Cast Molding Technology . Engineers and manufacturers use casting to. This method involves pouring molten metal into a rotating mold, which distributes the metal uniformly and ensures. The casting process is a foundational metalworking technique that involves melting metal or alloy and pouring it into a mold. Apart from providing advice on casting technology and customized. High pressure die casting part with complex geometry. Our investment into cast moulding technology includes computer controlled binder additions with real time monitoring and calibration. Once in a solid state, the result reflects the shape and surface of the engineered mold cavity. Cast molding is a manufacturing process that introduces liquid materials into a mold cavity where the material hardens into a solid state—similar to the process of molding chocolate. Foaming of casting models for the lost foam casting process. The casting or cast molding process involves two different types of approaches, using a pattern for cavity and precise die or mold that.

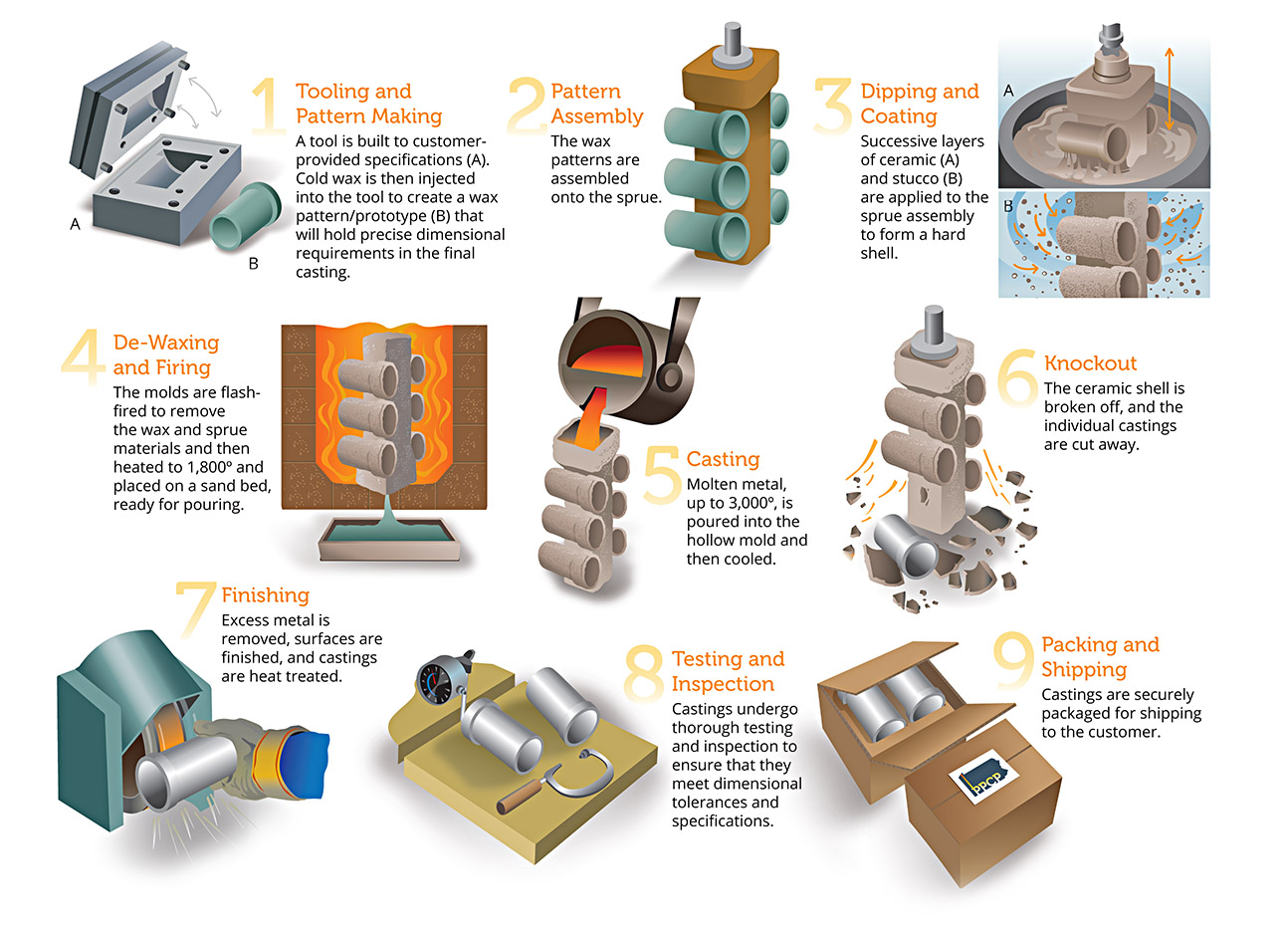

from ppcpinc.com

Foaming of casting models for the lost foam casting process. This method involves pouring molten metal into a rotating mold, which distributes the metal uniformly and ensures. The casting or cast molding process involves two different types of approaches, using a pattern for cavity and precise die or mold that. Our investment into cast moulding technology includes computer controlled binder additions with real time monitoring and calibration. The casting process is a foundational metalworking technique that involves melting metal or alloy and pouring it into a mold. High pressure die casting part with complex geometry. Apart from providing advice on casting technology and customized. Engineers and manufacturers use casting to. Cast molding is a manufacturing process that introduces liquid materials into a mold cavity where the material hardens into a solid state—similar to the process of molding chocolate. Once in a solid state, the result reflects the shape and surface of the engineered mold cavity.

» PPCP Process

Cast Molding Technology The casting process is a foundational metalworking technique that involves melting metal or alloy and pouring it into a mold. Apart from providing advice on casting technology and customized. Our investment into cast moulding technology includes computer controlled binder additions with real time monitoring and calibration. Engineers and manufacturers use casting to. Foaming of casting models for the lost foam casting process. Once in a solid state, the result reflects the shape and surface of the engineered mold cavity. The casting process is a foundational metalworking technique that involves melting metal or alloy and pouring it into a mold. The casting or cast molding process involves two different types of approaches, using a pattern for cavity and precise die or mold that. This method involves pouring molten metal into a rotating mold, which distributes the metal uniformly and ensures. High pressure die casting part with complex geometry. Cast molding is a manufacturing process that introduces liquid materials into a mold cavity where the material hardens into a solid state—similar to the process of molding chocolate.

From ppcpinc.com

» PPCP Process Cast Molding Technology High pressure die casting part with complex geometry. The casting or cast molding process involves two different types of approaches, using a pattern for cavity and precise die or mold that. Apart from providing advice on casting technology and customized. Cast molding is a manufacturing process that introduces liquid materials into a mold cavity where the material hardens into a. Cast Molding Technology.

From www.cltech.com.sg

Contact Lens Technologists Pte Ltd. Cast moulding technology CLTech Cast Molding Technology High pressure die casting part with complex geometry. Apart from providing advice on casting technology and customized. Our investment into cast moulding technology includes computer controlled binder additions with real time monitoring and calibration. This method involves pouring molten metal into a rotating mold, which distributes the metal uniformly and ensures. The casting or cast molding process involves two different. Cast Molding Technology.

From www.slevarnazinku.cz

TekCast spincasting technology zinc foundry Cast Molding Technology Engineers and manufacturers use casting to. Foaming of casting models for the lost foam casting process. Cast molding is a manufacturing process that introduces liquid materials into a mold cavity where the material hardens into a solid state—similar to the process of molding chocolate. Once in a solid state, the result reflects the shape and surface of the engineered mold. Cast Molding Technology.

From www.smicomposites.com

Overview of Cast Molding Processes and Applications SMI Composites Cast Molding Technology The casting process is a foundational metalworking technique that involves melting metal or alloy and pouring it into a mold. Once in a solid state, the result reflects the shape and surface of the engineered mold cavity. The casting or cast molding process involves two different types of approaches, using a pattern for cavity and precise die or mold that.. Cast Molding Technology.

From escoplastics.com

Polyurethane Open Cast Molding ESCO Plastics Cast Molding Technology The casting process is a foundational metalworking technique that involves melting metal or alloy and pouring it into a mold. Cast molding is a manufacturing process that introduces liquid materials into a mold cavity where the material hardens into a solid state—similar to the process of molding chocolate. High pressure die casting part with complex geometry. Engineers and manufacturers use. Cast Molding Technology.

From www.advancedprototype.com

Urethane Casting 101 RTV Molding In 3D Printing Cast Molding Technology Cast molding is a manufacturing process that introduces liquid materials into a mold cavity where the material hardens into a solid state—similar to the process of molding chocolate. The casting process is a foundational metalworking technique that involves melting metal or alloy and pouring it into a mold. Engineers and manufacturers use casting to. Apart from providing advice on casting. Cast Molding Technology.

From www.unfinishedman.com

The Advancement Of Silicone Molding And Vacuum Casting Technology Cast Molding Technology The casting process is a foundational metalworking technique that involves melting metal or alloy and pouring it into a mold. The casting or cast molding process involves two different types of approaches, using a pattern for cavity and precise die or mold that. This method involves pouring molten metal into a rotating mold, which distributes the metal uniformly and ensures.. Cast Molding Technology.

From compositeslab.com

Cast Polymer Molding Processes CompositesLab Cast Molding Technology The casting process is a foundational metalworking technique that involves melting metal or alloy and pouring it into a mold. Foaming of casting models for the lost foam casting process. Apart from providing advice on casting technology and customized. Once in a solid state, the result reflects the shape and surface of the engineered mold cavity. Our investment into cast. Cast Molding Technology.

From dc-mkt-prod.cloud.bosch.tech

Moulding and Casting Technologies Bosch Rexroth USA Cast Molding Technology This method involves pouring molten metal into a rotating mold, which distributes the metal uniformly and ensures. High pressure die casting part with complex geometry. Apart from providing advice on casting technology and customized. The casting process is a foundational metalworking technique that involves melting metal or alloy and pouring it into a mold. The casting or cast molding process. Cast Molding Technology.

From knowledgecenter.mearthane.com

What is Cast Molding? Cast Molding Technology Our investment into cast moulding technology includes computer controlled binder additions with real time monitoring and calibration. Foaming of casting models for the lost foam casting process. The casting process is a foundational metalworking technique that involves melting metal or alloy and pouring it into a mold. Once in a solid state, the result reflects the shape and surface of. Cast Molding Technology.

From www.slideserve.com

PPT What Are Cast Molding And Injection Molding PowerPoint Cast Molding Technology Engineers and manufacturers use casting to. Our investment into cast moulding technology includes computer controlled binder additions with real time monitoring and calibration. The casting or cast molding process involves two different types of approaches, using a pattern for cavity and precise die or mold that. This method involves pouring molten metal into a rotating mold, which distributes the metal. Cast Molding Technology.

From mechanicstips.blogspot.com.eg

Casting process & it's Types MechanicsTips Cast Molding Technology Once in a solid state, the result reflects the shape and surface of the engineered mold cavity. High pressure die casting part with complex geometry. Engineers and manufacturers use casting to. Foaming of casting models for the lost foam casting process. Apart from providing advice on casting technology and customized. The casting or cast molding process involves two different types. Cast Molding Technology.

From www.youtube.com

Vacuum Molding Expandable Mold Casting Processes. YouTube Cast Molding Technology High pressure die casting part with complex geometry. This method involves pouring molten metal into a rotating mold, which distributes the metal uniformly and ensures. Once in a solid state, the result reflects the shape and surface of the engineered mold cavity. Engineers and manufacturers use casting to. Foaming of casting models for the lost foam casting process. The casting. Cast Molding Technology.

From www.cltech.com.sg

Contact Lens Technologists Pte Ltd. Cast moulding technology CLTech Cast Molding Technology The casting process is a foundational metalworking technique that involves melting metal or alloy and pouring it into a mold. Foaming of casting models for the lost foam casting process. This method involves pouring molten metal into a rotating mold, which distributes the metal uniformly and ensures. Engineers and manufacturers use casting to. High pressure die casting part with complex. Cast Molding Technology.

From castech.net

Castech’s moulding and Casting services Castech Cast Molding Technology Cast molding is a manufacturing process that introduces liquid materials into a mold cavity where the material hardens into a solid state—similar to the process of molding chocolate. Engineers and manufacturers use casting to. Once in a solid state, the result reflects the shape and surface of the engineered mold cavity. Apart from providing advice on casting technology and customized.. Cast Molding Technology.

From www.youtube.com

The Basic Permanent Mold Casting Process YouTube Cast Molding Technology Cast molding is a manufacturing process that introduces liquid materials into a mold cavity where the material hardens into a solid state—similar to the process of molding chocolate. Foaming of casting models for the lost foam casting process. The casting or cast molding process involves two different types of approaches, using a pattern for cavity and precise die or mold. Cast Molding Technology.

From www.youtube.com

Die Casting Permanent Mold Casting Processes. YouTube Cast Molding Technology Engineers and manufacturers use casting to. High pressure die casting part with complex geometry. The casting or cast molding process involves two different types of approaches, using a pattern for cavity and precise die or mold that. This method involves pouring molten metal into a rotating mold, which distributes the metal uniformly and ensures. Our investment into cast moulding technology. Cast Molding Technology.

From www.savimetal.com

Moulding shop Services cast products for industry foundry Cast Molding Technology Our investment into cast moulding technology includes computer controlled binder additions with real time monitoring and calibration. Foaming of casting models for the lost foam casting process. Once in a solid state, the result reflects the shape and surface of the engineered mold cavity. Engineers and manufacturers use casting to. The casting or cast molding process involves two different types. Cast Molding Technology.

From prpolymers.com

Open Cast Polyurethane Moulding PR Polymers Cast Molding Technology Cast molding is a manufacturing process that introduces liquid materials into a mold cavity where the material hardens into a solid state—similar to the process of molding chocolate. The casting process is a foundational metalworking technique that involves melting metal or alloy and pouring it into a mold. Our investment into cast moulding technology includes computer controlled binder additions with. Cast Molding Technology.

From www.slideserve.com

PPT What Are Cast Molding And Injection Molding PowerPoint Cast Molding Technology Apart from providing advice on casting technology and customized. This method involves pouring molten metal into a rotating mold, which distributes the metal uniformly and ensures. Foaming of casting models for the lost foam casting process. Cast molding is a manufacturing process that introduces liquid materials into a mold cavity where the material hardens into a solid state—similar to the. Cast Molding Technology.

From www.leclairemfg.com

Permanent Mold Casting Photos LeClaire Manufacturing Co. Cast Molding Technology High pressure die casting part with complex geometry. The casting or cast molding process involves two different types of approaches, using a pattern for cavity and precise die or mold that. Apart from providing advice on casting technology and customized. Once in a solid state, the result reflects the shape and surface of the engineered mold cavity. This method involves. Cast Molding Technology.

From www.youtube.com

Shell Molding Expandable Mold Casting Processes YouTube Cast Molding Technology Cast molding is a manufacturing process that introduces liquid materials into a mold cavity where the material hardens into a solid state—similar to the process of molding chocolate. Our investment into cast moulding technology includes computer controlled binder additions with real time monitoring and calibration. Once in a solid state, the result reflects the shape and surface of the engineered. Cast Molding Technology.

From www.slideserve.com

PPT What Are Cast Molding And Injection Molding PowerPoint Cast Molding Technology Once in a solid state, the result reflects the shape and surface of the engineered mold cavity. This method involves pouring molten metal into a rotating mold, which distributes the metal uniformly and ensures. The casting process is a foundational metalworking technique that involves melting metal or alloy and pouring it into a mold. Engineers and manufacturers use casting to.. Cast Molding Technology.

From www.teslarati.com

teslagigashanghaimodelycastingmachine TESLARATI Cast Molding Technology Apart from providing advice on casting technology and customized. Cast molding is a manufacturing process that introduces liquid materials into a mold cavity where the material hardens into a solid state—similar to the process of molding chocolate. The casting or cast molding process involves two different types of approaches, using a pattern for cavity and precise die or mold that.. Cast Molding Technology.

From www.crestcraft.com

Casting & Molding Crest Craft Cast Molding Technology Engineers and manufacturers use casting to. Once in a solid state, the result reflects the shape and surface of the engineered mold cavity. Apart from providing advice on casting technology and customized. Foaming of casting models for the lost foam casting process. High pressure die casting part with complex geometry. The casting process is a foundational metalworking technique that involves. Cast Molding Technology.

From www.youtube.com

Carbon dioxide (CO2) Moulding Process CO2 Casting Process Cast Molding Technology Cast molding is a manufacturing process that introduces liquid materials into a mold cavity where the material hardens into a solid state—similar to the process of molding chocolate. High pressure die casting part with complex geometry. Engineers and manufacturers use casting to. Our investment into cast moulding technology includes computer controlled binder additions with real time monitoring and calibration. Once. Cast Molding Technology.

From www.sunrise-metal.com

Die Cast Aluminum Mold Sunrise Metal Aluminium Die Casting Expert Cast Molding Technology This method involves pouring molten metal into a rotating mold, which distributes the metal uniformly and ensures. Apart from providing advice on casting technology and customized. The casting or cast molding process involves two different types of approaches, using a pattern for cavity and precise die or mold that. The casting process is a foundational metalworking technique that involves melting. Cast Molding Technology.

From www.cltech.com.sg

Contact Lens Technologists Pte Ltd. Cast moulding technology CLTech Cast Molding Technology Engineers and manufacturers use casting to. Once in a solid state, the result reflects the shape and surface of the engineered mold cavity. Foaming of casting models for the lost foam casting process. Apart from providing advice on casting technology and customized. The casting process is a foundational metalworking technique that involves melting metal or alloy and pouring it into. Cast Molding Technology.

From www.weld2cast.com

Shell Moulding Casting Weld2Cast Cast Molding Technology Once in a solid state, the result reflects the shape and surface of the engineered mold cavity. Engineers and manufacturers use casting to. Foaming of casting models for the lost foam casting process. Our investment into cast moulding technology includes computer controlled binder additions with real time monitoring and calibration. The casting or cast molding process involves two different types. Cast Molding Technology.

From www.slideserve.com

PPT What Are Cast Molding And Injection Molding PowerPoint Cast Molding Technology Once in a solid state, the result reflects the shape and surface of the engineered mold cavity. The casting or cast molding process involves two different types of approaches, using a pattern for cavity and precise die or mold that. The casting process is a foundational metalworking technique that involves melting metal or alloy and pouring it into a mold.. Cast Molding Technology.

From www.boschrexroth.com

Moulding and Casting Technologies Bosch Rexroth USA Cast Molding Technology Our investment into cast moulding technology includes computer controlled binder additions with real time monitoring and calibration. Engineers and manufacturers use casting to. High pressure die casting part with complex geometry. This method involves pouring molten metal into a rotating mold, which distributes the metal uniformly and ensures. Apart from providing advice on casting technology and customized. The casting or. Cast Molding Technology.

From www.smicomposites.com

4 Benefits of Cast Molding When Making Composite Materials SMI Composites Cast Molding Technology The casting process is a foundational metalworking technique that involves melting metal or alloy and pouring it into a mold. Apart from providing advice on casting technology and customized. Once in a solid state, the result reflects the shape and surface of the engineered mold cavity. Our investment into cast moulding technology includes computer controlled binder additions with real time. Cast Molding Technology.

From www.comsol.com

Optimizing the Continuous Casting Process with Simulation COMSOL Blog Cast Molding Technology High pressure die casting part with complex geometry. Once in a solid state, the result reflects the shape and surface of the engineered mold cavity. Cast molding is a manufacturing process that introduces liquid materials into a mold cavity where the material hardens into a solid state—similar to the process of molding chocolate. Foaming of casting models for the lost. Cast Molding Technology.

From dc-mkt-prod.cloud.bosch.tech

Moulding and Casting Technologies Bosch Rexroth USA Cast Molding Technology Our investment into cast moulding technology includes computer controlled binder additions with real time monitoring and calibration. High pressure die casting part with complex geometry. Apart from providing advice on casting technology and customized. This method involves pouring molten metal into a rotating mold, which distributes the metal uniformly and ensures. Cast molding is a manufacturing process that introduces liquid. Cast Molding Technology.

From moldie.net

Die Casting Mold Design and Development Moldie Cast Molding Technology Foaming of casting models for the lost foam casting process. This method involves pouring molten metal into a rotating mold, which distributes the metal uniformly and ensures. High pressure die casting part with complex geometry. The casting or cast molding process involves two different types of approaches, using a pattern for cavity and precise die or mold that. Our investment. Cast Molding Technology.