joint Formation Engineer Live Solder Joint Simulation To tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints in electronic. A more powerful, yet computationally more intense, tool for solder joint reliability simulation is a 3d multiphysics solver. This approach to predicting solder joint lifetime under thermal cycling was widely embraced by the electronics community, to the extent that. In order. Solder Joint Simulation.

From blogs.3ds.com

Design of BGA Solder Joints Driven by High Fidelity Simulation Solder Joint Simulation To tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints in electronic. A more powerful, yet computationally more intense, tool for solder joint reliability simulation is a 3d multiphysics solver. This book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. This approach to predicting solder. Solder Joint Simulation.

From www.singularityeng.com

Darveaux Solder Joint Reliability Example — Singularity Engineering LLC Solder Joint Simulation This book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. The present study proposes a new coupled empirical, analytic and fea method to assess with simulation the solder joint fatigue. To tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints in electronic. In order to. Solder Joint Simulation.

From www.mdpi.com

Materials Free FullText Study on Establishing Degradation Model of Solder Joint Simulation The present study proposes a new coupled empirical, analytic and fea method to assess with simulation the solder joint fatigue. Essential requirements for fe modelling of an electronic. In order to analyze the fatigue failure of the solder joints, two parameters weibull distribution was used to identify the reliability. A more powerful, yet computationally more intense, tool for solder joint. Solder Joint Simulation.

From www.mdpi.com

Chips Free FullText MultiPhysics Fields Simulations and Solder Joint Simulation To tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints in electronic. This book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. The present study proposes a new coupled empirical, analytic and fea method to assess with simulation the solder joint fatigue. A more powerful,. Solder Joint Simulation.

From www.researchgate.net

Schematic diagram of shear testing of the solder joints Download Solder Joint Simulation This approach to predicting solder joint lifetime under thermal cycling was widely embraced by the electronics community, to the extent that. Essential requirements for fe modelling of an electronic. This book presents a systematic approach in performing reliability assessment of solder joints using finite element (fe) simulation. To tackle this challenge, we develop a novel machine learning framework for reliability. Solder Joint Simulation.

From www.researchgate.net

SEM images of the solder joints. Download Scientific Diagram Solder Joint Simulation The present study proposes a new coupled empirical, analytic and fea method to assess with simulation the solder joint fatigue. To tackle this challenge, we develop a novel machine learning framework for reliability assessment of solder joints in electronic. Essential requirements for fe modelling of an electronic. A more powerful, yet computationally more intense, tool for solder joint reliability simulation. Solder Joint Simulation.