Zamak Coating . Understand how zamak alloy composition impacts your products. Zamak alloys were first developed during the 1920's by the new jersey zinc company. Zamak 3 has the base composition for the zamak alloys (96% zinc, 4% aluminum), it is the standard for the zamak series of zinc alloys, all other. Zamak is the first choice when considering a hot chambered zinc die casting alloy. Zamak die casting stands as a cornerstone in the realm of metalworking, offering unparalleled precision, durability, and versatility across various industries. Zamak 3 (astm ag40a), or zinc alloy 3, is the most widely used zinc alloy in north america and is usually the first choice when. The name zamak draws upon the basic metallurgy. Zamak comes in multiple forms for multiple applications. Learn about the properties, applications, and benefits of different types of zamak alloys in manufacturing. The former has been in use for nearly a century whereas the latter is more of a recent development.

from www.royal-source.com

Zamak alloys were first developed during the 1920's by the new jersey zinc company. Zamak die casting stands as a cornerstone in the realm of metalworking, offering unparalleled precision, durability, and versatility across various industries. Zamak 3 has the base composition for the zamak alloys (96% zinc, 4% aluminum), it is the standard for the zamak series of zinc alloys, all other. The former has been in use for nearly a century whereas the latter is more of a recent development. Learn about the properties, applications, and benefits of different types of zamak alloys in manufacturing. Zamak is the first choice when considering a hot chambered zinc die casting alloy. The name zamak draws upon the basic metallurgy. Zamak comes in multiple forms for multiple applications. Understand how zamak alloy composition impacts your products. Zamak 3 (astm ag40a), or zinc alloy 3, is the most widely used zinc alloy in north america and is usually the first choice when.

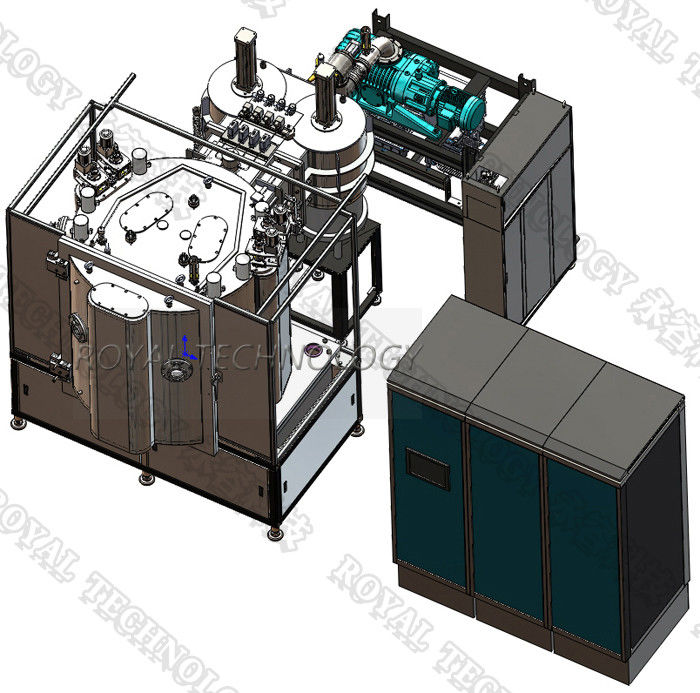

CE Certified PVD Arc evaporation system, Zinc Alloy Product Gold Plating, Zamak PVD TiN Coating

Zamak Coating Zamak comes in multiple forms for multiple applications. The name zamak draws upon the basic metallurgy. Zamak comes in multiple forms for multiple applications. Understand how zamak alloy composition impacts your products. Zamak alloys were first developed during the 1920's by the new jersey zinc company. Zamak die casting stands as a cornerstone in the realm of metalworking, offering unparalleled precision, durability, and versatility across various industries. Zamak 3 (astm ag40a), or zinc alloy 3, is the most widely used zinc alloy in north america and is usually the first choice when. Learn about the properties, applications, and benefits of different types of zamak alloys in manufacturing. Zamak is the first choice when considering a hot chambered zinc die casting alloy. The former has been in use for nearly a century whereas the latter is more of a recent development. Zamak 3 has the base composition for the zamak alloys (96% zinc, 4% aluminum), it is the standard for the zamak series of zinc alloys, all other.

From www.rvs-products.nl

Muurflens 90° 19 mm Zamak PVD coating model 0516 Zamak Coating Zamak die casting stands as a cornerstone in the realm of metalworking, offering unparalleled precision, durability, and versatility across various industries. Understand how zamak alloy composition impacts your products. Zamak alloys were first developed during the 1920's by the new jersey zinc company. Zamak 3 (astm ag40a), or zinc alloy 3, is the most widely used zinc alloy in north. Zamak Coating.

From www.youtube.com

All the zamak die casting parts after polishing and chrome coating. YouTube Zamak Coating Learn about the properties, applications, and benefits of different types of zamak alloys in manufacturing. Zamak is the first choice when considering a hot chambered zinc die casting alloy. Zamak 3 (astm ag40a), or zinc alloy 3, is the most widely used zinc alloy in north america and is usually the first choice when. The former has been in use. Zamak Coating.

From www.zincametal.com

ZAMAK CASTING Zinca Metal Zamak Coating The former has been in use for nearly a century whereas the latter is more of a recent development. Zamak comes in multiple forms for multiple applications. Zamak 3 (astm ag40a), or zinc alloy 3, is the most widely used zinc alloy in north america and is usually the first choice when. Learn about the properties, applications, and benefits of. Zamak Coating.

From www.iqsdirectory.com

Zinc Die Casting What Is It? How Is it Made? Advantages Zamak Coating Understand how zamak alloy composition impacts your products. Zamak 3 (astm ag40a), or zinc alloy 3, is the most widely used zinc alloy in north america and is usually the first choice when. Zamak comes in multiple forms for multiple applications. Learn about the properties, applications, and benefits of different types of zamak alloys in manufacturing. Zamak alloys were first. Zamak Coating.

From material-properties.org

What is Zamak Zinc Alloy Properties Definition Material Properties Zamak Coating Zamak comes in multiple forms for multiple applications. The name zamak draws upon the basic metallurgy. The former has been in use for nearly a century whereas the latter is more of a recent development. Zamak die casting stands as a cornerstone in the realm of metalworking, offering unparalleled precision, durability, and versatility across various industries. Understand how zamak alloy. Zamak Coating.

From www.belmontmetals.com

What Manufacturers Need To Know About Zamak Alloys Belmont Metals Zamak Coating Zamak 3 (astm ag40a), or zinc alloy 3, is the most widely used zinc alloy in north america and is usually the first choice when. Zamak 3 has the base composition for the zamak alloys (96% zinc, 4% aluminum), it is the standard for the zamak series of zinc alloys, all other. The former has been in use for nearly. Zamak Coating.

From www.royal-source.com

Zamak Door Hinges And Screws PVD Vacuum Coating Machine Polishing Gold / Black , Brushing Gold Zamak Coating Zamak 3 (astm ag40a), or zinc alloy 3, is the most widely used zinc alloy in north america and is usually the first choice when. Zamak is the first choice when considering a hot chambered zinc die casting alloy. The name zamak draws upon the basic metallurgy. The former has been in use for nearly a century whereas the latter. Zamak Coating.

From www.royal-source.com

High Productivity Cathodic Arc Deposition System For Sanitary Ware / Brass Alloy Faucets, Zamak Zamak Coating Zamak alloys were first developed during the 1920's by the new jersey zinc company. The name zamak draws upon the basic metallurgy. The former has been in use for nearly a century whereas the latter is more of a recent development. Zamak 3 has the base composition for the zamak alloys (96% zinc, 4% aluminum), it is the standard for. Zamak Coating.

From belgcast.be

Zamak alloy Belgcast Zamak Coating Zamak die casting stands as a cornerstone in the realm of metalworking, offering unparalleled precision, durability, and versatility across various industries. The former has been in use for nearly a century whereas the latter is more of a recent development. Zamak alloys were first developed during the 1920's by the new jersey zinc company. Zamak comes in multiple forms for. Zamak Coating.

From szsenbao.en.made-in-china.com

Factory Custom Aluminum Zinc Zamak Alloy Plating Powder Coating Die Casting Part China Zamak Coating Zamak die casting stands as a cornerstone in the realm of metalworking, offering unparalleled precision, durability, and versatility across various industries. The name zamak draws upon the basic metallurgy. Understand how zamak alloy composition impacts your products. The former has been in use for nearly a century whereas the latter is more of a recent development. Zamak 3 has the. Zamak Coating.

From info.techwallp.xyz

Que Es El Zamak Management And Leadership Zamak Coating Learn about the properties, applications, and benefits of different types of zamak alloys in manufacturing. The former has been in use for nearly a century whereas the latter is more of a recent development. Zamak 3 has the base composition for the zamak alloys (96% zinc, 4% aluminum), it is the standard for the zamak series of zinc alloys, all. Zamak Coating.

From qdaces.en.made-in-china.com

China Casting Supplier Powder Coating OEM Zinc Alloy Die Casting Zamak Parts China Alloy Zamak Coating Zamak die casting stands as a cornerstone in the realm of metalworking, offering unparalleled precision, durability, and versatility across various industries. Zamak alloys were first developed during the 1920's by the new jersey zinc company. Zamak comes in multiple forms for multiple applications. The name zamak draws upon the basic metallurgy. Understand how zamak alloy composition impacts your products. Learn. Zamak Coating.

From segede.com

Le zamac, qu’estce que c’est Zamak Coating The former has been in use for nearly a century whereas the latter is more of a recent development. Zamak 3 (astm ag40a), or zinc alloy 3, is the most widely used zinc alloy in north america and is usually the first choice when. Understand how zamak alloy composition impacts your products. Zamak alloys were first developed during the 1920's. Zamak Coating.

From www.rvs-products.nl

Muurflens 45° 19 mm Zamak PVD coating model 0626 Zamak Coating Zamak die casting stands as a cornerstone in the realm of metalworking, offering unparalleled precision, durability, and versatility across various industries. Learn about the properties, applications, and benefits of different types of zamak alloys in manufacturing. Zamak alloys were first developed during the 1920's by the new jersey zinc company. Understand how zamak alloy composition impacts your products. Zamak 3. Zamak Coating.

From www.bruschitech.com

Coating, plating and other kind of surface treatments Zamak Coating The former has been in use for nearly a century whereas the latter is more of a recent development. The name zamak draws upon the basic metallurgy. Zamak comes in multiple forms for multiple applications. Zamak die casting stands as a cornerstone in the realm of metalworking, offering unparalleled precision, durability, and versatility across various industries. Zamak 3 (astm ag40a),. Zamak Coating.

From hzhardware.en.made-in-china.com

New Design Zinc Alloy Window Handle, Zamak Powder Coating Sliding Window Hardware Open or Close Zamak Coating Learn about the properties, applications, and benefits of different types of zamak alloys in manufacturing. Understand how zamak alloy composition impacts your products. Zamak 3 has the base composition for the zamak alloys (96% zinc, 4% aluminum), it is the standard for the zamak series of zinc alloys, all other. The former has been in use for nearly a century. Zamak Coating.

From dg-huicheng.en.made-in-china.com

Hcvac Brass Zamak Plastic Faucet Sanitary PVD Vacuum Chrome Coating Plating Machine China Zamak Coating Zamak die casting stands as a cornerstone in the realm of metalworking, offering unparalleled precision, durability, and versatility across various industries. Zamak is the first choice when considering a hot chambered zinc die casting alloy. The former has been in use for nearly a century whereas the latter is more of a recent development. Understand how zamak alloy composition impacts. Zamak Coating.

From funmak.com

Fabricación a medida de piezas de Zamak Funmak Zamak Coating Understand how zamak alloy composition impacts your products. Zamak 3 (astm ag40a), or zinc alloy 3, is the most widely used zinc alloy in north america and is usually the first choice when. Zamak is the first choice when considering a hot chambered zinc die casting alloy. Zamak alloys were first developed during the 1920's by the new jersey zinc. Zamak Coating.

From decoprod.com

Zamak 3 The Most Widely Used Zinc Alloy Zamak Coating Learn about the properties, applications, and benefits of different types of zamak alloys in manufacturing. The former has been in use for nearly a century whereas the latter is more of a recent development. The name zamak draws upon the basic metallurgy. Zamak is the first choice when considering a hot chambered zinc die casting alloy. Zamak die casting stands. Zamak Coating.

From www.youtube.com

How to die cast zamak parts? What will zinc look like after polishing and chrome coating? YouTube Zamak Coating The name zamak draws upon the basic metallurgy. Understand how zamak alloy composition impacts your products. Zamak is the first choice when considering a hot chambered zinc die casting alloy. Learn about the properties, applications, and benefits of different types of zamak alloys in manufacturing. The former has been in use for nearly a century whereas the latter is more. Zamak Coating.

From www.experience-zamak.fr

Ecoating et cataphorèse Expérience Zamak Zamak Coating Zamak die casting stands as a cornerstone in the realm of metalworking, offering unparalleled precision, durability, and versatility across various industries. Understand how zamak alloy composition impacts your products. Zamak is the first choice when considering a hot chambered zinc die casting alloy. Zamak alloys were first developed during the 1920's by the new jersey zinc company. The former has. Zamak Coating.

From www.alibaba.com

Custom Precision Iron Stainless Steel Aluminium Alloy Zamak Gravity Sand Die Casting Molds Zamak Coating Zamak 3 (astm ag40a), or zinc alloy 3, is the most widely used zinc alloy in north america and is usually the first choice when. Zamak is the first choice when considering a hot chambered zinc die casting alloy. The name zamak draws upon the basic metallurgy. Zamak 3 has the base composition for the zamak alloys (96% zinc, 4%. Zamak Coating.

From www.royal-source.com

CE Certified PVD Arc evaporation system, Zinc Alloy Product Gold Plating, Zamak PVD TiN Coating Zamak Coating Zamak is the first choice when considering a hot chambered zinc die casting alloy. Zamak die casting stands as a cornerstone in the realm of metalworking, offering unparalleled precision, durability, and versatility across various industries. Zamak 3 has the base composition for the zamak alloys (96% zinc, 4% aluminum), it is the standard for the zamak series of zinc alloys,. Zamak Coating.

From www.experience-zamak.fr

8 raisons de choisir le Zamak Expérience Zamak Zamak Coating Zamak comes in multiple forms for multiple applications. Zamak is the first choice when considering a hot chambered zinc die casting alloy. Zamak 3 has the base composition for the zamak alloys (96% zinc, 4% aluminum), it is the standard for the zamak series of zinc alloys, all other. The name zamak draws upon the basic metallurgy. The former has. Zamak Coating.

From www.bruschitech.com

ZAMAK molding in hot chamber die casting chemical composition Zamak Coating The name zamak draws upon the basic metallurgy. The former has been in use for nearly a century whereas the latter is more of a recent development. Zamak is the first choice when considering a hot chambered zinc die casting alloy. Zamak 3 has the base composition for the zamak alloys (96% zinc, 4% aluminum), it is the standard for. Zamak Coating.

From blog.thepipingmart.com

Advantages and Disadvantages of Zamak Metal Zamak Coating Learn about the properties, applications, and benefits of different types of zamak alloys in manufacturing. Understand how zamak alloy composition impacts your products. The name zamak draws upon the basic metallurgy. Zamak die casting stands as a cornerstone in the realm of metalworking, offering unparalleled precision, durability, and versatility across various industries. Zamak 3 has the base composition for the. Zamak Coating.

From www.zincametal.com

ZAMAK CASTING Zinca Metal Zamak Coating The former has been in use for nearly a century whereas the latter is more of a recent development. Zamak alloys were first developed during the 1920's by the new jersey zinc company. Understand how zamak alloy composition impacts your products. Zamak comes in multiple forms for multiple applications. Zamak is the first choice when considering a hot chambered zinc. Zamak Coating.

From www.zamak.au

Zamak or Zinc Die Casting Alloys ZAMAK Zamak Coating The former has been in use for nearly a century whereas the latter is more of a recent development. Zamak 3 has the base composition for the zamak alloys (96% zinc, 4% aluminum), it is the standard for the zamak series of zinc alloys, all other. Zamak comes in multiple forms for multiple applications. The name zamak draws upon the. Zamak Coating.

From aurican.en.made-in-china.com

Powder Coating Zamak / Zinc Alloy European Aluminium Window Handle with Button (112044) China Zamak Coating The former has been in use for nearly a century whereas the latter is more of a recent development. Zamak 3 has the base composition for the zamak alloys (96% zinc, 4% aluminum), it is the standard for the zamak series of zinc alloys, all other. Zamak die casting stands as a cornerstone in the realm of metalworking, offering unparalleled. Zamak Coating.

From codam.com.ar

Características, virtudes y durabilidad del zamak Codam S.A. Zamak Coating Zamak die casting stands as a cornerstone in the realm of metalworking, offering unparalleled precision, durability, and versatility across various industries. Zamak 3 (astm ag40a), or zinc alloy 3, is the most widely used zinc alloy in north america and is usually the first choice when. Zamak comes in multiple forms for multiple applications. Understand how zamak alloy composition impacts. Zamak Coating.

From www.researchgate.net

SEM surface morphologies of (a) zamak surface before electroless... Download Scientific Diagram Zamak Coating Zamak die casting stands as a cornerstone in the realm of metalworking, offering unparalleled precision, durability, and versatility across various industries. The former has been in use for nearly a century whereas the latter is more of a recent development. Understand how zamak alloy composition impacts your products. Zamak 3 (astm ag40a), or zinc alloy 3, is the most widely. Zamak Coating.

From aurican.en.made-in-china.com

Powder Coating Zamak / Zinc Alloy European Aluminium Window Handle with Lock (113055) China Zamak Coating The former has been in use for nearly a century whereas the latter is more of a recent development. Understand how zamak alloy composition impacts your products. Zamak comes in multiple forms for multiple applications. Zamak is the first choice when considering a hot chambered zinc die casting alloy. The name zamak draws upon the basic metallurgy. Zamak 3 has. Zamak Coating.

From qdaces.en.made-in-china.com

China Custom Powder Coating Metal Casting A365 Die Casting Aluminum Zamak Parts China Casting Zamak Coating Zamak comes in multiple forms for multiple applications. The former has been in use for nearly a century whereas the latter is more of a recent development. Learn about the properties, applications, and benefits of different types of zamak alloys in manufacturing. Zamak die casting stands as a cornerstone in the realm of metalworking, offering unparalleled precision, durability, and versatility. Zamak Coating.

From rinoxusa.com

Zamak Glass Clip for 3/8″ & 1/2″ Tempered; Mounted to 1.66″ Dia. Pipe. Excellent for Powder Zamak Coating Zamak 3 has the base composition for the zamak alloys (96% zinc, 4% aluminum), it is the standard for the zamak series of zinc alloys, all other. The former has been in use for nearly a century whereas the latter is more of a recent development. Zamak 3 (astm ag40a), or zinc alloy 3, is the most widely used zinc. Zamak Coating.

From www.alibaba.com

Customized Aluminum Zinc Zamak Die Cast With Power Coating Buy Zamak Die Cast,Zinc Die Casting Zamak Coating The former has been in use for nearly a century whereas the latter is more of a recent development. Understand how zamak alloy composition impacts your products. The name zamak draws upon the basic metallurgy. Zamak is the first choice when considering a hot chambered zinc die casting alloy. Zamak 3 (astm ag40a), or zinc alloy 3, is the most. Zamak Coating.